In-tube propelled coal material decomposition device

A propulsive, material technology, applied in the direction of lighting and heating equipment, special forms of dry distillation, furnace types, etc., can solve the problems that cannot meet the production needs of rapid decomposition and separation, increase the difficulty of installation and maintenance, and limit product output. Achieve ideal heating effect, facilitate inspection and maintenance, and improve utilization rate and utilization level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

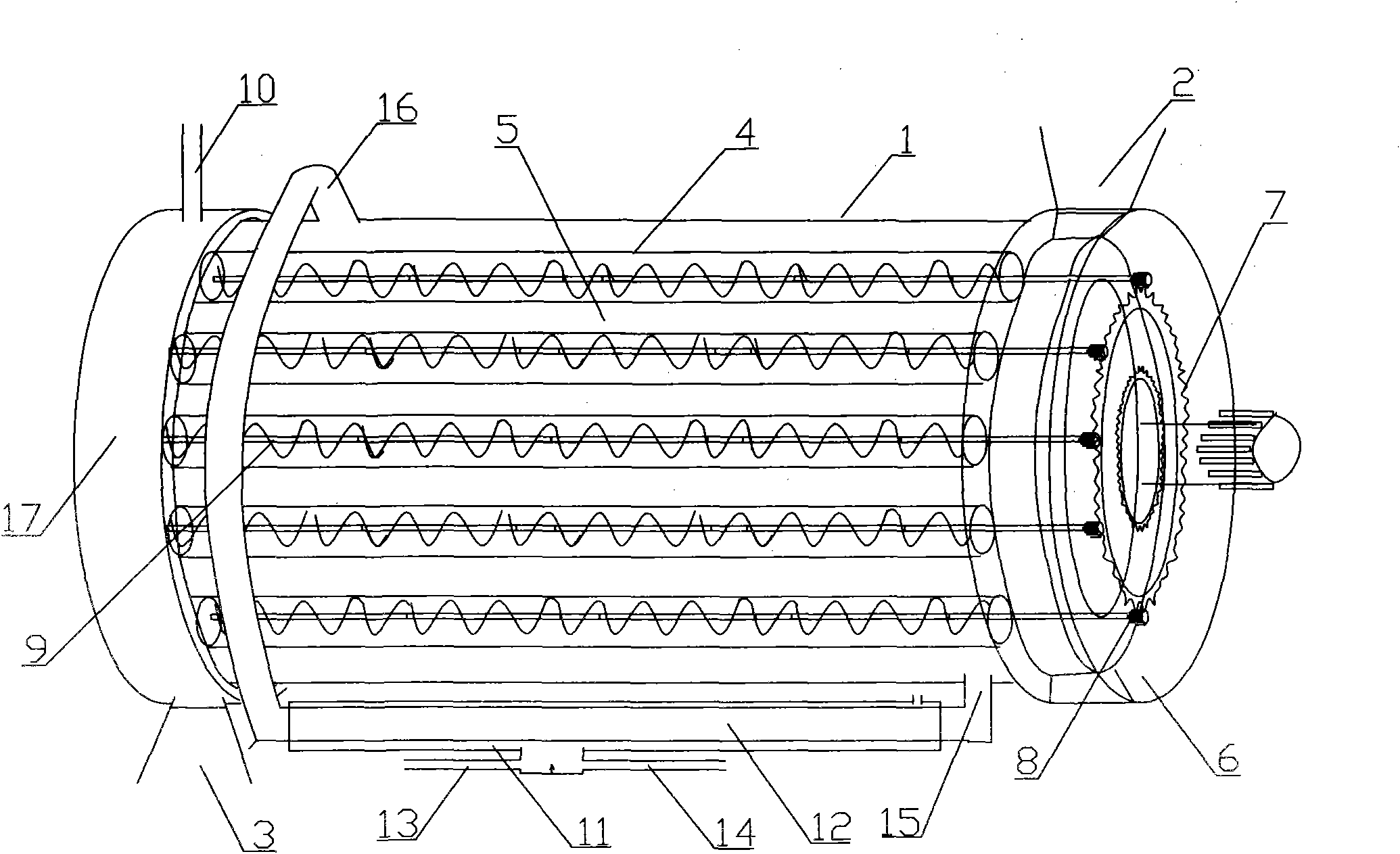

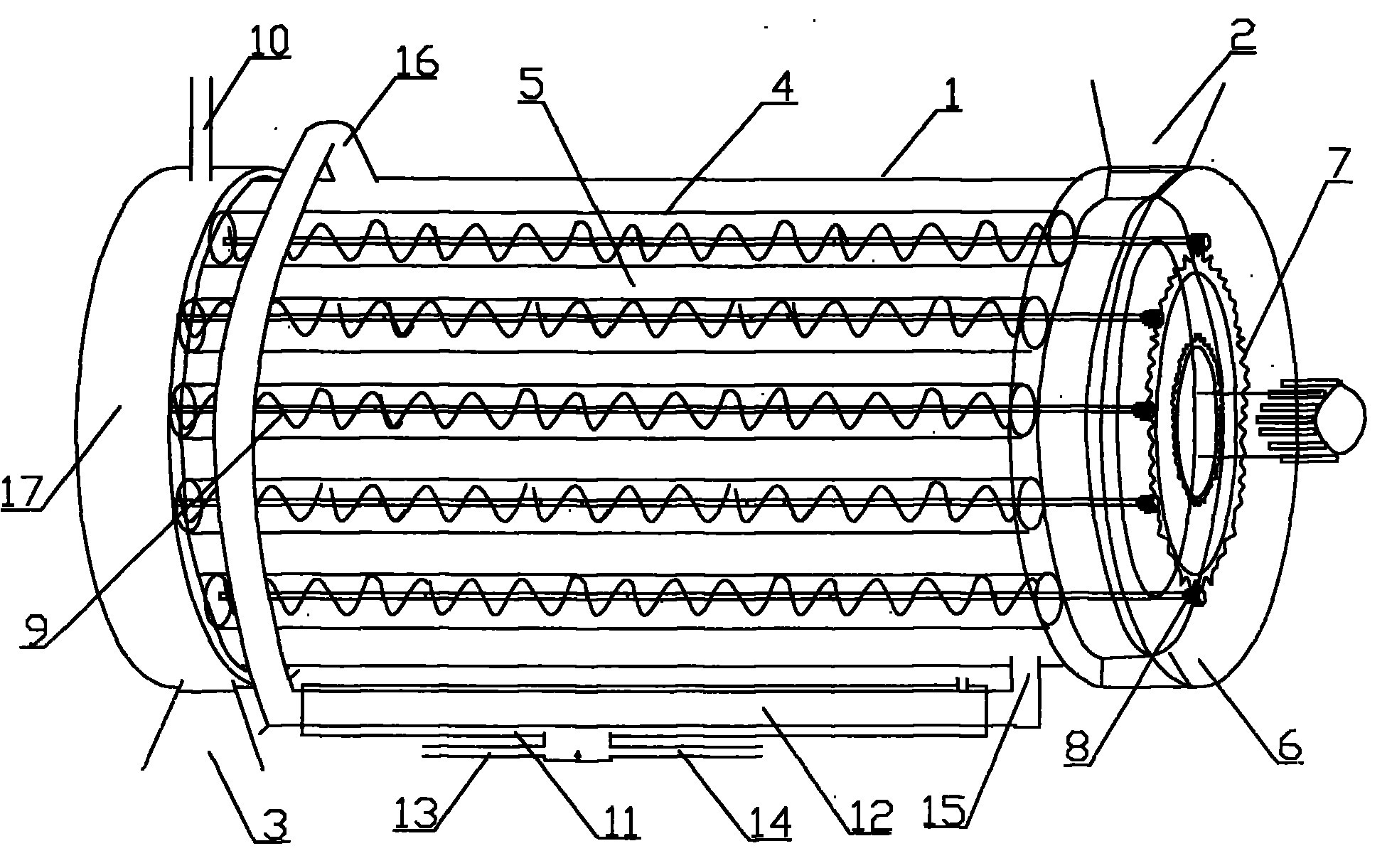

[0015] Such as figure 1 Shown:

[0016] An in-pipe propelling type coal decomposition equipment, comprising a sealed kiln body 1, a coal propelling and decomposing pipeline 4 is arranged in the kiln body 1, and a coal inlet 2, a coal outlet 3 and a coal propelling and decomposing pipeline 4 are set The decomposition gas collection pipe 10 is connected with the rotary power mechanism 7 arranged outside the kiln body 1, and the heat exchange chamber 5 is formed between the coal material propelling decomposition pipe 4 and the inner wall of the kiln body 1, and the heat exchange chamber 5 passes through the The air pipe 16 is connected to the high-temperature gas heating mechanism, and the heat exchange chamber 5 is provided with a heating gas outlet 15 on a side away from the high-temperature gas heating mechanism. The high temperature gas heating mechanism includes a fuel supply pipe 13 , an air supply pipe 14 and a combustion chamber 11 . The coal material propulsion and dec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com