Method for preparing graphene porous membrane

A graphene and porous membrane technology, applied in the field of materials, can solve the problems of porous membrane volume expansion, non-uniform pore size, high energy consumption, etc., and achieve the effects of preventing fine deformation, simple instrument operation, and increasing the amount of material fed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Add 50 mg of graphite oxide to 50 mL of water to obtain a graphite oxide dispersion, and ultrasonically disperse for 1 h to obtain a graphene oxide solution;

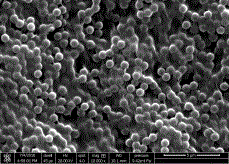

[0027] (2) adding 1 g of polystyrene microspheres to the above graphene oxide solution, so that the polystyrene microspheres are uniformly dispersed in the graphene oxide, and dried to obtain a composite film of graphene oxide and polystyrene microspheres;

[0028] (3) The composite film of graphene oxide and polystyrene microspheres was reduced by using 0.2L of hydroiodic acid solution with a concentration of 57% by volume, the reaction temperature was 80°C, the reduction time was 2h, and washed to obtain graphite. Composite film of alkene and polystyrene microspheres;

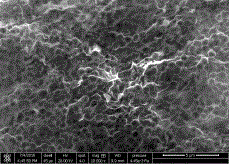

[0029] (4) The polystyrene microspheres were removed with tetrahydrofuran, and the tetrahydrofuran was replaced with anhydrous ethanol several times. The treated samples were stored in anhydrous ethanol and further treated by critical point ...

Embodiment 2

[0031] (1) Add 500 mg of graphite oxide to 50 mL of water to obtain a graphite oxide dispersion, and ultrasonically disperse for 5 hours to obtain a graphene oxide solution;

[0032] (2) Add 0.05g polymethyl methacrylate microspheres to the above graphene oxide solution, so that the polymethyl methacrylate microspheres are uniformly dispersed in the graphene oxide, and suction filtration to obtain graphene oxide and polymethyl methacrylate. Composite film of methyl acrylate microspheres;

[0033] (3) The composite film of graphene oxide and polymethyl methacrylate microspheres was reduced by using 5L of hydroiodic acid solution with a concentration of 40% by volume, the reaction temperature was 100°C, the reduction time was 8h, washed, A composite film of graphene and polymethyl methacrylate microspheres is obtained;

[0034] (4) The polymethyl methacrylate microspheres were removed with toluene, and the toluene was replaced with anhydrous ethanol several times. The treated s...

Embodiment 3

[0036] (1) Add 200 mg of graphite oxide to 50 mL of water to obtain a graphite oxide dispersion, and ultrasonically disperse for 1.5 h to obtain a graphene oxide solution;

[0037] (2) Add 0.1 g of poly[styrene-methyl methacrylate-acrylic acid] microspheres to the above graphene oxide solution, so that the poly[styrene-methyl methacrylate-acrylic acid] microspheres are uniformly dispersed in the graphite oxide. and drying to obtain a composite film of graphene oxide and poly[styrene-methyl methacrylate-acrylic acid] microspheres;

[0038] (3) The composite film of graphene oxide and poly[styrene-methyl methacrylate-acrylic acid] microspheres was reduced by using 0.5L of a hydroiodic acid solution with a concentration of 47% by volume, and the reaction temperature was 90 °C , the reduction time is 4h, and washing is performed to obtain a composite film of graphene and poly[styrene-methyl methacrylate-acrylic acid] microspheres;

[0039] (4) Remove the poly[styrene-methyl metha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com