Palladium nano-composite catalyst loaded by N-doped three-dimensional graphene and preparing method and application thereof

A nitrogen-doped graphene and composite catalyst technology, which is applied in the field of catalysis, can solve the problems of decreased cycle efficiency and stability of noble metal/3D graphene composite materials, lack of active sites, and limited applications, and achieves excellent reuse performance, Improve catalytic activity and stability, reduce bleed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Preparation of graphene oxide:

[0022] Take graphite powder and sodium nitrate, add concentrated sulfuric acid and stir evenly, then put it into an ice bath, add potassium permanganate while stirring, keep the temperature below 20°C, then raise the temperature to 35°C and keep it warm for 1~2h, then slowly add to remove Deionized water, the volume ratio of deionized water and concentrated sulfuric acid added is 2:1, and the temperature is raised to 85~95°C, kept for 15 minutes, and then 10mL of 30% hydrogen peroxide and deionized water are added, and the deionized water added at this time The volume ratio of water to concentrated sulfuric acid is 6:1, and the obtained product is centrifuged, washed with dilute hydrochloric acid, dried, and ground to obtain graphene oxide; the mass ratio of graphite powder to sodium nitrate is 2:1, concentrated sulfuric acid and graphite The ratio of powder is 23mL / mg, and the mass ratio of potassium permanganate to graphite powder ...

Embodiment 2

[0027] (1) The preparation of graphene oxide is the same as in Example 1;

[0028] (2) Preparation of nitrogen-doped three-dimensional graphene supported palladium nanocomposite catalyst:

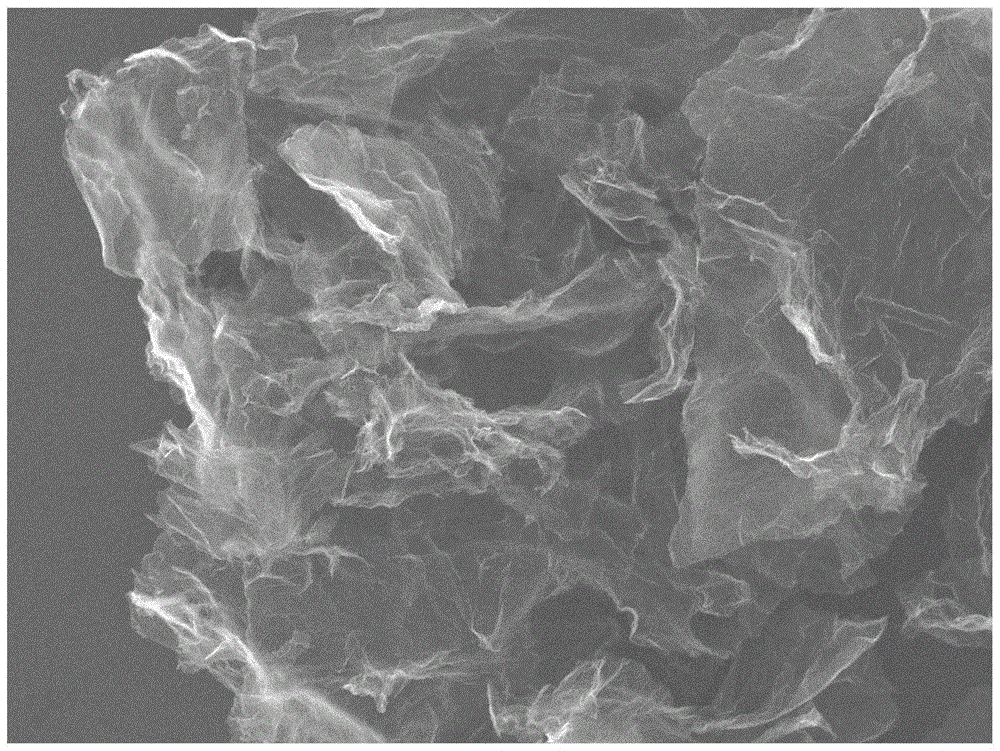

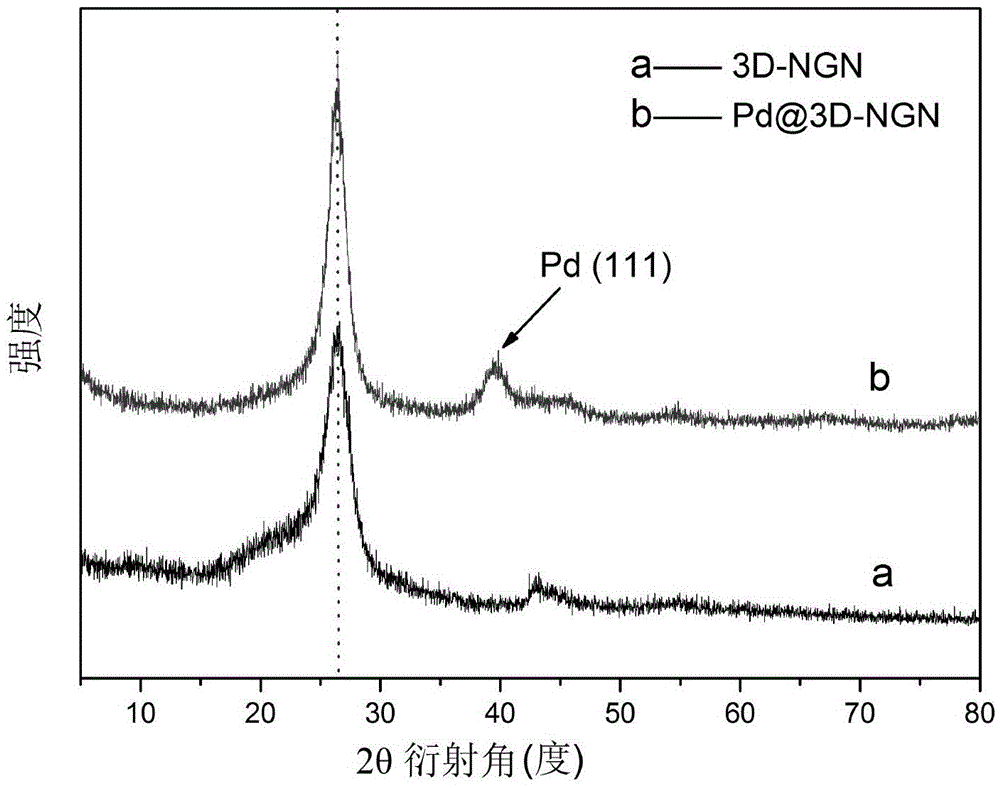

[0029] Weigh 150 mg of the above-prepared graphene oxide and add it to a beaker, add 30 mL of deionized water, ultrasonically disperse for 90 min, add 1 mL of formaldehyde solution (37%wt) and 300 mg of urea to it in turn, and transfer the resulting solution to a polytetrafluoroethylene hydrothermal In the liner of the reaction kettle, seal it, and keep the temperature at a reaction temperature of 150°C for 12h. After the reaction, the reactor was naturally cooled to room temperature, and the three-dimensional nitrogen-doped graphene carrier material (3D-NGN) was obtained after freeze-drying.

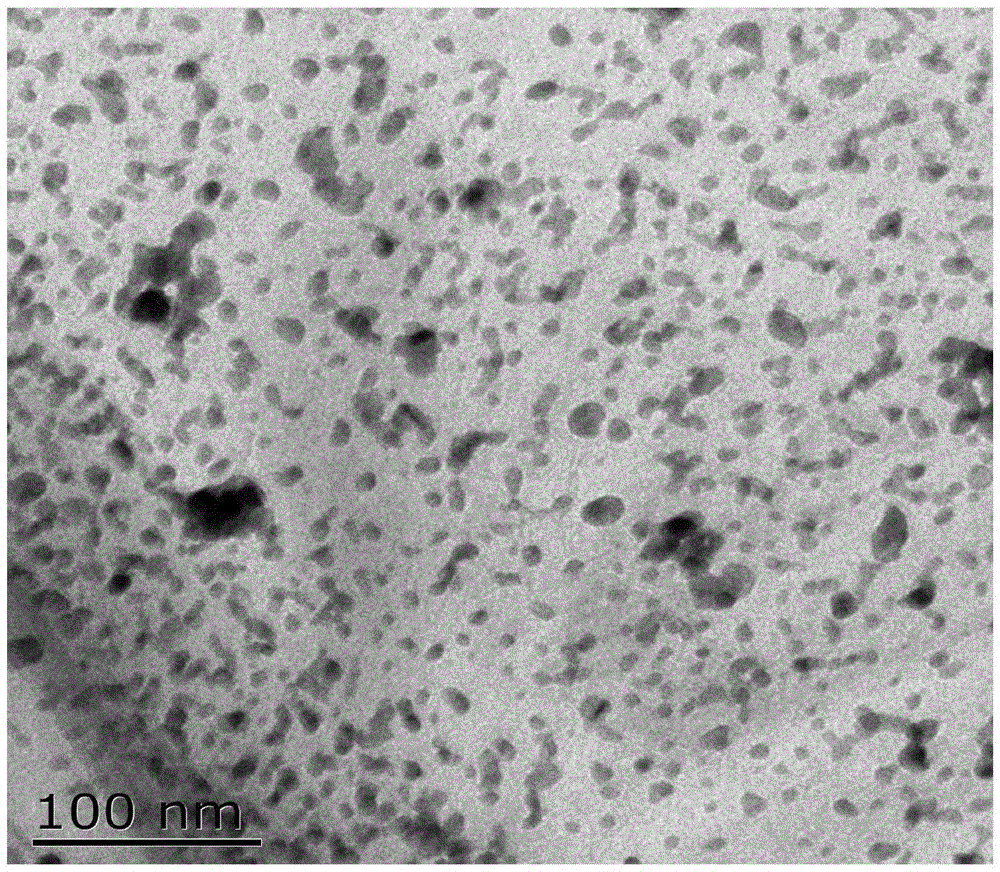

[0030] Disperse 50mg of 3D-NGN composite material in 10mL of deionized water, add dropwise 2mL of 0.01mol / LH 2 PdCl 4 solution, continue to stir and react for 2h, add 3mL concentration of 0.2mol / L s...

Embodiment 3

[0032] (1) The preparation of graphene oxide is the same as in Example 1;

[0033] (2) Preparation of nitrogen-doped three-dimensional graphene-supported palladium nanocomposite catalyst:

[0034] Weigh 150 mg of the above-prepared graphene oxide and add it to a beaker, add 30 mL of deionized water, ultrasonically disperse for 90 min, add 1.5 mL of formaldehyde solution (37%wt) and 450 mg of urea to it in turn, and transfer the resulting solution to polytetrafluoroethylene water In the liner of the thermal reaction kettle, seal it, and keep the temperature at 180°C for 24 hours. After the reaction, the reactor was naturally cooled to room temperature, and the three-dimensional nitrogen-doped graphene carrier material (3D-NGN) was obtained after freeze-drying.

[0035] Disperse 100mg of 3D-NGN composite material in 20mL of deionized water, add dropwise 6mL of 0.01mol / LH 2 PdCl 4 The solution was stirred and reacted for 3 hours, 9 mL of ascorbic acid with a concentration of 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com