Preparation method of flexible super capacitor based on carbon cloth

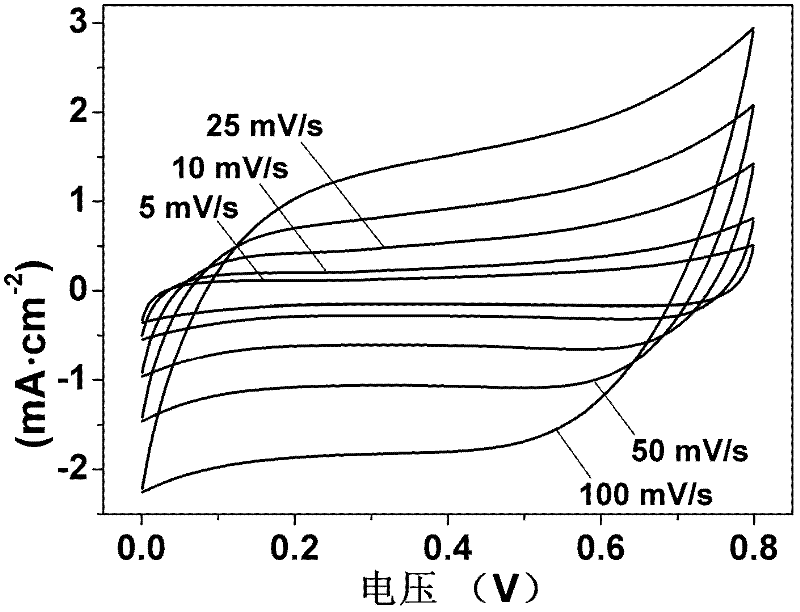

A technology of supercapacitors and carbon cloth, which is applied in the direction of capacitors, electrolytic capacitors, solid electrolytic capacitors, etc., can solve the problems of complex preparation process and difficulty in large-scale production, and achieve simple methods, easy large-scale preparation, good electrochemical characteristics and The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

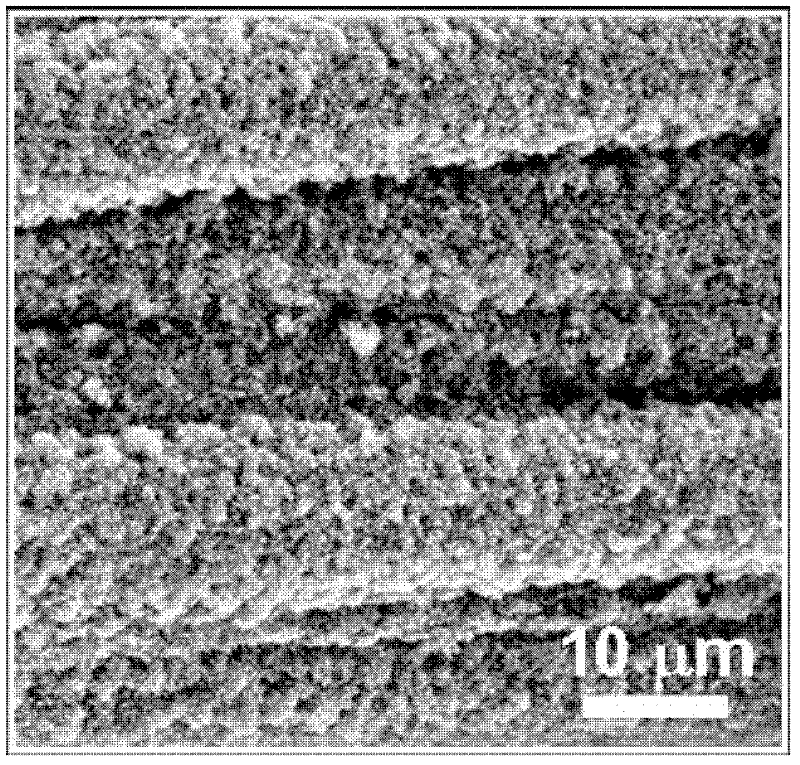

[0028] 1. Cut the carbon cloth to a suitable size and place it in the center of the flame of the alcohol lamp. After a period of time, the carbon cloth is removed, and the carbon cloth facing the flame of the alcohol lamp is covered with a layer of black carbon nanoparticles.

[0029] Or a layer of carbon nanotubes is grown on the carbon cloth, specifically: deposit a thin layer of metal iron, cobalt, nickel or their alloys on the carbon cloth by magnetron sputtering, electron beam deposition, etc. After the cloth is soaked in a solution containing salts of iron, cobalt, and nickel and annealed at a high temperature, it is placed in the center of the flame of an alcohol lamp. After a period of time, the carbon cloth was removed, and a layer of carbon nanotubes grew on the carbon cloth.

[0030] 2. Turn the carbon cloth over and repeat step 1.

[0031] 3. Immerse the carbon cloth grown with carbon nanoparticles or carbon nanotubes in a mixed solution of manganese acetate and ...

Embodiment 2

[0035] 1. Cut the carbon cloth into a suitable size, and treat the carbon cloth with hydrophilicity by chemical soaking or plasma treatment.

[0036] 2. Then put the hydrophilic treated carbon cloth into a mixed solution of zinc nitrate and hexamethylene tetraammonia with a certain ratio and concentration, and zinc oxide nanowires can be grown on the carbon cloth at a certain temperature for a certain period of time . In this embodiment, the concentration of zinc nitrate and hexamethylene tetraammonia mixed solution, and the reaction temperature and reaction time can be selected by those skilled in the art according to the time requirement. The ammonia ratio is 1:1, the reaction temperature is 80-140 degrees Celsius, and the reaction time is 2-14 hours.

[0037] 3. Immerse the above-mentioned carbon cloth grown with zinc oxide nanowires in a certain concentration of pyrrole and sulfuric acid solution, and electrodeposit a layer of polypyrrole on the surface of zinc oxide by e...

Embodiment 3

[0041] 1. Cut the carbon cloth into a certain size, wash and dry it for later use.

[0042] 2. Use ceramic sheets as gaskets, place carbon cloth on top of the tungsten boat, pass in a certain proportion of argon and oxygen, and grow tungsten oxide and three Molybdenum oxide nanowires.

[0043] 3. Molybdenum trioxide is reduced to molybdenum dioxide by hydrogen reduction at high temperature.

[0044] 4. Immerse the carbon cloth grown with tungsten oxide or molybdenum dioxide in a mixed solution of a certain concentration of manganese acetate and ammonium acetate, and deposit a certain amount of manganese oxide on the carbon nanoparticles by electroplating.

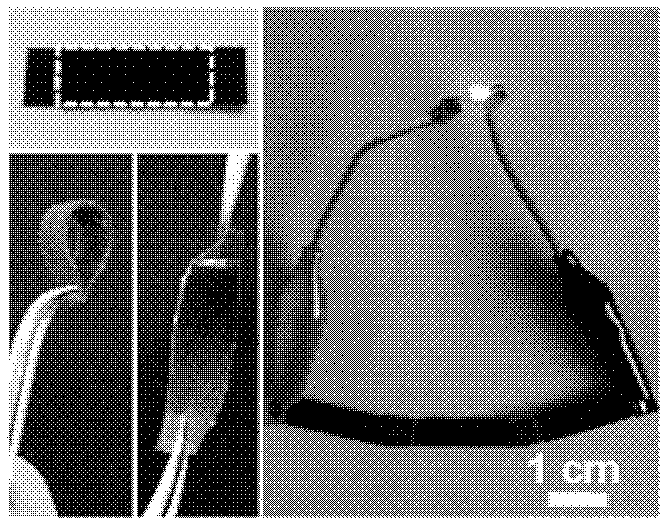

[0045] 5. Take two pieces of carbon cloth deposited with tungsten oxide and manganese oxide or molybdenum dioxide and manganese oxide and soak them in a mixed solution of polyvinyl alcohol and phosphoric acid or sodium hydroxide at a certain concentration for a certain period of time, then take them out and stick them toge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com