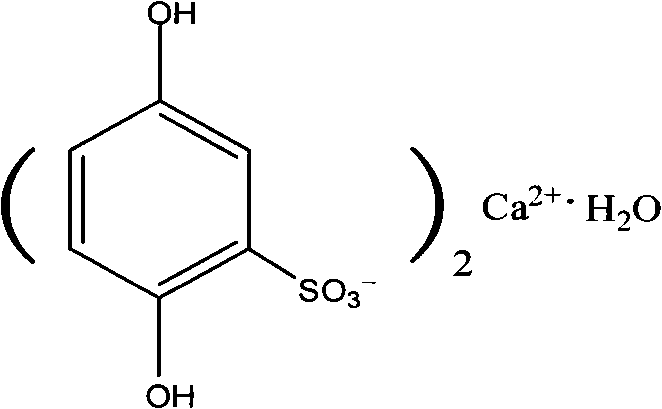

Synthetic reaction of calcium dobesilate hydrate

A calcium dobesilate hydrate and sulfonation reaction technology, which is applied in the preparation of sulfonate, organic chemistry, etc., can solve the problems of long synthesis route, complex process, high equipment requirements, etc., achieve mild reaction conditions and simplify process steps , The effect of improving crystal purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0025] Put 1.2kg of concentrated sulfuric acid with a concentration of 90% in the reaction kettle, add 1.25kg of hydroquinone under stirring, then add 0.4kg of concentrated sulfuric acid, heat up to 80°C while stirring, keep stirring for 2 hours, add 2.5kg of purified water, stirred, slowly added calcium carbonate, kept at 60°C until the pH value of the liquid reached 4.5, which was the end point of the reaction, and stopped adding calcium carbonate to the reaction kettle; centrifugally filtered, the filter cake was washed with purified water, separated Calcium sulfate, take the filtrate and put it in a concentration kettle, heat and concentrate until the specific gravity of the medicinal solution is 1.3g / ml, then stop the concentration, take the concentrated solution, cool and crystallize at room temperature, filter, and obtain about 2.4kg of crude product.

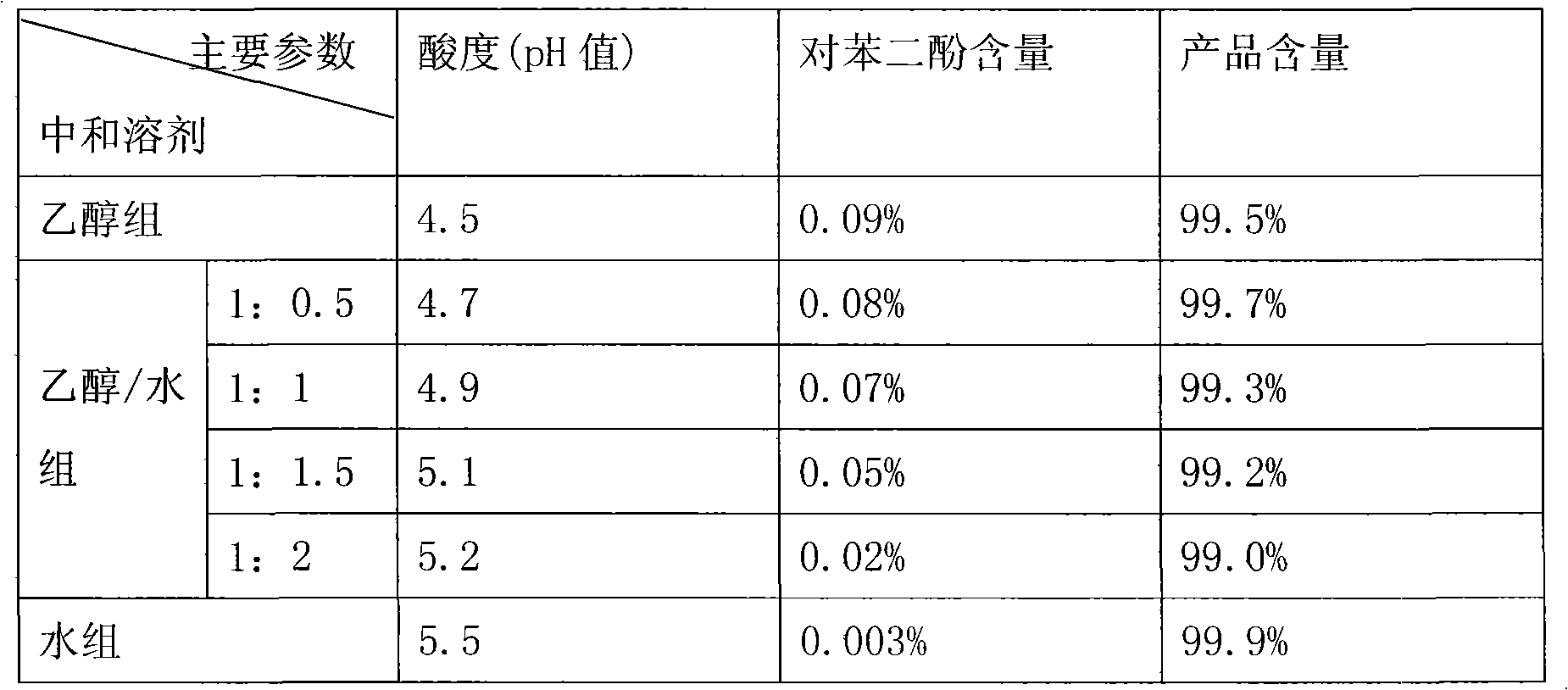

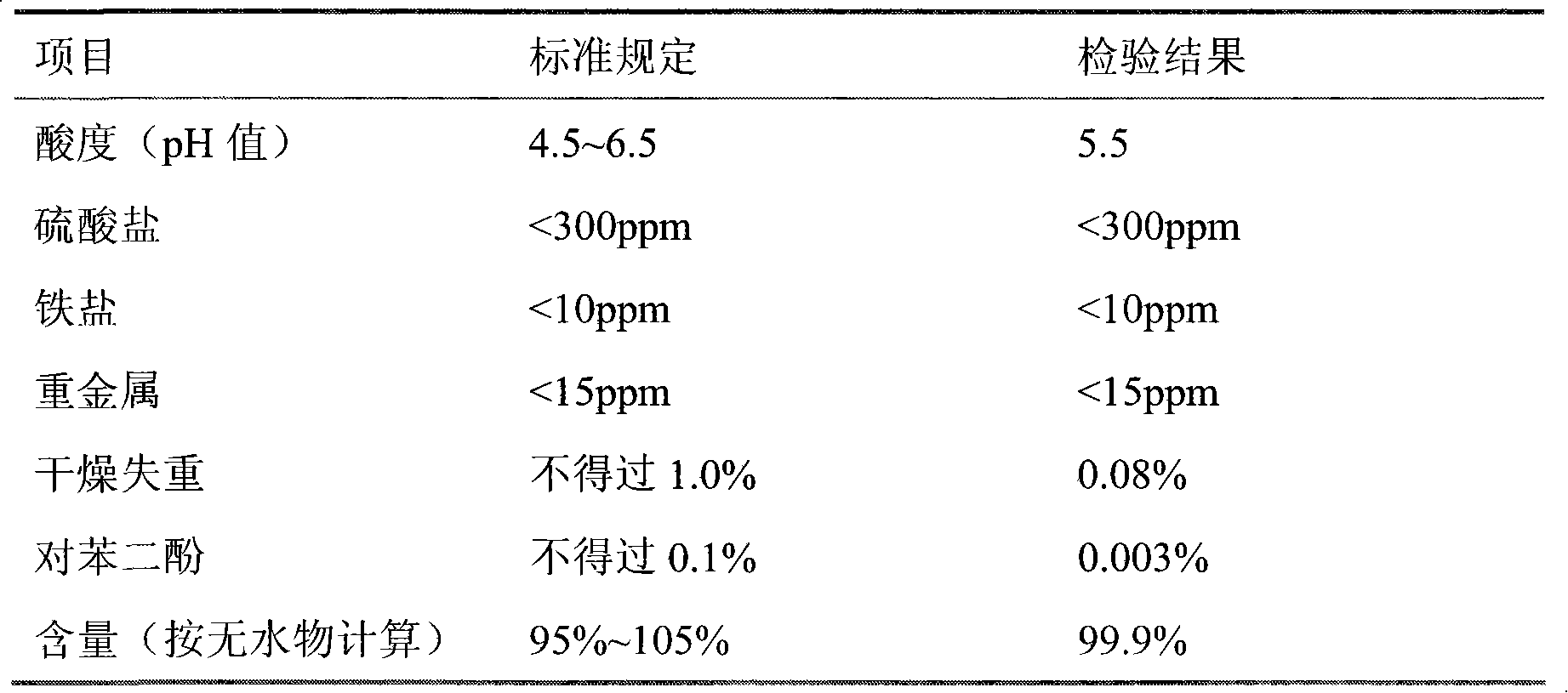

[0026] Put 2.4kg of crude product in a concentration kettle, add 0.8kg of purified water, stir, raise the temperature t...

example 2

[0031] Put 1.25kg of concentrated sulfuric acid with a concentration of 85% in the reaction kettle, add 1.25kg of hydroquinone under stirring, heat up to 70°C while stirring, keep warm and stir for 1 hour, add 3.0kg of purified water, stir, slowly Slowly add calcium carbonate, keep at 60°C until the pH value of the liquid reaches 4.5, which is the end point of the reaction, stop adding calcium carbonate to the reaction kettle; centrifugally filter, wash the filter cake with purified water, separate calcium sulfate, take the filtrate and put it in the concentration kettle Concentrate by heating until the specific gravity of the medicinal solution is 1.3g / ml, stop the concentration, take the concentrated solution, cool and crystallize at 6°C, and filter to obtain about 2.2kg of crude product.

[0032] Put 2.2kg of crude product in a concentration kettle, add 0.8kg of purified water, stir, raise the temperature to 60°C, keep the temperature, concentrate under reduced pressure unti...

example 3

[0037] Put 1.7kg of concentrated sulfuric acid with a concentration of 90% in the reaction kettle, add 1.25kg of hydroquinone under stirring, raise the temperature to 85°C while stirring, keep stirring for 1 hour, lower the reaction temperature to 25°C, and add purified water 2.5kg, stir, slowly add calcium carbonate, and slowly raise the temperature to 60 ° C, keep warm, add calcium carbonate until the pH value of the liquid reaches 3.5, which is the end of the reaction, stop adding calcium carbonate to the reaction kettle; centrifuge, filter Wash the cake with purified water, separate the calcium sulfate, take the filtrate and put it in the concentration kettle, heat and concentrate until the specific gravity of the liquid is 1.3g / ml, stop the concentration, take the concentrated solution, cool and crystallize at room temperature, and filter to obtain the crude product About 2.5kg.

[0038] Put 2.5kg of crude product in a concentration kettle, add 0.8kg of purified water, st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com