Genetically engineered bacterium for producing 5-hydroxytryptophan, and construction method and application of genetically engineered bacterium

A technology of hydroxytryptophan and genetically engineered bacteria, applied in the field of genetically engineered bacteria and its construction, can solve the problems that the natural product extraction method is difficult to meet the market demand of 5-HTP, unstable, and the market price of 5-HTP remains high. , to achieve good application prospects, good growth traits, and the effect of convenient trait improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

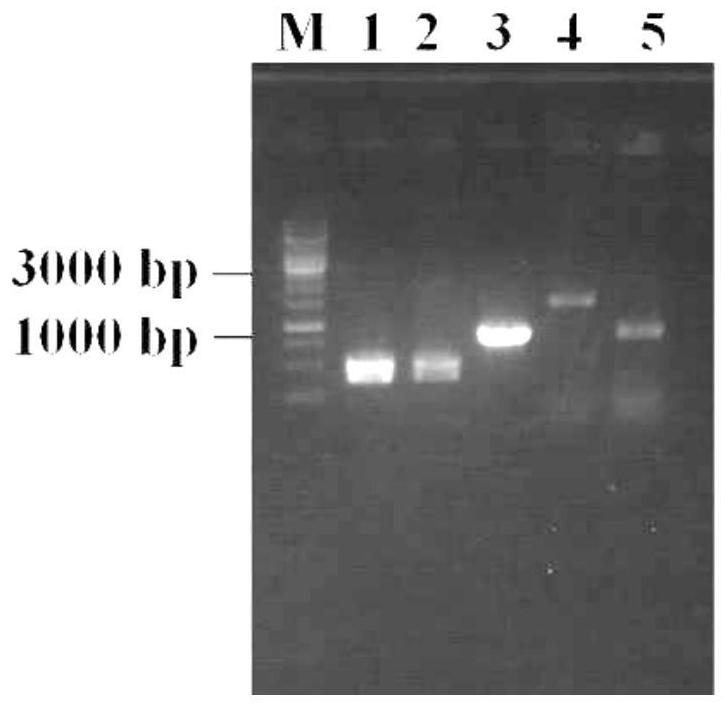

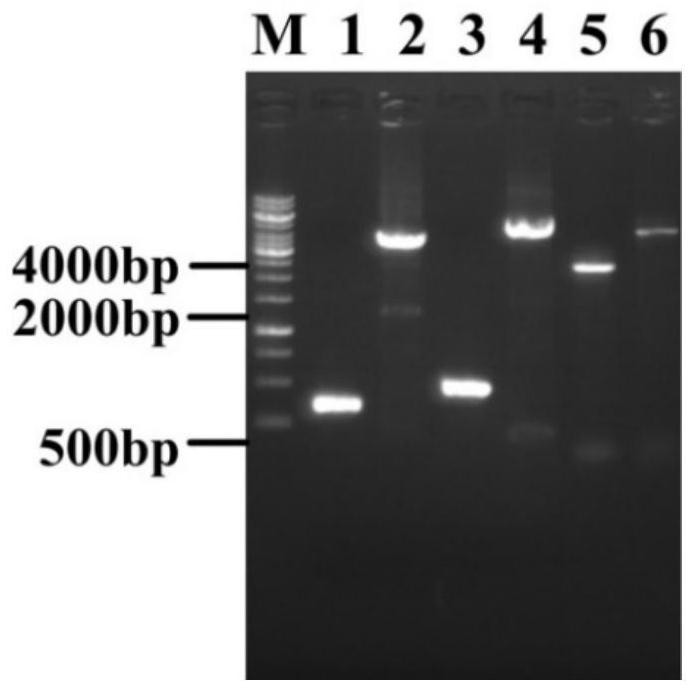

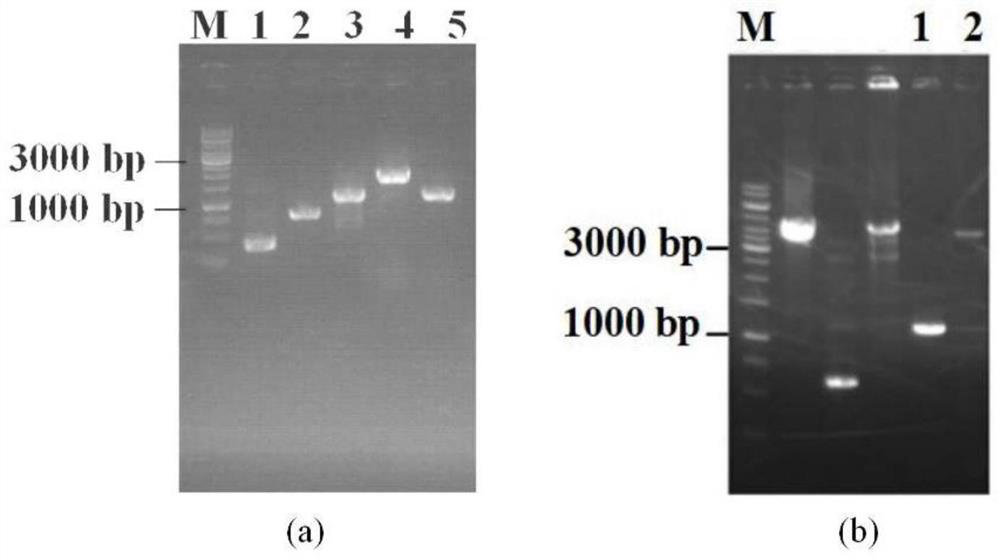

[0088] Construction of strain E.coli HTP10

[0089] 1. Methods of gene editing

[0090] The gene editing method used in the present invention is carried out with reference to the literature (Li Y, Lin Z, Huang C, et al. Metabolic engineering of Escherichia coli using CRISPR-Cas9 mediated genome editing. Metabolic Engineering, 2015, 31: 13-21.), the method For the two plasmid maps used see Figure 10 . Among them, pREDCas9 carries the elimination system of gRNA expression plasmid pGRB, the Red recombination system of λ phage and the Cas9 protein expression system, spectinomycin resistance (working concentration: 100mg / L), cultured at 32°C; pGRB uses pUC18 as the backbone, including the promoter J23100, gRNA-Cas9 binding region sequence and terminator sequence, ampicillin resistance (working concentration: 100mg / L), cultured at 37°C.

[0091] Such as Figure 9 As shown, the specific steps of the method are as follows:

[0092] 1.1 pGRB plasmid construction

[0093] The pur...

Embodiment 2

[0149] Utilize the Escherichia coli genetically engineered bacterium described in Example 1 to produce 5-hydroxytryptophan by fermentation in shake flasks

[0150] 1. Medium

[0151] 1.1 Incline medium

[0152] Glucose 1-3g / L, peptone 5-10g / L, beef extract 5-10g / L, yeast extract powder 2-5g / L, sodium chloride 2-5g / L, agar powder 15-30g / L, dissolved in water And adjust the volume to the required volume, adjust the pH to 7.0-7.2 with sodium hydroxide, sterilize in a high-pressure steamer at 121°C for 20 minutes, and then pack into test tubes.

[0153] 1.2 Seed medium

[0154] Glucose 20-40g / L, yeast extract powder 2-5g / L, ammonium sulfate 1-5g / L, potassium dihydrogen phosphate 1-5g / L, anhydrous magnesium sulfate 0.5-2g / L, ferrous sulfate heptahydrate 10 -30mg / L, manganese sulfate monohydrate 10-30mg / L, V H 0.1-0.5mg / L, V B1 0.5-1mg / L, trace element mixture 1-2mL / L, phenol red: 2% of the constant volume, adjust the pH to 7.0-7.2 with sodium hydroxide, and sterilize in a hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com