Compound fertilizer for farmland soil improvement and preparation process thereof

A compound fertilizer and soil improvement technology, applied in the field of compound fertilizer for farmland soil improvement and its preparation, can solve the problems of insignificant soil improvement effect, destruction of soil aggregate structure, influence on crop growth, etc., so as to improve physical and chemical properties and promote crop growth. , the effect of prolonging the storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

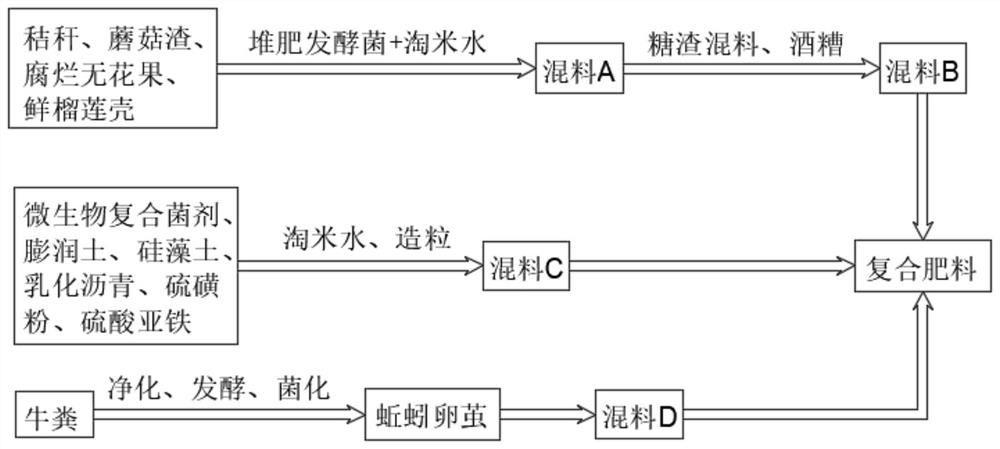

[0033] Example 1: See figure 1 , the present invention provides a compound fertilizer for improving farmland soil, comprising the following components by weight: 3-6 parts of microbial compound bacteria agent, 6-10 parts of earthworm egg cocoons, 15-20 parts of cow dung, compost fermentation 5-7 parts of bacteria, 20-30 parts of straw, 15-20 parts of mushroom slag, 20-25 parts of rotten fig, 15-20 parts of fresh durian shell, 20-25 parts of sugar residue mixture, 18-25 parts of bentonite, silicon 15-20 parts of algae earth, 8-12 parts of emulsified asphalt, 10-15 parts of distiller's grains, 5-7 parts of sulfur powder, 8-10 parts of ferrous sulfate, and the balance is rice washing water; Phosphorous bacteria, silicate bacteria, Bacillus natto and Bacillus megaterium; the sugar dregs mixture is prepared by mixing sugar beet dregs, corn dregs, and sugar cane dregs in a ratio of 1:1.2:1.4.

[0034] The present invention also provides a preparation process for compound fertilizer...

Embodiment 2

[0043] Embodiment 2: The compound fertilizer includes the following components by weight ratio: 5-6 parts of microbial compound bacteria agent, 8-10 parts of earthworm egg cocoons, 15-17 parts of cow dung, 6-7 parts of compost fermentation bacteria, 23 parts of straw -25 parts, 15-17 parts of mushroom dregs, 24-25 parts of rotten figs, 18-20 parts of fresh durian shells, 21-23 parts of sugar residue mixture, 18-20 parts of bentonite, 15-17 parts of diatomaceous earth, emulsified 9-10 parts of asphalt, 10-12 parts of distiller's grains, 5-7 parts of sulfur powder, 8-10 parts of ferrous sulfate, and the balance is rice washing water.

[0044] The preparation technology of this compound fertilizer is identical with embodiment 1.

[0045] The compound fertilizer in the embodiment 1 and 2 utilizes the characteristics that the cow dung fiber is rich and the air permeability is good, and it is used as the covering layer of the earthworm egg cocoon, and serves as the effect of raising...

Embodiment 3

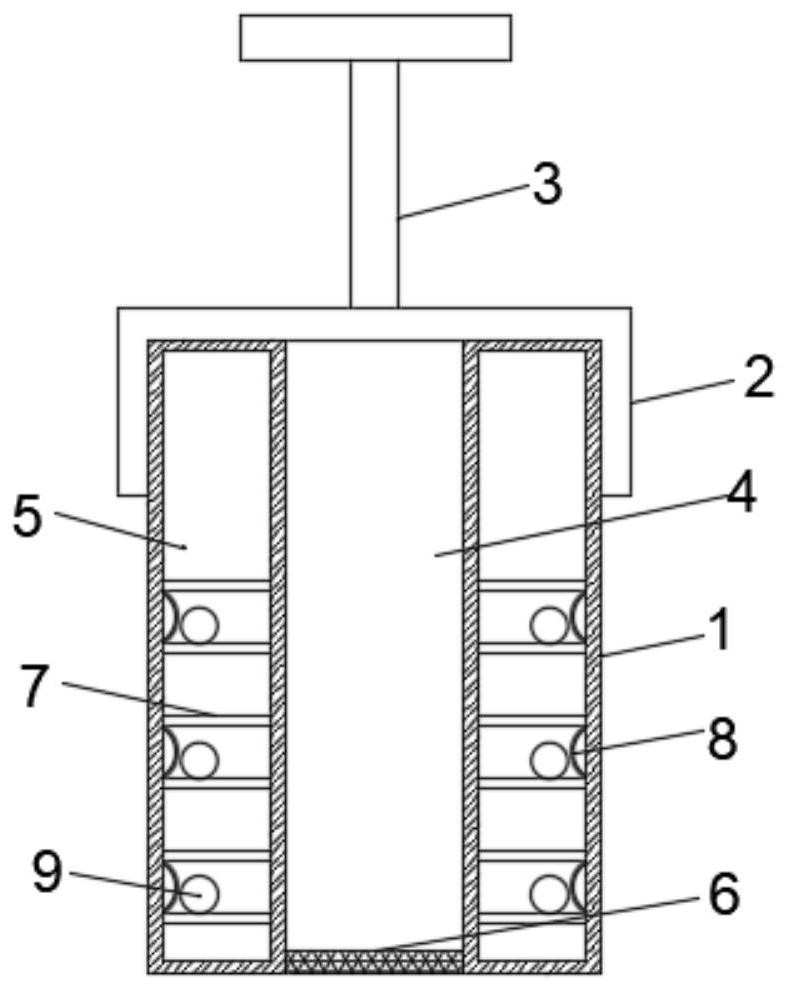

[0046] Example 3: See figure 2 , the screening mechanism in the above step S4 includes a screening cylinder 1 and a cylinder cover 2, one end of the screening cylinder 1 is open, and is threadedly connected with the cylinder cover 2, and the cylinder cover 2 is provided with a handle 3; The material chamber 4 in the middle and the oscillation chamber 5 placed on both sides of the material chamber 4 are separated by a partition. The top of the material chamber 4 is open for the material to be put in. The bottom of the chamber is equipped with a screen 6. There are multiple vibrating chambers at intervals up and down in the oscillation chamber 5. Horizontal guide channels 7, each guide channel 7 is placed with an oscillating ball 8, and each guide channel 7 is provided with an arched arc-shaped shrapnel 9 at the end far away from the material chamber 4, and the arc-shaped shrapnel 9 is used for vibration. Ball 8 collides and bounces it back.

[0047] The cultured earthworm egg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com