Preparation method of molybdenum powder

A molybdenum powder and powder technology, which is applied in the field of rare metal powder metallurgy, can solve the problems of poor material consistency, short service life, and low strength of molybdenum-copper alloy compacts, and achieve good material consistency, long service life and high yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

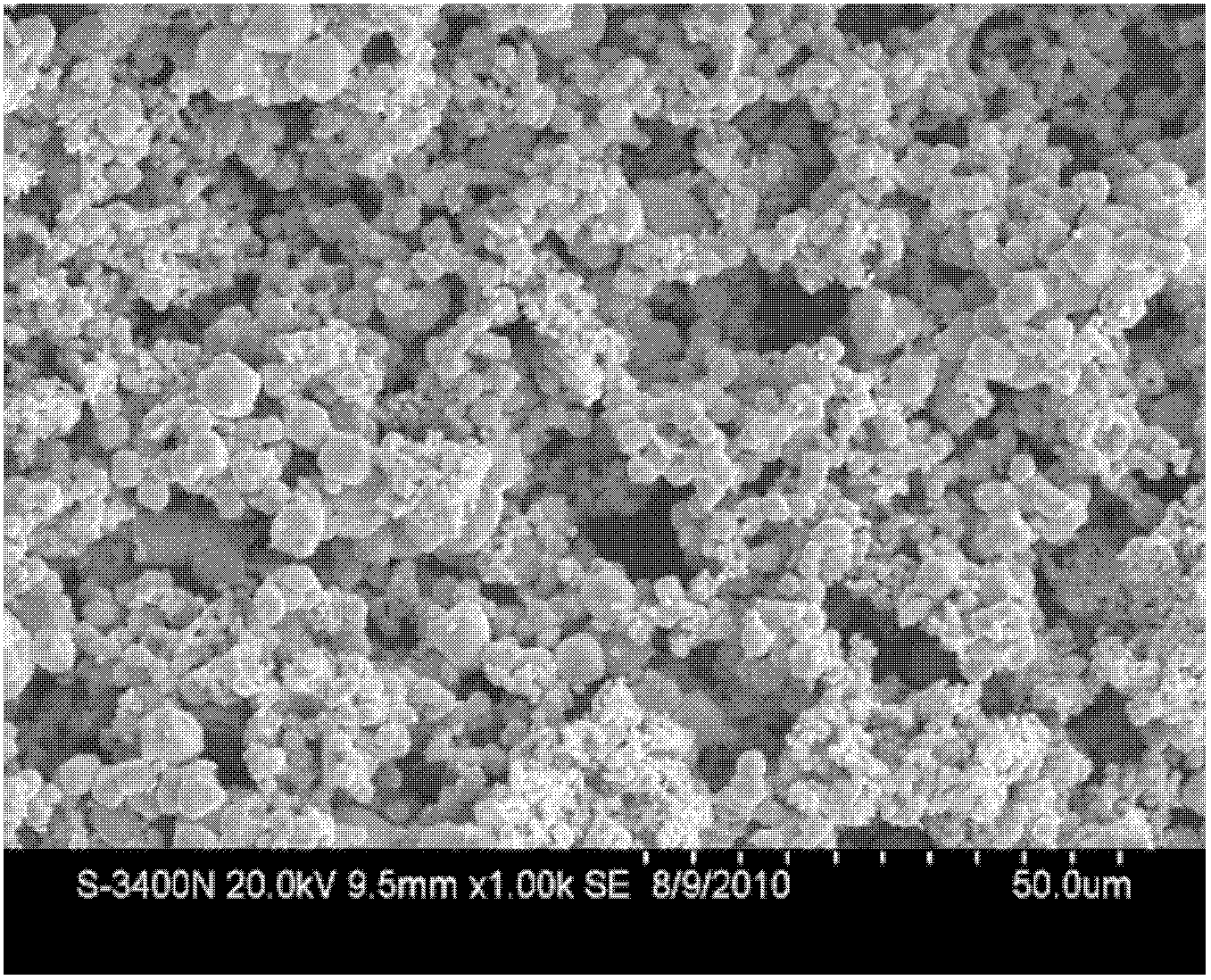

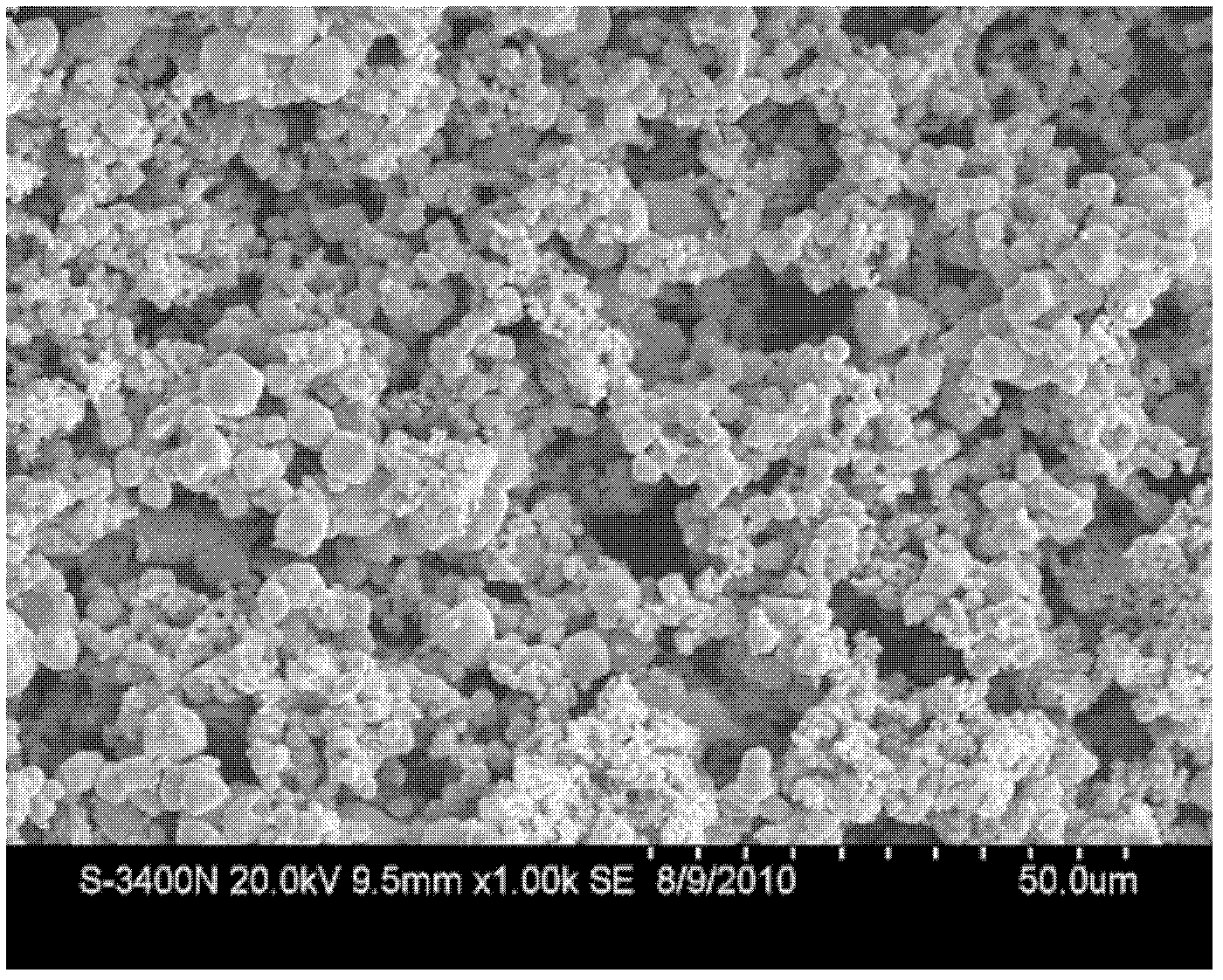

Image

Examples

Embodiment 1

[0027] The preparation method of the present embodiment comprises the following steps:

[0028] Step 1, passing molybdenum trioxide with a mass purity of 99.95% through a 40-mesh sieve to obtain molybdenum trioxide powder; the average Fischer particle size of the molybdenum trioxide is 4.0 μm, and the average bulk density is 1.0 g / cm 3 ;

[0029] Step 2, the molybdenum trioxide powder described in step 1 is loaded into the material boat with the loading capacity of 2.0kg / boat, and the molybdenum trioxide powder in the material boat is carried out a hydrogen reduction in the reduction four temperature zones of the primary reduction furnace, Push the boat once every 30min, after the primary hydrogen reduction finishes, the material boat is cooled to room temperature in the cooling zone of the primary reduction furnace, and the primary redox product molybdenum dioxide is obtained in the material boat; the initial temperature of the primary hydrogen reduction is 340°C, the final ...

Embodiment 2

[0037] The preparation method of the present embodiment comprises the following steps:

[0038] Step 1, passing molybdenum trioxide with a mass purity of 99.97% through a 40-mesh sieve to obtain molybdenum trioxide powder; the average Fischer particle size of the molybdenum trioxide is 6.0 μm, and the average bulk density is 1.2 g / cm 3 ;

[0039] Step 2, the molybdenum trioxide powder described in step 1 is loaded into the material boat with the loading capacity of 3.0kg / boat, and the molybdenum trioxide powder in the material boat is carried out a hydrogen reduction in the reduction five-temperature zone of the primary reduction furnace, Push the boat once every 30min, after the primary hydrogen reduction finishes, the material boat is cooled to room temperature in the cooling zone of the primary reduction furnace, and the primary redox product molybdenum dioxide is obtained in the material boat; the initial temperature of the primary hydrogen reduction is 340°C, the final t...

Embodiment 3

[0046] The preparation method of the present embodiment comprises the following steps:

[0047] Step 1, passing molybdenum trioxide with a mass purity of 99.98% through a 40-mesh sieve to obtain molybdenum trioxide powder; the average Fischer particle size of the molybdenum trioxide is 9.0 μm, and the average bulk density is 1.4 g / cm 3 ;

[0048] Step 2, the molybdenum trioxide powder described in the step 1 is loaded into the material boat with the loading capacity of 4.0kg / boat, and the molybdenum trioxide powder in the material boat is carried out a hydrogen reduction in the reduction five temperature zones of the primary reduction furnace, Push the boat once every 30min, after the primary hydrogen reduction finishes, the material boat is cooled to room temperature in the cooling zone of the primary reduction furnace, and the primary redox product molybdenum dioxide is obtained in the material boat; the initial temperature of the primary hydrogen reduction is 600°C, the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average fischer particle size | aaaaa | aaaaa |

| Average fischer particle size | aaaaa | aaaaa |

| Fisherman's particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com