Preparation methods and applications of multilayer graphene and multilayer graphene modified electrode

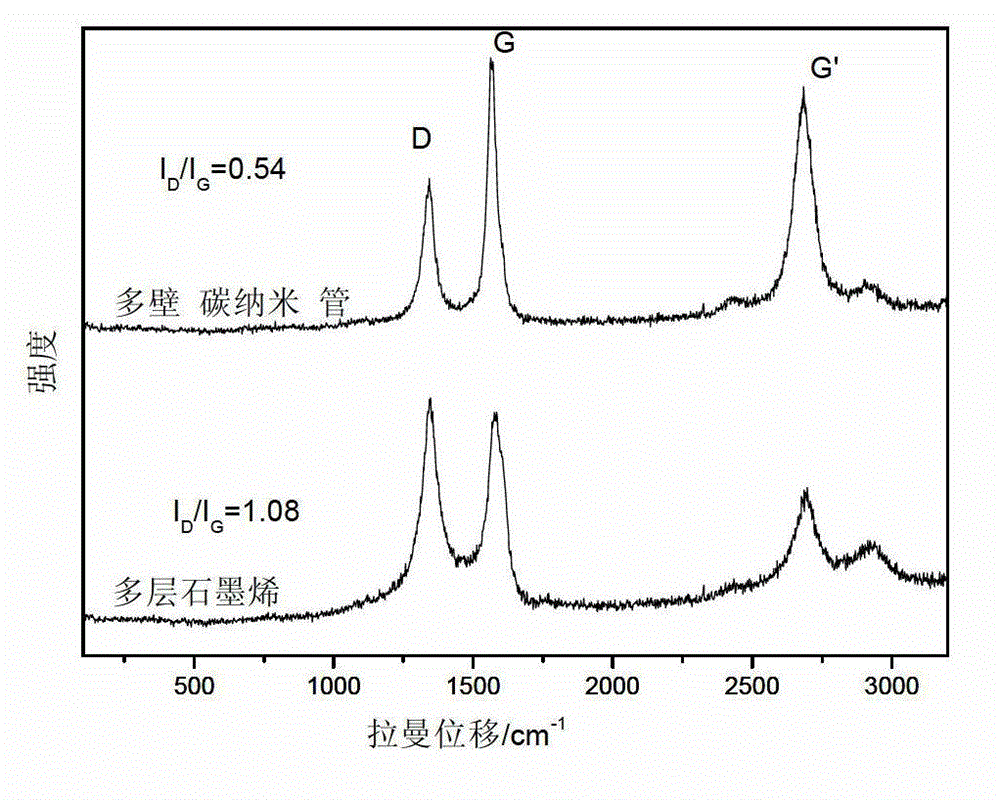

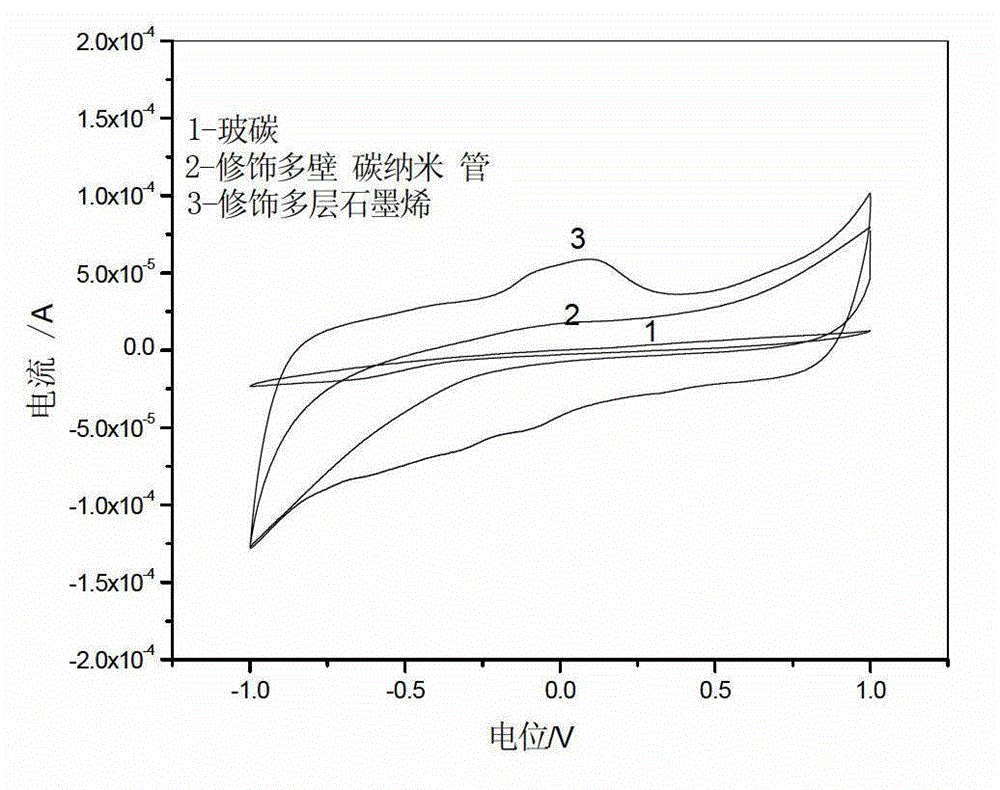

A technology of multi-layer graphene and modified electrodes, applied in the direction of graphene, material electrochemical variables, nano-carbon, etc., can solve the problem of small specific surface area, achieve large specific surface area, high detection sensitivity, and high electron transfer rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

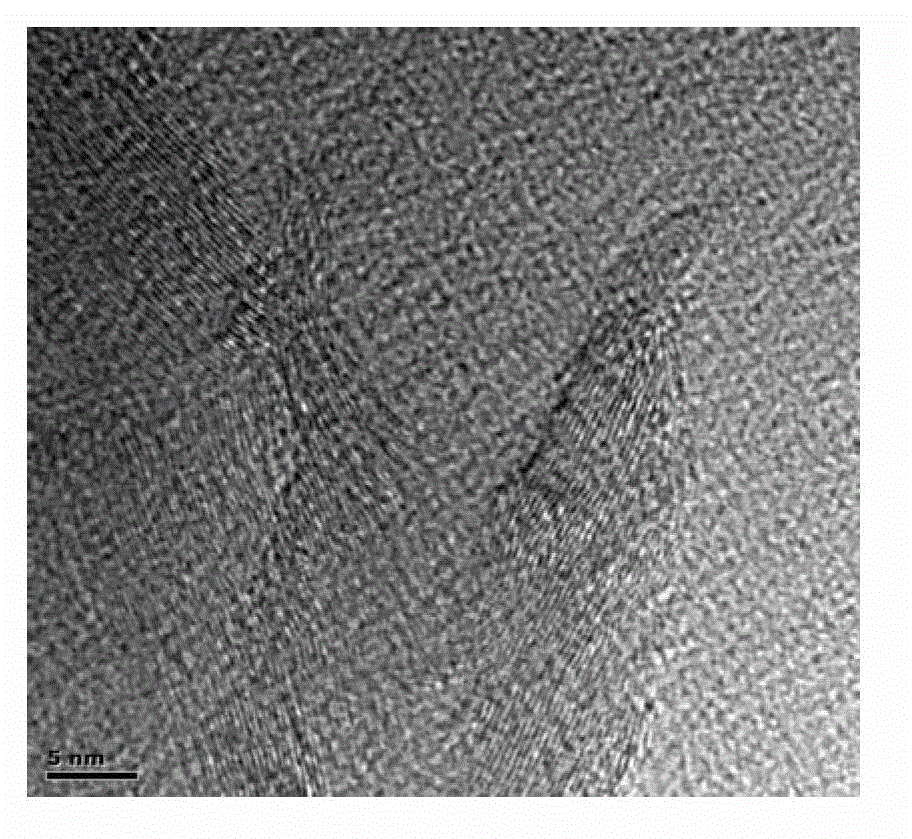

Embodiment 1

[0041] Put 50g of concentrated sulfuric acid, 10g of potassium permanganate and 1g of multi-walled carbon nanotubes (with a purity of more than 90%) between 20 and 30 layers into a 150ml three-necked bottle and place it in a constant temperature water bath at 80°C. The stirring rate is After stirring at 500rpm for 12h, pour the mixed solution into deionized water containing hydrogen peroxide (the content of hydrogen peroxide in the total weight is 2wt%), vacuum filter and wash until neutral, and dry in a vacuum oven at 60°C After 24 hours, the multi-layer graphene powder with layers between 20 and 30 can be obtained; since the distance between the walls of multi-walled carbon nanotubes is about 0.34nm, and as the number of layers increases, there are The greater the gravitational force, the more obvious the shielding effect and the less likely it is to be opened. Therefore, for carbon nanotubes with more layers, the higher the ratio of concentrated sulfuric acid and potassium p...

Embodiment 2

[0047] Put 50g of concentrated sulfuric acid, 5g of potassium permanganate and 2g of multi-walled carbon nanotubes (with a purity of more than 90%) between 10 and 20 layers into a 150ml three-necked bottle and place it in a constant temperature water bath at 50°C. The stirring rate is After stirring at 800rpm for 10h, pour the mixed solution into deionized water containing hydrogen peroxide (the content of hydrogen peroxide in the total weight is 5wt%), vacuum filter and wash until neutral, and dry in a vacuum oven at 60°C After 24 hours, multi-layer graphene powder with layers between 10 and 20 can be obtained;

[0048] Take 10 mg of the obtained multi-layer graphene powder and disperse it in 10 ml of dimethylformamide, place it in an ultrasonic instrument with a power of 30 W for 7 hours to obtain a uniformly dispersed dispersion, and use a micro-sampler to draw 5 μl of the dispersion and drop-coat it on Dry the surface of the glassy carbon electrode under an infrared lamp w...

Embodiment 3

[0052] Add 50g of concentrated sulfuric acid, 10g of potassium permanganate and 0.1g of multi-walled carbon nanotubes (with a purity of more than 90%) between 40 and 60 layers into a 150ml three-necked bottle and place it in a constant temperature water bath at 90°C. After stirring for 5 hours at 1200rpm, pour the mixed solution into deionized water containing hydrogen peroxide (the content of hydrogen peroxide in the total weight is 10wt%), vacuum filter and wash until neutral, and put it in a vacuum drying oven at 60°C After drying for 24 hours, a multilayer graphene powder with layers between 40 and 60 can be obtained;

[0053] Take 1mg of the obtained multi-layer graphene powder and disperse it in 10ml of ethanol, place it in an ultrasonic instrument with a power of 50W for 10h to obtain a uniformly dispersed dispersion, and use a micro-sampler to draw 5μl of the dispersion and drop-coat it on the glassy carbon electrode The surface is dried under an infrared lamp with a w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com