Method for reducing bottom oxygen content of polycrystalline silicon ingot casting

A polysilicon ingot furnace and polysilicon technology, applied in the direction of polycrystalline material growth, chemical instruments and methods, crystal growth, etc., can solve the problem that the quality of the ingot product is greatly affected, the ingot product has high oxygen content, and is easy to form hard Points and other problems, to achieve the effect of easy control of the coating process, good heating effect, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

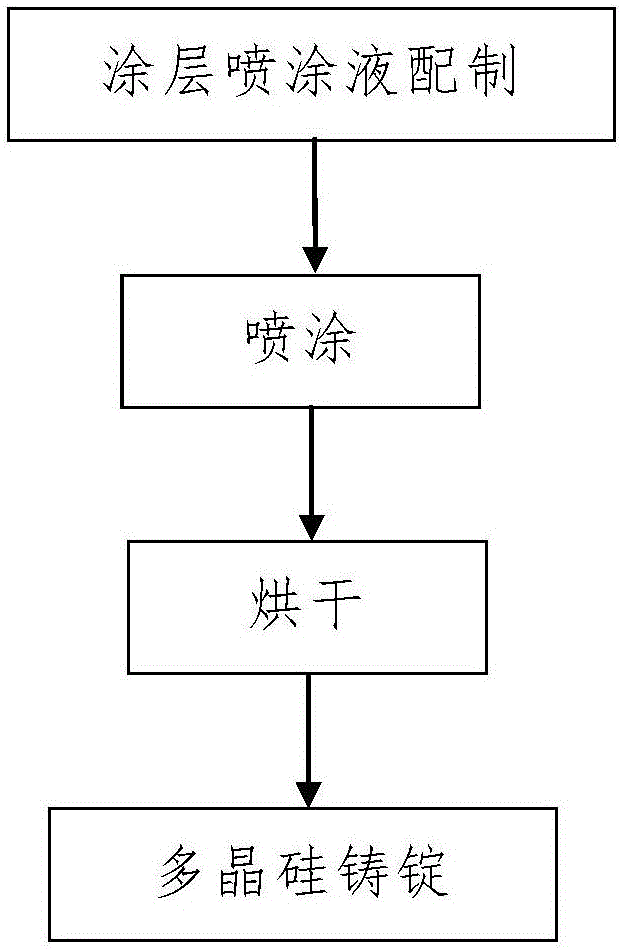

[0047] like figure 1 A method for reducing the oxygen content at the bottom of the polysilicon ingot is shown, comprising the following steps:

[0048] Step 1, preparation of the coating on the bottom of the crucible, the process is as follows:

[0049] Step 101, preparation of coating spraying liquid: uniformly mixing organic binder, deionized water and boron nitride at a mass ratio of 1:2.2:1 to obtain coating spraying liquid;

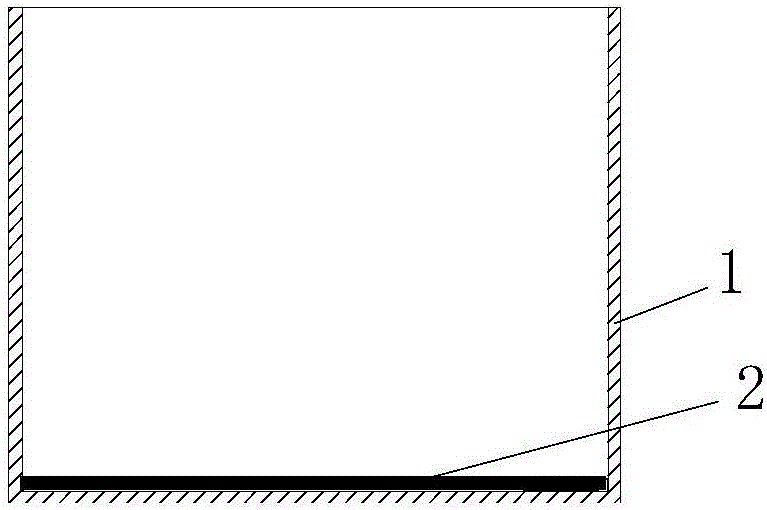

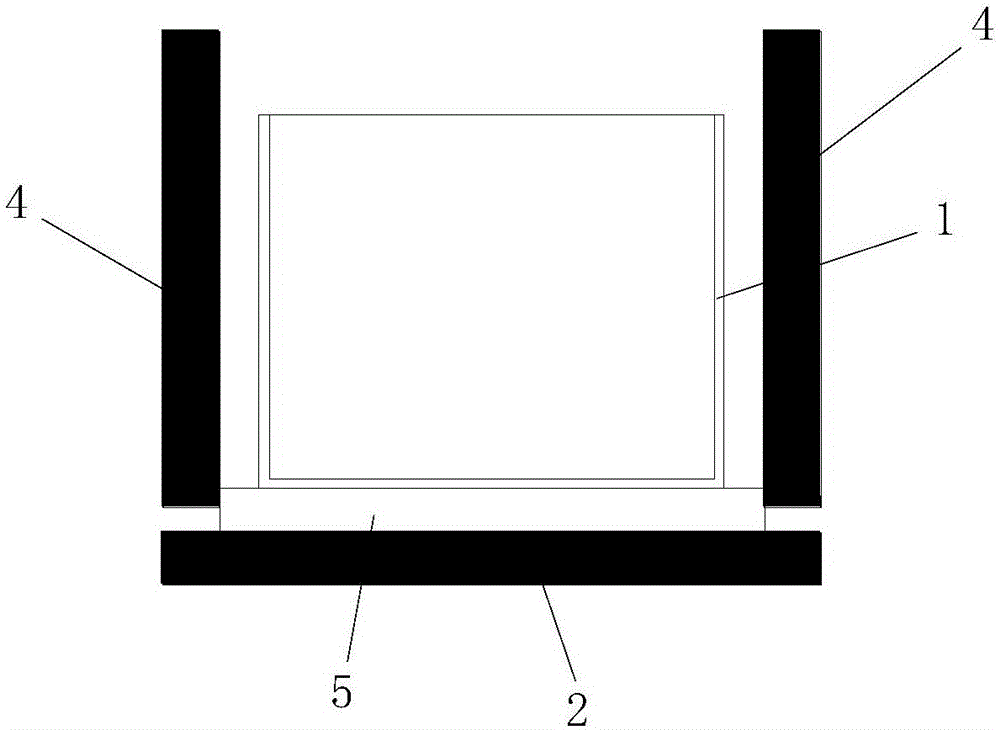

[0050] Step 102, spraying: use spraying equipment to evenly spray the coating spray liquid described in step 101 on the inner bottom surface of the crucible 1, and the inner bottom surface of the crucible 1 is 1 m 2 The mass of boron nitride contained in the coating spray liquid sprayed in the area is 100g-150g;

[0051] The crucible 1 is a quartz crucible for a polysilicon ingot furnace;

[0052] Step 103, drying: place the crucible 1 in step 102 horizontally in the drying equipment, and use the drying equipment to spray the coating sprayed on th...

Embodiment 2

[0080] In this embodiment, the difference from Embodiment 1 is that when polysilicon ingots are cast in step 2, the process is as follows:

[0081] Step 201, charging: loading silicon material into the crucible 1 with bottom coating 2 in step 1;

[0082] Step 202, preheating: using the polysilicon ingot furnace to preheat the silicon material in the crucible 1, and gradually raising the heating temperature of the polysilicon ingot furnace to T1; the preheating time is 5 hours, where T1 =1200°C;

[0083] Step 203, melting: using the polysilicon ingot furnace to melt the silicon material loaded in the crucible 1, the melting temperature is T1-T2; where T2=1550°C;

[0084] After the silicon material in the crucible 1 is completely melted, the heating temperature of the polysilicon ingot furnace is controlled at T2, and then the heating power of the polysilicon ingot furnace starts to decrease, and the heating power of the polysilicon ingot furnace stops decreasing And after the...

Embodiment 3

[0133] In this example, the difference from Example 2 is: in step 202, the preheating time is 4 hours and T1=1285°C, P1=100kW; in step 203, T2=1560°C, t=20min, P2=45kW, Q1=650mbar ; In the first step, the holding time is 0.4h; in the second step to the fifth step, T4=1325°C, and the heating time is 0.4h; in the sixth step, T5=1460°C, and the heating time is 3.5h; in the seventh step, T6 =1510°C and the heating time is 3.5h; the heating time in the 8th step is 3.5h; the holding time in the 9th step is 3.5h; the holding time in the 10th step is 4h.

[0134] In the present embodiment, when heating up and pressurizing in the 2nd step to the 5th step, the process is as follows:

[0135] The second step, the first step of raising: raising the heating temperature of the polysilicon ingot furnace 9 from 1285° C. to 1290° C., and the heating time is 5 minutes.

[0136]The third step, the second step of raising: raising the heating temperature of the polycrystalline silicon ingot furna...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com