A system and method for full combustion optimization for pulverized coal-fired steam boilers

A combustion optimization, boiler technology, applied in the direction of combustion method, combustion fuel, control combustion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

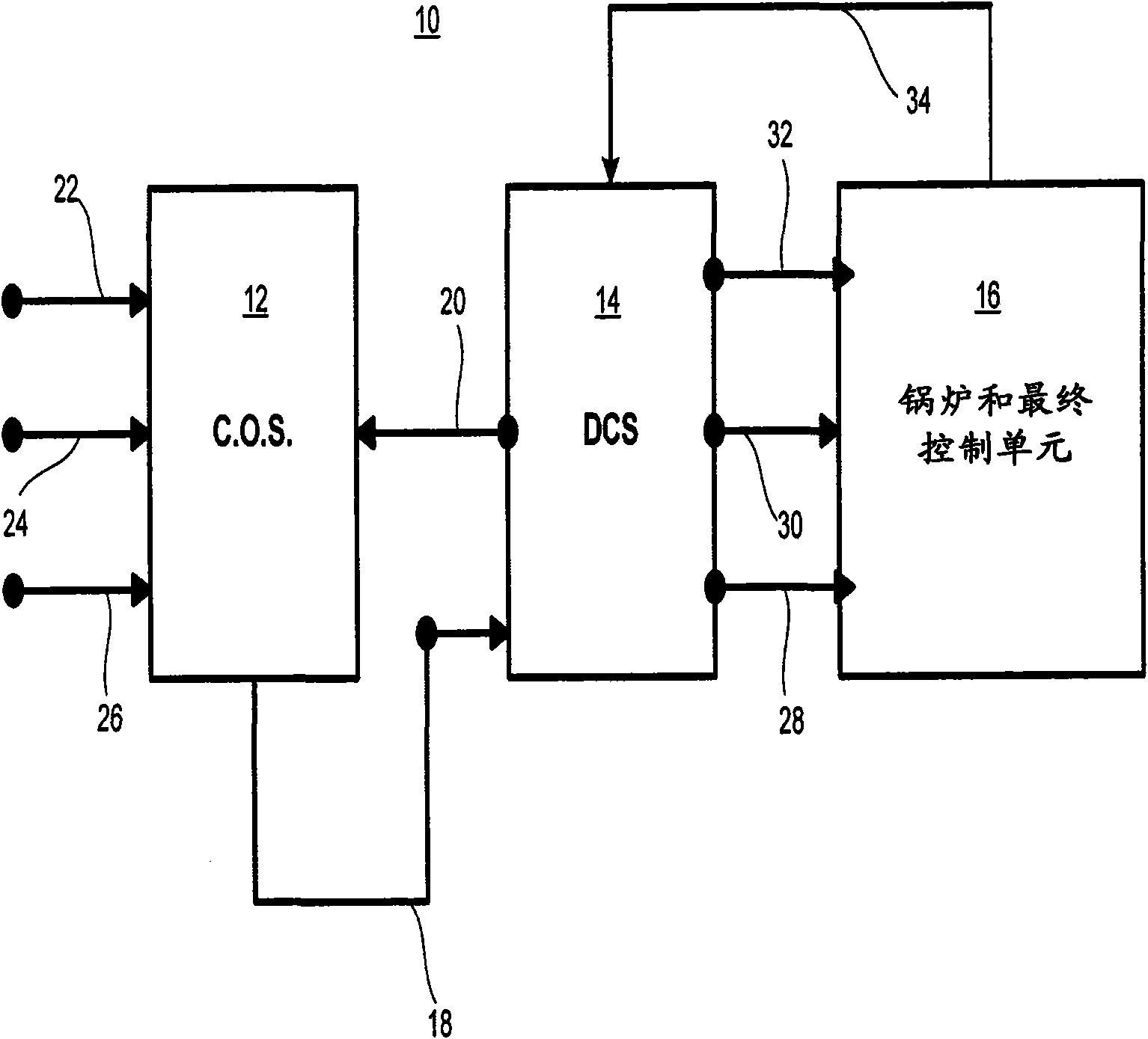

[0015] now refer to figure 2 , shows a block diagram of one embodiment of the system 10 used in the present invention. System 10 includes advanced combustion control and optimization system (COS) 12 . COS 12 models the multivariate nonlinear relationships of the combustion process. Identify the relationship between signals / parameters by analyzing the historical data of the signals / parameters. The COS 12 is based on advanced model predictive control techniques and uses a combustion model and a cost function describing weighted customer optimization objectives to provide setpoints and setpoint bias values 18 to a distributed control system (DCS) 14 of the system 10 . DCS 14 includes operator setpoints and provides process values 20 to COS 12 . The COS 12 has a model of the process and has as inputs constrained variable limits 22 , controlled variable targets 24 , and manipulated variable targets and limits 26 . An example of a COS 12 is the Optimax Combustion Optimizer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com