Folded tube external heating coal material decomposition equipment

An external heating, material technology, applied in special forms of dry distillation, indirect heating dry distillation, petroleum industry, etc., can solve the production needs that cannot meet the rapid decomposition and separation, the rotary seal affects the separation of decomposition gas and heating gas, and limits product output It can achieve ideal heating effect, improve utilization rate and utilization level, and facilitate repair and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

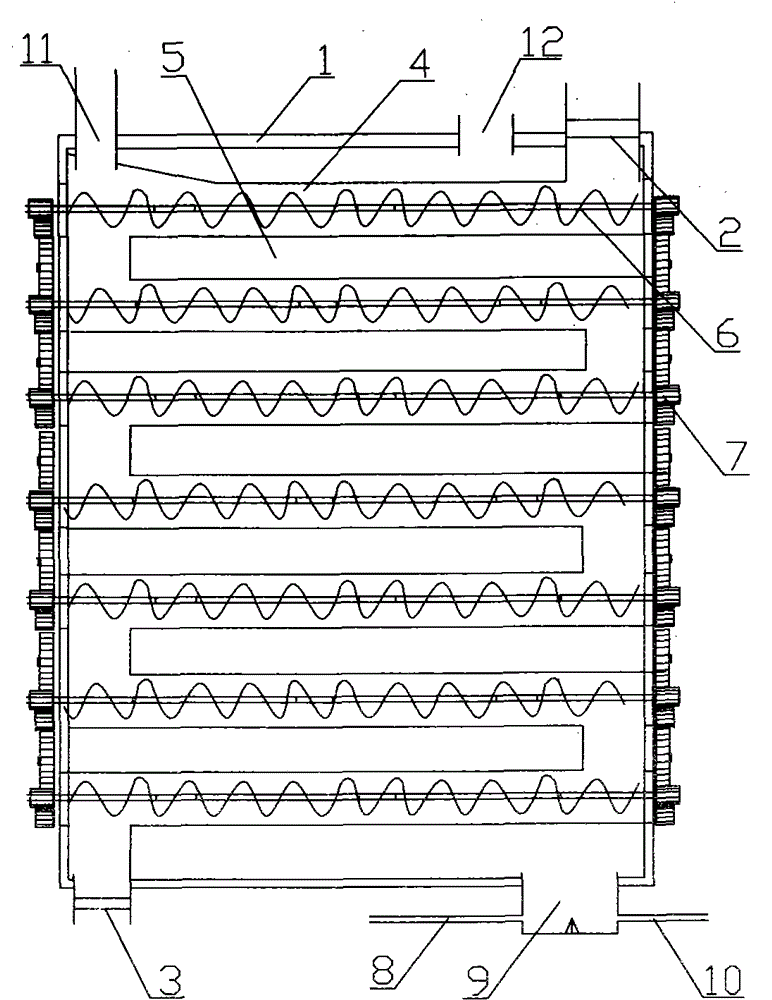

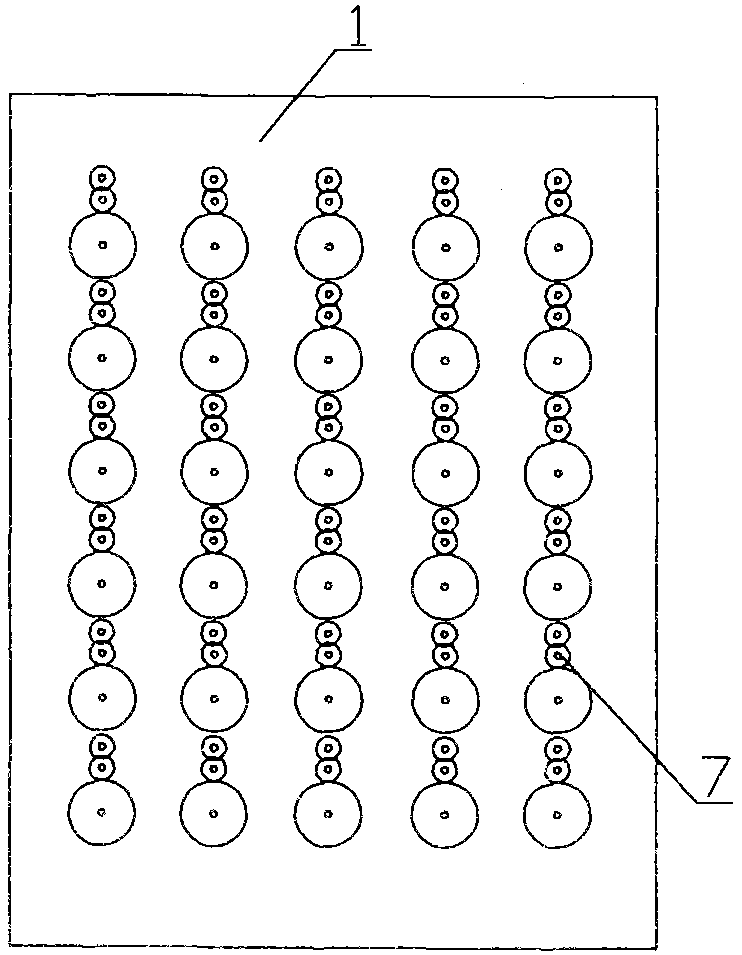

[0017] Such as figure 1 , figure 2 Shown: a folded tube external heating type coal material decomposition equipment, including a sealed kiln body 1, a coal material propelling and decomposing pipeline 4 is arranged in the kiln body 1, and a coal material propelling and decomposing pipeline 4 is provided with a coal inlet 2, The coal outlet 3 and the decomposition gas collection pipe 11 are arranged in the form of multi-layer broken line pipelines, and a screw propeller 6 is arranged in each layer of pipeline, and the screw propeller 6 is connected with the rotating power through the gear protruding outside the kiln body 1. It is connected with the moving mechanism 7, and the heat exchange chamber 5 is formed between the coal material propelling and decomposing pipeline 4 and the inner wall of the kiln body 1. The heat exchange chamber 5 is connected with the high-temperature gas heating mechanism, and the heat exchange chamber 5 is far away from the high-temperature gas heati...

Embodiment 2

[0019] A coal material decomposition equipment of folded tube external heating type, comprising a sealed kiln body 1, a coal material propelling and decomposing pipeline 4 is arranged in the kiln body 1, and the coal material propelling and decomposing pipeline 4 is provided with a coal inlet 2 and a coal outlet 3 and the decomposition gas collection pipe 11, which are arranged in the form of multi-layer broken line pipelines, and each layer of pipelines is equipped with a discharge scraper, and the pushing scraper passes through the gear extending outside the kiln body 1 and the rotating power linkage mechanism 7 connected, the coal material propelling decomposition pipeline 4 and the inner wall of the kiln body 1 form a heat exchange chamber 5, the heat exchange chamber 5 is connected to the high-temperature gas heating mechanism, and the heat exchange chamber 5 is on the side away from the high-temperature gas heating mechanism A heating gas outlet 12 is provided. The high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com