Patents

Literature

376 results about "Molybdenum dioxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

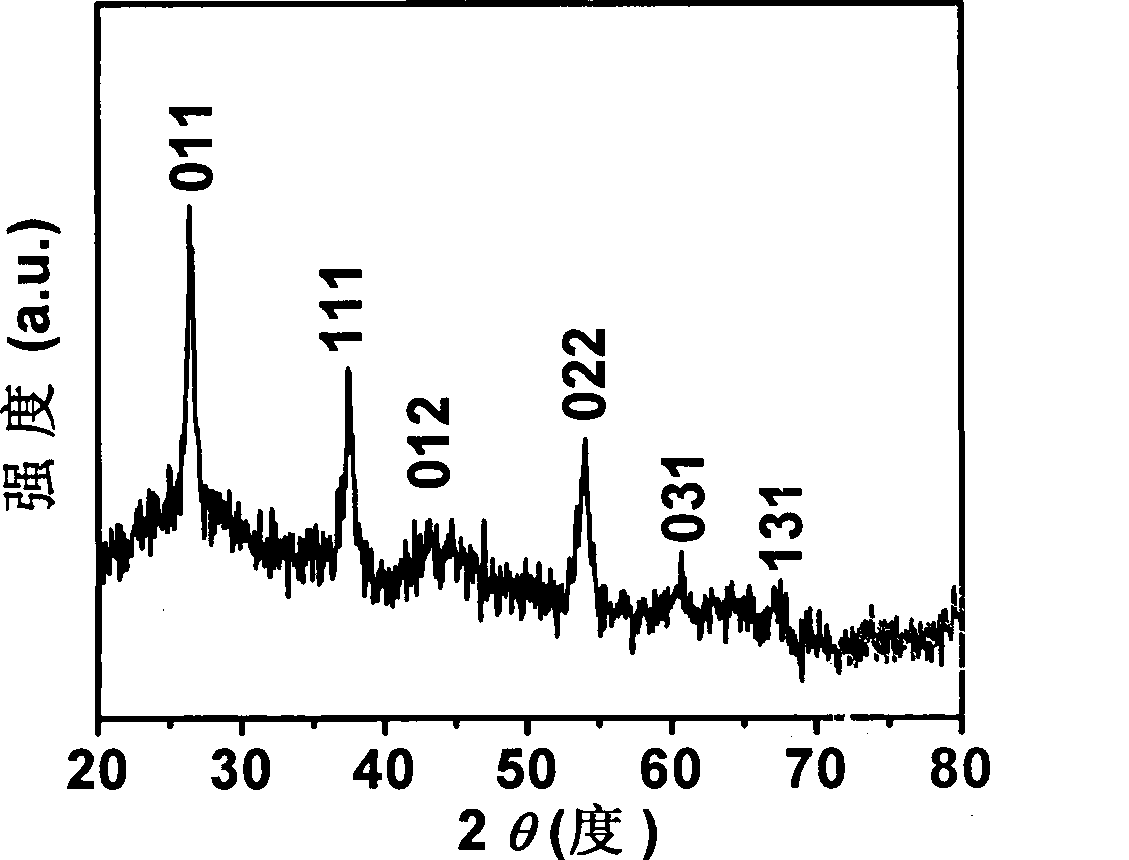

Molybdenum dioxide is the chemical compound with the formula MoO₂. It is a violet-colored solid and is a metallic conductor. It crystallizes in a monoclinic cell, and has a distorted rutile, (TiO₂) crystal structure. In TiO₂ the oxide anions are close packed and titanium atoms occupy half of the octahedral interstices (holes). In MoO₂ the octahedra are distorted, the Mo atoms are off-centre, leading to alternating short and long Mo – Mo distances and Mo-Mo bonding. The short Mo – Mo distance is 251 pm which is less than the Mo – Mo distance in the metal, 272.5 pm. The bond length is shorter than would be expected for a single bond. The bonding is complex and involves a delocalisation of some of the Mo electrons in a conductance band accounting for the metallic conductivity. MoO₂ can be prepared...

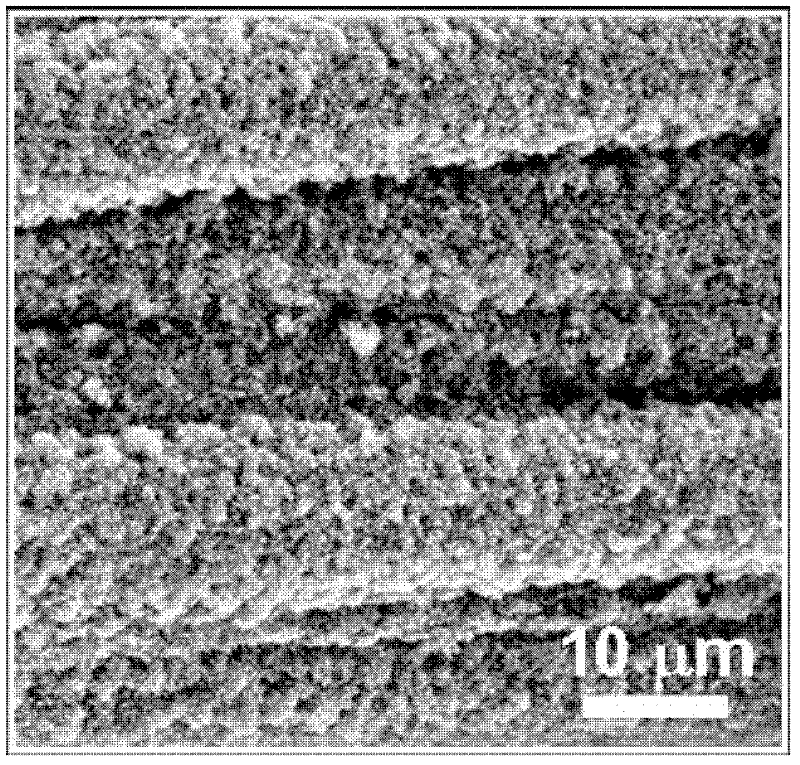

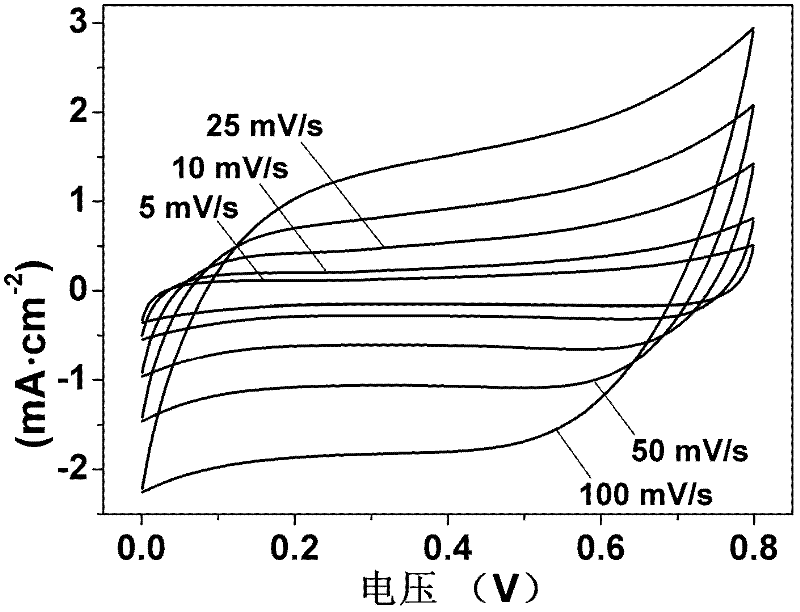

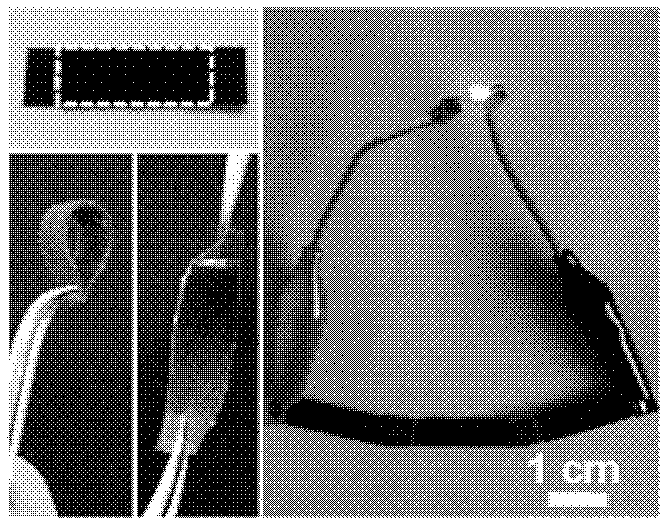

Preparation method of flexible super capacitor based on carbon cloth

InactiveCN102509635ASimple methodEasy to controlSolid electrolytic capacitorsSolid state electrolyteConductive polymer

The invention discloses a preparation method of a flexible super capacitor based on carbon cloth. The preparation method comprises the following steps of: firstly, growing carbon nanometer particles, carbon nanometer tubes, zinc oxides or tungsten oxide on the carbon cloth, or generating molybdenum dioxide on the carbon cloth; then, preparing manganese oxide or conductive polymers on the substances grown or generated on the carbon cloth for forming electrode materials; and finally, overlapping two electrode materials through solid electrolytes, separating the two electrode materials through a diaphragm and preparing the solid super capacitor. The flexible super capacitor prepared by the method provided by the invention has good electrochemical characteristics and the bending performance and has good application prospects in energy storage aspects.

Owner:HUAZHONG UNIV OF SCI & TECH

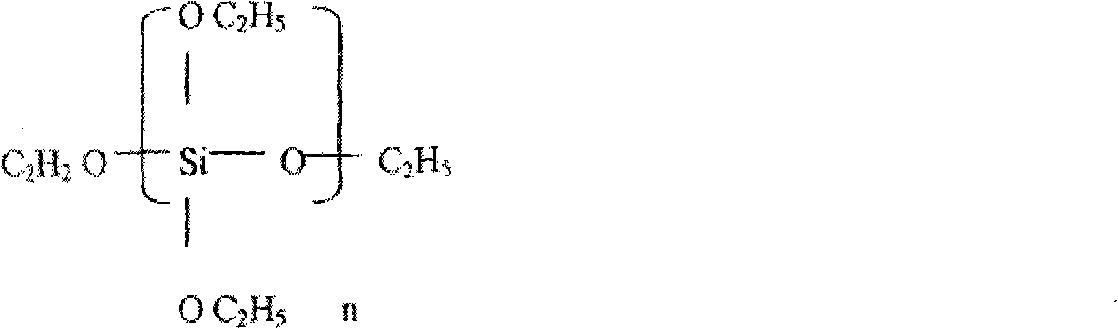

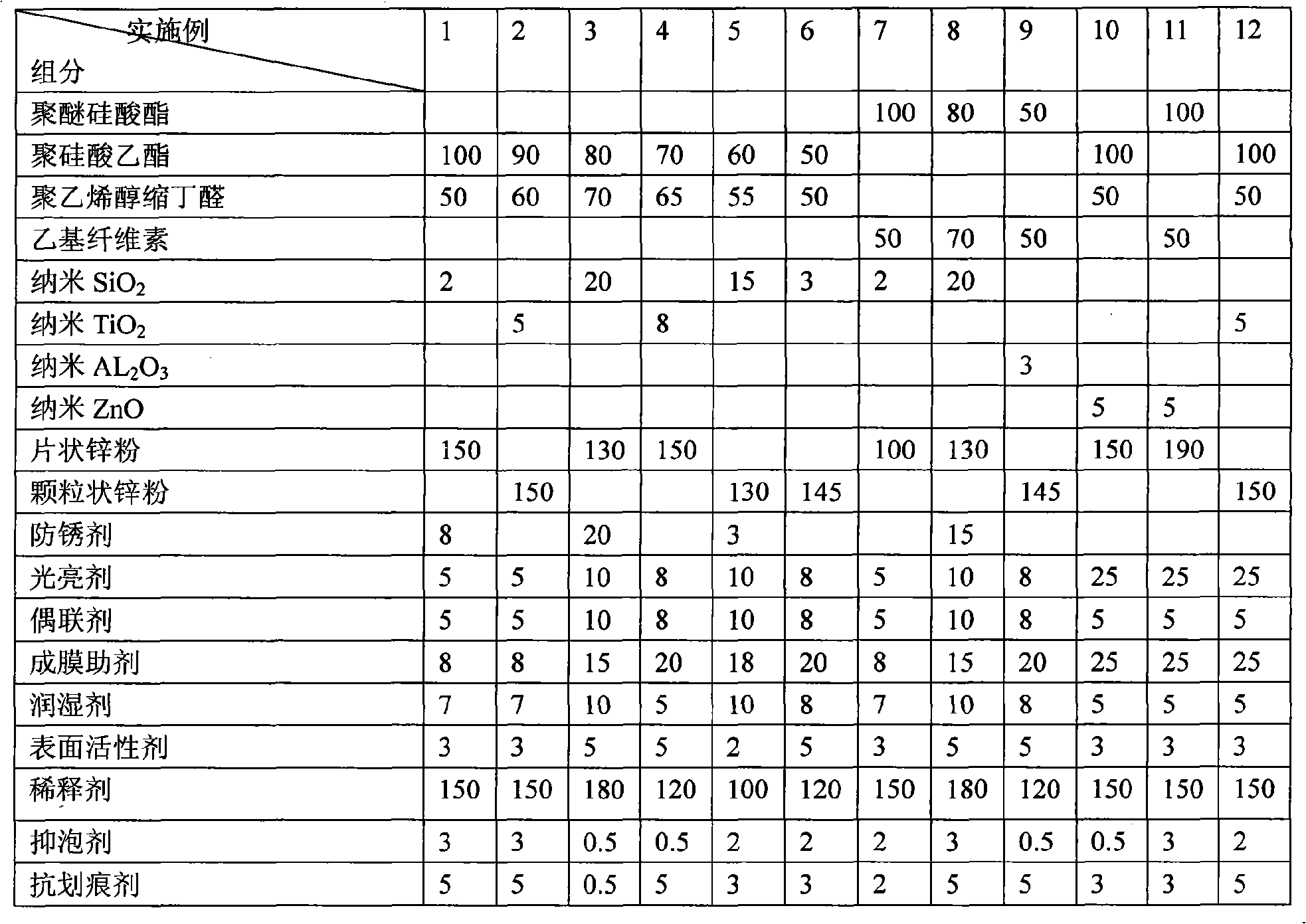

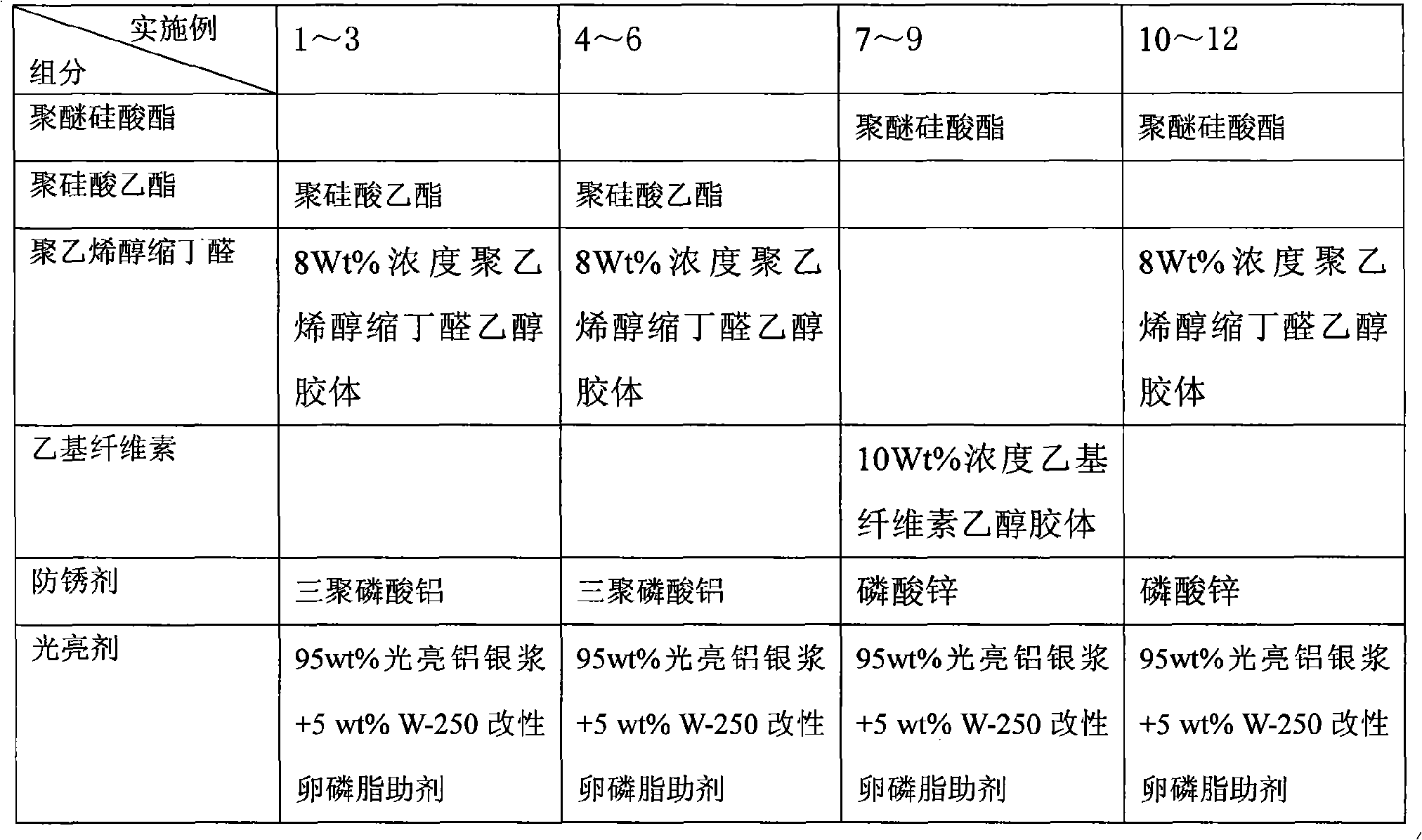

Zinc metallic coating

The invention discloses a zinc metal coating layer, the zinc metal coating is characterized in that when being calculated according to the parts by weight, the components of the the zinc metal coating are as follows: 50 parts to 100 parts of polyether silicate ester or polymerized silica acid ester, 50 parts to 100 parts of polyvinyl butyral or ethyl cellulose, 1 part to 20parts of one or a plurality of component (s) among nanometer silicon dioxide, nanometer titanium dioxide, nanometer molybdenum dioxide, or nanometer zinc oxide, 80 parts to 200 parts of zinc powder, 0 to 20 parts of rust preventing agent,, 5 parts to 100 parts of coupling agent, 5 parts to 25 parts of brightening agent, 8 parts to 250 parts of film forming auxiliary agent, 5 parts to 10 parts of wettinh agent, 1 part to 5 parts of surface activating agent, 100 parts to 200 parts of thinning agent, 0.5 part to 3 parts of anti-foaming agent and 0.5 part to 5 parts of anti-scratching agent. The bright metal zinc coating layer related by the invention can be taken as the anti-corrosive oxidation resistant zinc metal coating layer of metal product, particularly the black metal product, which can replace the commonly adopted galvanizing technology. The bright zinc metal coating layer of the invention can very conveniently and effectively paint a zinc metal coating layer the binding of which is firm on the metal product, particularly the black metal product.

Owner:胡仲寅

Method for preparing submicron molybdenum powder

The invention discloses a method for preparing submicron molybdenum powder, which comprises the following steps that: ammonium molybdate or molybdenum trioxide are put in a mechanical crusher to be crushed into fine-particle raw materials, and the fine particle raw materials are put in a material boat; the fine-particle raw materials in the material boat are subjected to the primary hydrogen reduction in a reduction temperature region in a primary reduction furnace, and the product of the primary hydrogen reduction is molybdenum dioxide; then the material boat filled with the molybdenum dioxide is directly pushed into a secondary reduction furnace, the molybdenum dioxide in the material boat is subjected to the secondary hydrogen reduction in a reduction temperature region in the secondary reduction furnace, and the product of the secondary hydrogen reduction in the material boat is molybdenum powder; and finally, the sub-micron molybdenum powder can be obtained by sieving with a 160-mesh screen. The method for preparing the submicron molybdenum powder adopts the reduction temperature lower than the conventional reduction temperature, and short temperature region used in the reduction process, thereby reducing cost; and the average Fisher particle size of the prepared molybdenum powder is small, the specific surface area is large, and the activity is high, thereby being favorable for the follow-up sintering process.

Owner:JINDUICHENG MOLYBDENUM CO LTD

Preparation method of molybdenum powder

The invention discloses a preparation method of molybdenum powder, comprising the following steps of: firstly, sieving the raw material of molybdenum trioxide to obtain molybdenum trioxide powder; secondly, carrying out primary reductive reaction on the molybdenum trioxide powder and hydrogen gas in a primary reduction furnace to generate molybdenum dioxide; thirdly, carrying out secondary reductive reaction on molybdenum dioxide and hydrogen gas in a secondary reduction furnace to generate rough molybdenum powder; and fourthly, sieving the rough molybdenum powder and mixing to obtain the finished molybdenum powder. The preparation method provided by the invention is easy to control, simple and convenient to operate, safe and reliable and suitable for industrial mass production. A molybdenum block pressed by using the molybdenum powder prepared by using the preparation method provided by the invention is high in flexural strength, and the prepared molybdenum and copper alloy is high in yield, good in material consistency, long in service life and capable of being used as a braking / heat radiating material.

Owner:JINDUICHENG MOLYBDENUM CO LTD

Fine crystal rare earth oxide molybdenum alloy-doped and its preparation method

InactiveCN1757775AGood mechanical propertiesImprove room temperature fracture toughnessRare earthMuffle furnace

A RE oxide doped fine-crystal Mo-alloy is prepared from MoO2 through doping RE oxide by atomizing method, ball grinding, sieving, reducing in H2 atmosphere in muffle furnace at 800-1100 deg.C, cold isostatic pressing under 150-200 MPa for shaping, segmental sintering in MF induction furnace and mechanical deforming to obtain rod or plate. It has high strength, ductility and toughness.

Owner:山东铭特金属材料科技有限公司

Preparation method of high-purity molybdenum powder

The invention provides a preparation method of high-purity molybdenum powder, which comprises the steps: enabling molybdenum dioxide ore powder and chlorine gas to carry out a chlorination reaction; condensing to obtain MoO2C12 solid; then, enabling the MoO2C12 solid and ammonia water to carry out an ammonia leaching reaction to obtain ammonium paramolybdate and HCl gas; further roasting the ammonium paramolybdate to obtain MoO3; and finally, enabling MoO3 and reaction gas to carry out a reduction reaction to obtain high-purity molybdenum powder. Compared with a hydrometallurgical purification method of molybdenum ore sources in the prior art, the preparation method provided by the invention utilizes the molybdenum dioxide ore powder as a raw material to enable the chlorine gas and MoO2 to carry out a selective reaction. As the chlorine gas only reacts with metal Mo, other elements almost do not react; therefore, the content of product impurities is greatly reduced; a high-purity product is obtained; and the effects of the varieties and the contents of the impurities in the molybdenum ore sources of the raw material on the product purity are avoided.

Owner:湖南顶立科技股份有限公司

Welding flux for use in arc-welding of stainless steels, method of welding stainless steel members using the welding flux

InactiveUS20050199317A1Increase weld penetrationImprove welding efficiencyWelding/cutting media/materialsSoldering mediaManganeseSilicon dioxide

A welding flux for use in welding stainless steel parts to increase welding penetration, consisting essentially a base material obtained from manganese peroxide (MnO2), and an activator selected from a material group that includes zinc oxide (ZnO), silicon dioxide (SiO2), chromium oxide (CrO2), titanium dioxide (TiO2), molybdenum dioxide (MoO2), and iron oxide (Fe2O2).

Owner:NAT CHIAO TUNG UNIV

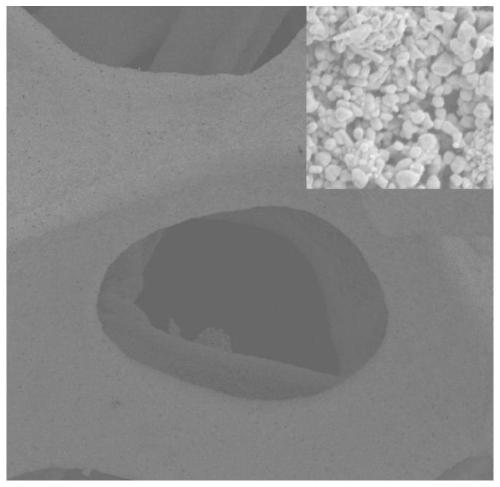

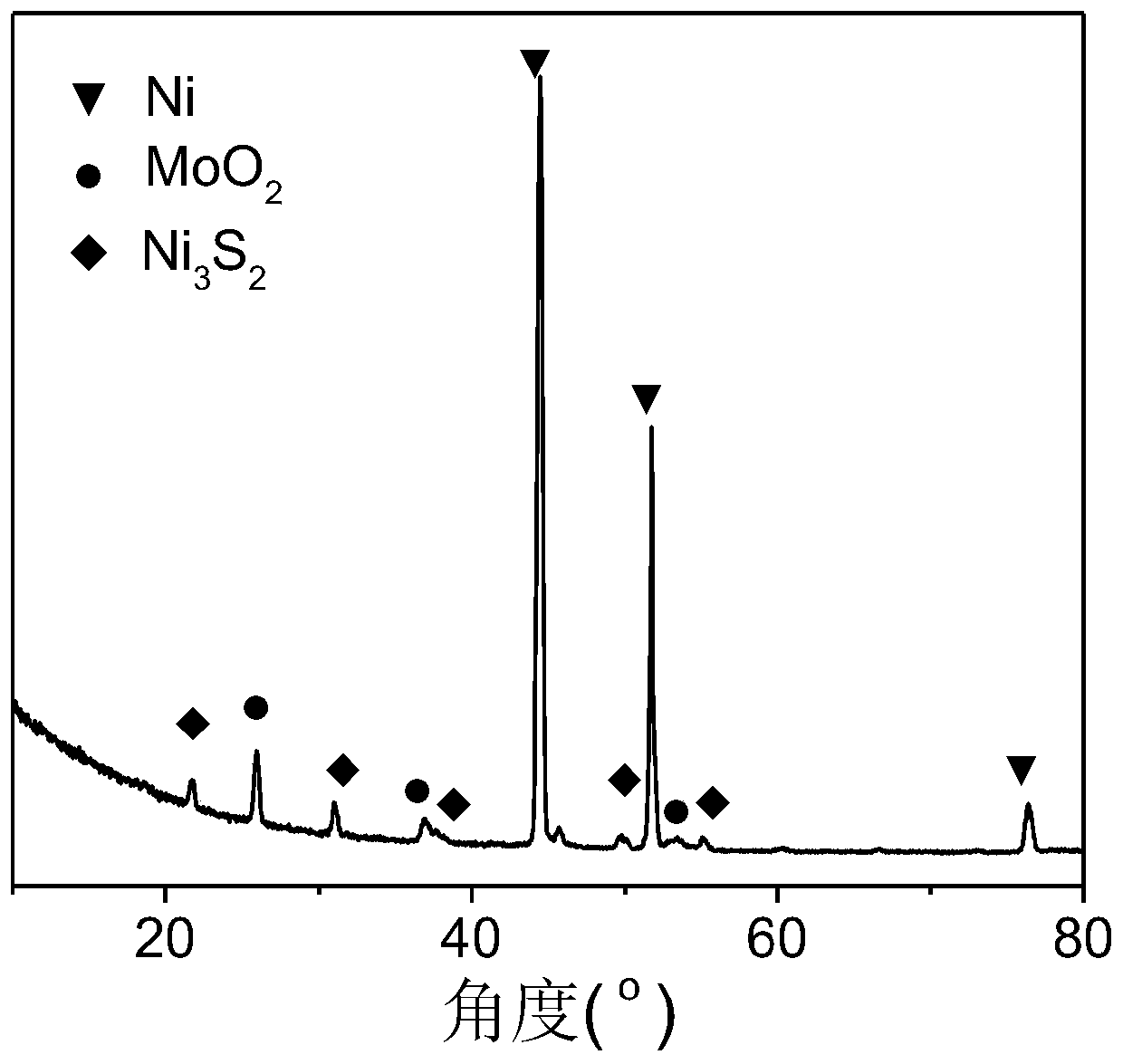

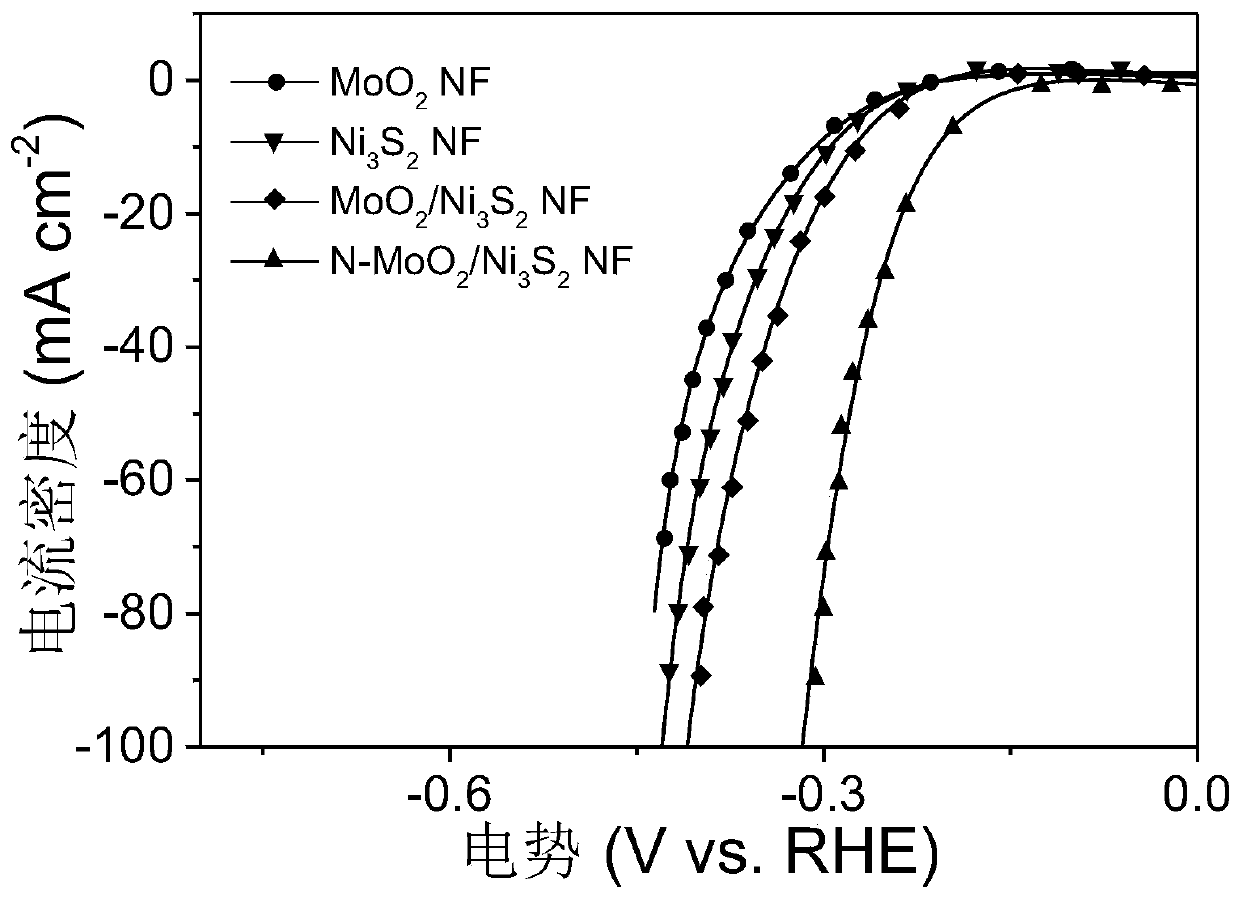

Three-dimensional nitrogen-doped transition metal oxide/nickel sulfide composite catalyst and preparation method and application thereof

ActiveCN110201697AOptimize electronic structureImprove electrocatalytic activityPhysical/chemical process catalystsElectrodesNickel sulfideCalcination

The invention discloses a three-dimensional nitrogen-doped transition metal oxide / nickel sulfide composite catalyst. The catalyst includes nickel foam, nitrogen-doped transition metal oxide and nickelsulfide, wherein the nickel foam serves as a substrate, and the nitrogen-doped transition metal oxide grows on the nickel foam in situ. The invention further discloses a preparation method of the three-dimensional nitrogen-doped transition metal oxide / nickel sulfide composite catalyst. The method includes the following steps that the nickel foam substrate is impregnated in an ammonium tetrathiomolybdate solution and dried after impregnation, and an ammonium tetrathiomolybdate contained nickel foam precursor is obtained; the nickel foam precursor is subjected to vacuum high-temperature calcination, and the molybdenum dioxide / nickel sulfide composite catalyst is obtained; the molybdenum dioxide / nickel sulfide composite materials are subjected to thermal ammoniation, and the three-dimensional nitrogen-doped transition metal oxide / nickel sulfide composite catalyst is obtained. The invention further provides the application of the composite catalyst as a cathode catalyst material in an electrolytic water cathode HER reaction, the composite catalyst shows excellent electrocatalytic performance in alkaline electrolyte and has good stability, and the possibility of hydrogen energy development and utilization is further improved.

Owner:ZHEJIANG UNIV

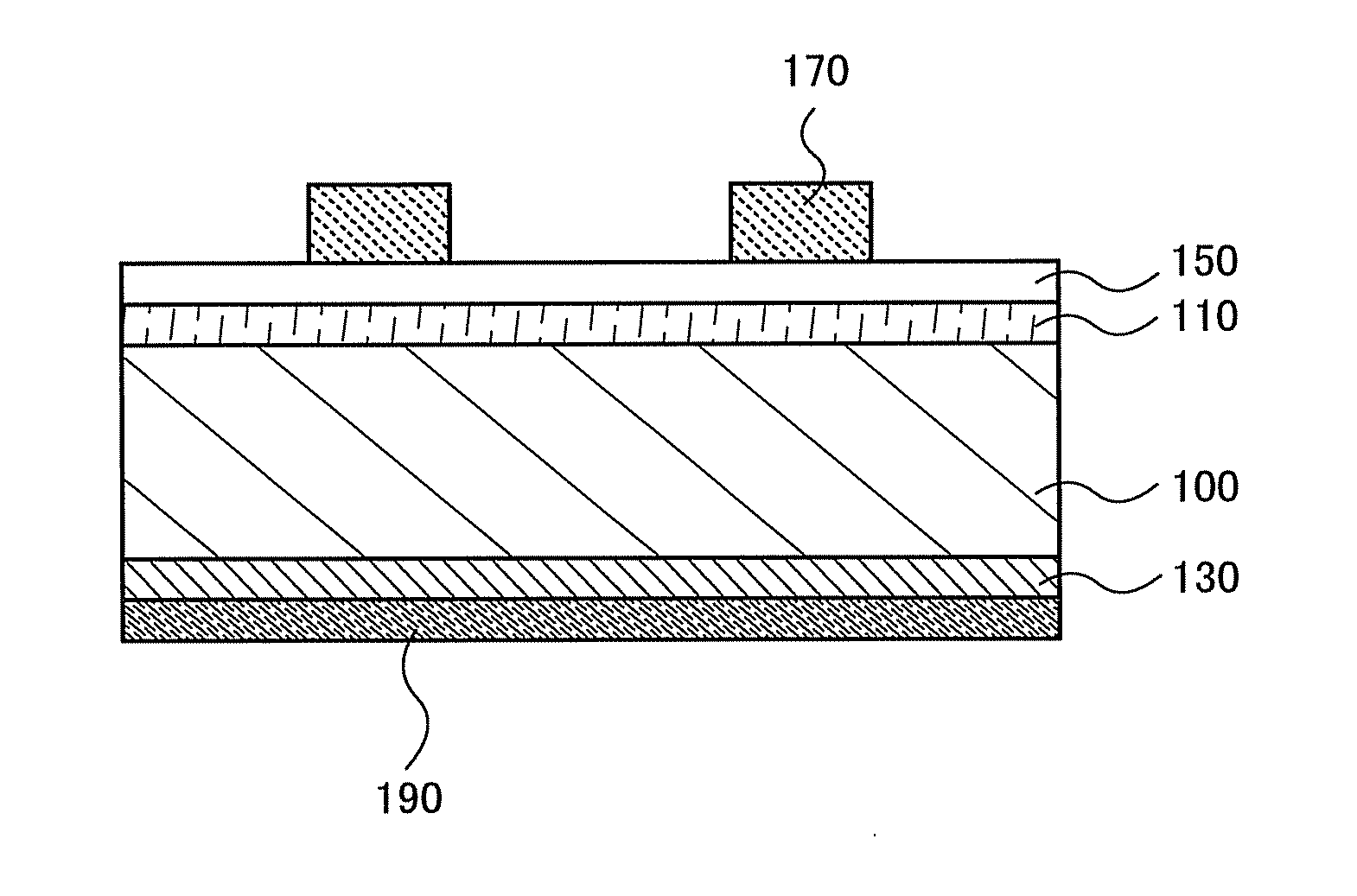

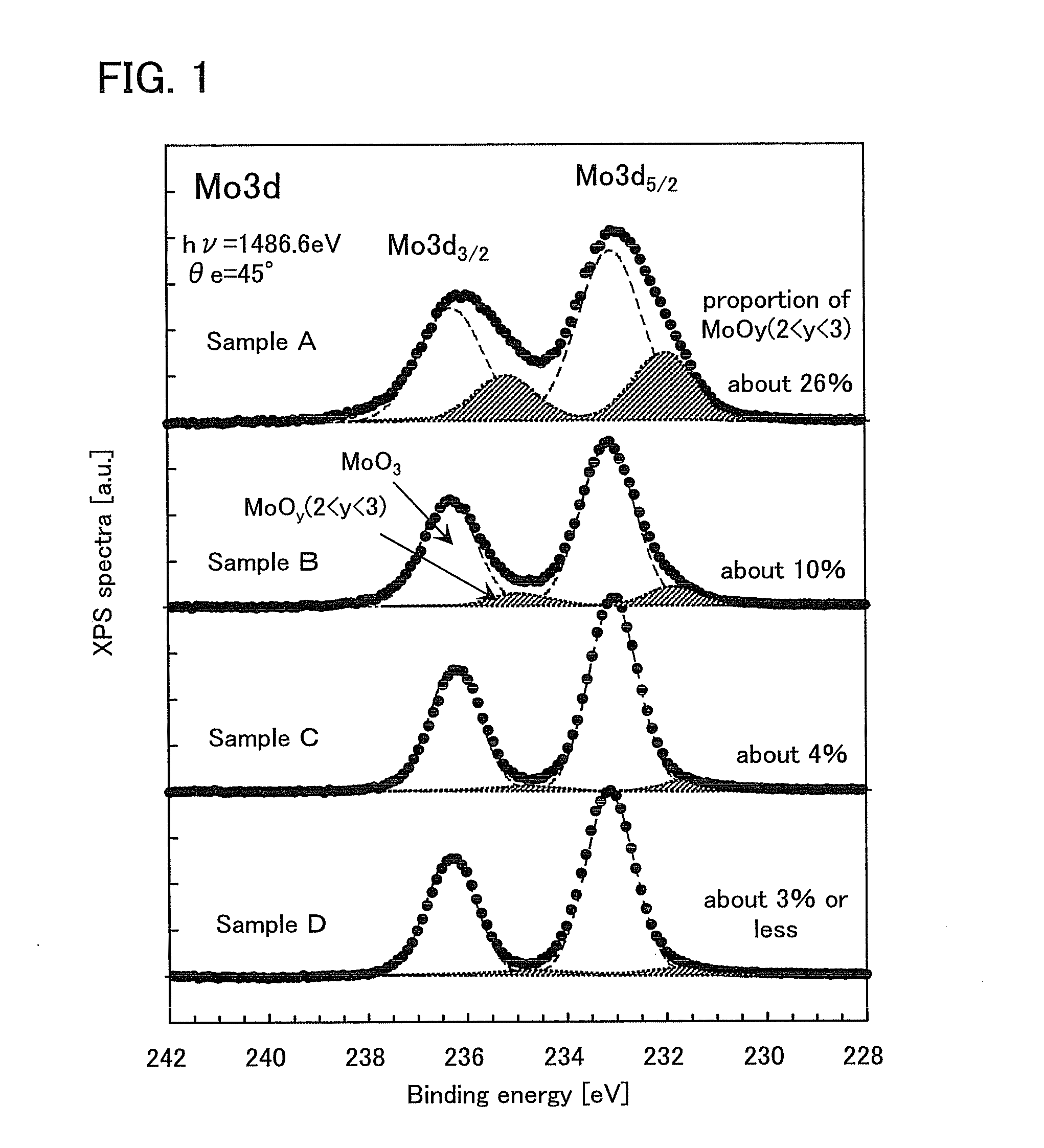

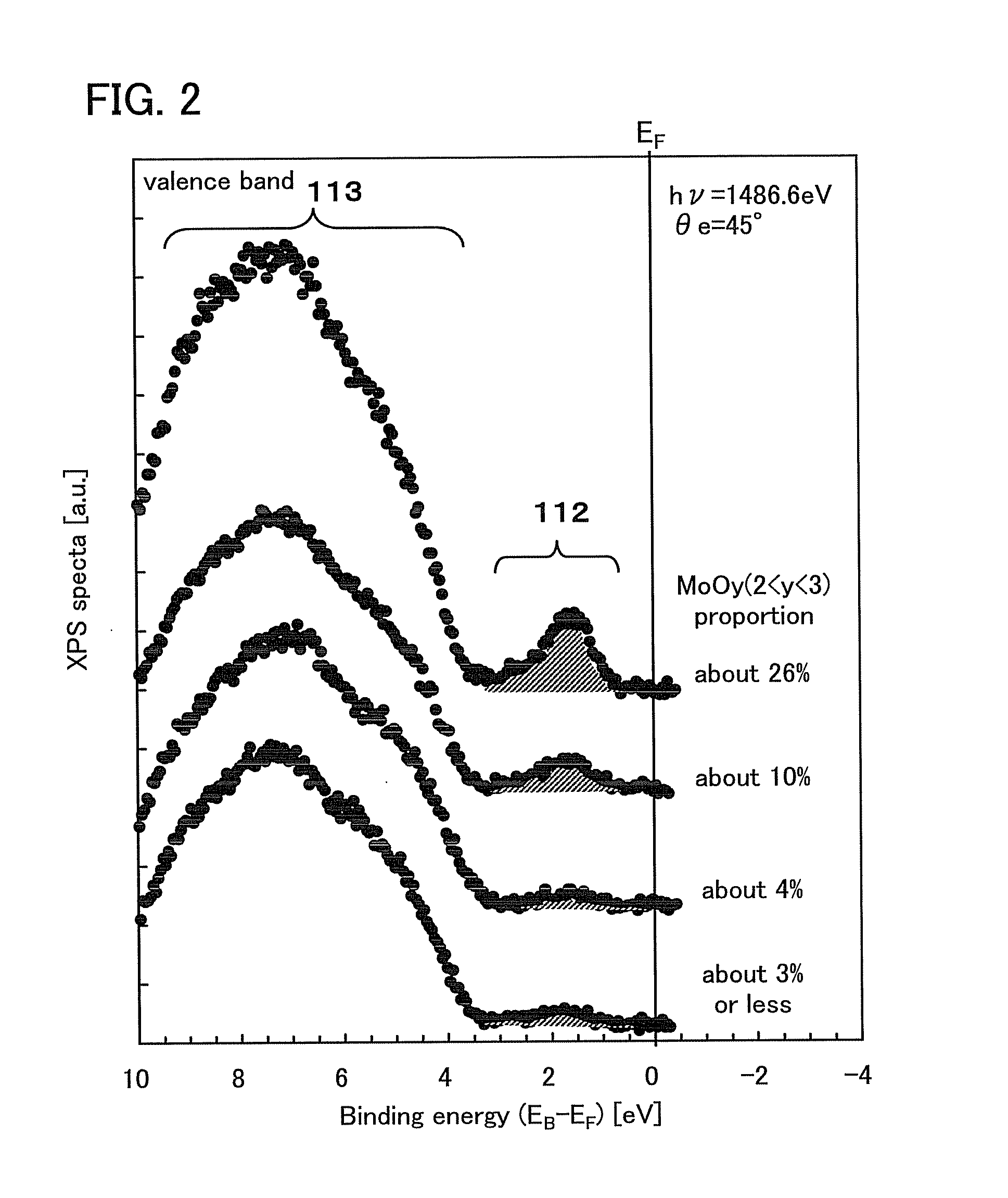

P-Type Semiconductor Material and Semiconductor Device

InactiveUS20130214271A1Reduce light absorption lossFavorable carrier extractionPhotovoltaic energy generationSemiconductor devicesSemiconductor materialsIntermediate composition

An oxide semiconductor material having p-type conductivity and a semiconductor device using the oxide semiconductor material are provided. The oxide semiconductor material having p-type conductivity can be provided using a molybdenum oxide material containing molybdenum oxide (MoOy (2<y<3)) having an intermediate composition between molybdenum dioxide and molybdenum trioxide. For example, a semiconductor device is formed using a molybdenum oxide material containing molybdenum trioxide (MoO3) as its main component and MoOy (2<y<3) at 4% or more.

Owner:SEMICON ENERGY LAB CO LTD

Molybdenum-yttrium alloy wire preparation method

InactiveCN101642812AImprove performance consistencyImprove uniformityHydrogenHigh volume manufacturing

The invention provides a molybdenum-yttrium alloy wires preparation method and is characterized in that the preparation method comprises the following steps: immersing molybdenum dioxide powder in yttrium nitrate solution, drying, mixing evenly, reducing with hydrogen at 800-1000 DEG C to obtain molybdenum powder doped with rare earth oxide Y2O3, isostatic pressing the obtained molybdenum powder at 160-200MPa to prepare rods, then sintering the rods at high temperature and finally rotary swaging and drawing to obtain molybdenum wires. The method of the invention effectively increases the uniformity of doping elements and can be used in mess production, the uniformity of the processed molybdenum-yttrium alloy wires is good and the rolled molybdenum foil strip has good using effect.

Owner:金堆城钼业光明(山东)股份有限公司

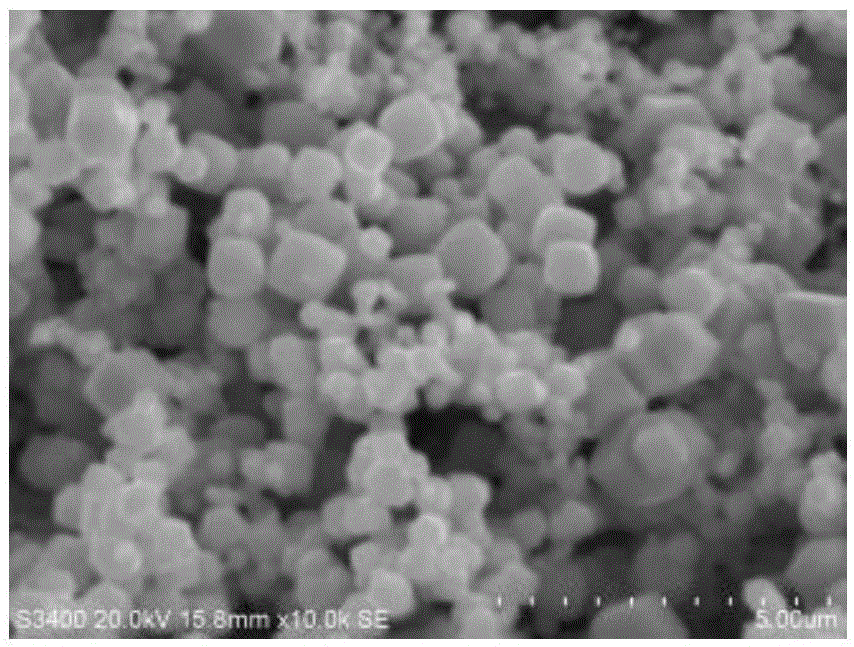

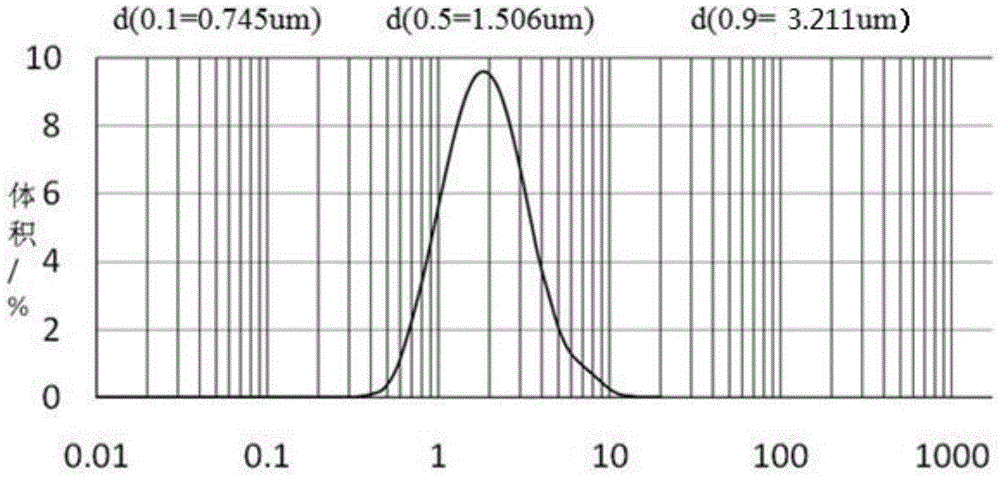

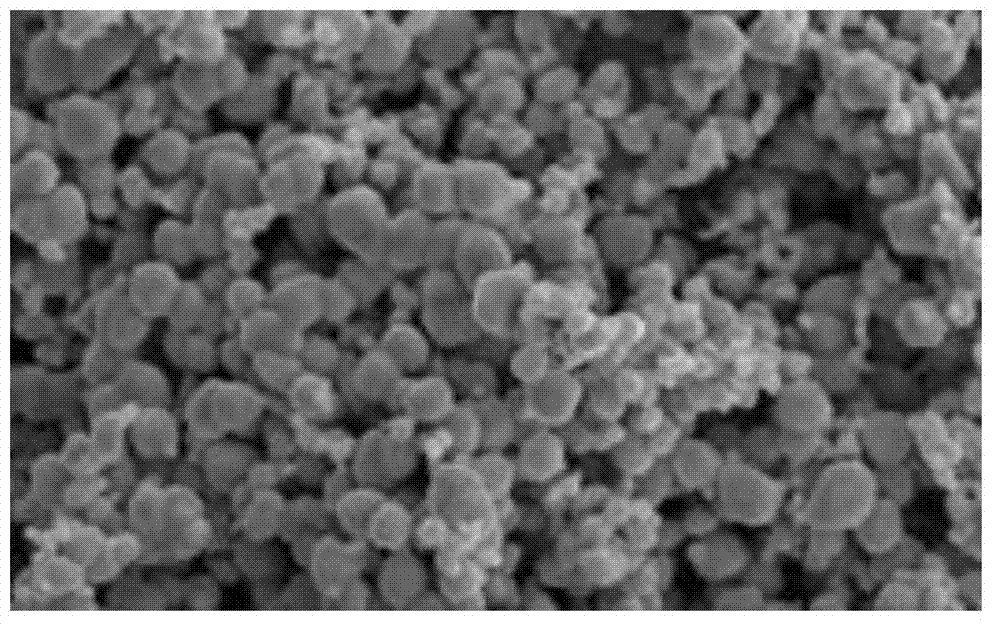

Preparation method for highly-dispersed ultrafine molybdenum powder with narrow particle size distribution

ActiveCN105458280AImprove particle size distributionNarrow particle size distributionHydrogenRoom temperature

The invention discloses a preparation method for highly-dispersed ultrafine molybdenum powder with narrow particle size distribution. The preparation method comprises the following steps: filling molybdenum trioxide powder produced by a sublimation method into a molybdenum boat, carrying out first-section reduction on the molybdenum trioxide powder, then, cooling the molybdenum trioxide powder to the room temperature in a furnace; then, carrying out second-section reduction on the molybdenum trioxide powder, charging nitrogen into a cooling zone to cool the molybdenum trioxide powder, and screening to obtain the highly-dispersed ultrafine molybdenum powder with narrow particle size distribution. According to the preparation method for the highly-dispersed ultrafine molybdenum powder with narrow particle size distribution, the sublimated molybdenum trioxide is used as a raw material, hydrogen gas is adopted for reducing, dry hydrogen is adopted at the first-section reduction, and flow of the hydrogen gas is relatively great, so that sheet-shaped molybdenum dioxide is realized, and the formation of regular ultrafine molybdenum powder is facilitated; wet hydrogen with a hydrogen dew point of (-)30 DEG C to 20 DEG C is adopted for the second-section reduction, and the reduction temperature and the flow of the hydrogen gas are regulated, so that production for single-particle and highly-dispersed ultrafine molybdenum powder with narrow particle size distribution can be realized.

Owner:JINDUICHENG MOLYBDENUM CO LTD

Special line cutting electrode molybdenum wire and its manufacturing method

InactiveCN1850412AEasy to processShrink tightlyElectrical-based machining electrodesDecompositionRare earth

The present invention relates to a special wire-cutting electrode molybdenum wire. Its weight composition includes molybdenum powder and doped rare-earth oxide La2O3, the weight content of La2O3 is 0.2-0.6%. Its preparation method includes the following steps: adding lanthanum nitrate aqueous solution into molybdenum dioxide powder, heating to make decomposition at 80-100 deg.C, uniformly mixing, then make hydrogenation reduction in furnace at 800-1000 deg.C to obtain the molybdenum powder in which rare earth oxide La2O3 is doped, finally making the molybdenum powder into molybdenum wire.

Owner:金堆城钼业光明(山东)股份有限公司

Method for manufacturing molybdenum powder

The invention discloses a method for manufacturing molybdenum powder. The method includes performing thermal decomposition for washing ammonium dimolybdate to obtain gray and white molybdenum trioxide; and performing para-hydrogen reduction for the molybdenum trioxide to obtain semi-finished products and uniformly mixing the semi-finished products to obtain the molybdenum powder. The method for manufacturing the molybdenum powder has the advantages that the washing ammonium dimolybdate is used as a raw material, accordingly, environmental pollution is prevented, the gray and white molybdenum trioxide is obtained by means of low-temperature calcination, energy consumption is reduced, and the productivity is improved; the molybdenum trioxide is reduced to form molybdenum dioxide, and the molybdenum dioxide is heated in four temperature zones of a horizontal four-tube reduction furnace and then is naturally cooled, so that energy consumption is reduced, the production cost is lowered, and the molybdenum dioxide can be assuredly dispersed; the method for manufacturing the molybdenum powder is simple, safe and reliable in operation and suitable for batch production; and the manufactured molybdenum powder is dispersed uniformly without being calcined, the Fisher particle size of the manufactured molybdenum powder ranges from 3.2 micrometers to 4.5 micrometers, the apparent density of the manufactured molybdenum powder ranges from 1.0g / cm<3> to 1.3g / cm<3>, and the yield reaches 90% at least after the manufactured molybdenum powder is screened by 200-mesh screen cloth.

Owner:JINDUICHENG MOLYBDENUM CO LTD

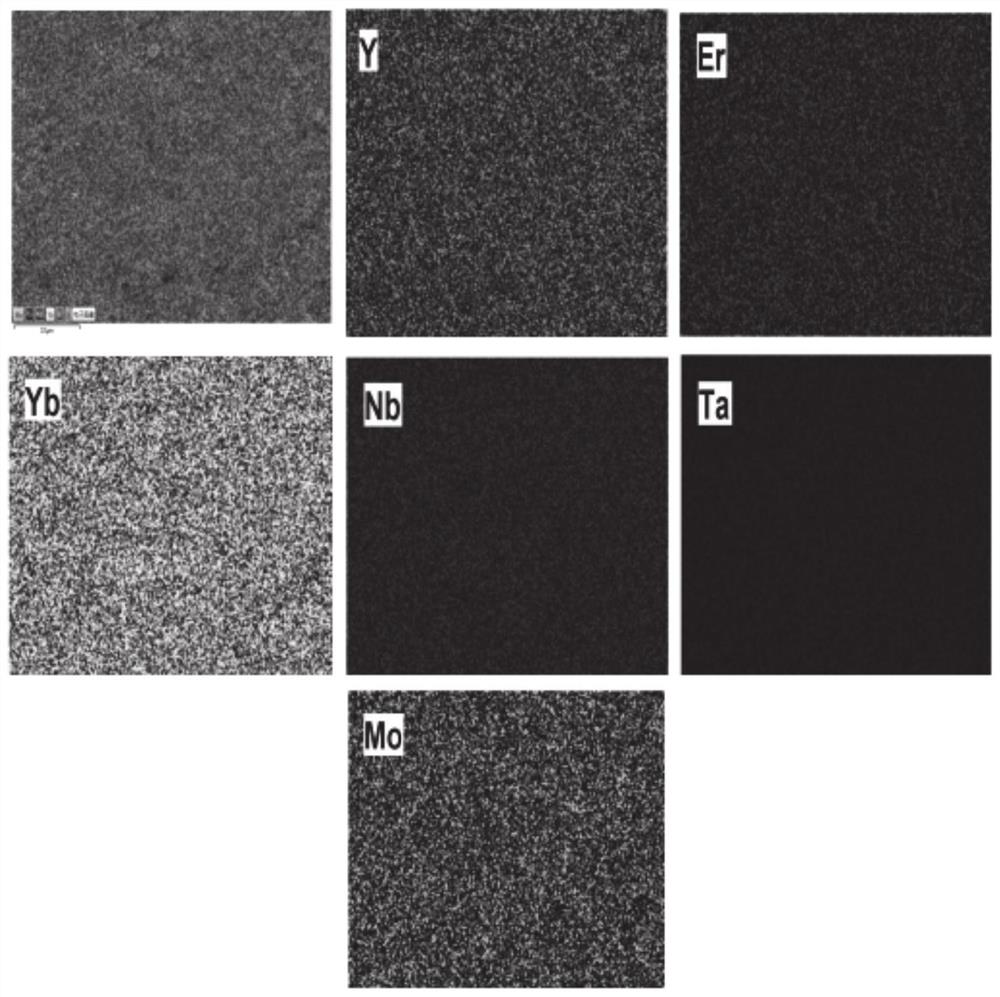

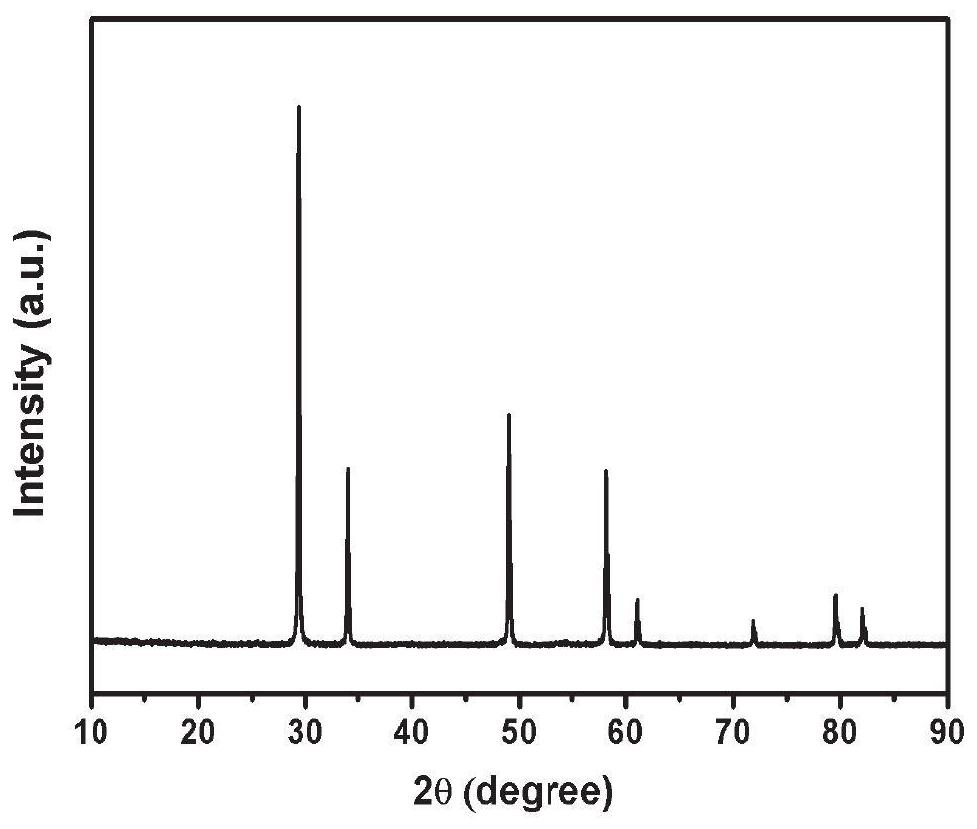

High-entropy rare earth niobium/tantalum/molybdate ceramic and preparation method thereof

The invention relates to the technical field of high-entropy ceramic materials, and particularly provides high-entropy rare earth niobium / tantalum / molybdate ceramic and a preparation method thereof. The chemical formula of the high-entropy rare earth niobium / tantalum / molybdate ceramic is RE3(Nb1 / 3Ta1 / 3Mo1 / 3)O7, RE is any 3-7 different elements of Y, Nd, Sm, Eu, Gd, Dy, Ho, Er, Yb and Lu. The preparation method comprises the following steps of (1) weighing rare earth oxide, niobium pentoxide, tantalum pentoxide, molybdenum trioxide and molybdenum dioxide according to a stoichiometric ratio, (2) adding a solvent and a ball-milling medium, ball-milling and mixing the raw materials by adopting a wet method, and carrying out vacuum drying and sieving to obtain uniformly mixed powder, (3) placing the uniformly mixed powder in a stainless steel mold for hydraulic compaction, and then carrying out cold isostatic pressing to obtain a densified green body, and (4) putting the green body into an alumina crucible, putting the alumina crucible into a high-temperature sintering furnace, and sintering in an air atmosphere. The prepared high-entropy ceramic is low in heat conductivity, the adopted preparation method has the advantages of being simple and rapid in process, low in equipment requirement, low in energy consumption, high in controllability and the like, and large-scale production is easy to achieve.

Owner:SHANDONG UNIV

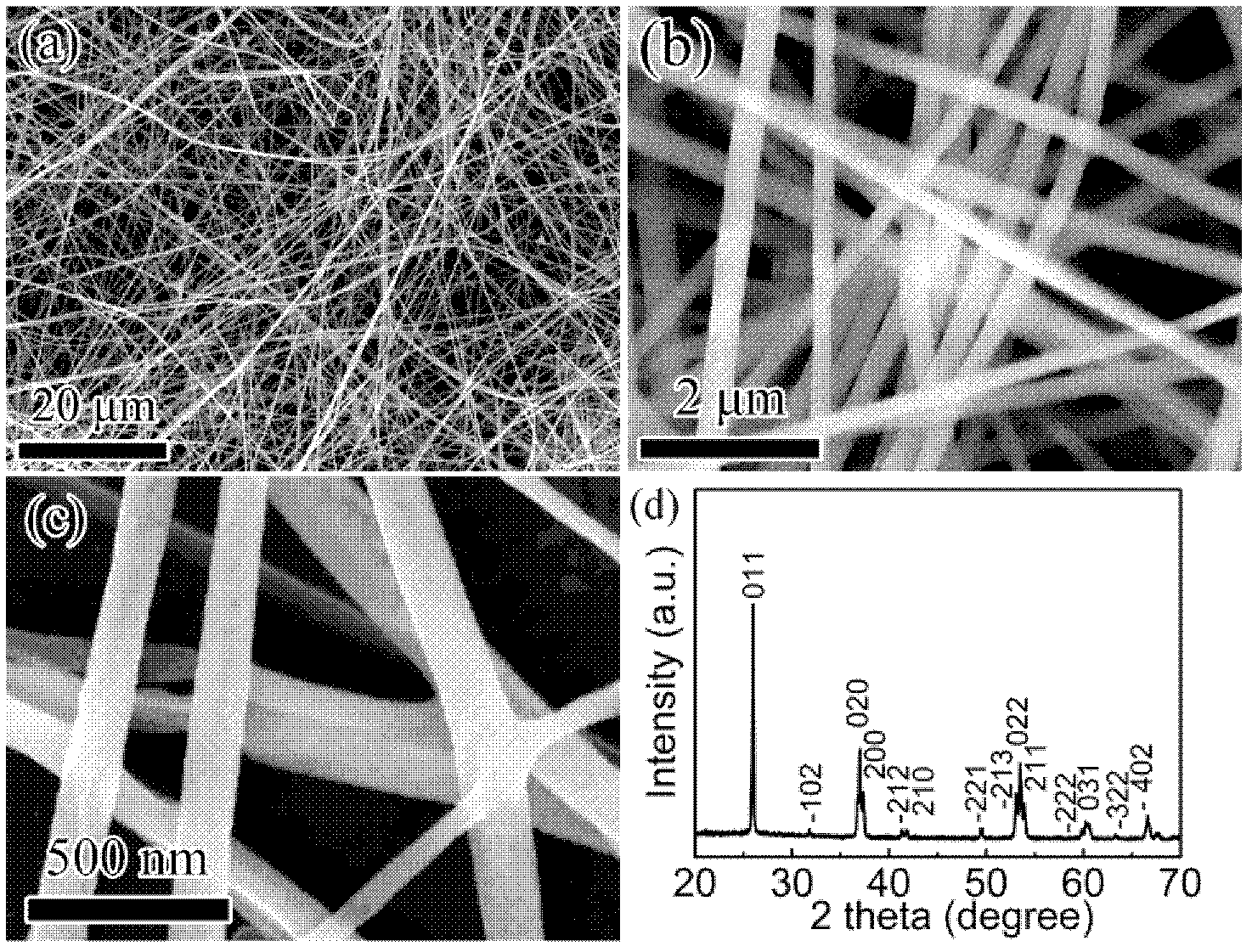

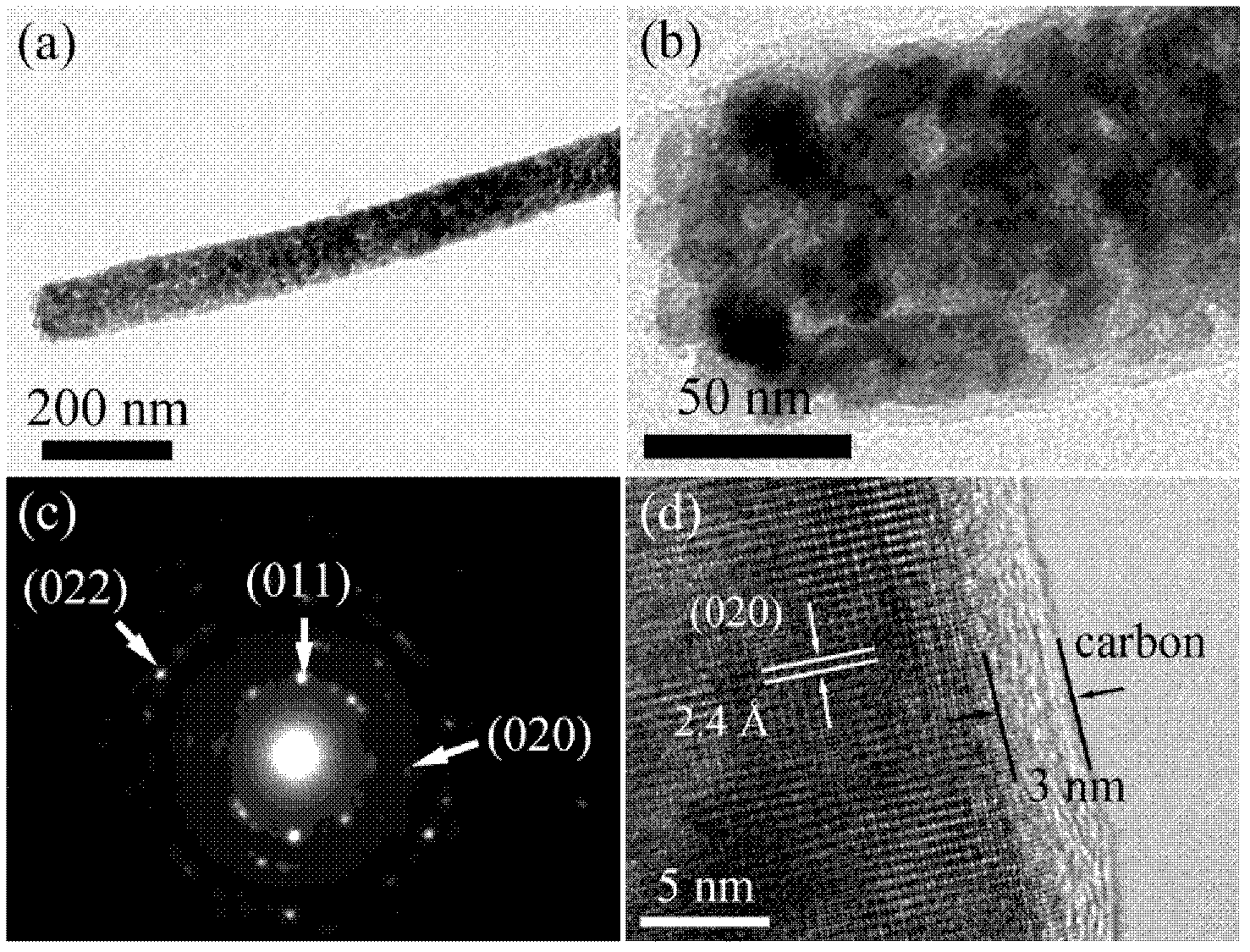

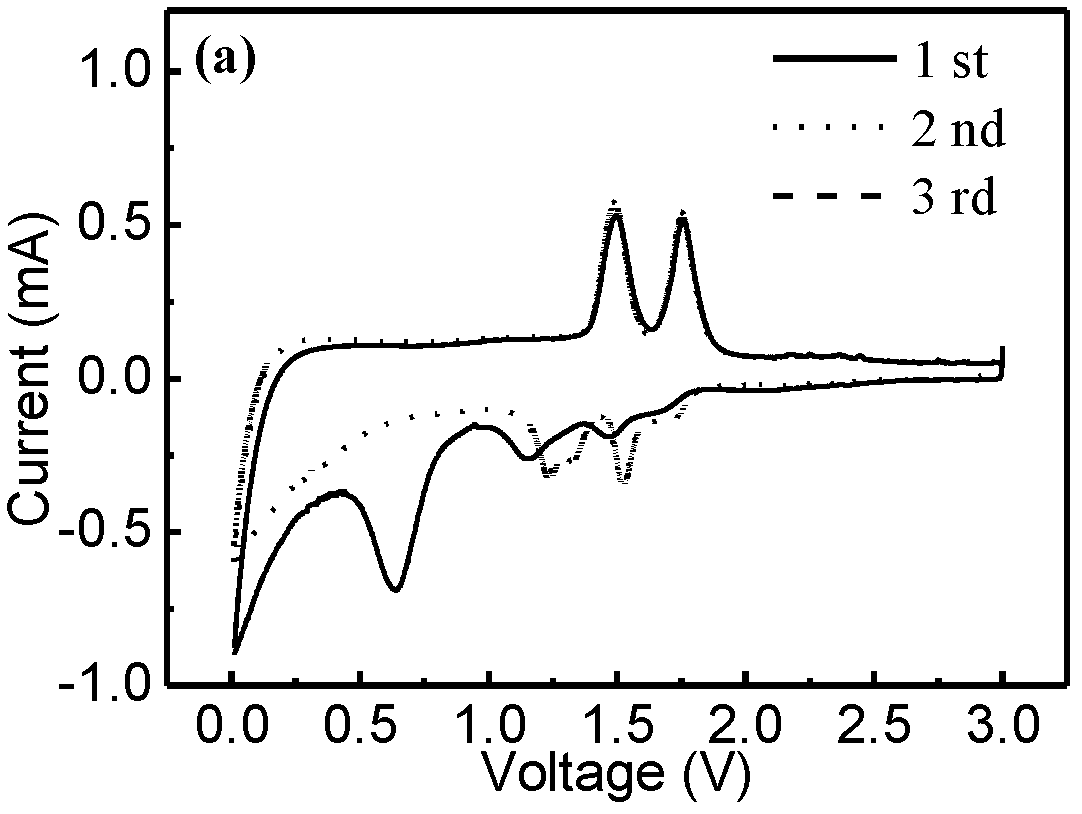

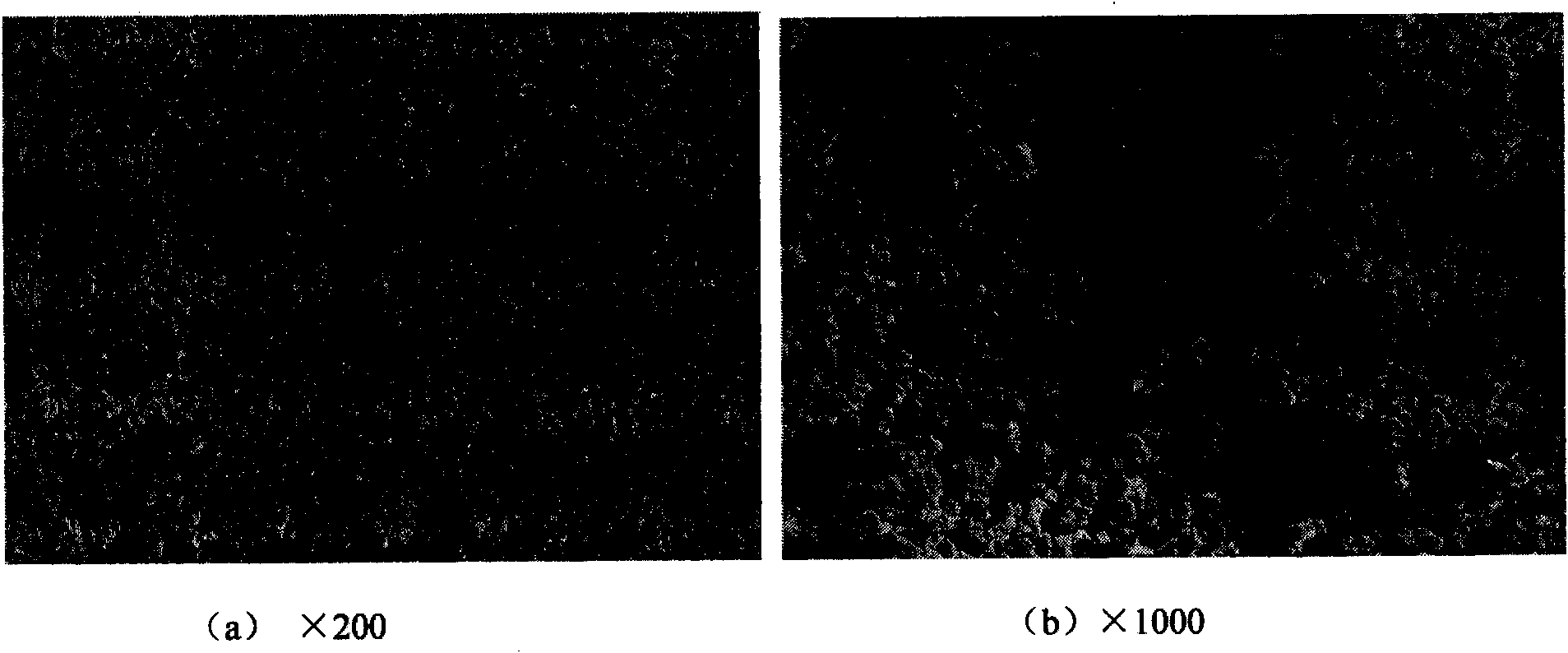

Preparation method for high-capacity molybdenum dioxide anode material and application of high-capacity molybdenum dioxide anode material

InactiveCN102623687AHigh specific capacityExcellent rate performanceCell electrodesCarbon coatingHigh rate

The invention discloses a preparation method for a high-capacity molybdenum dioxide anode material. The method comprises the following steps of: 1) mixing de-ionized water, absolute ethanol and the solution of polyvinyl alcohol, and adding ammonium molybdate according to 0.02 to 0.04 grams per millimeter to obtain a precursor solution; 2) obtaining composite nano-fibers of the ammonium molybdate and polyvinyl alcohol by using the precursor solution under the action of 8KV static high voltage; 3) stabilizing the obtained nano-fibers in air; and 4) reducing and carbonizing the stabilized nano-fibers at high temperature in a reducing gas atmosphere to obtain a molybdenum dioxide nano-fiber composite material with a carbon coating. The invention also discloses an anode material prepared by the method, an electrode plate prepared from the anode material and a button cell comprising the electrode plate. A molybdenum dioxide nano-fiber prepared by the method has the diameter of about 120 nanometers and a length capable of reaching several microns, and the thickness of the carbon coating is about 3 nanometers; and when used as a lithium ion battery anode material, the molybdenum dioxide nano-fiber has high specific capacity, high rate capability and long cycle life.

Owner:HUAZHONG UNIV OF SCI & TECH

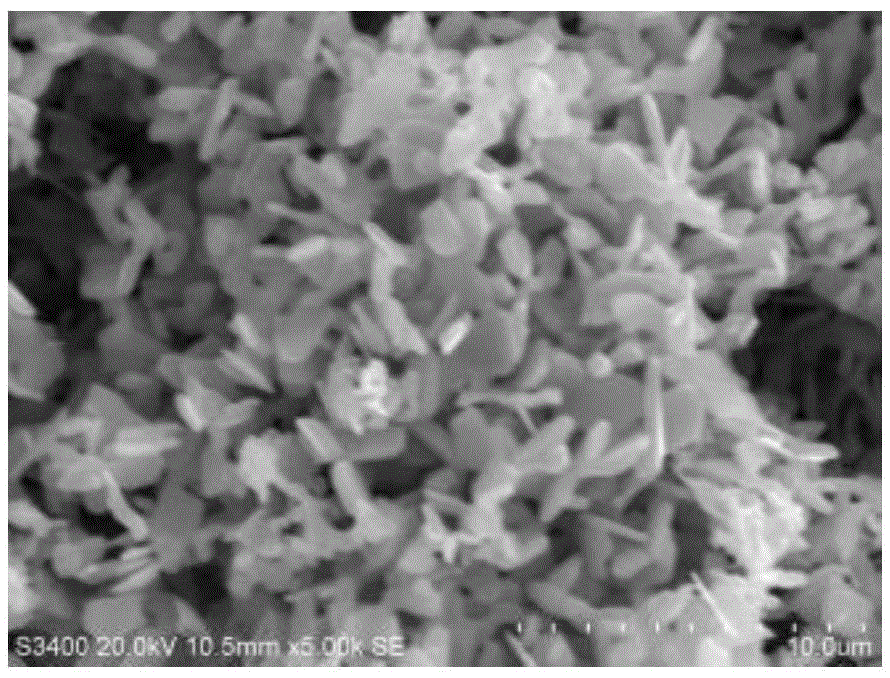

Preparation method of molybdenum dioxide nanorod

InactiveCN102815749ALow costControllable sizeMaterial nanotechnologyMolybdenum oxides/hydroxidesDecompositionAcetic oxide

The invention discloses a preparation method of a molybdenum dioxide nanorod. The preparation method comprises the following steps of: by taking sodium molybdate as a molybdenum source, acetic oxide as an additive, dimethylformamide as a solvent, concentrated hydrochloric acid as an acidifier, and tetrabutylammonium bromide as a settling agent, through a simple experiment device and reaction steps, controlling concentration of molybdate suspension, an additive amount of the additive, a pH value of the solution and the amount of the settling agent, recrystalizing and purifying to obtain precursor tetrabutyl ammonium hexamolybdate; and thermally treating the precursor tetrabutyl ammonium hexamolybdate in a quartz tube under an inert atmosphere to have decomposition to obtain a monoclinic phase molybdenum dioxide nanorod. The method, prepared by the invention, has the advantages of low cost and high reaction yield, and capability of overcoming the vices of expensive instrument device, rigorous reaction conditions and reduction at high temperature with H2 with safety hidden trouble of the conventional preparation method.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Gas generant composition

InactiveUS6302979B1Carbon monoxide and nitrogen oxides are decreasedImprove efficiencyNon-explosive/non-thermic compositionsPressure gas generationTetrazoleCopper oxide

A gas generant is provided which decreases toxic components, in particular carbon monoxide and nitrogen oxides, in generated gas to a concentration practical as an air bag system for automobile.A nitrogen-containing organic compound such as a compound containing amino group or amido group or a tetrazole derivative and a oxygen-containing inorganic oxidizer such as KNO3, Sr(NO3)2 or KClO4 are essential components. Therewith one or more metal oxides are contained in the mixed catalyst of the gas generant composition. The oxide is selected from manganese dioxide having a specific surface area not less than 50 m2 / g; copper oxide having a specific surface area not less than 1 m2 / g; molybdenum oxides such as molybdenum dioxide, molybdenum trioxide, molybdic acid and ammonium molybdate: and copper oxides, cobalt oxides, iron oxides and silver oxides.

Owner:DAICEL CHEM IND LTD

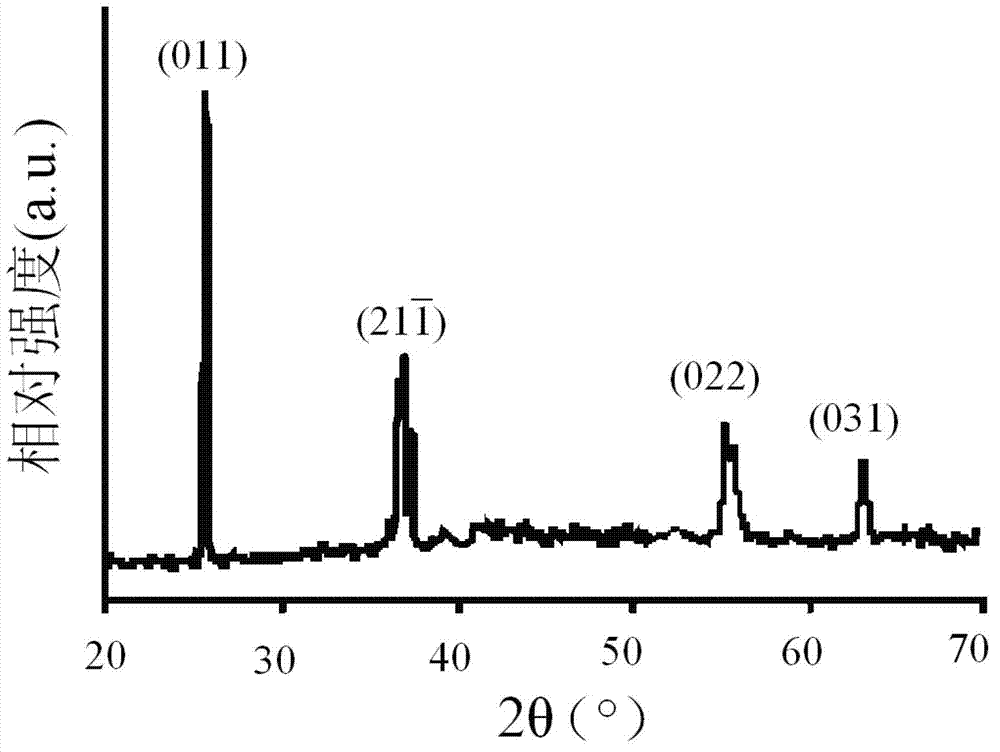

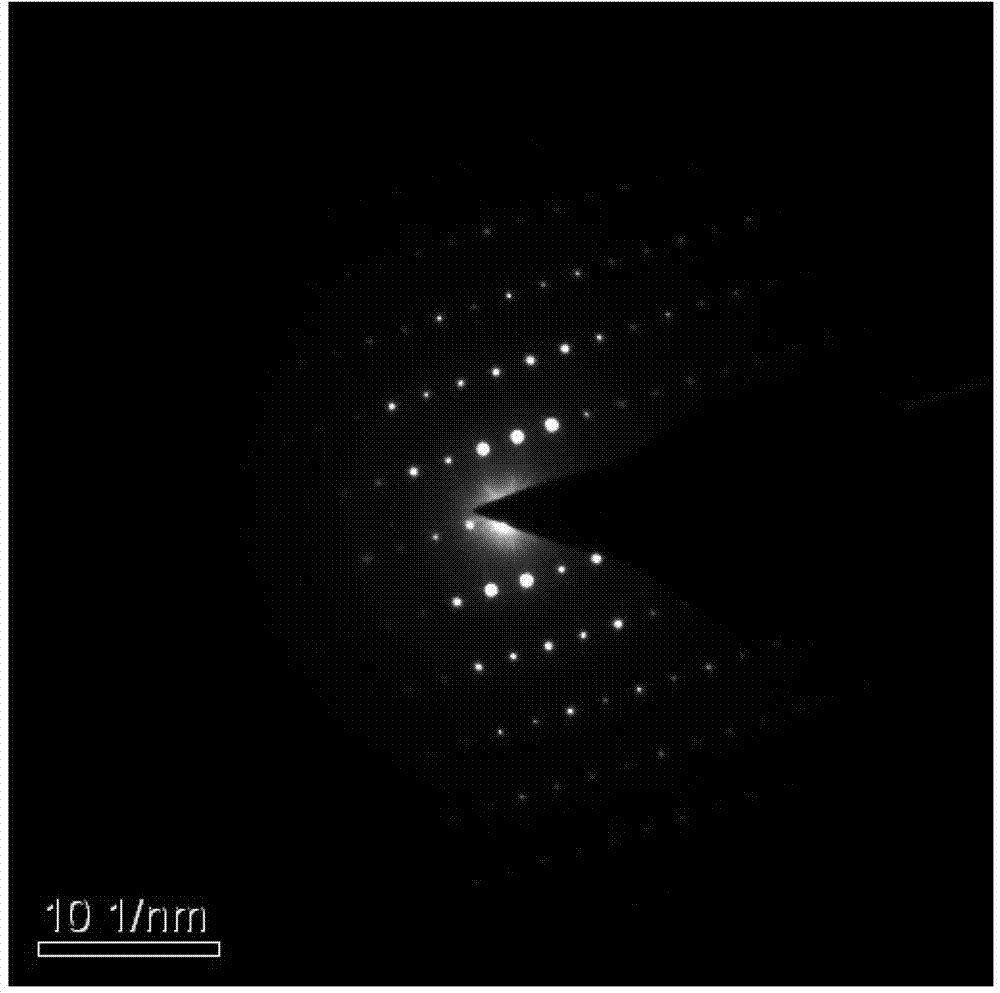

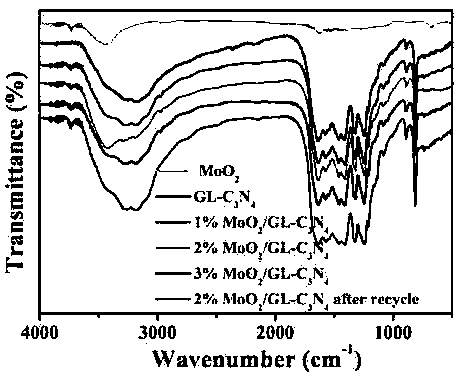

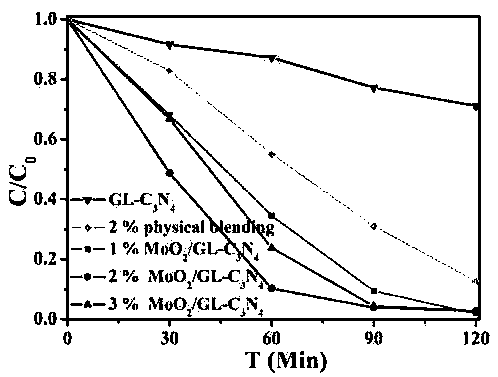

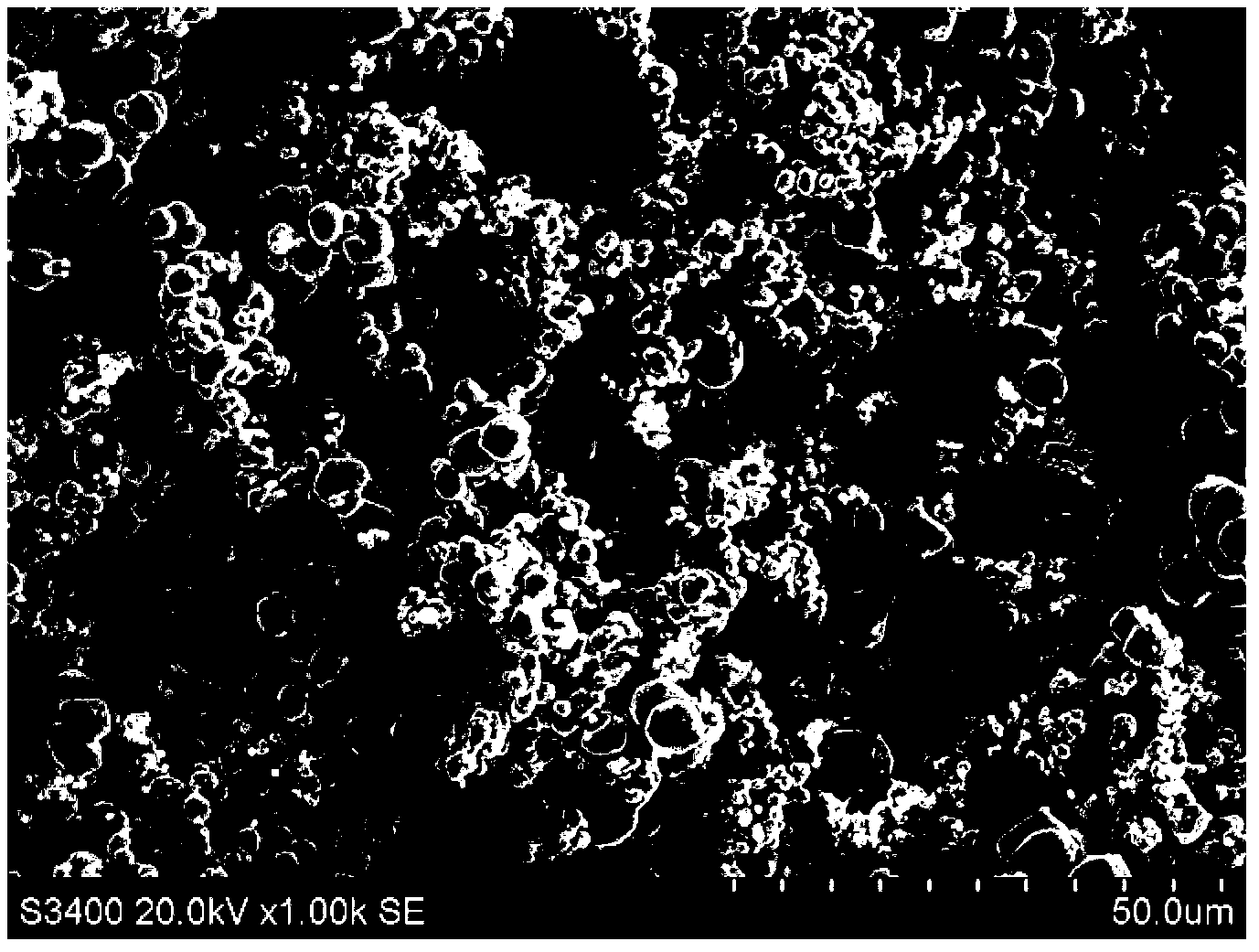

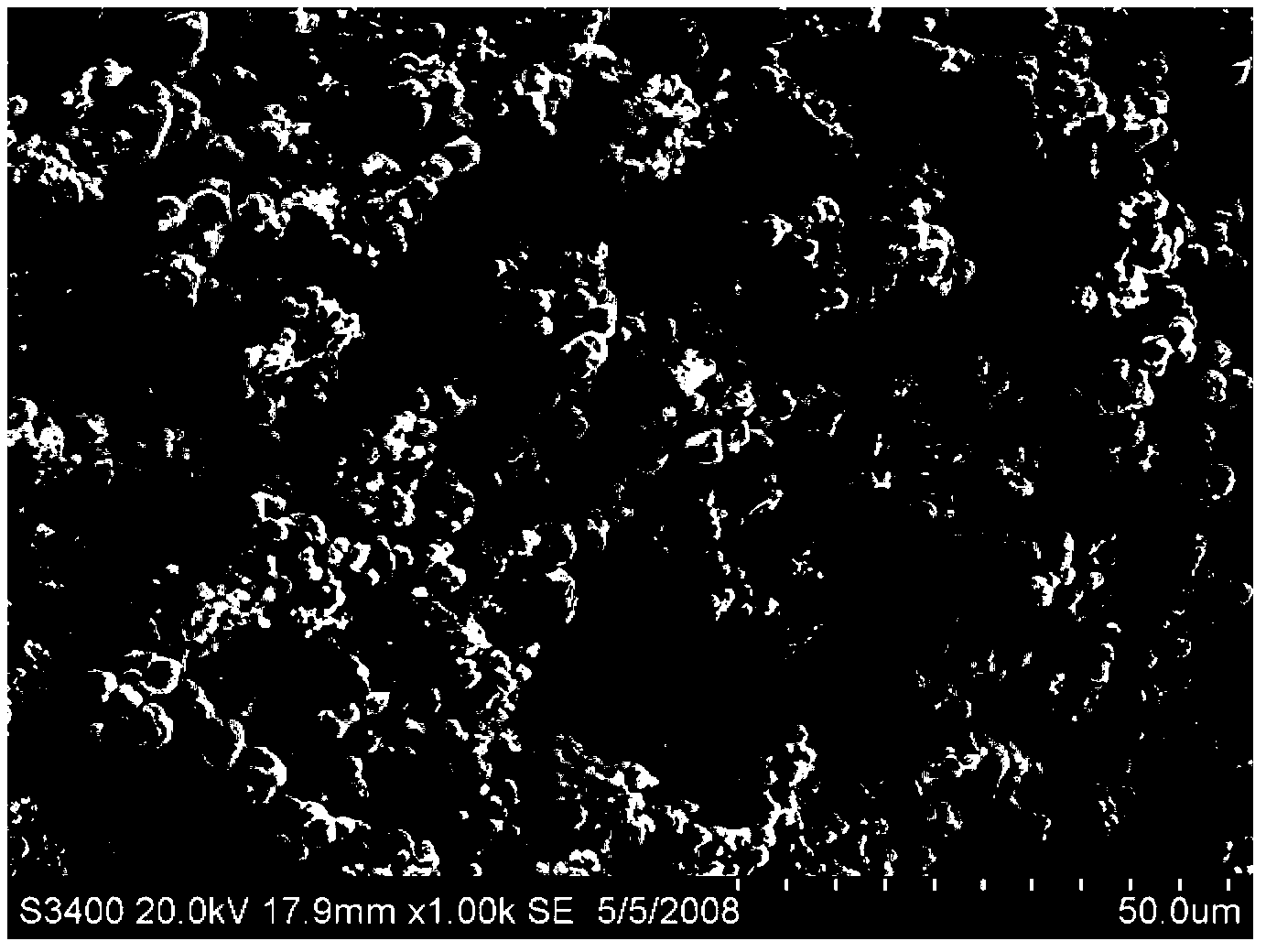

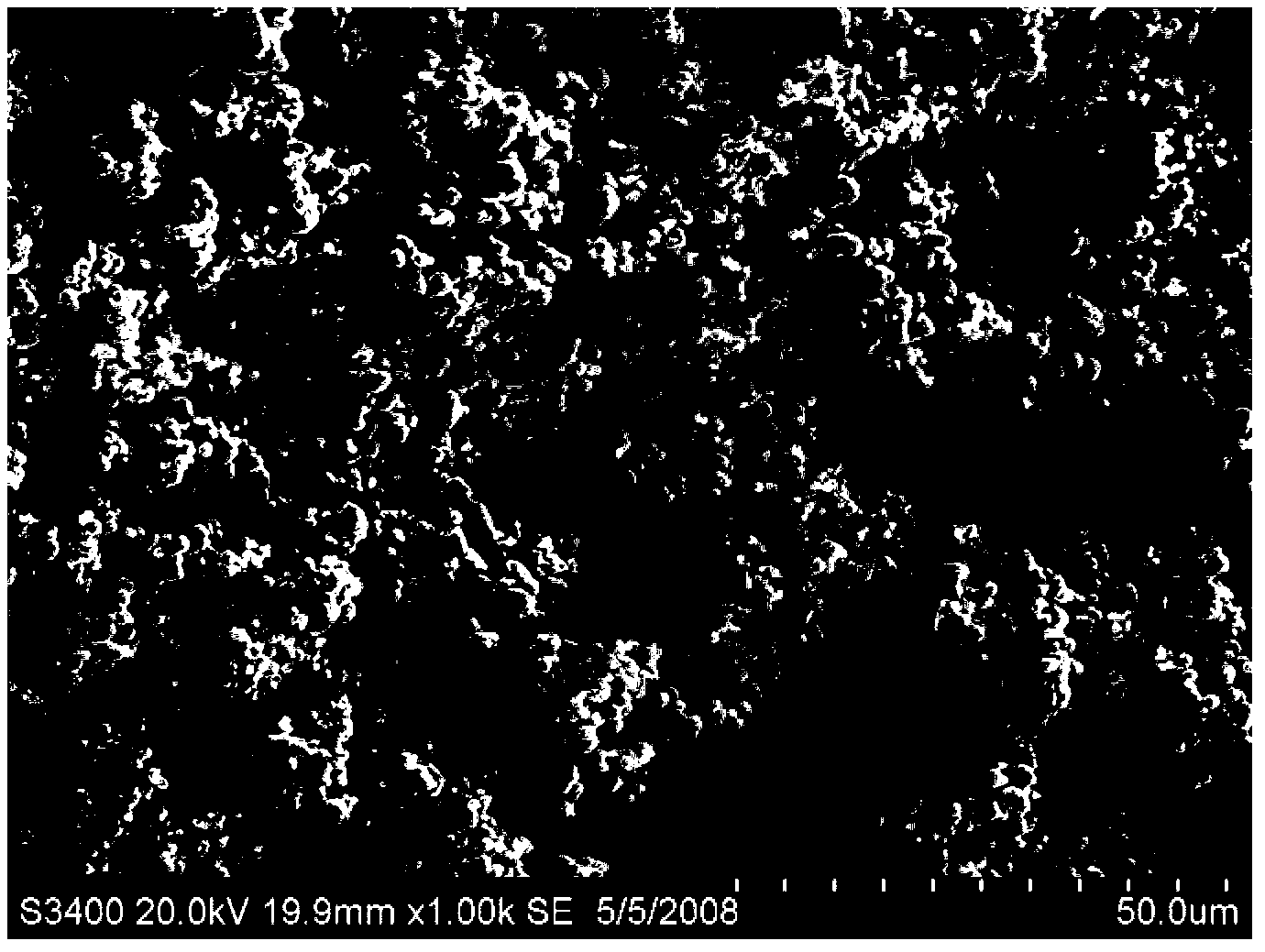

Molybdenum dioxide nanosheet/graphene-like carbon nitride photocatalytic material with visible-light response as well as preparation and application thereof

InactiveCN108786881AMany active sitesLarge specific surface areaPhysical/chemical process catalystsWater/sewage treatment by irradiationGlycol synthesisLight response

The invention relates to a preparation method of visible light responsive photocatalysts, in particular to a molybdenum dioxide nanosheet / graphene-like carbon nitride composite photocatalytic materialwhich can serve as an environment function material to be applied to the field of photocatalytic environment control. The composite photocatalyst is prepared by compounding molybdenum dioxide nanosheets (MoO2) and graphene-like carbon nitride (GL-C3N4) of a certain mass. The preparation method specifically comprises the following preparation steps: adding the prepared MoO2 and GL-C3N4 into ethylene glycol for performing stirred ultrasonic treatment, transferring the mixture into a reactor, and maintaining the temperature in a drying oven of 160-200 DEG C for 8-16 hours; finally, performing centrifugal washing and drying, so as to obtain the molybdenum dioxide nanosheet / graphene-like carbon nitride (MoO2 / GL-C3N4) composite photocatalyst. Experiments prove that compare with monomer carbon nitride, the composite photocatalyst has the advantage that the photocatalytic performance is obviously improved. In the preparation method provided by the invention, the raw materials are cheap, the process flow is simple, the reaction is mild, the whole synthetic process is green and environmental-friendly, the product cost is effectively reduced, and the composite photocatalyst has extremely high application prospects and application value in the aspects such as sewage treatment and the like.

Owner:JIANGSU UNIV +1

Gas generant composition

InactiveUS20020023699A1Carbon monoxide and nitrogen oxides are decreasedImprove efficiencyNon-explosive/non-thermic compositionsPressure gas generationPtru catalystTetrazole

A gas generant is provided which decreases toxic components, in particular carbon monoxide and nitrogen oxides, in generated gas to a concentration practical as an air bag system for automobile. A nitrogen-containing organic compound such as a compound containing amino group or amido group or a tetrazole derivative and a oxygen-containing inorganic oxidizer such as KNO3, Sr(NO3)2 or KClO4 are essential components. Therewith one or more metal oxides are contained in the mixed catalyst of the gas generant composition. The oxide is selected from manganese dioxide having a specific surface area not less than 50 m2 / g; copper oxide having a specific surface area not less than 1 m2 / g; molybdenum oxides such as molybdenum dioxide, molybdenum trioxide, molybdic acid and ammonium molybdate; and copper oxides, cobalt oxides, iron oxides and siver oxides.

Owner:DAICEL CHEM IND LTD

Wear-resistant paper-plastic composite bag and preparation method for same

ActiveCN104909034AImprove wear resistanceThe method is simpleSynthetic resin layered productsBagsEpoxySodium stearate

The invention discloses a wear-resistant paper-plastic composite bag and a preparation method for the same. The wear-resistant paper-plastic composite bag comprises a plastic layer and a paper layer, wherein the plastic layer is arranged on the surface of the paper layer, and comprises polypropylene, polyethylene, epoxy resin, ultrahigh molecular weight polyethylene, organic silicon, phenol formaldehyde resin, fiberglass, polytetrafluoroethylene, molybdenum dioxide, glycerin, dimethyl phthalate and sodium stearate. The wear-resistant paper-plastic composite bag has high wear resistance, and the preparation method is convenient, easy, mild in condition and suitable for large-scale production.

Owner:TONGLING FOUNDER PLASTICS TECH

Method for preparing molybdenum powder by molybdenum trioxide

The invention provides a method for preparing molybdenum powder by molybdenum trioxide. The method includes the steps: firstly, sieving the molybdenum trioxide by a 40-mesh sieve to obtain oversize materials and then throwing the sieved oversize materials into a ball mill for ball-milling to obtain molybdenum trioxide powder; secondly, performing primary hydrogen reduction treatment for the molybdenum trioxide powder by a primary reduction furnace in hydrogen atmosphere to obtain molybdenum dioxide; thirdly, performing secondary hydrogen reduction treatment for the molybdenum dioxide by a secondary reduction furnace in the hydrogen atmosphere to obtain rough molybdenum powder; and fourthly, sieving the rough molybdenum powder and then uniformly mixing the rough molybdenum powder in a mixer to obtain finished molybdenum powder. The method is simple in preparation process, safe, reliable and suitable for industrial batch production. The molybdenum powder prepared by the method can meet the technical requirement of the national standard GB / T3461-2006, and can be widely used for preparing raw materials for molybdenum and molybdenum alloy products such as molybdenum slabs, molybdenum bar billets, molybdenum ejector headers and molybdenum special-shaped parts.

Owner:JINDUICHENG MOLYBDENUM CO LTD

Process for producing high capacity molybdenum dioxide/carbon cathode materials

InactiveCN102623677AEasy to shapeIncrease capacitySecondary cellsNon-aqueous electrolyte accumulator electrodesFiberCarbon composites

The invention discloses a process for producing high capacity molybdenum dioxide / carbon cathode materials. The process includes the steps of 1) immersing cotton fiber fabric of a certain size in an ethanol solution of phosphomolybdic acid and stirring; 2) drying and ageing the immersed cotton fiber fabric; and 3) subjecting the dried and aged cotton fiber fabric to heat treatment in mixed gases, and obtaining the molybdenum dioxide / the carbon (MoO2 / C) composite materials. The invention further discloses cathode materials which are produced by the process, an electrode slice which is made of the cathode materials and a button cell which comprises the electrode slice. According to the molybdenum dioxide / the carbon composite materials produced by the process, the specific capacity is high, the multiplying power property and the cycling stability are good, and the coulomb efficiency is high. The process is simple and suitable for large-scale production.

Owner:HUAZHONG UNIV OF SCI & TECH

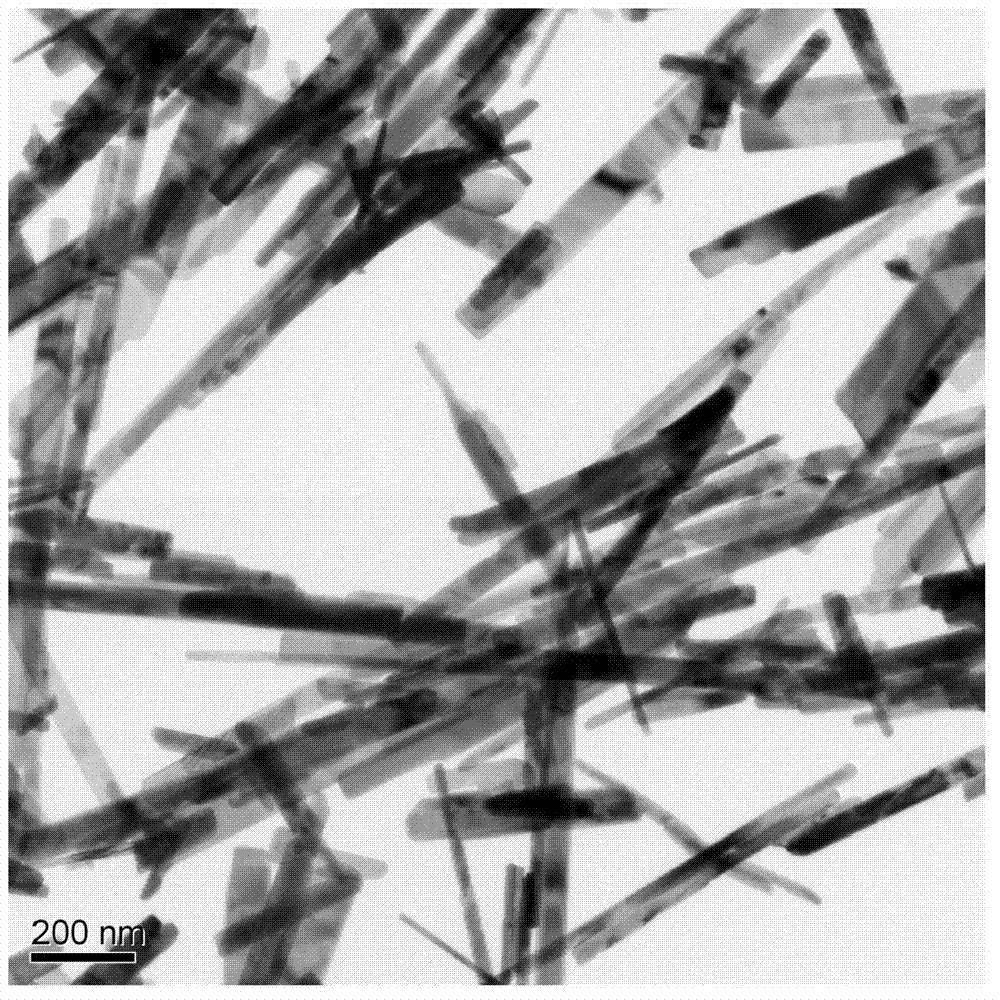

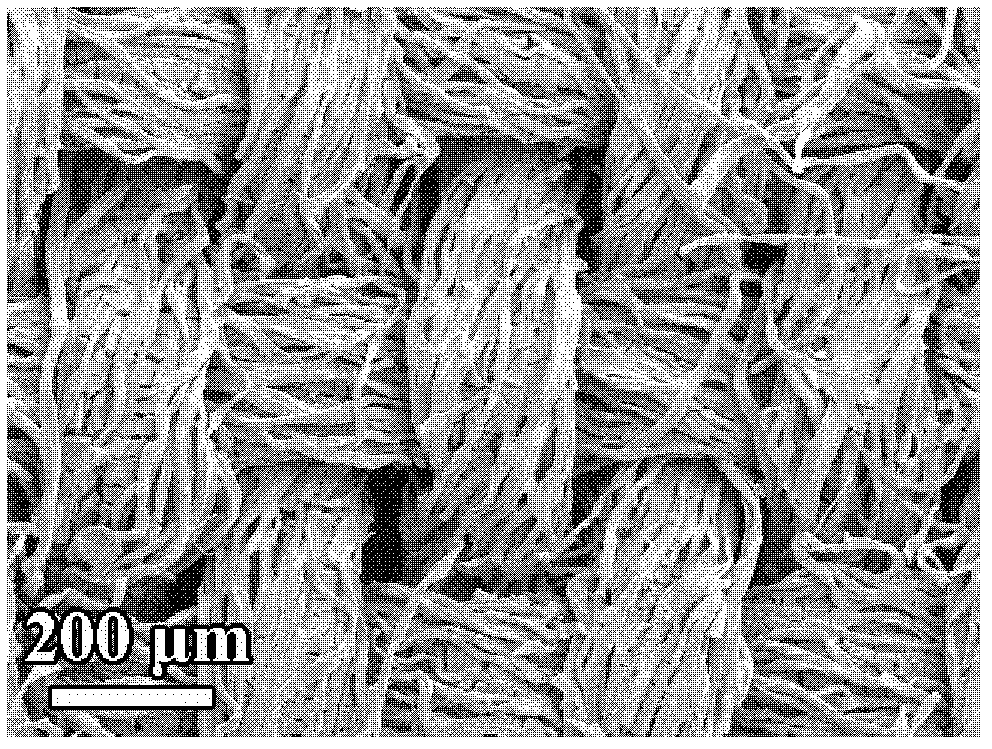

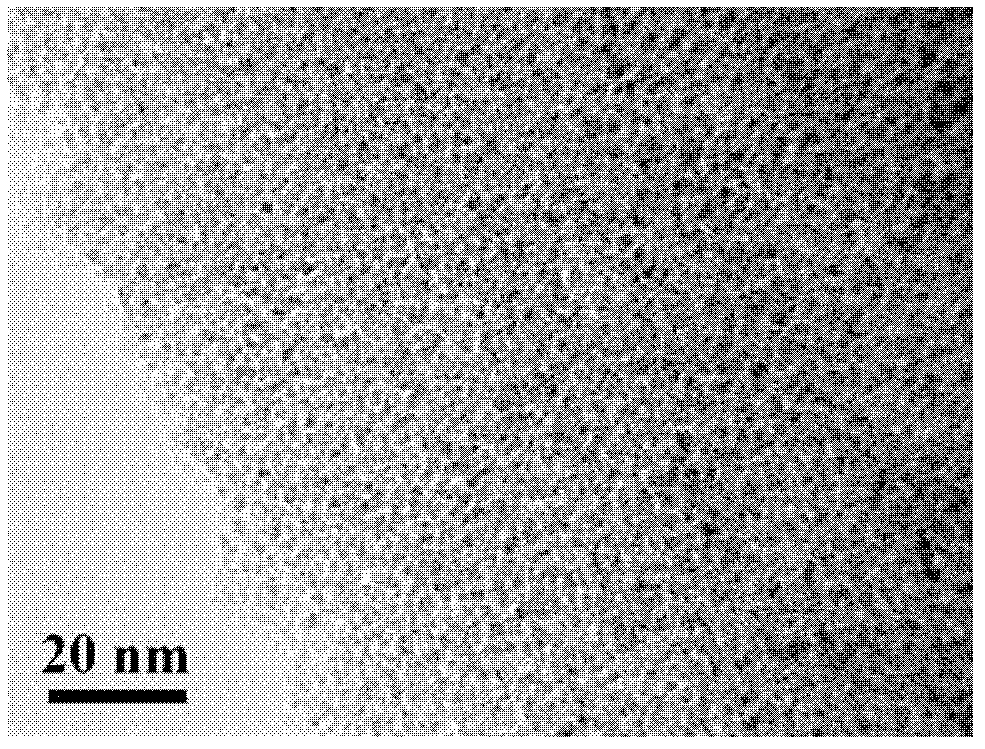

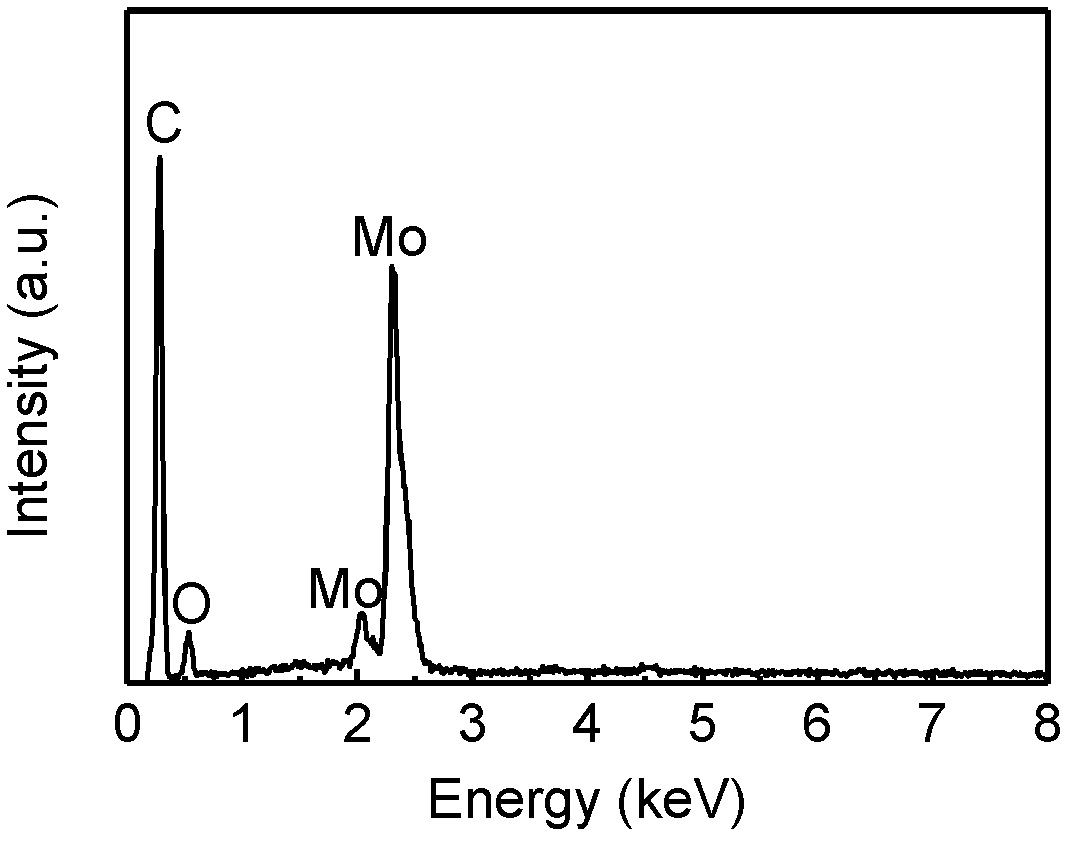

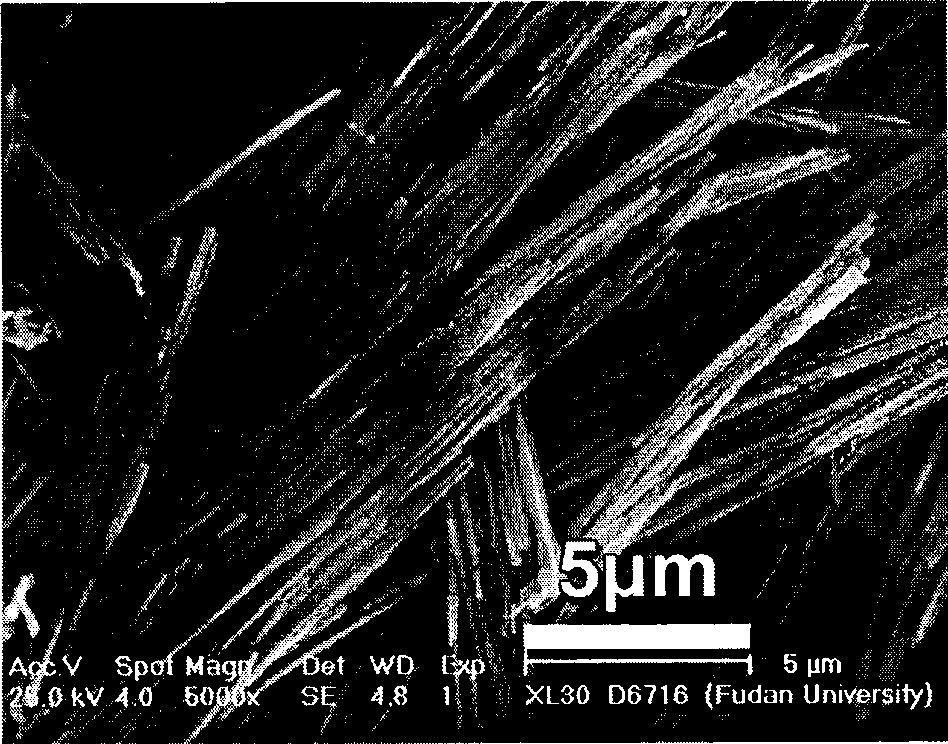

Method for synthesizing molybdenum dioxide-carbon composite nano-wire

InactiveCN101381105AThe synthesis method is simpleEasy to operateMolybdenum oxides/hydroxidesCarbon compositesMolybdate

The invention relates to the technical field of nanometer material and discloses a method for synthesizing a molybdenum dioxide-carbon composite nanowire. The method comprises the following steps: molybdate is dissolved in water; the molar concentration of molybdenum atoms is between 0.01 and 2.0 mol / L; organic amine is injected; the molar ratio of the molybdenum atoms in the organic amine and a molybdate solution is between 10.0:1 and 1.0:1; the solution is dripped with inorganic acid to regulate the PH value of between 3 and 6 till white precipitate occurs; the reaction solution is transferred to an oil bath at the temperature of 30 and 60 DEG C and reacts for 6 to 24 hours; the product is subjected to washing, extraction, filtering, drying and roasting in an inertia atmosphere; the roasting temperature is between 550 and 650 DEG C; and the roasting time is between 2 and 10 hours. The method has the advantages that a one-dimensional composite nanowire is formed and has a carbon composite structure with subnanometer scale, regulable and controllable physicochemical property, large specific surface area and regulable and controllable property of thickness and length; and the method is applied to a lot of fields and has the yield of over 95 percent, simple and easily controllable conditions, has low cost, high preparation efficiency and good application and industrialization prospect.

Owner:FUDAN UNIV

Preparation method of molybdenum powder

The invention relates to a preparation method of molybdenum powder, in particular to a process method of the molybdenum powder with even particle size, good dispersibility and no aggregates. The method is characterized by comprising the following steps: taking molybdenum dioxide as a raw material, and firstly sieving and grading the molybdenum dioxide power; respectively reducing the sieved and graded molybdenum dioxide with two temperature regions to obtain the molybdenum powder by a high temperature-first and low temperature-last hydrogen reduction process; and then sieving the prepared molybdenum powder to obtain the molybdenum powder with even particle size, good dispersibility and no aggregates. The method has simple, safe and reliable operation, and is applicable to batch productionof the molybdenum powder; and compared with the conventional molybdenum powder, the molybdenum powder prepared by the method has even particle size, good dispersibility and no aggregates and agglomeration, and is mostly present in a single particle form. Fisher particle size of the finished molybdenum powder is 2.5-4.5 mu m, and yield rate thereof is more than 90% after being sieved with a 500-mesh sieve.

Owner:JINDUICHENG MOLYBDENUM CO LTD

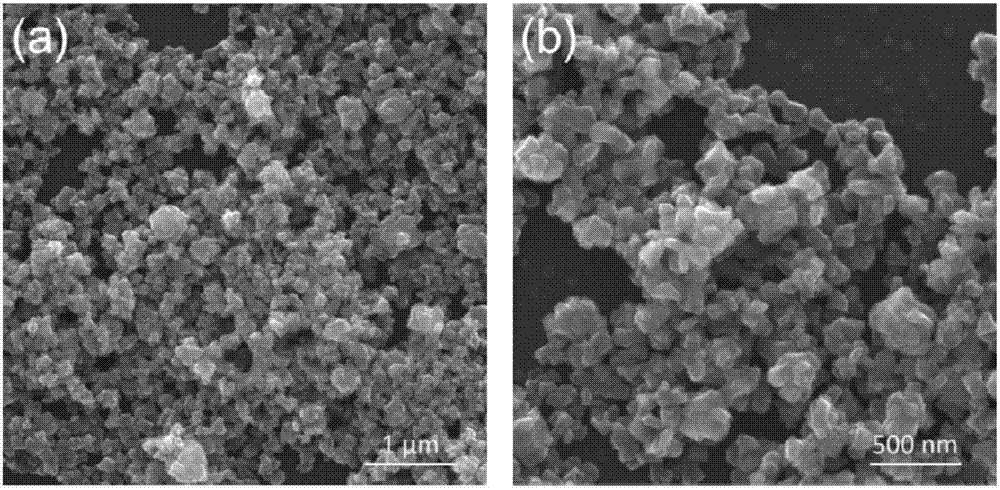

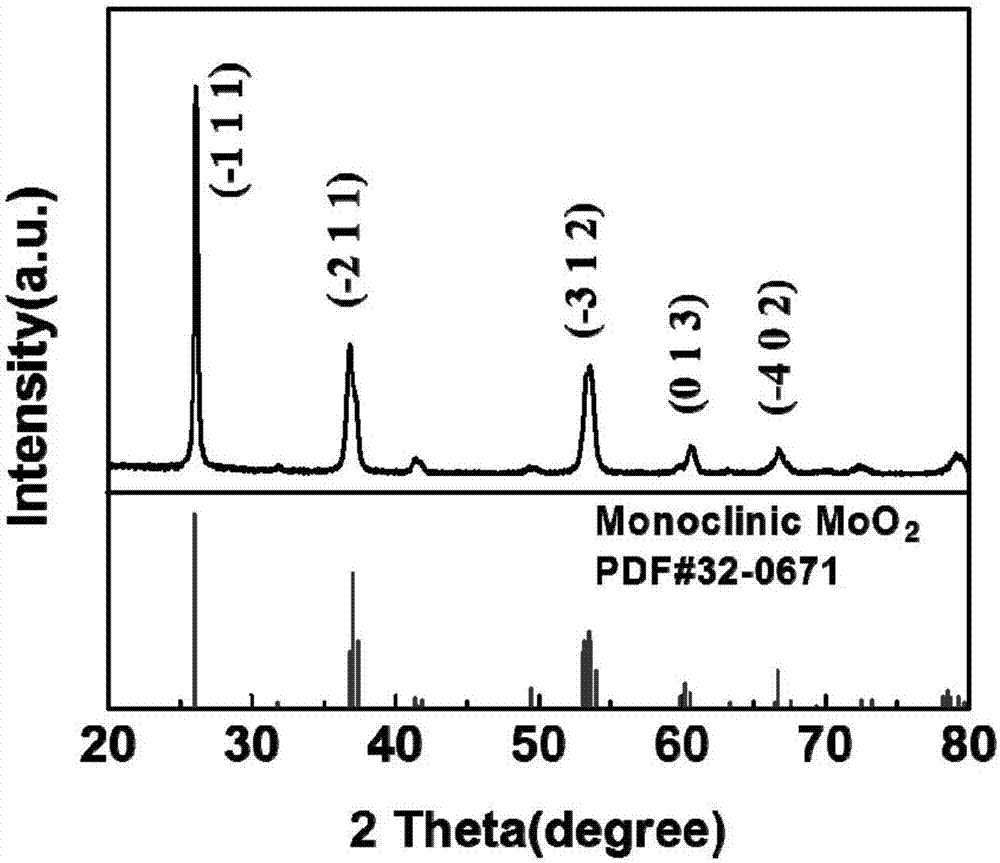

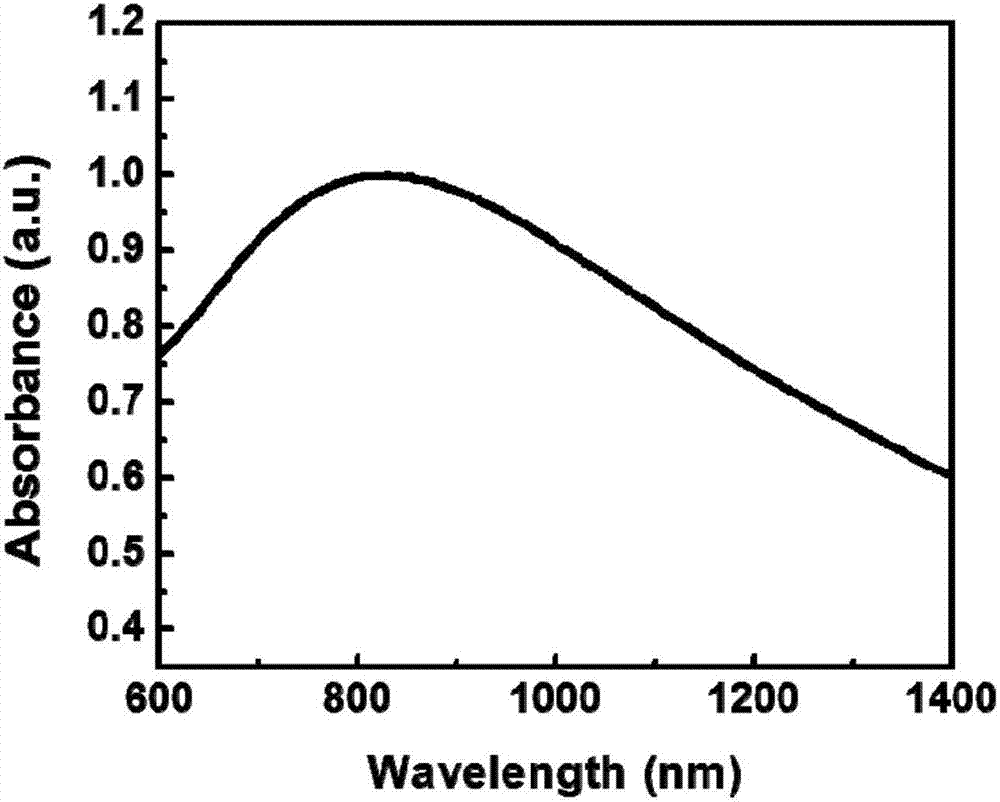

Molybdenum dioxide nano photothermal conversion material and preparation method and application thereof

ActiveCN106938857AHas surface plasmon resonance propertiesEfficient conversionMaterial nanotechnologyEnergy modified materialsThermal energyCancer cell

The invention discloses a molybdenum dioxide nano photothermal conversion material and a preparation method and application thereof. A high activity solvothermal precursor is obtained by laser ablation of high pure molybdenum in a mixed solution by combination of a liquid phase laser ablation technique and a solvothermal method; and molybdenum dioxide nano nanoparticles are synthesized by reaction under mild conditions by the solvothermal method. The prepared molybdenum dioxide nano nanoparticles have surface plasmon resonance properties, can produce strong light absorption in a near infrared band, can be used for effective conversion of absorbed light into heat so as to kill cancer cells under near infrared laser irradiation, have excellent photothermal stability and biological compatibility, and can be used for the preparation of a photothermal treatment reagent, the photothermal treatment reagent comprising the molybdenum dioxide nano photothermal conversion material is injected into a tumor site, tumor is irradiated by near infrared laser, the growth of the tumor can be effectively inhibited, and the molybdenum dioxide nano photothermal conversion material has wide application prospect in the field of tumor photothermal therapy.

Owner:NANJING UNIV OF SCI & TECH

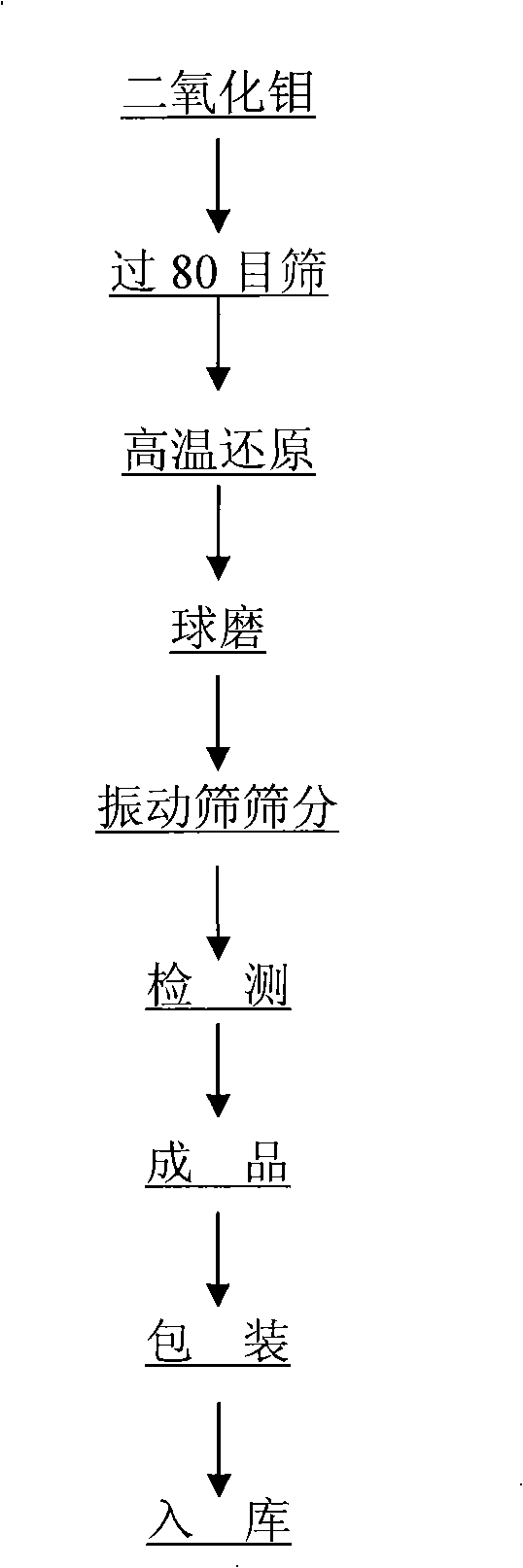

Method for preparing low-potassium molybdenum powder

InactiveCN101352758ALower requirementThe production process is simple and easy to controlApparent densityHydrogen

The invention relates to a method for preparing molybdenum powder with low kalium which is characterized in that molybdenum dioxide with a kalium content less than 160ppm is adopted as material; after the molybdenum dioxide is screened, the molybdenum powder with low kalium is prepared by carrying out two process hydrogen reducing, vacuum breaking and ball milling as well as screening. The method of the invention has low demands on the materials and the materials are easily obtained; the production technique is easy to be controlled; the operation is simple, safe, reliable and is applicable to mass production; the granularity of a product is uniformly distributed and the consistency is good; compared with the common molybdenum powder, the kalium content of the product obtained by the method of the invention can be controlled under 20ppm; the content of carbon can be controlled under 20ppm; the content of oxygen can be controlled under 600ppm. The granularity can be controlled between 3 and 7 Mum; the apparent density can be controlled between 1.4 and 2.8g / cm<3>; the tap density can be controlled between 3.5 and 4.5g / cm<3>. The product of the invention has broad application in the electron processing industry and has potential in the field of the target of an LCD in particular.

Owner:JINDUICHENG MOLYBDENUM CO LTD

Ferrum-based powder metallurgy antifriction material and preparation method thereof

The invention discloses a ferrum-based powder metallurgy antifriction material and a preparation method thereof. The material is prepared from the following raw materials in part by weight: 60 to 64 parts of iron powder, 6 to 10 parts of tin powder, 3 to 6 parts of carborundum powder, 3 to 6 parts of molybdenum dioxide powder, 4 to 7 parts of zirconium corundum powder, 10 to 14 parts of quartz sand powder, 1 to 4 parts of zirconium dioxide powder, 2 to 5 parts of cobalt powder, 2 to 5 parts of alumina powder, 2 to 5 parts of feldspar powder and 1 to 4 parts of copper powder. The preparation method comprises the following steps of preparing and mixing the raw materials, pressing for forming, sintering and cooling. The ferrum-based powder metallurgy antifriction material prepared by the method has a high friction coefficient, can quickly absorb kinetic energy and brake, is high in transmission speed and low in abrasion, is high in strength, high temperature resistant and good in thermal conductivity, and is good in anti-seizure property, corrosion resistant, and slightly influenced by grease and damp.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

Mo-Si-Al-K hot-rolled high-heat molybdenum plate and preparation method thereof

The invention relates to a Mo-Si-Al-K hot rolling high temperature molybdenum plate and a preparation method thereof. The invention is characterized in that alloy in plate materials contain three oxides of K2O, SiO2 and Al2O3. The weight percentage of the three oxides in the molybdenum alloy is 0.01 to 0.08 percent of K2O, 0.02 to 0.05 percent of SiO2 and 0 to 0.005 percent of Al2O3. The preparation process is: adding K2SiO3 and Al (NO3)3.9H2O solution in molybdenum dioxide; implementing the hydrogen reduction on the solution after the vacuum drying and doping to obtain Mo-Si-Al-K doping molybdenum powder; implementing the cold isostatic pressing on the Mo-Si-Al-K doping molybdenum powder to make sintering high temperature molybdenum billet; rolling the Mo-Si-Al-K sintering high temperature molybdenum billet into the high temperature molybdenum plate. Raw materials of the invention are cheap and are easy to be obtained. The prepared molybdenum plate has the advantages of strong high temperature strength, simple process, and unyieldingness, high ratio of finishing product, good consistency and long service life and can be widely used as a boat, a heating unit, a heat shield and other structural parts for the high temperature reduction.

Owner:JINDUICHENG MOLYBDENUM CO LTD

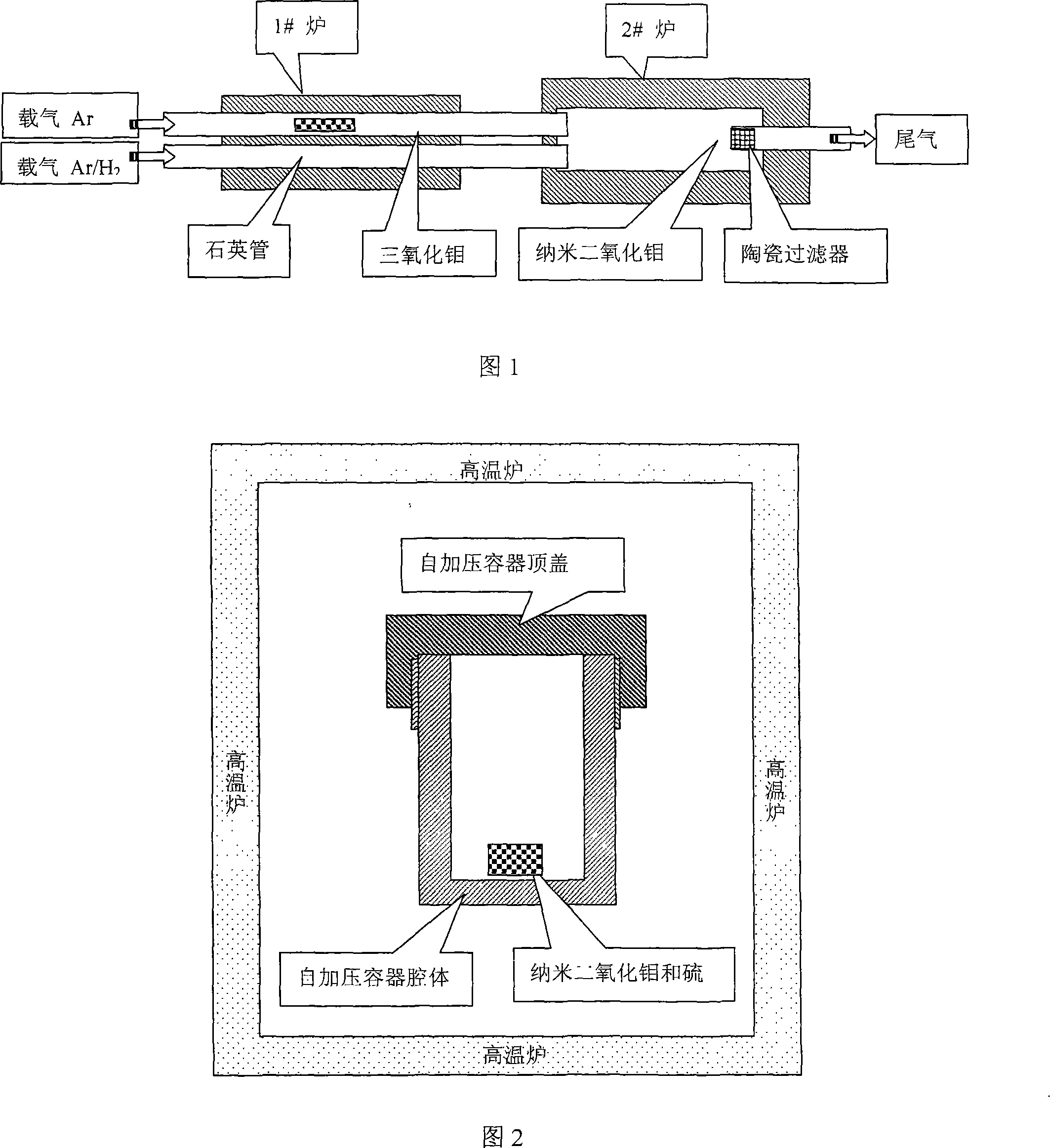

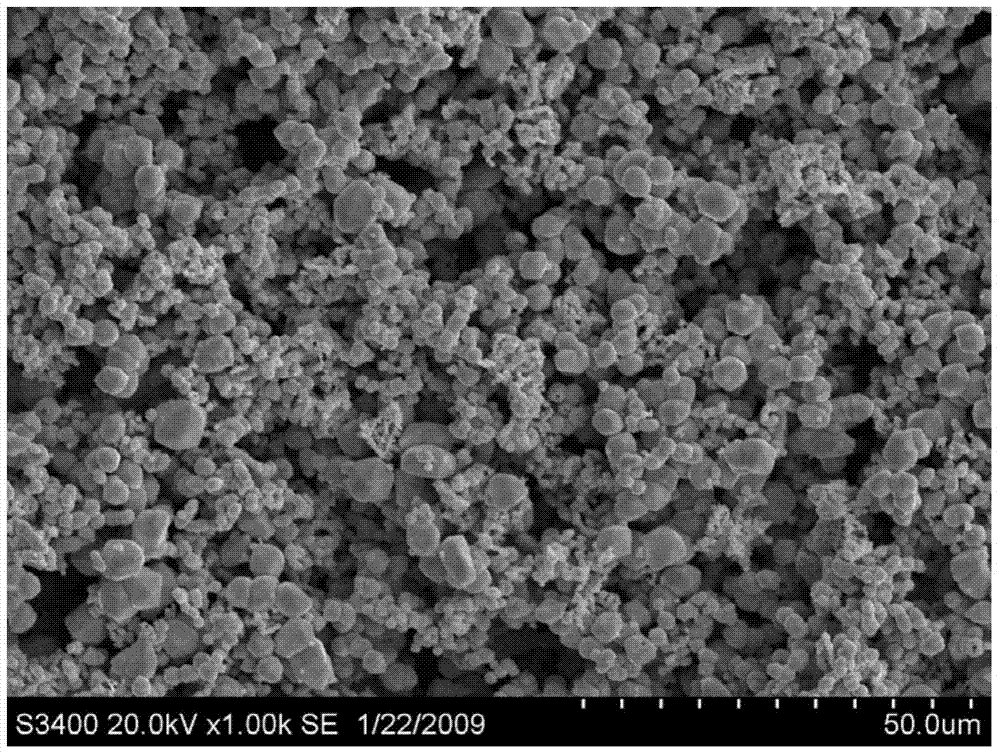

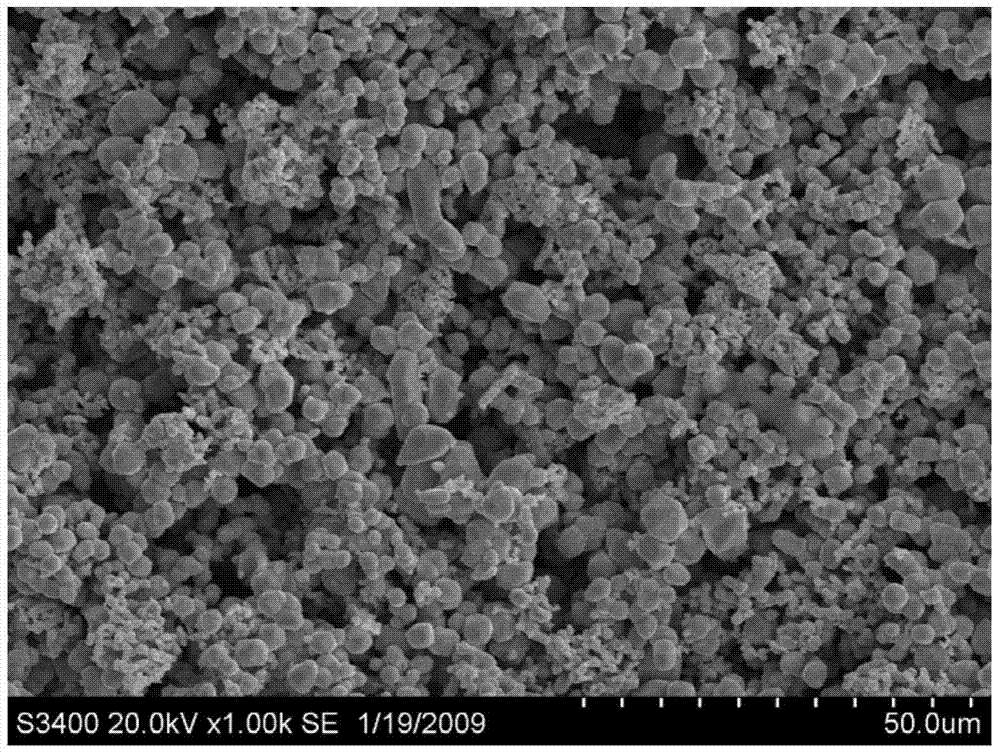

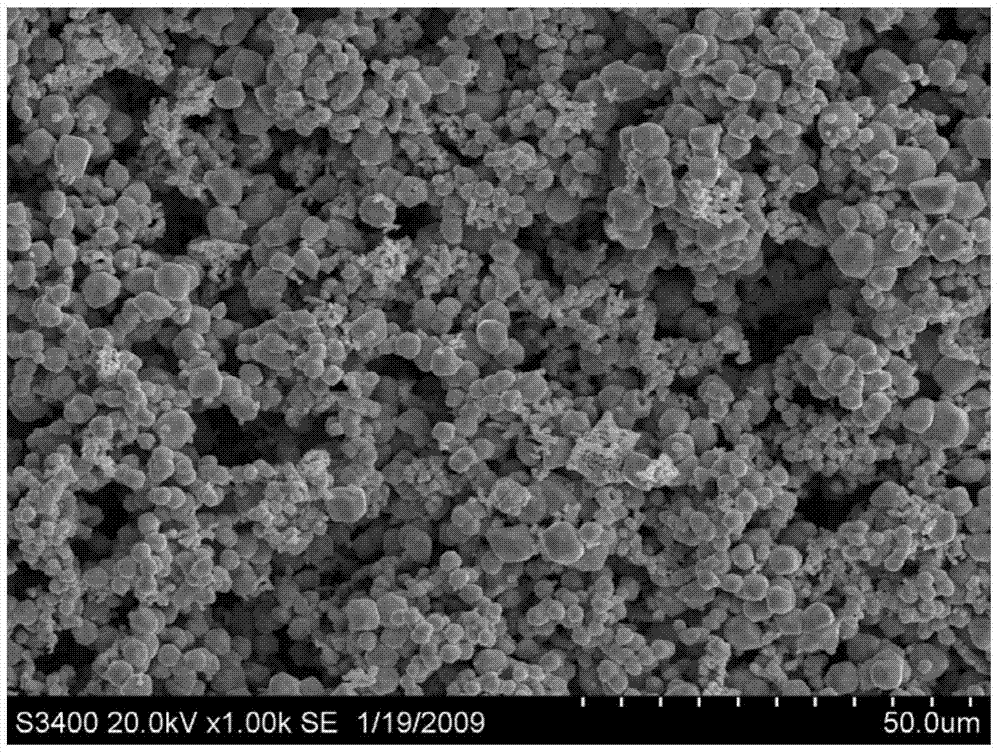

Method for preparing nano molybdenum disulfide with fullerene structure

The invention discloses a method for preparing nano molybdenum disulphide with a fullerene structure. The method comprises the following steps sequentially: by using industrial molybdenum trioxide as raw material, argon as carrier gas and hydrogen as reducing agent, molybdenum dioxide nano particle is generated by gas-phase reaction; the nano molybdenum disulphide and elemental sulfur are reacted under the condition of high temperature self-pressurization to produce powder material of the nano molybdenum disulphide with the fullerene structure; the molybdenum dioxide is nano particle generated directly by the reaction of the molybdenum trioxide after gasification under 700 to 1,000 DEG C with the hydrogen under 400 to 950 DEG C; the molybdenum disulphide with the fullerene structure is compound molybdenum disulphide by the self-pressurization reaction of the nano molybdenum dioxide and elemental sulfur in a vessel under 500 to 950 DEG C. The method for preparing the nano molybdenum disulphide with the fullerene structure has the advantages of simple process, high production efficiency, low cost of the raw material and product and short reaction time and the method can easily control the size of the molybdenum dioxide nano particle.

Owner:CHANGAN UNIV

Method for preparing molybdenum powder by ammonium molybdate

The invention provides a method for preparing molybdenum powder by ammonium molybdate. The method includes the steps: firstly, screening the ammonium molybdate by a 40-mesh screen to obtain an oversize product and placing the screened oversize product into a ball mill for ball-milling to obtain ammonium molybdate powder; secondly, performing primary hydrogen reduction treatment for the ammonium molybdate powder by the aid of a primary reduction furnace in hydrogen atmosphere to obtain molybdenum dioxide; thirdly, performing secondary hydrogen reduction treatment for the molybdenum dioxide by the aid of a secondary reduction furnace in the hydrogen atmosphere to obtain rough molybdenum powder; and fourthly, placing the screened rough molybdenum powder into a mixer for uniform mixing to obtain finished molybdenum powder. Preparation technology is simple, and the method is safe, reliable and suitable for industrialized mass production. The molybdenum powder prepared by the method can meet technical requirements of a national standard GB / T3461-2006, and can be widely used for preparing raw materials for molybdenum and molybdenum alloy products such as molybdenum slabs, molybdenum bars, molybdenum piercing mandrels and molybdenum fabricated parts.

Owner:JINDUICHENG MOLYBDENUM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com