Biochar soil remediation agent and preparation method thereof

A soil remediation agent, biochar technology, applied in soil conditioning materials, chemical instruments and methods, urea compound fertilizers, etc., can solve the problems of high cost, secondary pollution, slow effect, etc., to achieve simple operation, elimination of slow effect, The effect of increasing the content of organic matter and microorganisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

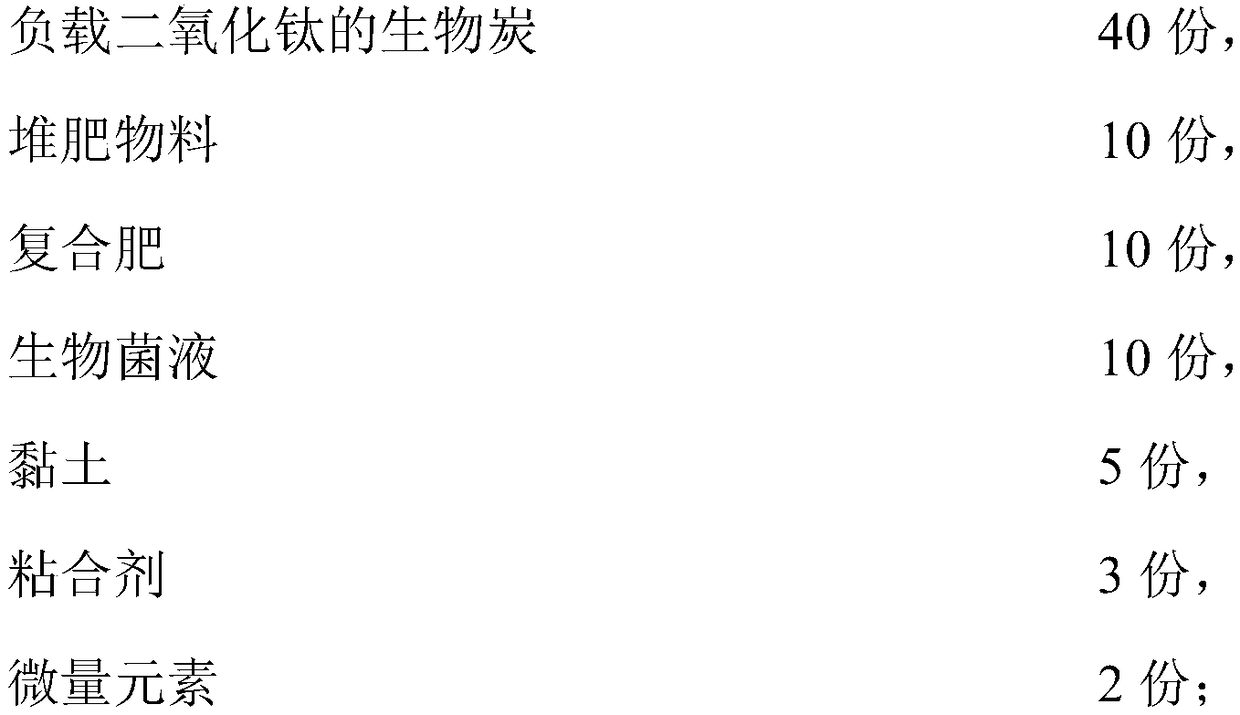

[0024] A biochar soil remediation agent is composed of the following raw materials in parts by weight:

[0025]

[0026] A preparation method of biochar soil remediation agent comprises the following steps:

[0027] Step 1, preparation of titanium dioxide-loaded biochar: first, simply clean the biomass material, air-dry it naturally, pulverize the biomass material, and pass through a 50-mesh sieve to obtain a biomass material powder; then prepare a titanium dioxide dispersion, The biomass material powder is completely immersed in the prepared titanium dioxide dispersion solution for soaking. During the treatment, magnetic stirring is carried out. The magnetic stirring speed is 200rpm / min, the temperature is maintained at 45°C, and the treatment time is 2h. The material powder is filtered, and then dried in a vacuum oven at a temperature of 45°C; finally, the dried biomass material loaded with titanium dioxide is placed in a tube furnace, and a protective gas is introduced t...

Embodiment 2

[0035] A biochar soil remediation agent is composed of the following raw materials in parts by weight:

[0036]

[0037] A preparation method of biochar soil remediation agent comprises the following steps:

[0038] Step 1, preparation of titanium dioxide-loaded biochar: firstly, the biomass material is simply cleaned, and after being dried by cold air, the biomass material is pulverized and passed through an 80-mesh sieve to obtain a biomass material powder; then, a titanium dioxide dispersion is prepared , the biomass material powder is completely immersed in the prepared titanium dioxide dispersion solution for soaking, and magnetic stirring is performed during the treatment process. The magnetic stirring speed is 500rpm / min, the temperature is maintained at 65°C, and the treatment time is 1h. The biomass material powder was filtered, and then dried in a vacuum oven at a temperature of 50 °C; finally, the dried biomass material loaded with titanium dioxide was placed in a ...

Embodiment 3

[0046] A biochar soil remediation agent is composed of the following raw materials in parts by weight:

[0047]

[0048] A preparation method of biochar soil remediation agent comprises the following steps:

[0049] Step 1, preparation of titanium dioxide-loaded biochar: first, simply clean the biomass material, and after drying with cold air, crush the biomass material, pass through a 60-mesh sieve, and obtain a biomass material powder; then prepare a titanium dioxide dispersion , the biomass material powder is completely immersed in the prepared titanium dioxide dispersion solution for soaking, and magnetic stirring is carried out during the treatment process. The magnetic stirring speed is 400rpm / min, the temperature is maintained at 50°C, and the treatment time is 1.5h. The biomass material powder is filtered, and then dried in a vacuum oven at a temperature of 48°C; finally, the dried biomass material loaded with titanium dioxide is placed in a tube furnace, and a prot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com