Trim method for high voltage drivers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

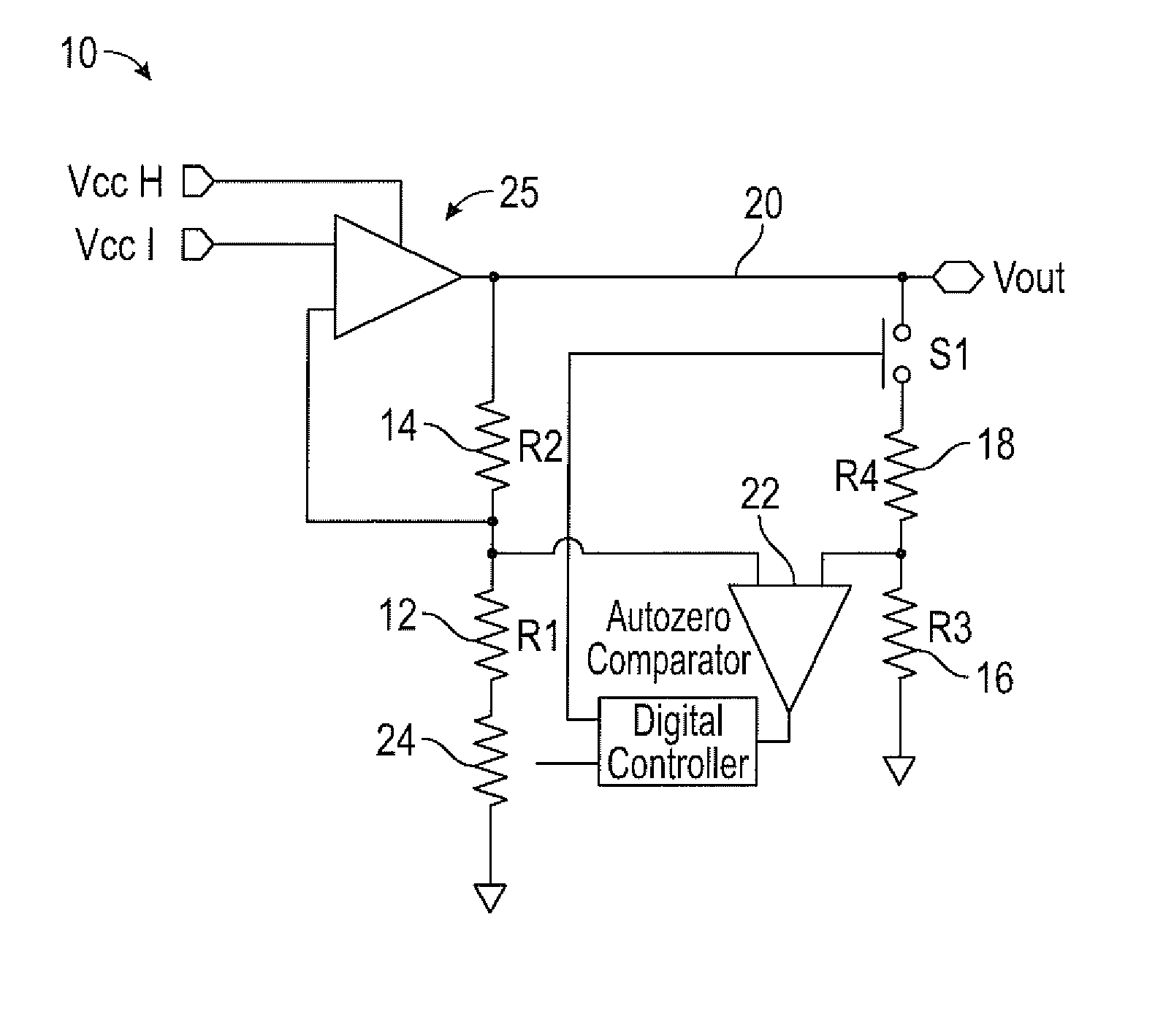

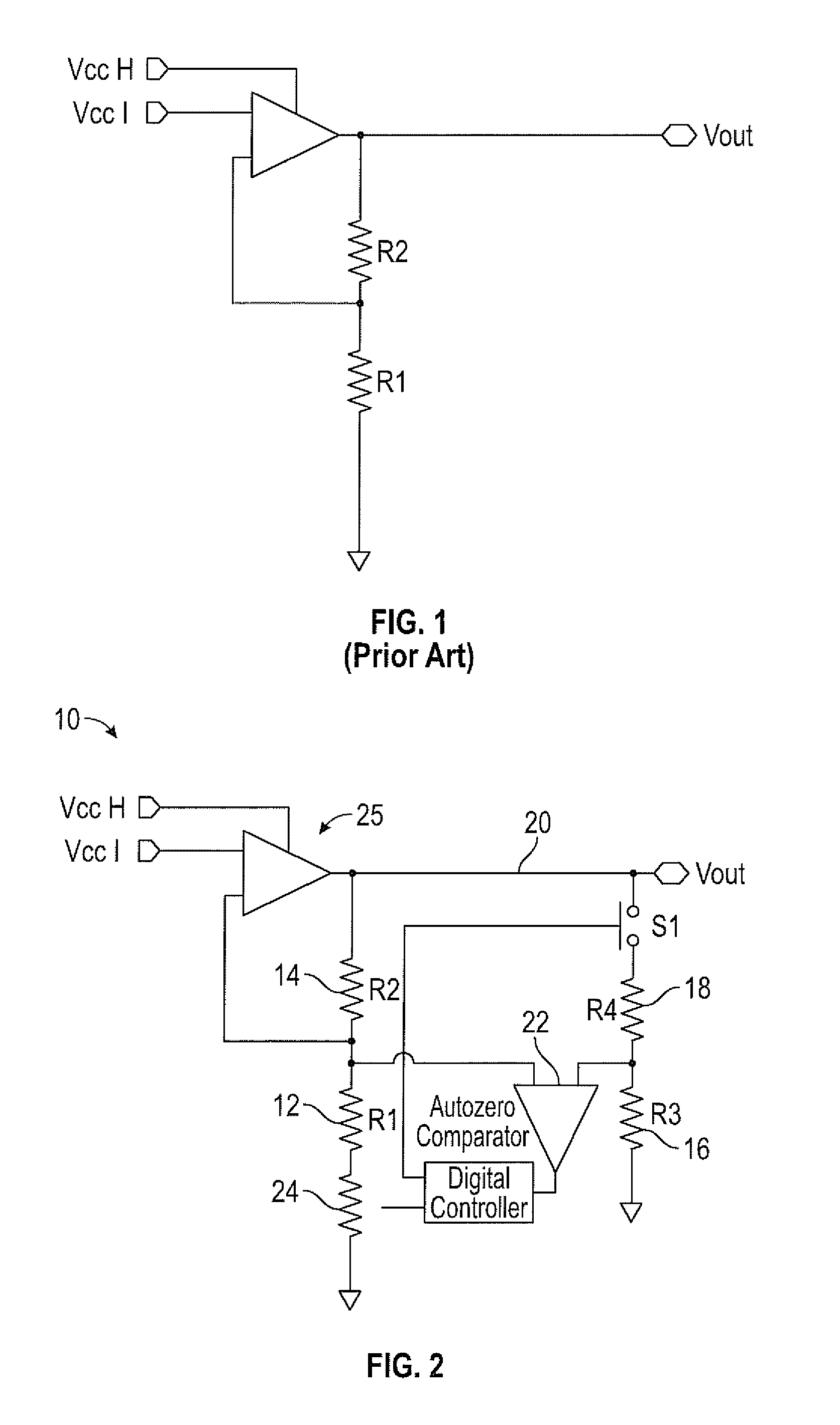

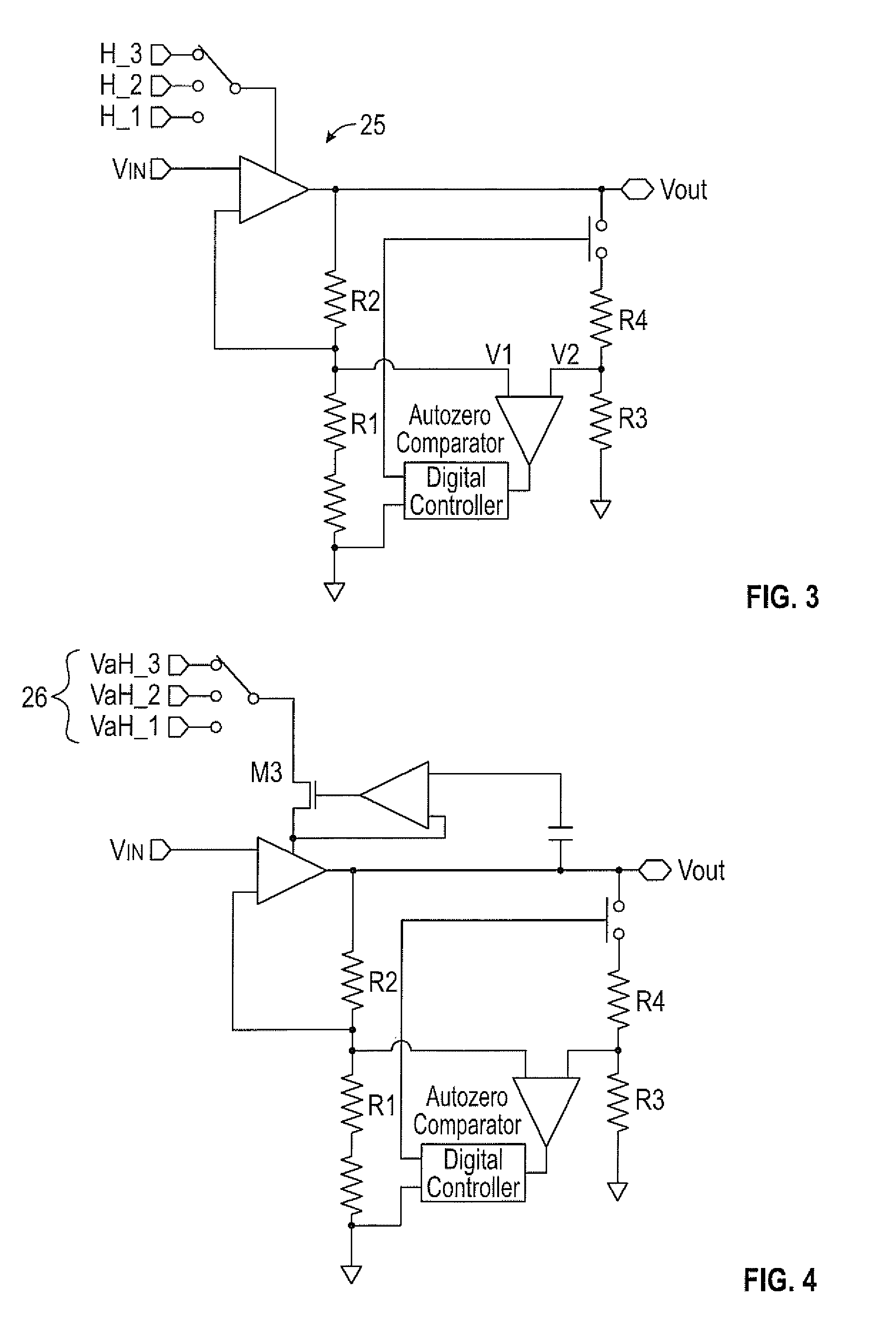

[0021]The present invention has utility as improved methods and circuits to create small, power minimizing, multi-channel high voltage drivers for micro-electromechanical systems (MEMS). A resistor calibration circuit is introduced to allow on chip resistor dividers to be calibrated against a single, low drift, precision, high-voltage resistor divider, eliminating the cost and required printed circuit board real estate associated with multiple resistor dividers connected to each channel. Additionally, a multiple-power rail circuit configuration is taught to reduce power to the overall system by producing several rails generated by a boost converter and / or a capacitive charge pump, where the voltage output of the rails is produced to group rails of lesser voltage requirement rather than connecting all channels to the same high voltage rail on a dynamic basis.

[0022]In embodiments of the invention, an integrated circuit device is introduced where two or more high voltage outputs are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com