Method for preparing nano molybdenum disulfide with fullerene structure

A technology of nano-molybdenum disulfide and fullerene structure, applied in the direction of molybdenum sulfide, etc., can solve the problems of complex process, high cost, unfavorable industrial production, etc., and achieve the effect of high reaction efficiency, low cost and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

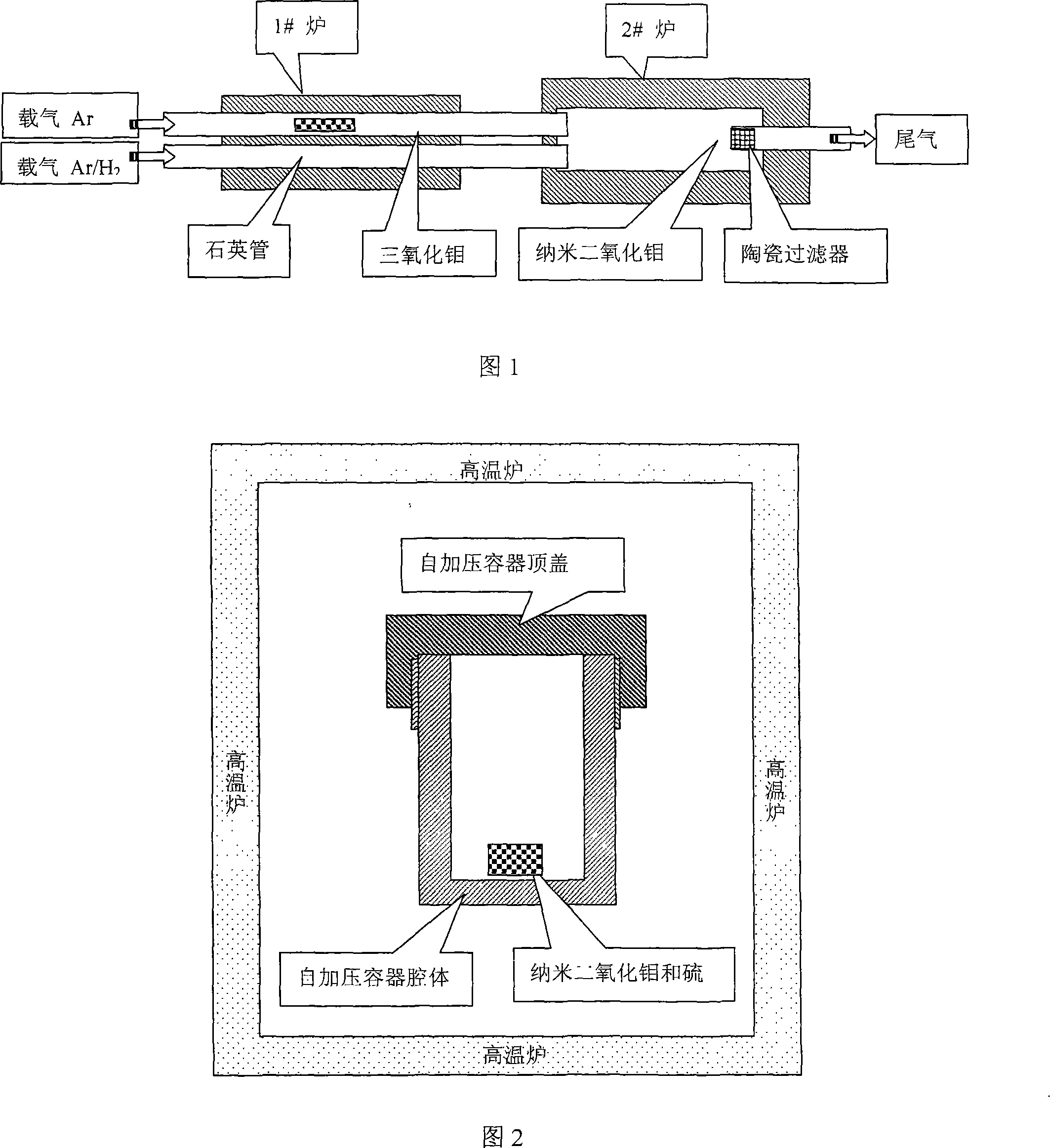

[0025] Fig. 1 shows the schematic diagram of the preparation device structure of nano-molybdenum dioxide, which is composed of two independently heated tube furnaces, wherein 1# furnace is the gasifier of molybdenum trioxide, and 2# furnace is the reduction of molybdenum dioxide Reactor.

[0026] After the two quartz glass tubes pass through the 1# furnace, they meet in the 2# furnace. The 1# furnace provides molybdenum trioxide gas, and the gasification amount of molybdenum trioxide is controlled by controlling the carrier gas flow and the gasification temperature of the 1# furnace. , by controlling the temperature of the 2# furnace to control the reduction reaction temperature conditions of molybdenum dioxide, the generated molybdenum dioxide is deposited on the ceramic filter in the quartz tube in the 2# furnace, after the reduction reaction is completed, the 2# furnace cools down to room temperature Take it out to obtain nanometer molybdenum dioxide product.

[0027] The ...

Embodiment 1

[0030] A kind of preparation method of nanomolybdenum disulfide with fullerene structure, its preparation process is to adopt two-step method, carry out according to the following steps successively:

[0031] 1) First, industrial molybdenum trioxide is used as raw material, argon is used as carrier gas, hydrogen is used as reducing agent, and nanometer molybdenum dioxide particles are generated through gas phase reaction;

[0032] 2) Reaction of nano-molybdenum disulfide and elemental sulfur under high-temperature self-pressurized conditions to generate nano-molybdenum disulfide powder materials with a fullerene structure;

[0033] 3) The molybdenum dioxide is a nanoparticle directly formed by the reaction of molybdenum trioxide at 700-1000°C with hydrogen at 400-950°C. Secondly, the molybdenum disulfide of the fullerene structure is a nanometer Molybdenum oxide and elemental sulfur are synthesized by self-pressurized reaction at a temperature of 500-950°C in a container;

[...

Embodiment 2

[0037] A kind of preparation method of described nano-molybdenum disulfide with fullerene structure is carried out according to the following steps successively:

[0038] 1) First, industrial molybdenum trioxide is used as raw material, argon is used as carrier gas, hydrogen is used as reducing agent, and nanometer molybdenum dioxide particles are generated through gas phase reaction;

[0039] 2) Reaction of nano-molybdenum disulfide and elemental sulfur under high-temperature self-pressurized conditions to generate nano-molybdenum disulfide powder materials with a fullerene structure;

[0040] 3) The molybdenum dioxide is a nanoparticle directly formed by the reaction of molybdenum trioxide at 720-980°C with hydrogen at 420-930°C. Secondly, molybdenum disulfide with a fullerene structure is a nanometer Molybdenum oxide and elemental sulfur are synthesized by self-pressurized reaction at a temperature of 550-930°C in a container;

[0041] 4), the synthetic reaction of described...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com