Method for manufacturing molybdenum powder

The technology of molybdenum powder and molybdenum trioxide is applied in the field of preparation of molybdenum powder, which can solve the problems of high cost and environmental pollution, and achieve the effects of increasing production capacity, reducing production cost and no sintering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

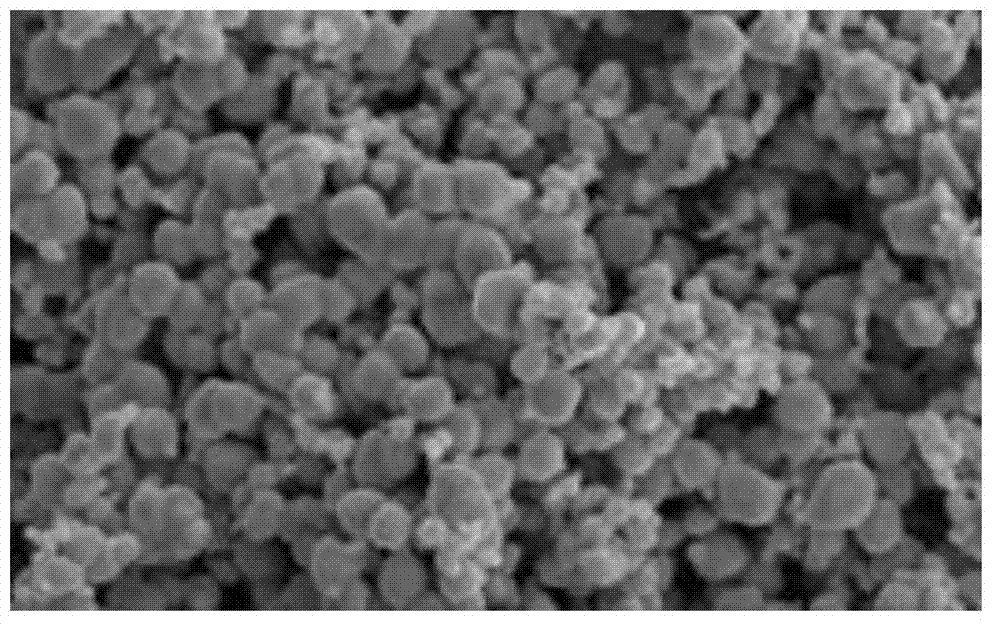

Image

Examples

preparation example Construction

[0024] The preparation method of the molybdenum powder of the present invention comprises firstly decomposing the water-washed ammonium dimolybdate to obtain gray and white molybdenum trioxide, and then mixing the molybdenum trioxide uniformly through inverse hydrogen reduction to obtain the molybdenum powder.

[0025] Specific steps are as follows:

[0026] In step 1, the Fischer particle size is 40-50 μm, and the bulk density is 1.4-1.5 g / cm 3 , the water-washed ammonium dimolybdate with a K content of 60-80ppm is thermally decomposed in a roasting furnace, and the highest roasting temperature is 500-520°C to obtain gray and white molybdenum trioxide;

[0027] In step 2, the molybdenum trioxide obtained in step 1 is subjected to inverse hydrogen reduction in four temperature zones of a flat four-tube reduction furnace, and the molybdenum trioxide obtained in step 1 is loaded into a feeding boat with a thickness of 16-18mm and a reduction temperature of 300- 540°C is set to ...

Embodiment 1

[0034] Step 1, the Fischer particle size is 45 μm, and the bulk density is 1.42g / cm 3 , the water-washed ammonium dimolybdate with a K content of 60ppm is thermally decomposed in a roasting furnace with a maximum roasting temperature of 510°C to obtain gray and white molybdenum trioxide;

[0035] Step 2, the molybdenum trioxide obtained in step 1 is subjected to inverse hydrogen reduction in four temperature zones of the flat four-tube reduction furnace, and the molybdenum trioxide obtained in step 1 is loaded into a feeding boat with a thickness of 16mm, and the reduction temperature is 300°C, 380°C °C, 480 °C and 520 °C step by step setting, the hydrogen flow rate is 6m 3 / h tube, after heating for 3.5h, cool naturally, and then sieve with an 80-mesh screen to obtain molybdenum dioxide powder;

[0036] Step 3: The molybdenum dioxide obtained in step 2 is subjected to inverse hydrogen reduction in 5 temperature zones of a flat four-tube reduction furnace, and the molybdenum ...

Embodiment 2

[0038] Step 1, the Fischer particle size is 40 μm, and the bulk density is 1.4g / cm 3 , the water-washed ammonium dimolybdate with a K content of 75ppm is thermally decomposed in a roasting furnace at a maximum roasting temperature of 500°C to obtain gray and white molybdenum trioxide;

[0039] Step 2, the molybdenum trioxide obtained in step 1 is subjected to inverse hydrogen reduction in four temperature zones of a flat four-tube reduction furnace, and the molybdenum trioxide obtained in step 1 is loaded into a boat with a thickness of 17mm, and the reduction temperature is 310°C, 390°C °C, 490 °C and 530 °C step by step setting, the hydrogen flow rate is 4m 3 / h tube, after heating for 4h, cool naturally, and then sieve with 80 mesh screen to obtain molybdenum dioxide powder;

[0040] Step 3, the molybdenum dioxide obtained in step 2 is subjected to inverse hydrogen reduction in 5 temperature zones of the flat four-tube reduction furnace, and the molybdenum dioxide powder o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Fisherman's particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com