Molybdenum dioxide nanosheet/graphene-like carbon nitride photocatalytic material with visible-light response as well as preparation and application thereof

A technology of carbon nitride and molybdenum dioxide, which is applied in the field of visible light-responsive molybdenum dioxide nanosheet/graphene-like carbon nitride photocatalyst material and its preparation and application, can solve the problem of low utilization rate and large band gap , high electron-hole recombination rate, etc., to achieve the effect of low cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

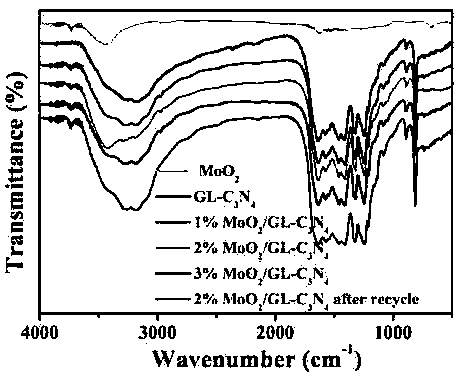

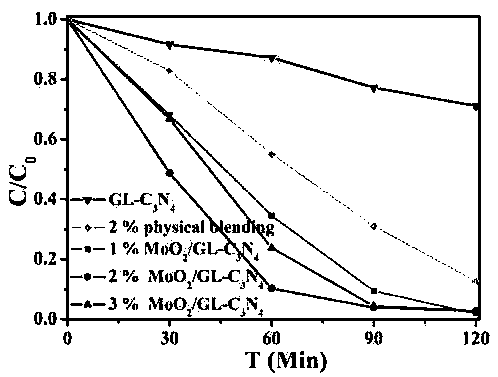

[0019] Embodiment 1: The present invention is a preparation method of a visible light-responsive molybdenum dioxide / graphene-like carbon nitride (1 wt%) composite photocatalyst, comprising the following steps:

[0020] (1) Put 6 g of dicyandiamide in a tube furnace, blow in nitrogen, and calcinate at 600 °C for 2 hours to obtain block graphite carbon nitride;

[0021] (2) Add 0.05 g of graphite-type carbon nitride and 0.15 g of ammonium chloride into deionized water, stir at room temperature, ultrasonically disperse, react in a reaction box at 180 °C for 12 h, wash and dry, and then in 350 °C Graphene-like carbon nitride (GL-C3N4) can be obtained by heating at low temperature for 120 min with a heating rate of 2°C / min;

[0022] (3) Disperse 300 mg of molybdic acid in deionized water, stir to make it evenly dispersed, add 3 ml of tert-dodecyl mercaptan, and then ultrasonicate for 30 min;

[0023] (4) Put the mixed solution in (3) into a reaction kettle, react at 190 °C for 12 ...

Embodiment 2

[0027] Embodiment 2: The present invention is a preparation method of a visible light-responsive molybdenum dioxide / graphene-like carbon nitride (2 wt%) composite photocatalyst, comprising the following steps:

[0028] (1) Put 6 g of dicyandiamide in a tube furnace, blow in nitrogen, and calcinate at 600 °C for 2 hours to obtain block graphite carbon nitride;

[0029] (2) Add 0.05 g of graphite-type carbon nitride and 0.15 g of ammonium chloride into deionized water, stir at room temperature, ultrasonically disperse, react in a reaction box at 180 °C for 12 h, wash and dry, and then in 350 °C Graphene-like carbon nitride (GL-C3N4) can be obtained by heating at low temperature for 120 min with a heating rate of 2°C / min;

[0030] (3) Disperse 300 mg of molybdic acid in deionized water, stir to make it evenly dispersed, add 3 ml of tert-dodecyl mercaptan, and then ultrasonicate for 30 min;

[0031] (4) Put the mixed solution in (3) into a reaction kettle, react at 190 °C for 12 ...

Embodiment 3

[0035] Embodiment 3: The present invention is a preparation method of a visible light-responsive molybdenum dioxide / graphene-like carbon nitride (3 wt%) composite photocatalyst, comprising the following steps:

[0036](1) Put 6 g of dicyandiamide in a tube furnace, blow in nitrogen, and calcinate at 600 °C for 2 hours to obtain block graphite carbon nitride;

[0037] (2) Add 0.05 g of graphite-type carbon nitride and 0.15 g of ammonium chloride into deionized water, stir at room temperature, ultrasonically disperse, react in a reaction box at 180 °C for 12 h, wash and dry, and then in 350 °C Graphene-like carbon nitride (GL-C3N4) can be obtained by heating at low temperature for 120 min with a heating rate of 2°C / min;

[0038] (3) Disperse 300 mg of molybdic acid in deionized water, stir to make it evenly dispersed, add 3 ml of tert-dodecyl mercaptan, and then ultrasonicate for 30 min;

[0039] (4) Put the mixed solution in (3) into a reaction kettle, react at 190 °C for 12 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com