Zinc metallic coating

A zinc metal and coating technology, applied in coatings, anti-corrosion coatings, etc., can solve serious problems such as safety, environmental protection, complicated process, and high process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

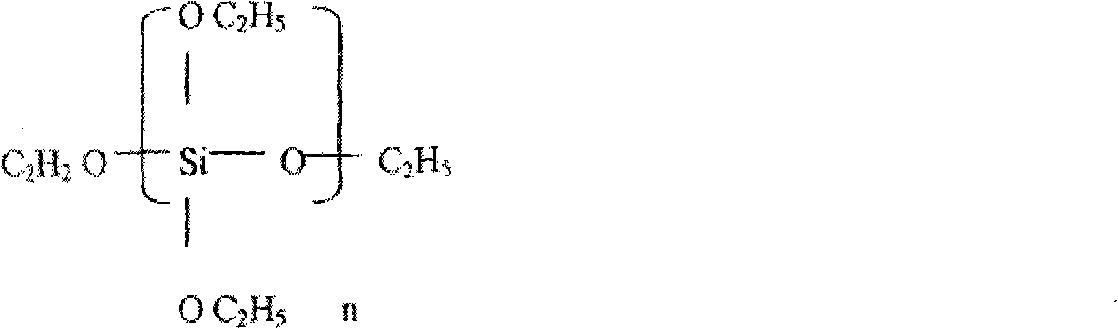

Method used

Image

Examples

Embodiment Construction

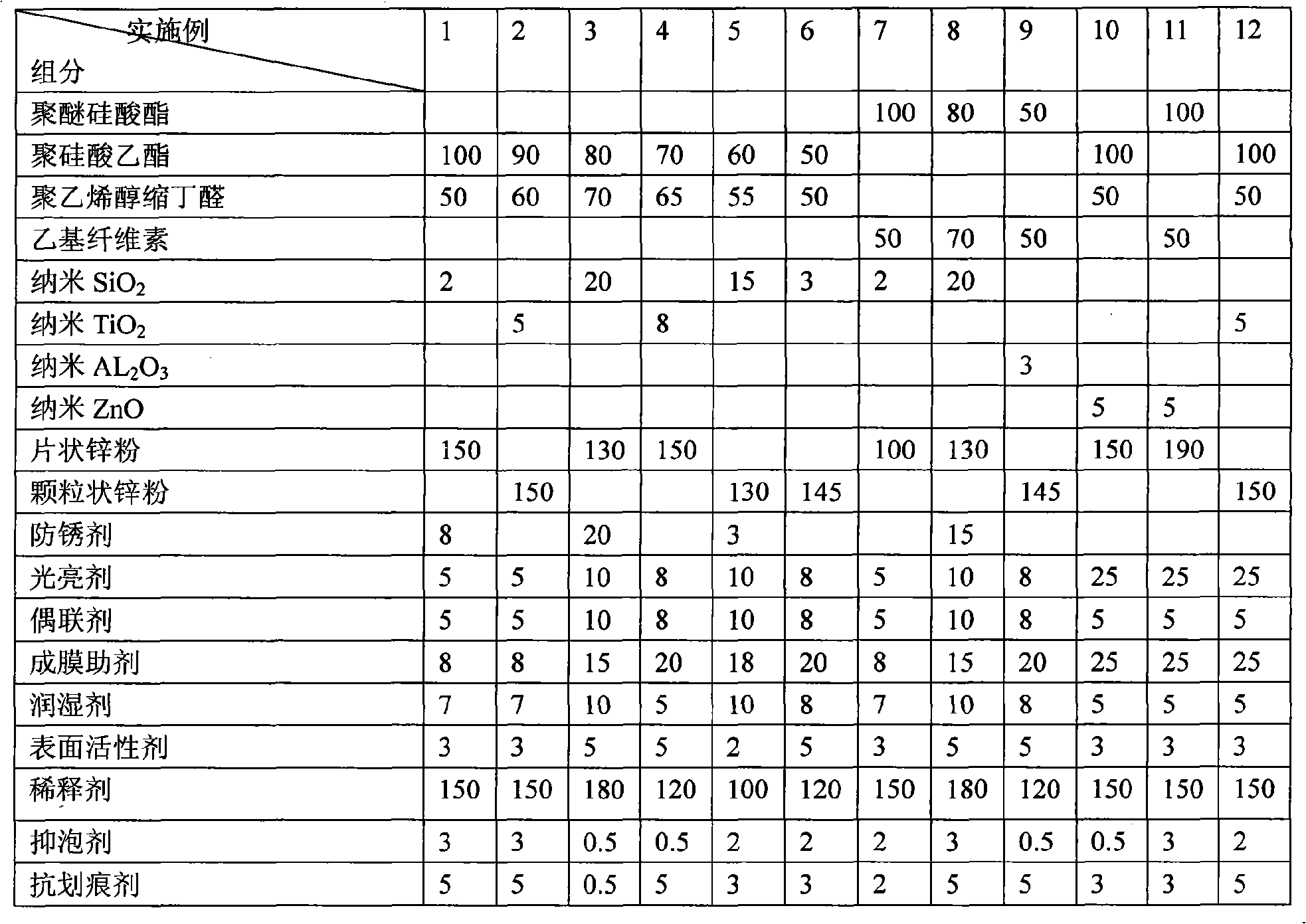

[0036] The present invention will be further described below in conjunction with specific embodiment:

[0037] by weight

[0038]

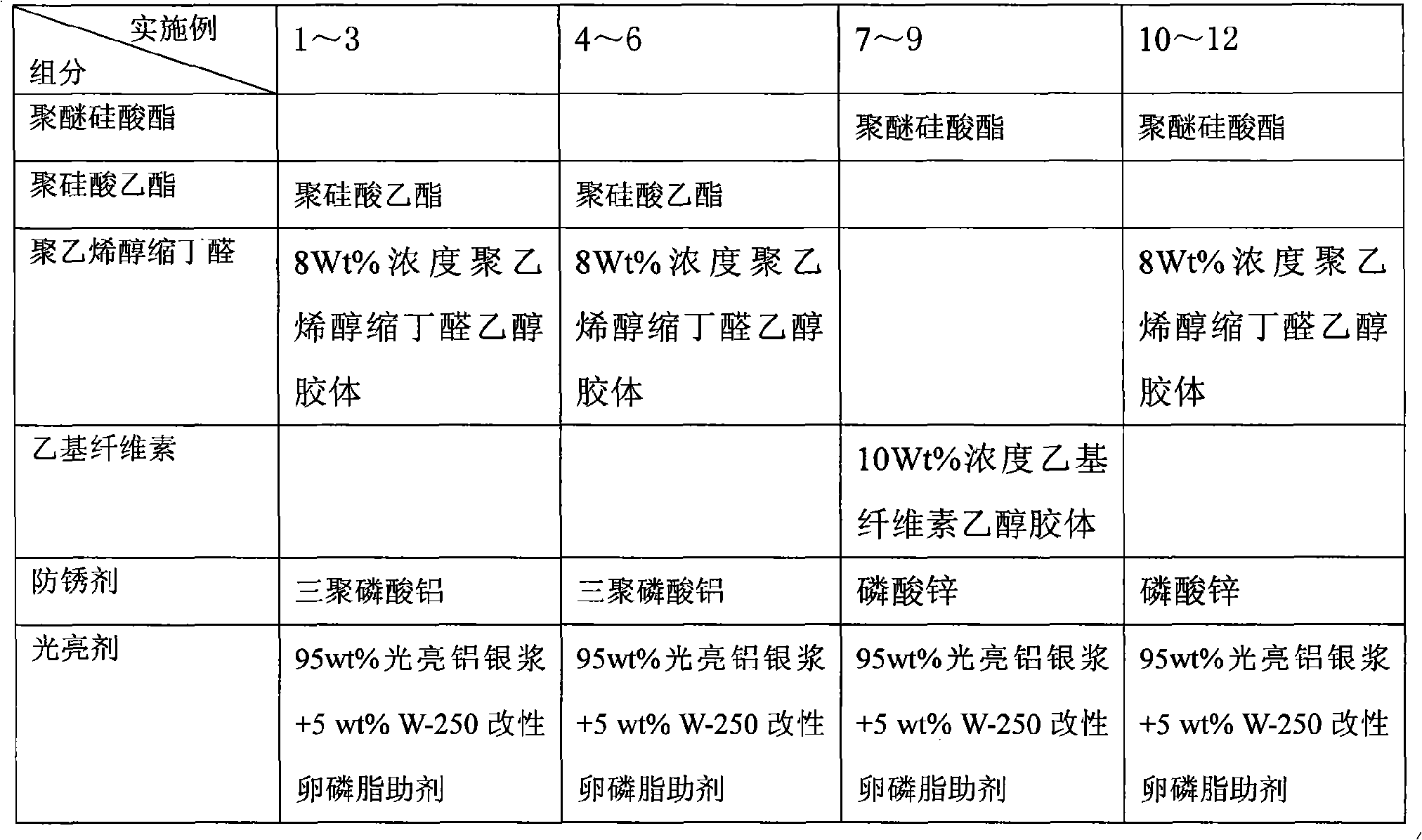

[0039] The component names in each embodiment are

[0040]

[0041]

[0042] The zinc metal coating in Example 1 is coated on M10×45 hexagonal head steel screws, the thickness of the zinc metal coating is: 12-18 μm; then carry out rapid aging test, accelerated aging (relative to salt spray test) test as follows:

[0043] A. Formula of aging impregnating solution

[0044] 30% hydrogen peroxide: 12ml; industrial salt: 8g; pure water: 80ml

[0045] B. Judging criteria

[0046] Immerse the bright zinc-coated galvanized parts in the above dipping solution and take them out after standing for 1.5 hours. If there is no rust on the parts, it can be judged to be equivalent to the 500-hour conventional salt spray test.

[0047] C. Experimental results: ≥12h, no rust occurs on the workpiece.

[0048]The above test methods are the enterprise st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com