Patents

Literature

48results about How to "Fast reduction reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

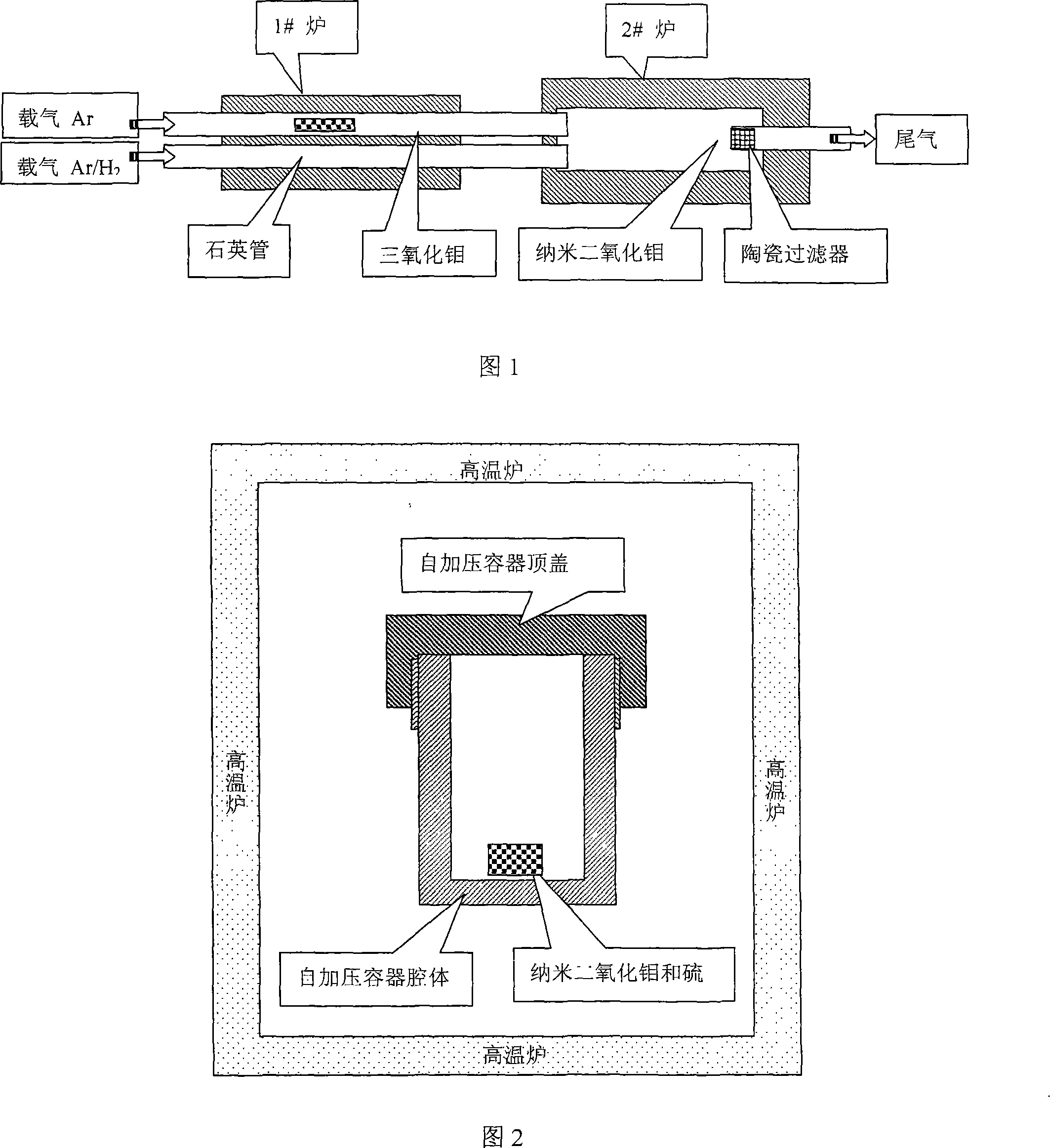

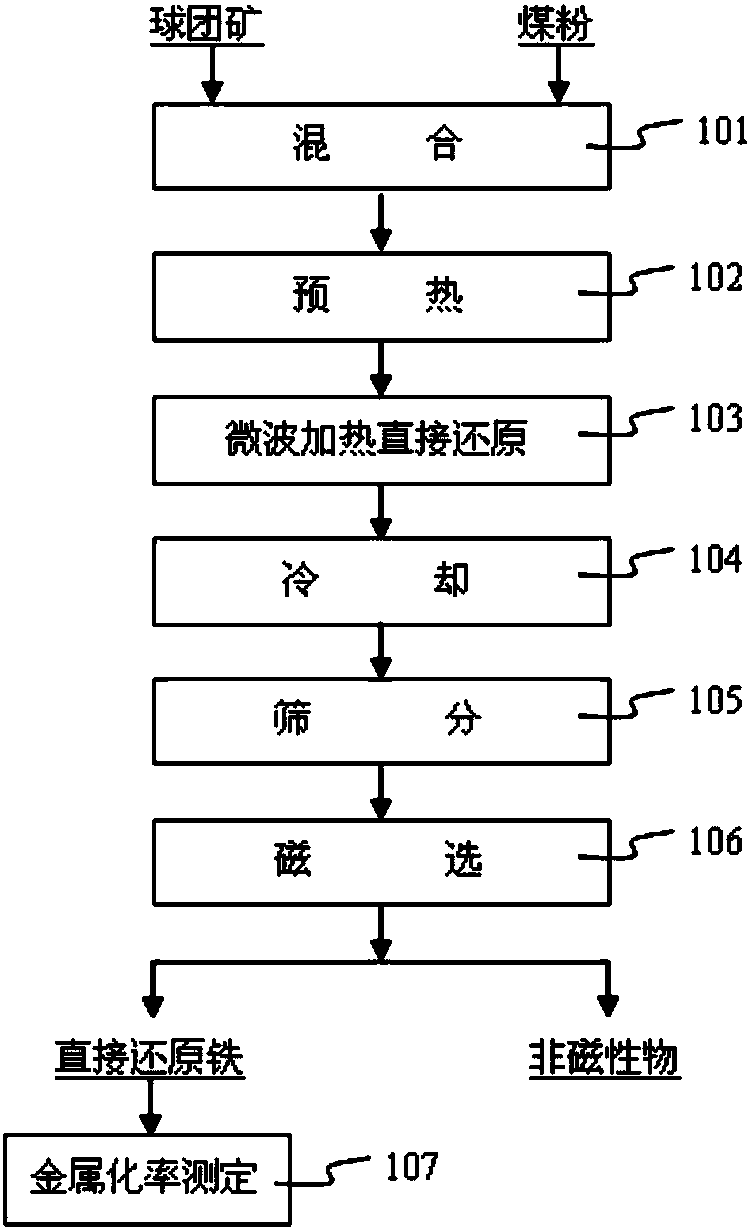

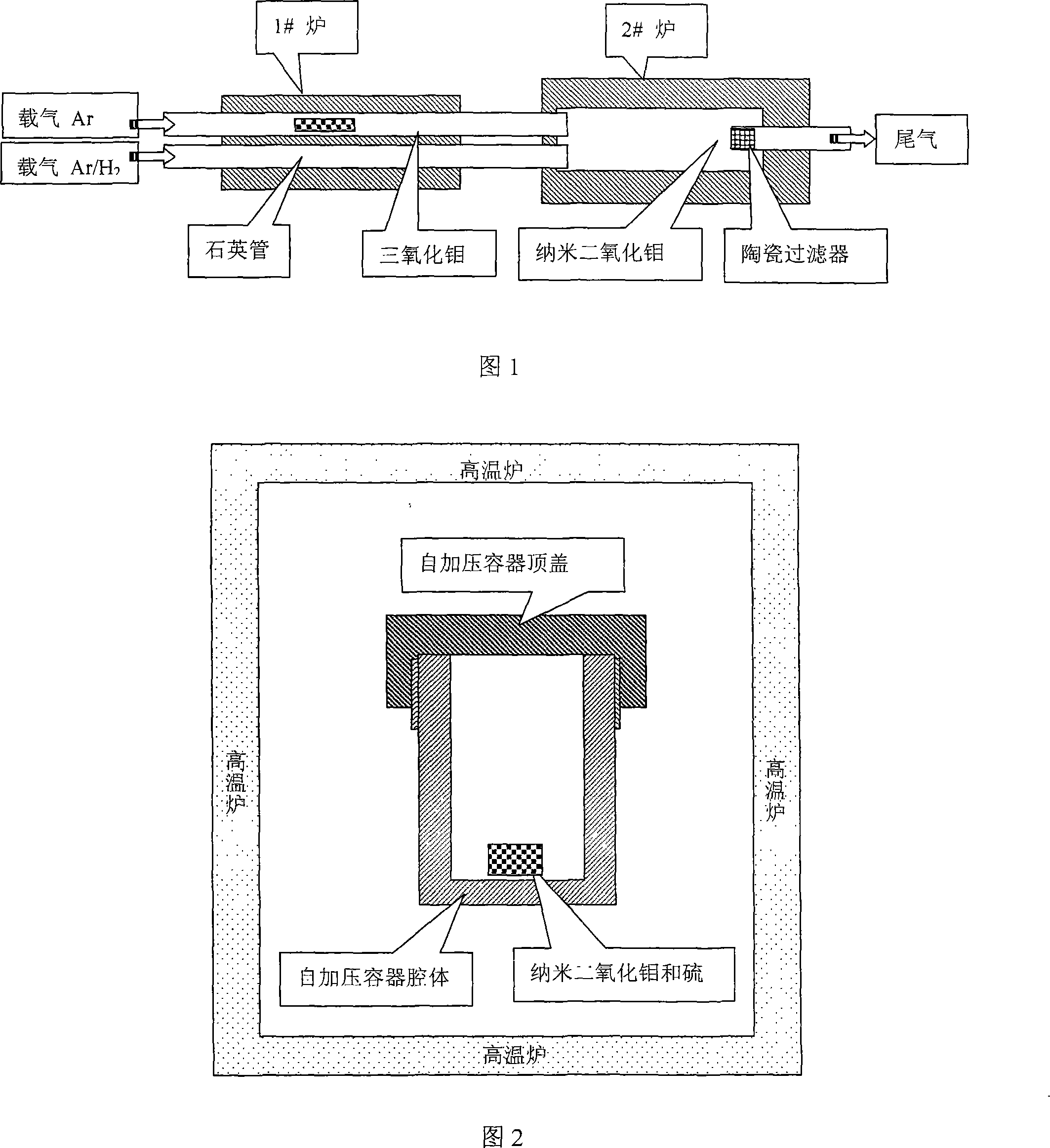

Method for preparing nano molybdenum disulfide with fullerene structure

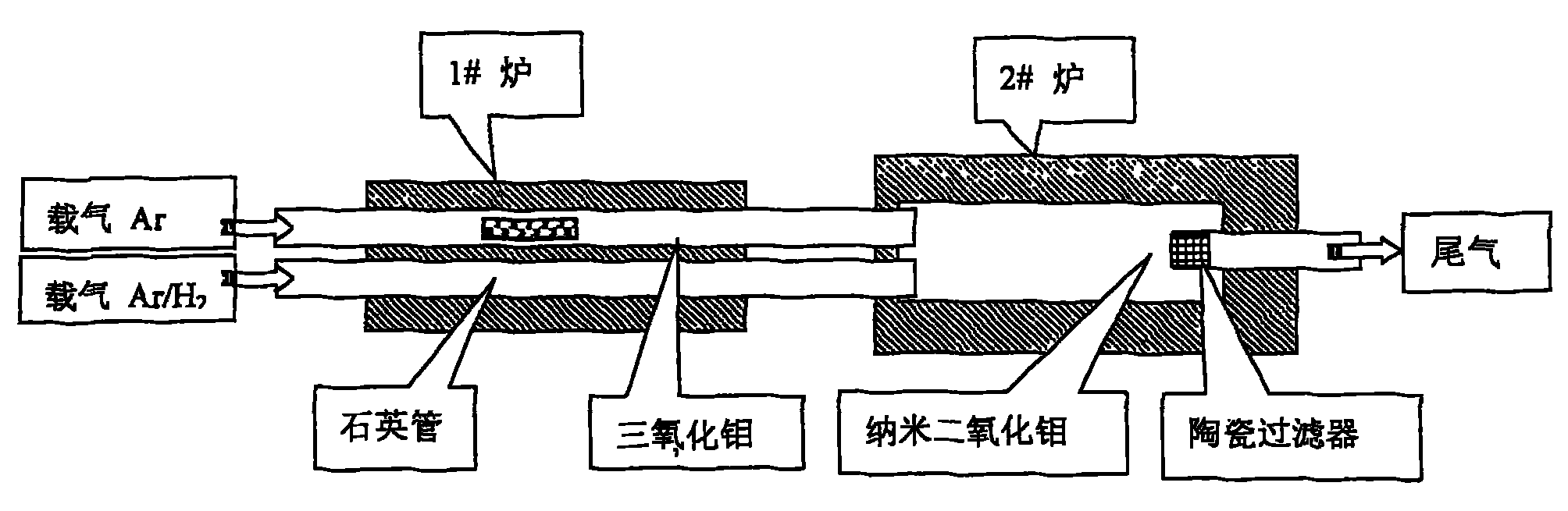

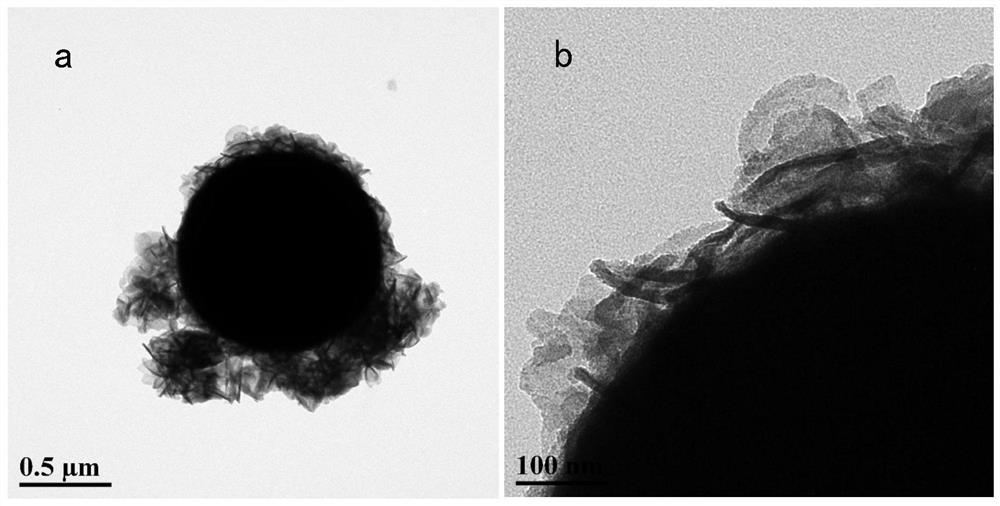

The invention discloses a method for preparing nano molybdenum disulphide with a fullerene structure. The method comprises the following steps sequentially: by using industrial molybdenum trioxide as raw material, argon as carrier gas and hydrogen as reducing agent, molybdenum dioxide nano particle is generated by gas-phase reaction; the nano molybdenum disulphide and elemental sulfur are reacted under the condition of high temperature self-pressurization to produce powder material of the nano molybdenum disulphide with the fullerene structure; the molybdenum dioxide is nano particle generated directly by the reaction of the molybdenum trioxide after gasification under 700 to 1,000 DEG C with the hydrogen under 400 to 950 DEG C; the molybdenum disulphide with the fullerene structure is compound molybdenum disulphide by the self-pressurization reaction of the nano molybdenum dioxide and elemental sulfur in a vessel under 500 to 950 DEG C. The method for preparing the nano molybdenum disulphide with the fullerene structure has the advantages of simple process, high production efficiency, low cost of the raw material and product and short reaction time and the method can easily control the size of the molybdenum dioxide nano particle.

Owner:CHANGAN UNIV

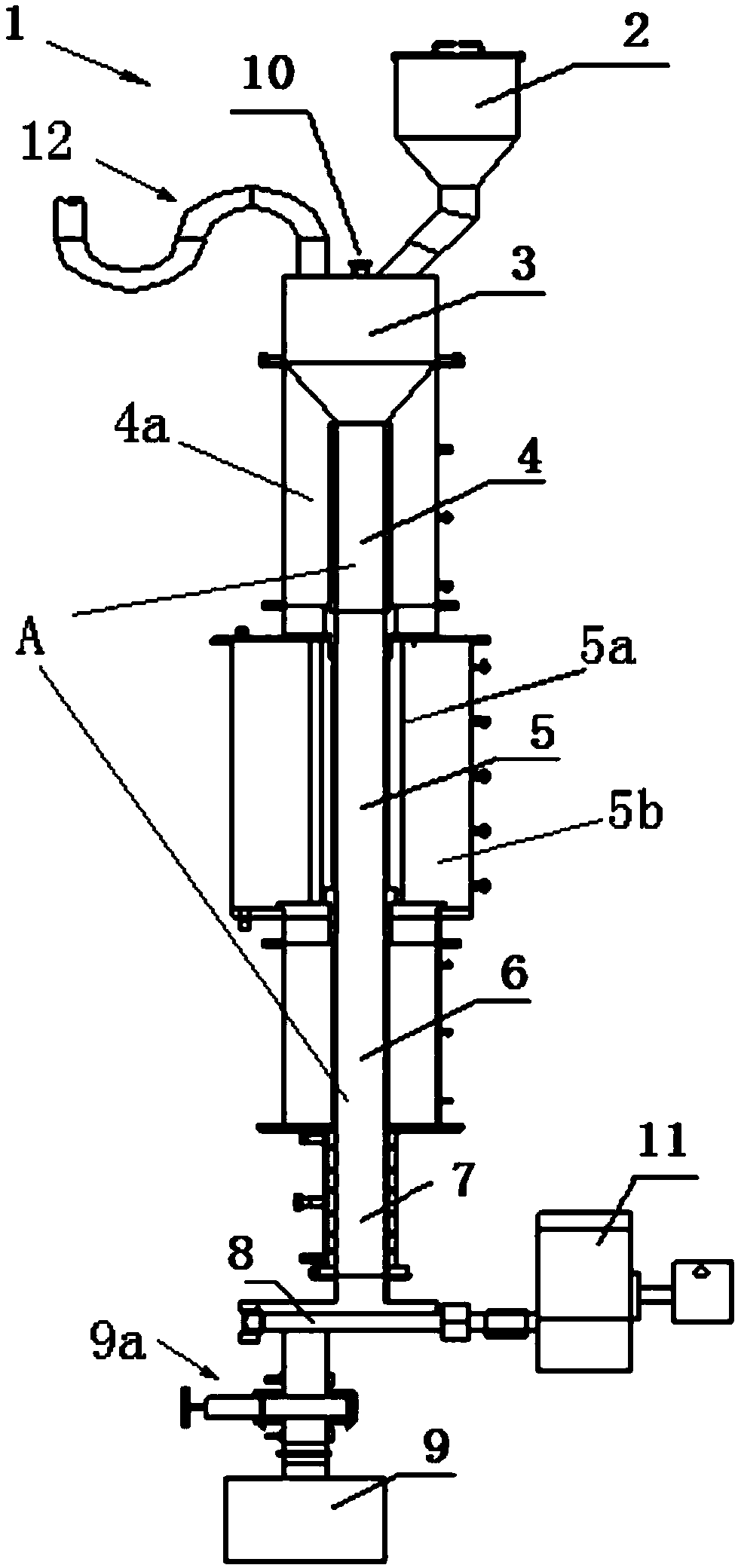

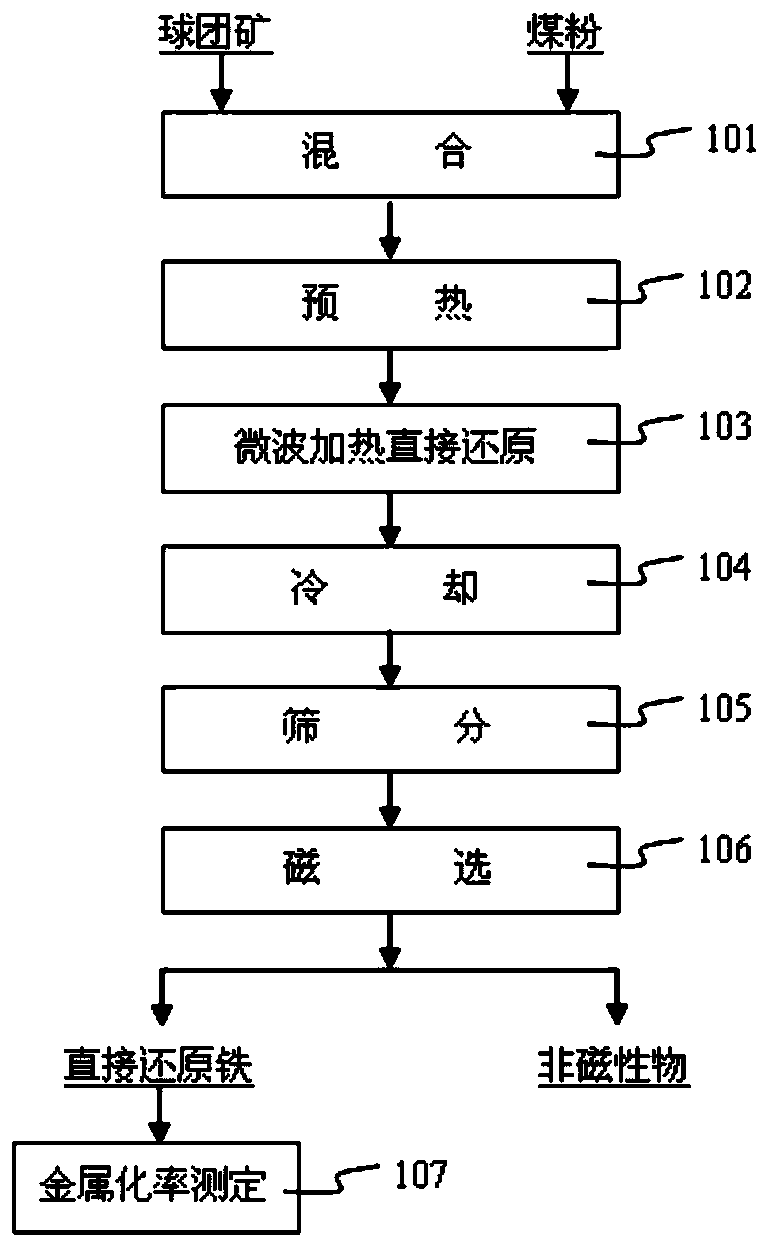

Method for preparing primary reduction iron powder by combining inner and outer carbon matching and microwave heating

The invention provides a method for preparing primary reduction iron powder by combining inner and outer carbon matching and microwave heating and belongs to the technical fields of microwave metallurgy and powdery metallurgy. The method comprises the following steps of: crushing raw materials including an iron-containing raw material, wood charcoal, coal and a CaCO3 raw material and carrying out layered material distribution, wherein a bottom layer is a mixture of the coal and the CaCO3 raw material, a middle layer is a mixture of the wood charcoal and the iron-containing raw material, and an upper layer is the coal; placing the distributed materials into a microwave reactor to be heated to be at 1000-1200 DEG C and keeping the heat for 5-60 minutes; and then cooling, crushing, sieving and carrying out wet type magnetic selection on reduced furnace materials, and drying to obtain the primary reduction iron powder. The method disclosed by the invention enables a process for preparing the high-grade primary reduction iron powder to be relatively reasonable; a unique material distribution manner and the rapid microwave heating are effectively combined so that the quality of primary reduction iron powder is guaranteed, the heat-preservation time is greatly shortened, the energy consumption is reduced and the production efficiency is improved; and the method can be used for rapidly producing the good-quality primary reduction iron powder.

Owner:KUNMING UNIV OF SCI & TECH

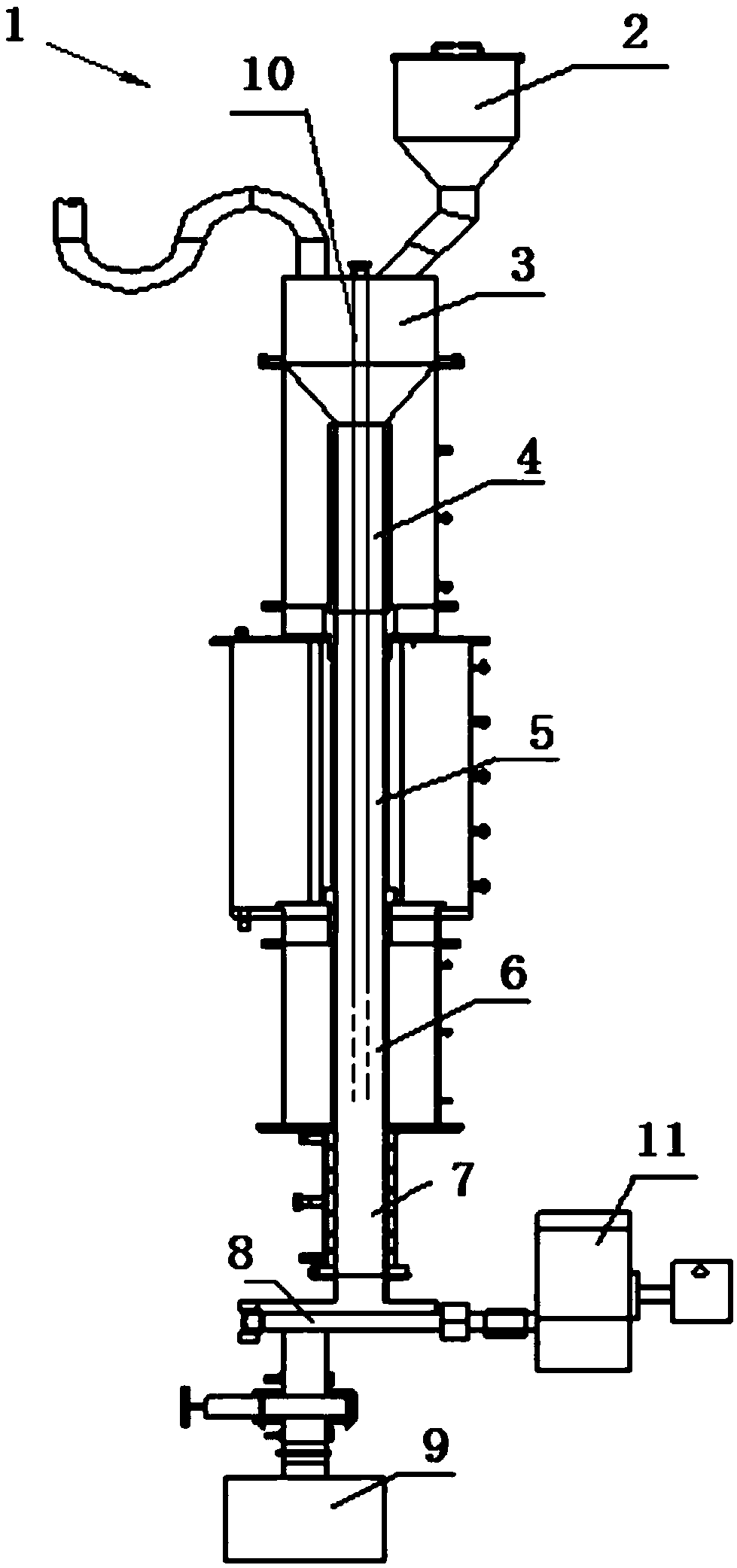

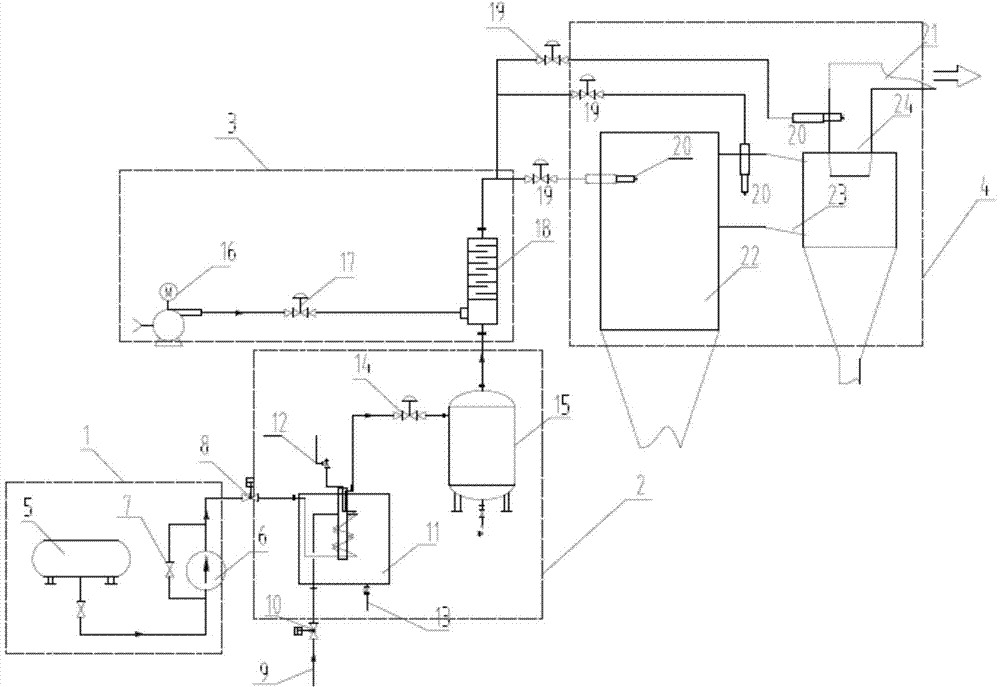

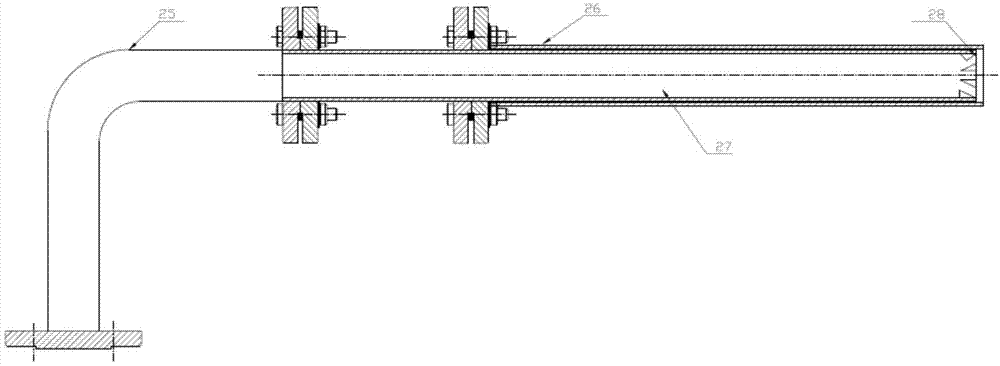

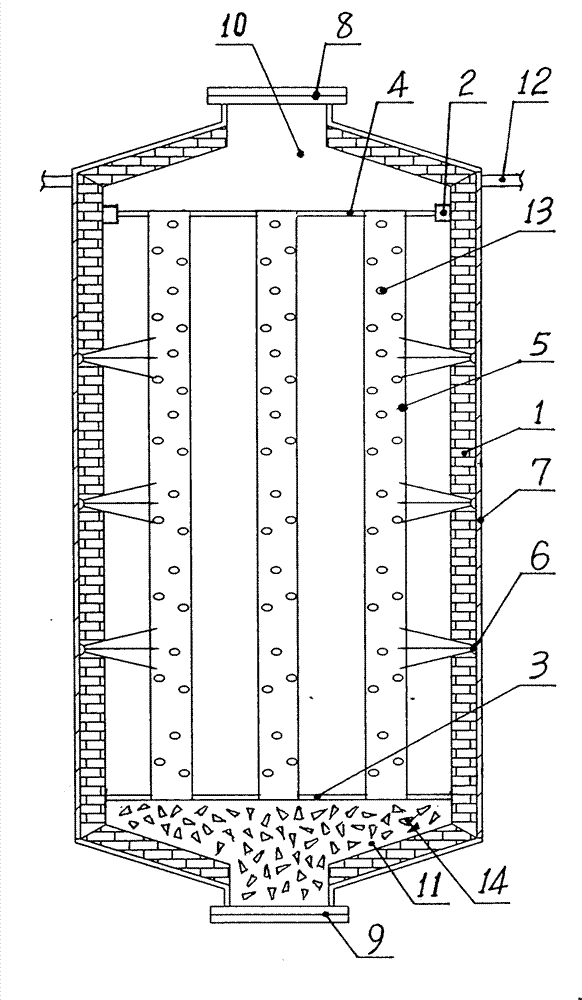

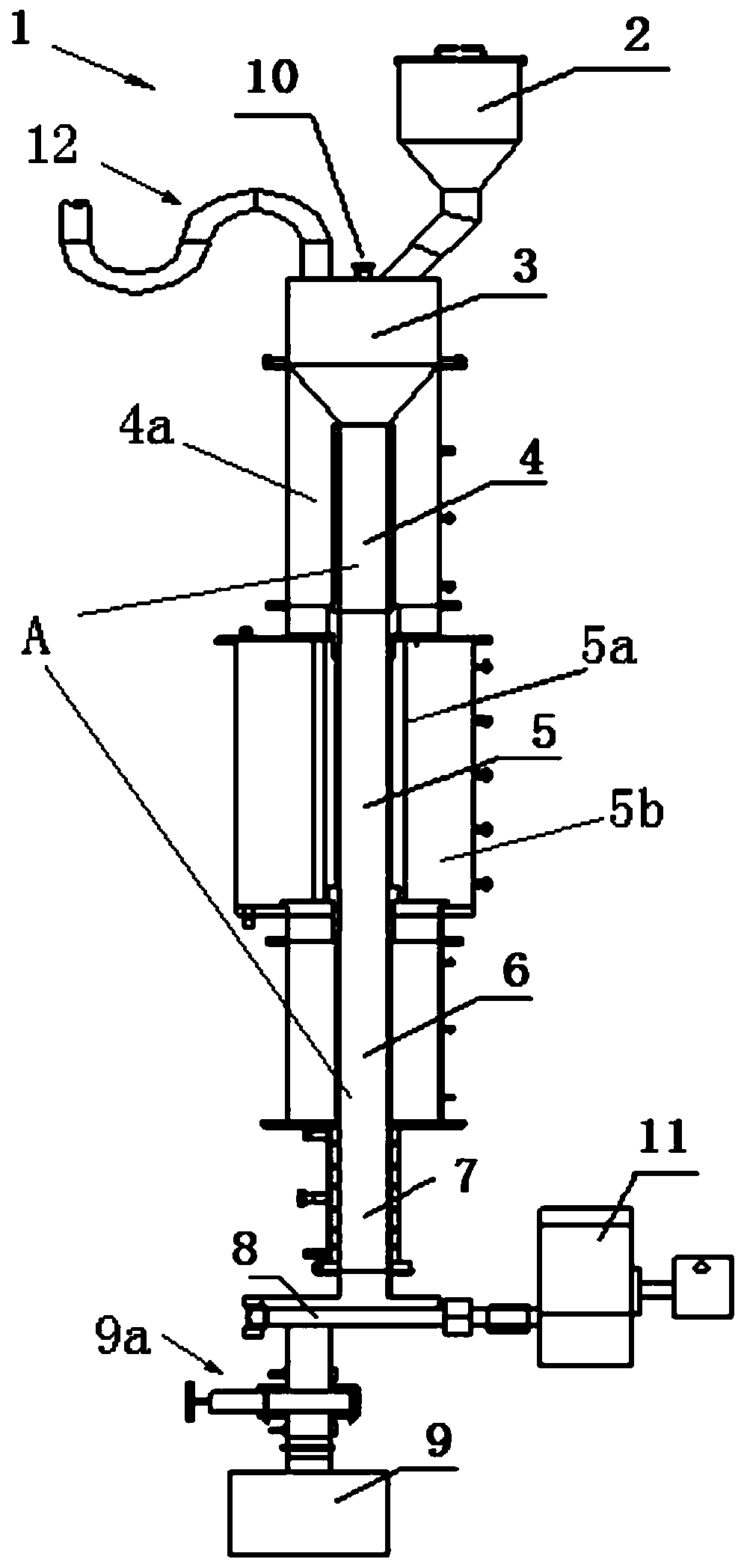

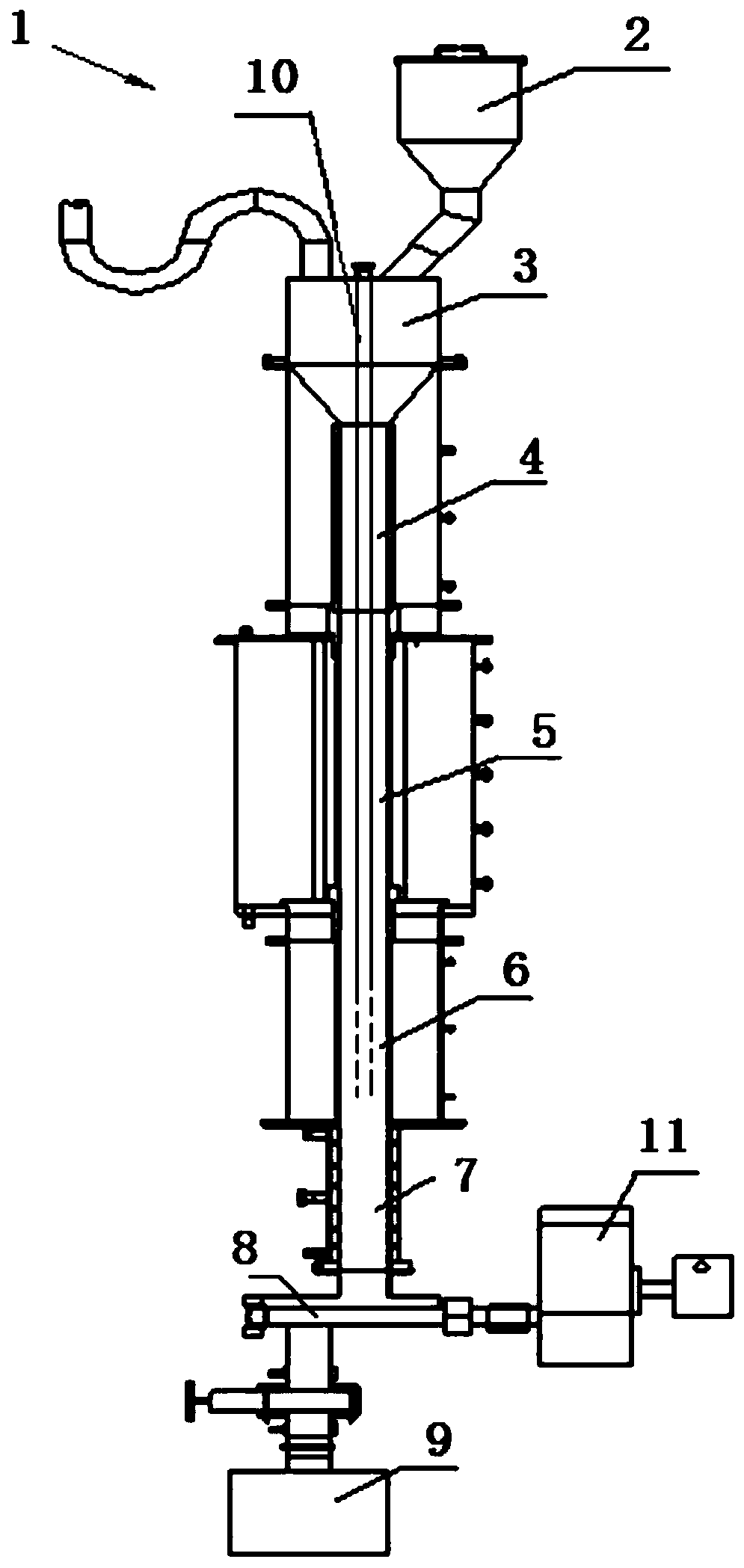

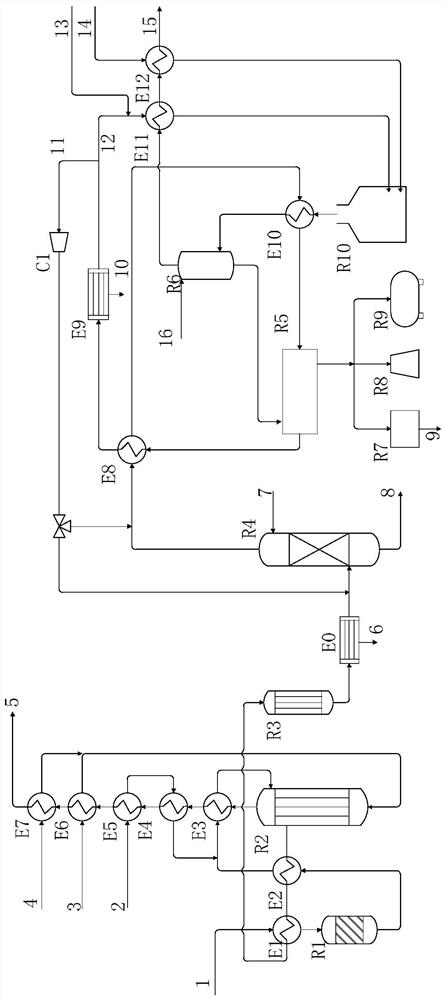

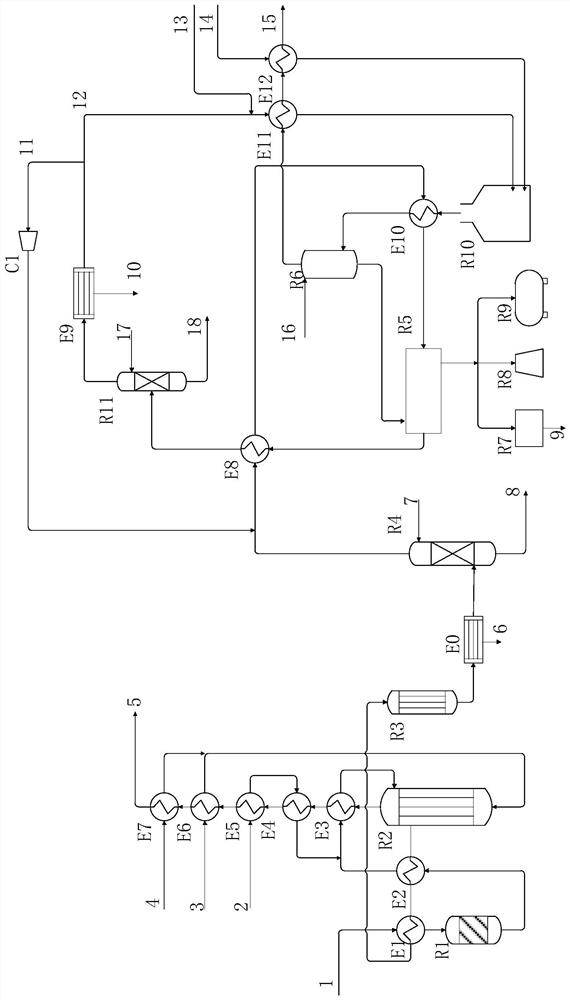

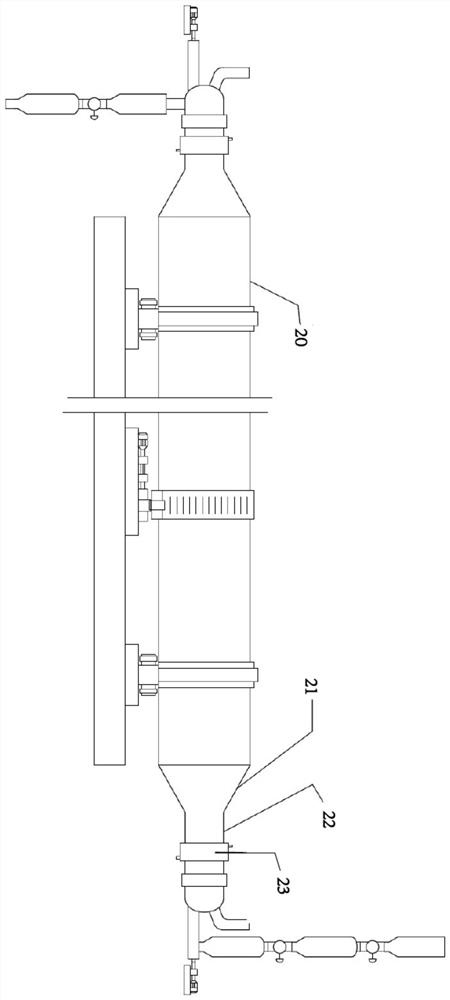

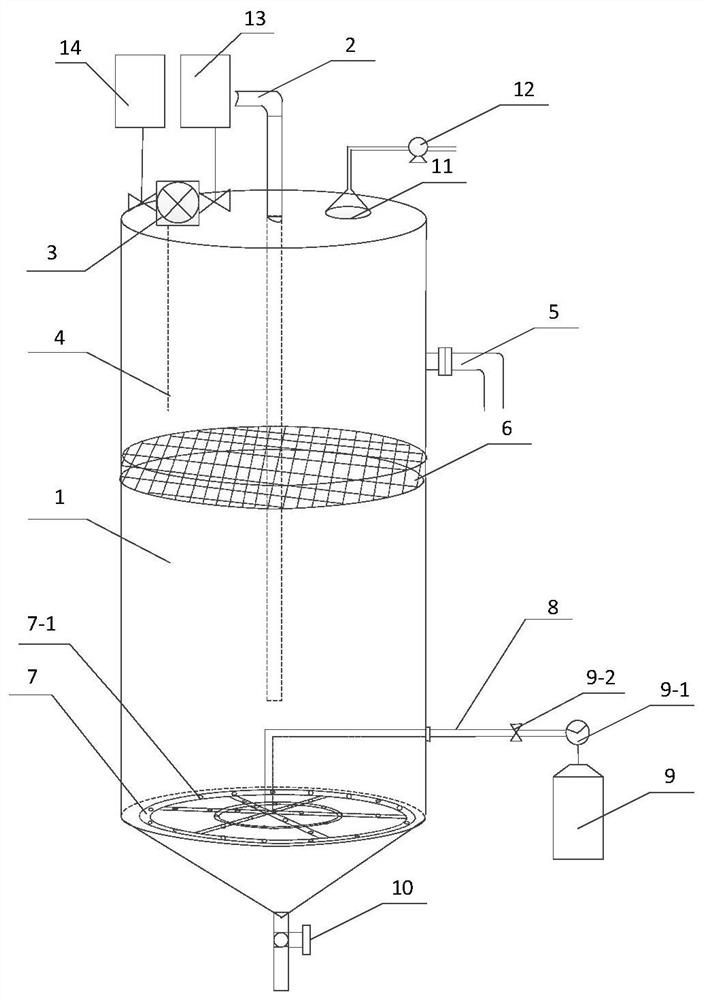

Direct reduced iron production method and device

ActiveCN107779536AImprove use valueQuick restoreShaft furnaceProcess efficiency improvementChemical reactionReaction temperature

The invention relates to a microwave shaft furnace direct reduction process adopting pellets and coal powder. According to the process, direct reduced iron is produced from raw material pellets and external matched material coal powder in a continuous microwave shaft furnace, selection heating, rapid heating, volume heating, activated metallurgical chemical reaction and other features of the microwave are fully utilized, gasification of fixed carbon is accelerated, and iron oxide is further reduced, so that the reduction temperature is lowered and the reaction time is shortened. The coal powder can serve as both a reducing agent and a heating element in the process, a gas-solid-heat exchange step is simplified, energy is saved and emission is reduced. The process contains low free oxygen content, and can produce CO with high purity of 95% or above; and the process is compact in structure, high in metallization degree, which is 94-98%, low in carbon content, which is less than 0.2%, andis low in quality requirements on coal powder, thereby being an environment-friendly iron making process.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Magnetizing and roasting method of iron oxide ore

InactiveCN104593587AIncrease magnetic susceptibilityPromote grain merging and growthMagnetic separationThermal insulationCrystallite

The invention discloses a magnetizing and roasting method of an iron oxide ore. The method comprises the following steps: adding a mixed material of which the fineness is -7mm to -10mm to a sealed reaction container, wherein the material comprises the following raw materials: 94.3%-97.1% of iron oxide ore, 1.8%-3.7% of a reducing agent bituminous coal and 1%-2.2% of a catalyst Na2CO3; 1 heating a container to 500 DEG C in a temperature rise zone, reacting C and O2 to generate CO2 and CO, and forming a weak reducing atmosphere by a reaction container; 2 heating a high-temperature zone to 820-850 DEG C, rapidly reacting CO and F2O3 under catalysis of Na2CO3 to generate CO2 and Fe3O4, dissociating Na<+> from Na2CO3, and prompting Fe3O4 crystalline grains to mix and grow; and 3 maintaining the temperature of a thermal insulation zone at 780-820 DEG C, finishing subsequent reducing reaction on CO and unreduced Fe2O3 in the step 2, and mixing the Fe3O4 in the step 3 with the Fe3O4 in the step 2 to grow. According to the method disclosed by the invention, the temperature of reducing reaction is divided into three zones, namely the temperature rise zone, the high-temperature zone and the thermal insulation zone, and full reducing reduction of the Fe2O3 is achieved, so that the magnetic susceptibility of the iron oxide ore is improved; and in addition, a catalyst Na2CO3 is capable of prompting the Fe3O4 crystalline grains to mix and grow; and the magnetic susceptibility is further improved.

Owner:陕西大山机械有限公司

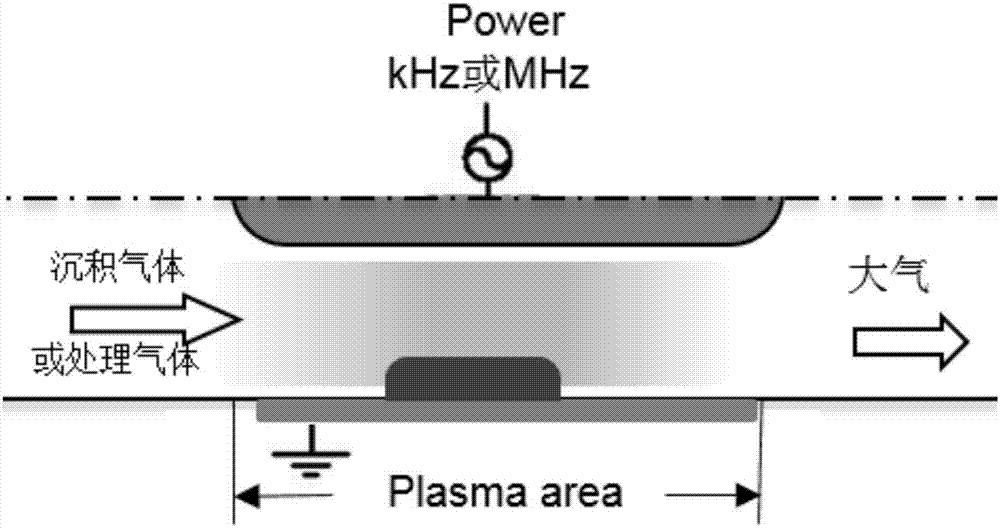

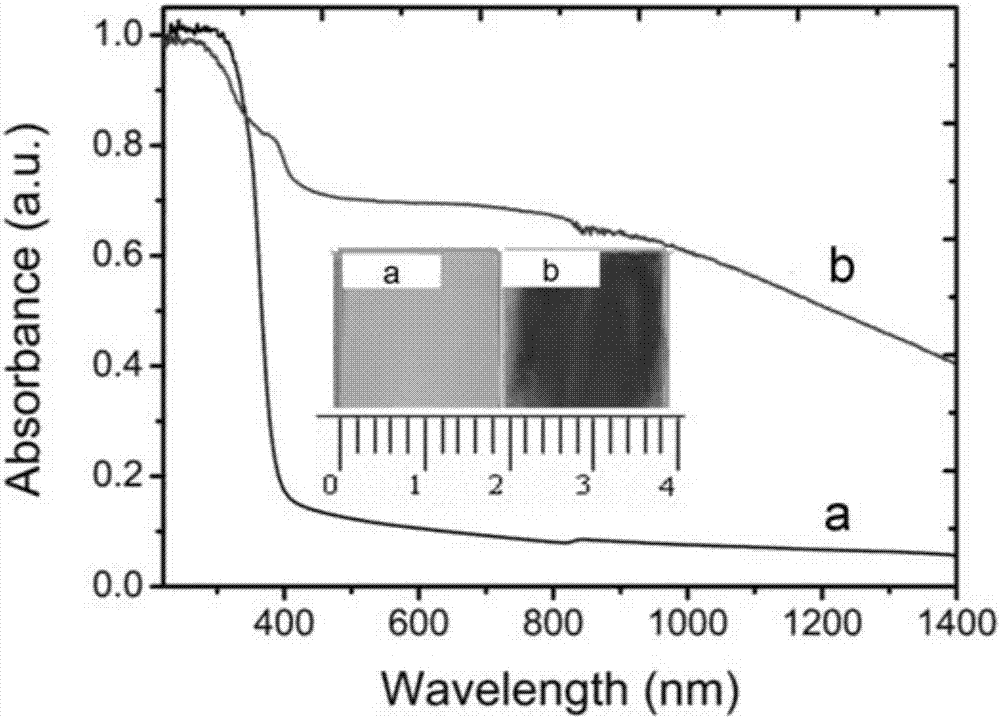

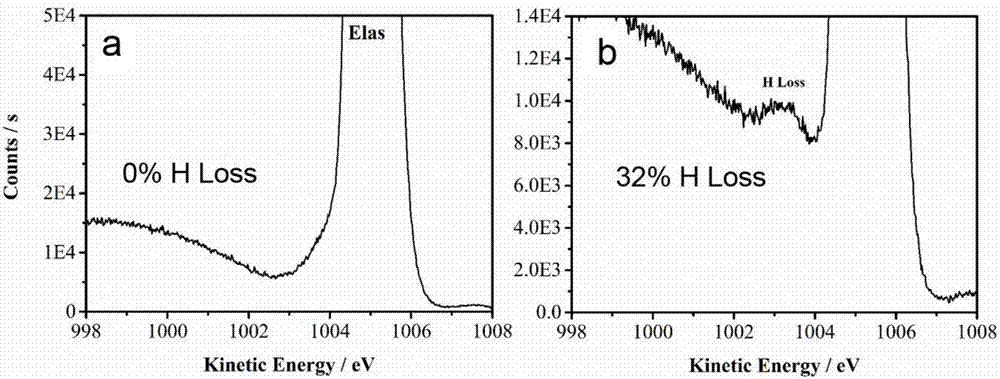

Preparation method of black TiO2 coating

InactiveCN107497413AHigh UVImprove featuresCatalyst activation/preparationChemical vapor deposition coatingEngineeringRadio frequency

The invention relates to a preparation method of a black TiO2 coating, which includes the steps of: 1) under normal pressure and at from room temperature to 200 DEG C, feeding a mixed gas of TiCl4, O2 and a discharging gas into a reaction chamber, and switching on a normal-pressure kHz radio frequency plasma power supply to deposit a TiO2 coating; 2) changing the power supply by a normal-pressure MHz radio frequency plasma power supply, feeding a mixed gas of He and H2, switching on the radio frequency power supply to generate hydrogen plasma, and treating the TiO2 coating at normal temperature to form the black TiO2 coating. The method greatly changes the energy band and photo-response range of the TiO2 material. The black TiO2 coating is improved in absorption in visible light and infrared light zones and is greatly improved in photocatalytic activity under visible light and infrared light. Meanwhile, the black TiO2 coating can be deposited on and coat the surface of materials, such as polymers, so that the black TiO2 coating has important value in practical applications such as dye-sensitized solar cells, hydrogen production with visible light, and environment management, etc.

Owner:DONGHUA UNIV

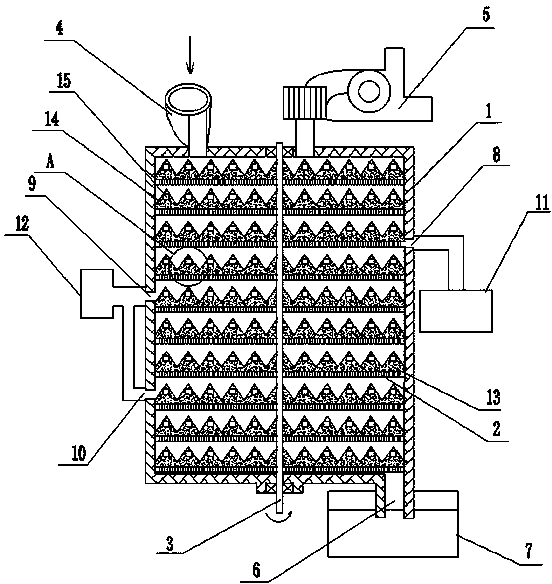

Powdery difficult-separation low-grade iron ore multistage fluidized magnetic roasting furnace and roasting method thereof

ActiveCN103468934AFlexible atmosphere controlLarge gas-solid contact areaMagnetic separationLower gradeLow graded

The invention provides a powdery difficult-separation low-grade iron ore multistage fluidized magnetic roasting furnace, and a difficult-separation low-grade iron ore multistage fluidized magnetic roasting method using the roasting furnace. The roasting furnace comprises a cylindrical furnace body, a plurality of partition boards are arranged in the furnace body, a rotating shaft is arranged in the center of the furnace body in penetration, a material outlet is arranged at the bottom of the furnace body, and a first smoke inlet, a second smoke inlet and a third smoke inlet are sequentially arranged at an upper portion, a middle portion and a lower portion of the furnace body; a water pool is arranged below the material outlet; the partition board is provided with a push arm, and the push arm is connected with the roasting shaft; and the partition board is provided with a blanking hole. The magnetic roasting furnace has the advantages of large adjustment range of the temperature in the furnace, flexible atmosphere control, large gas-solid contact area, high unit volume production capability, fast reduction reaction speed, high magnetic iron conversion efficiency and the like, and is a good magnetic roasting apparatus for processing powdery difficult-separation low-grade specularitem, hematite, limonite and siderite.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

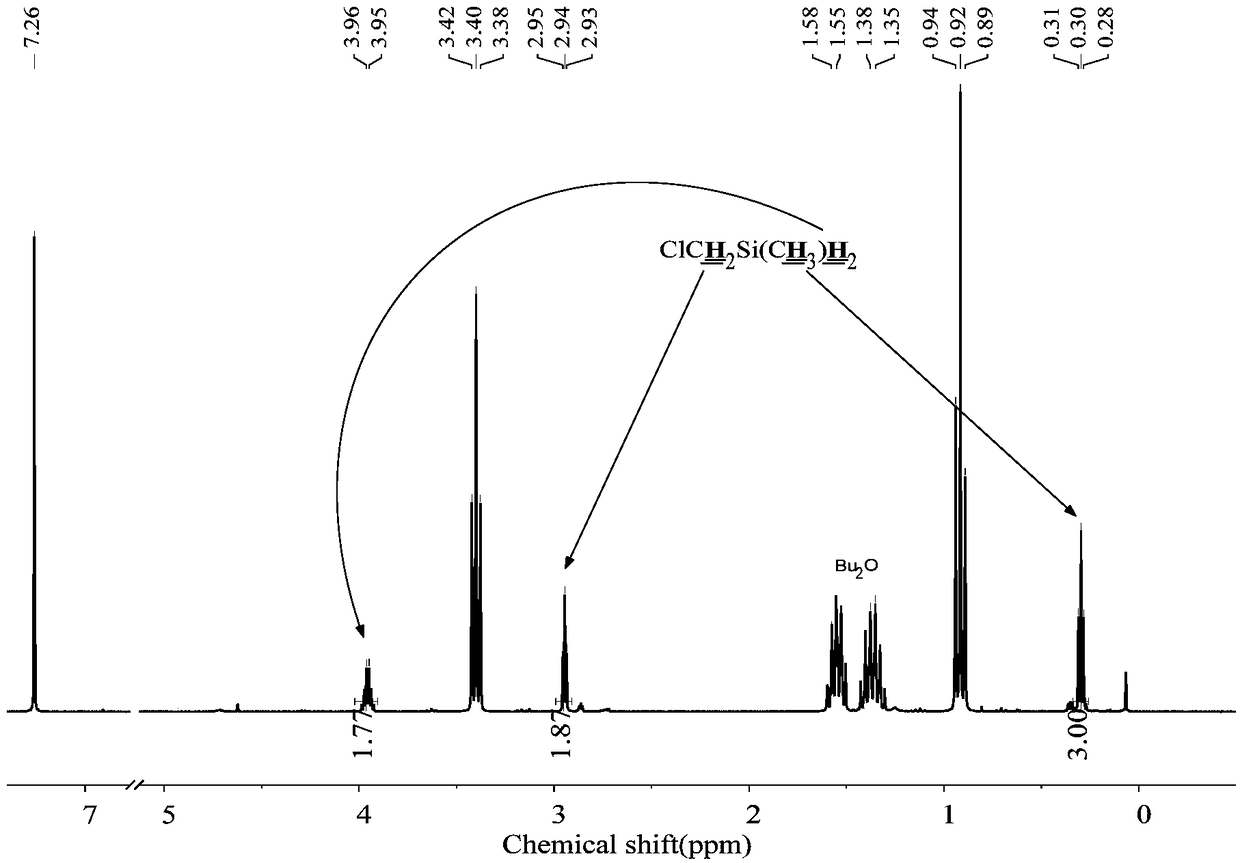

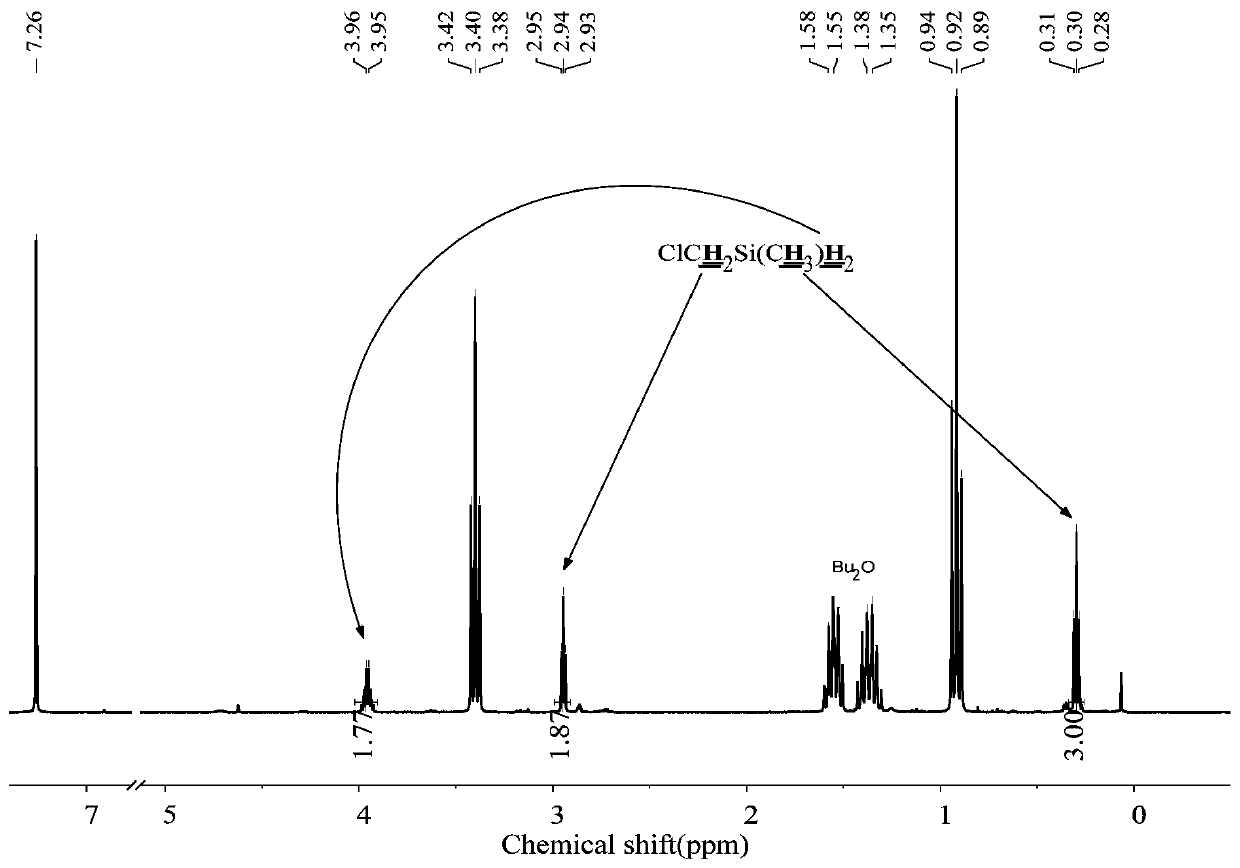

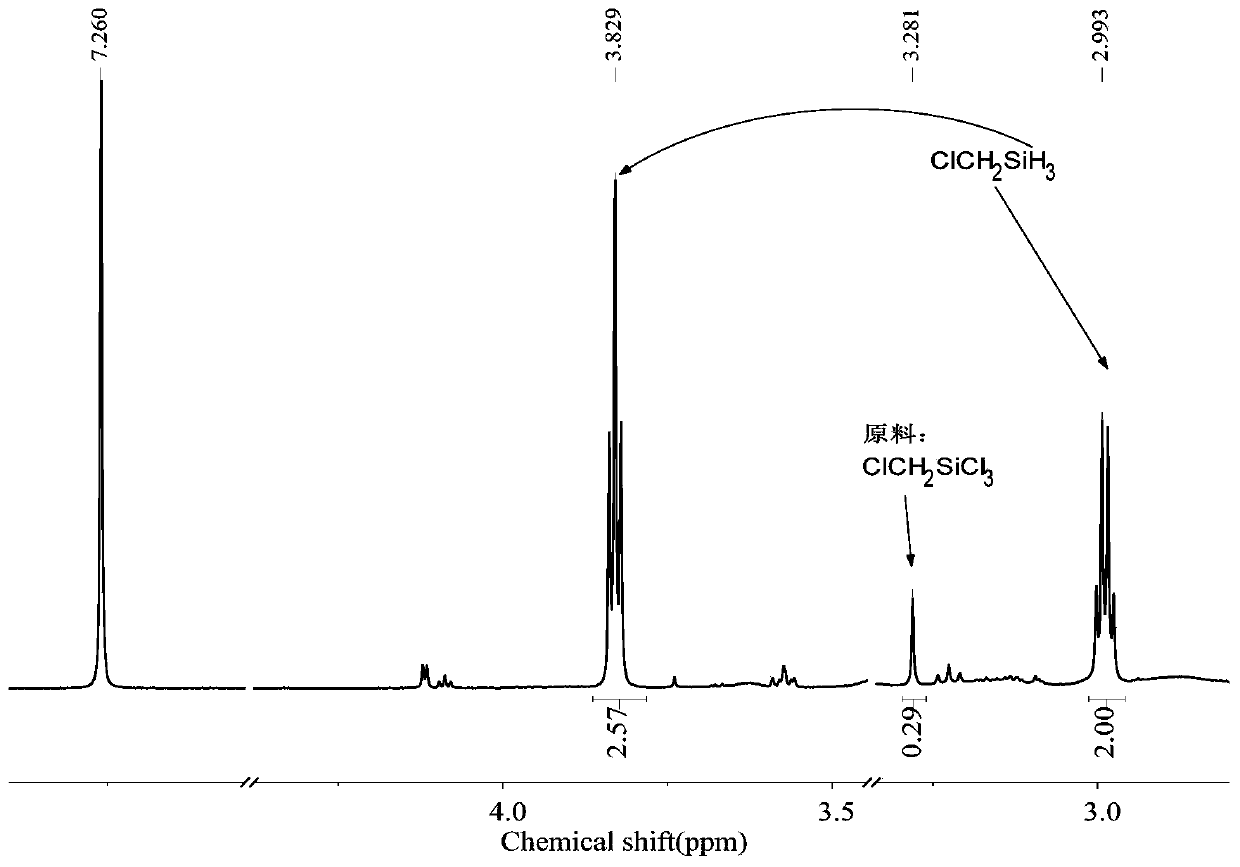

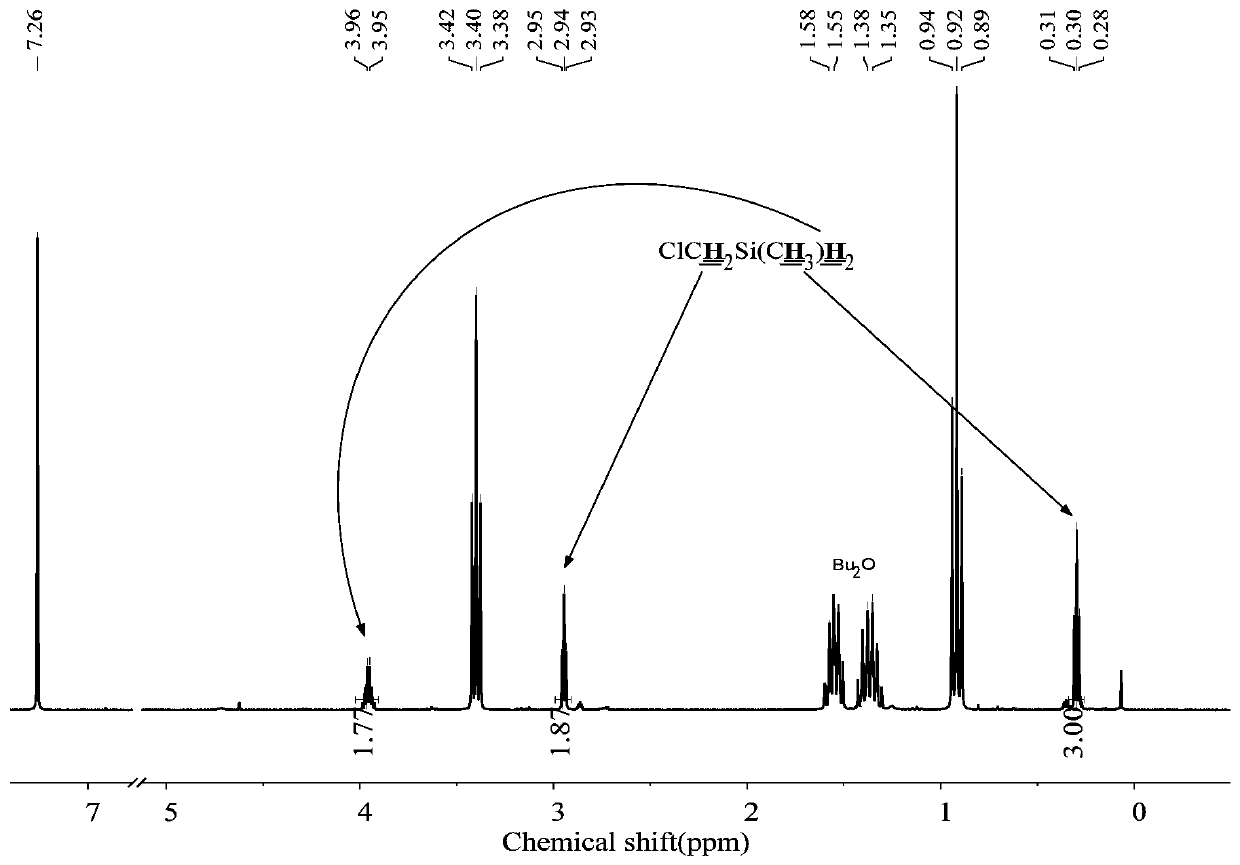

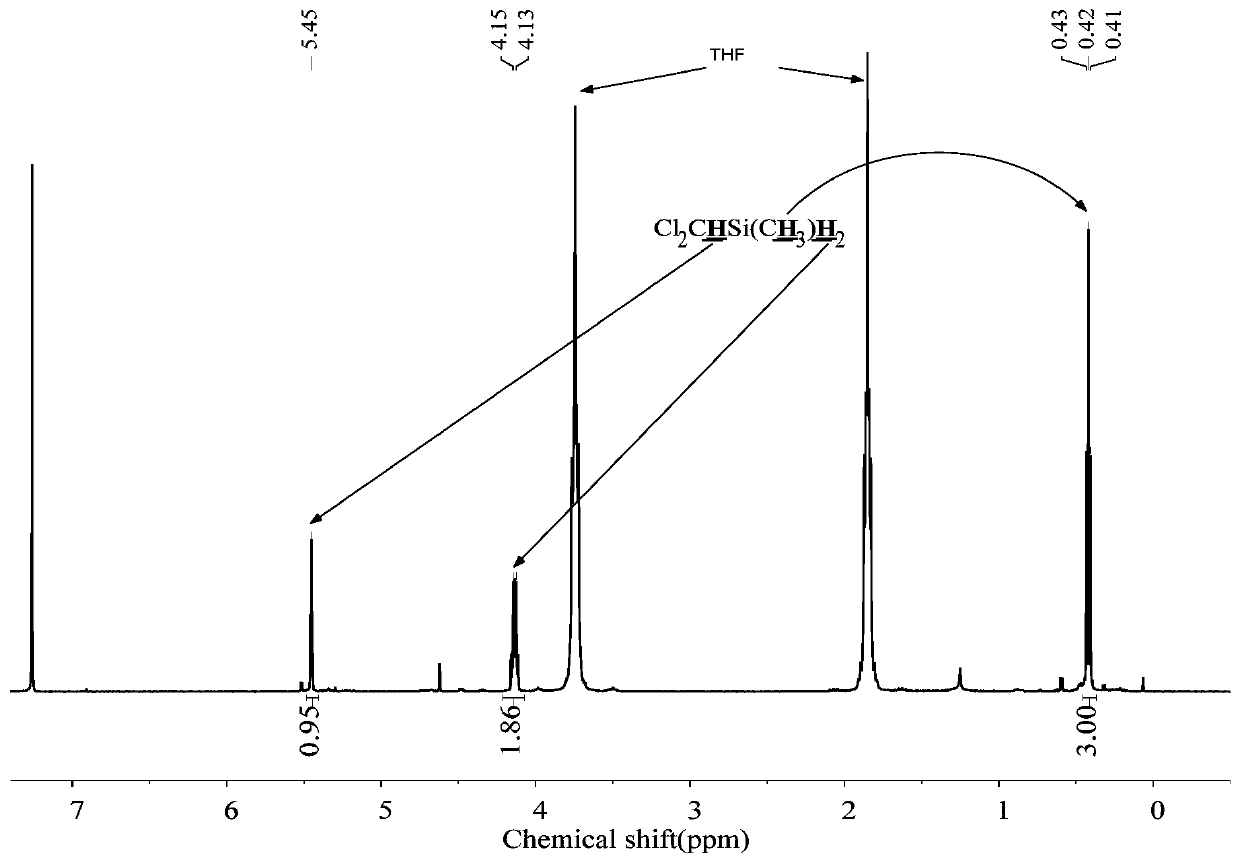

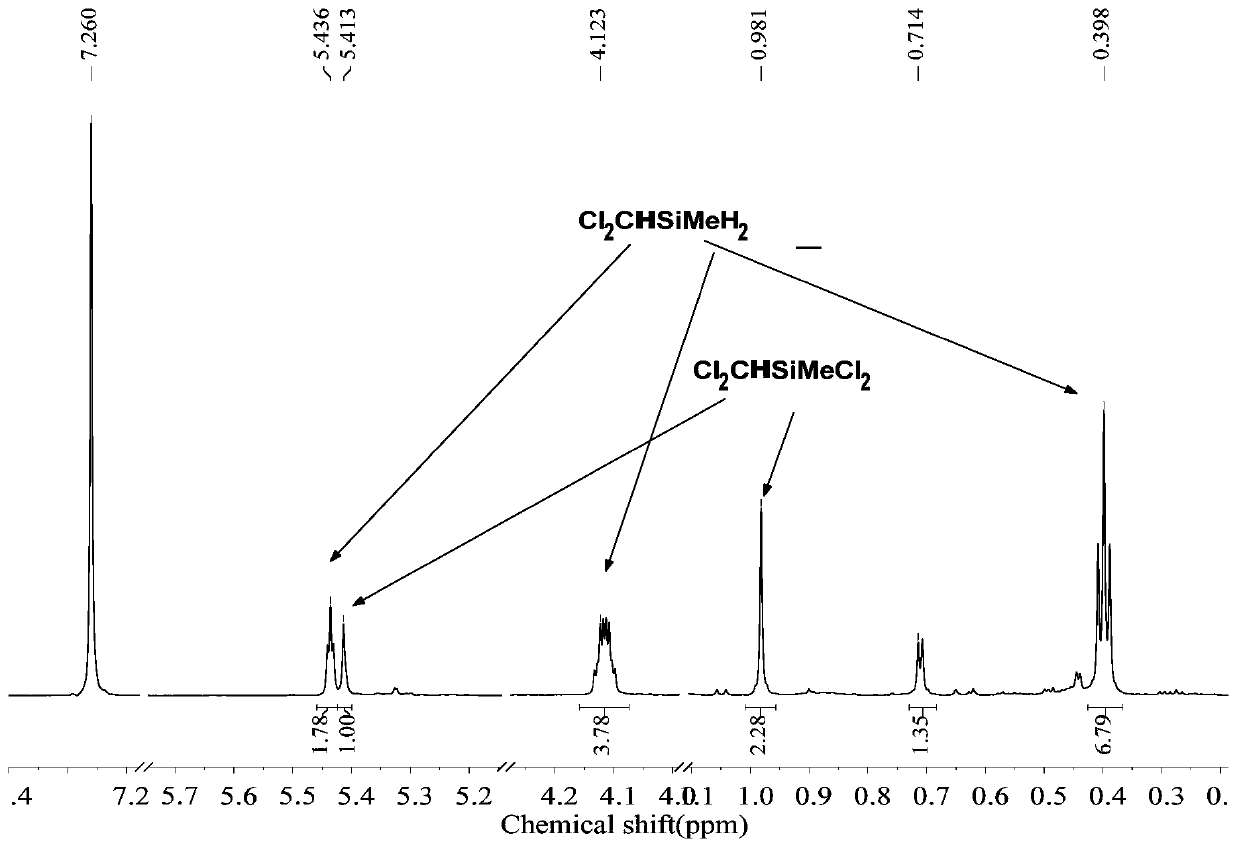

Preparation method of chloride alkyl hydrogen silane

The invention discloses a preparation method of chloride alkyl hydrogen silane, belongs to the technical field of reduction of the chloride alkylchlorosilane, and solves the problem that in the priorart, the chloride alkyl hydrogen silane cannot be prepared through selective reduction of the chloride alkyl chlorosilane. In an ether solvent, under the catalysis of a catalyst, LiH is adopted as a reducing agent, the chloride alkyl chlorosilane is reduced to the chloride alkyl hydrogen silane; the catalyst is boron hydride, borohydride or lithium aluminum hydride. The preparation method can be used for preparing the chloride alkyl hydrogen silane.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Liquid ammonia method SNCR (selective non-catalytic reduction) nitrate removal system suitable for circulating fluidized bed boiler

InactiveCN104764035AHigh degree of automationGuaranteed stabilityFluidized bed combustionDispersed particle separationChemical industryNitric oxide

Disclosed is a liquid ammonia method SNCR (selective non-catalytic reduction) nitrate removal system suitable for a circulating fluidized bed boiler. The liquid ammonia method SNCR nitrate removal system suitable for the circulating fluidized bed boiler comprises a liquid ammonia conveying system used to provide a nitrate removal reducing agent, a gas ammonia preparation system connected with an outlet of the liquid ammonia conveying system and used to prepare gas ammonia, a dilution system connected with an outlet of the gas ammonia preparation system and used to dilute the gas ammonia and a jet system connected with an outlet of the dilution system and used to convey the gas ammonia after being diluted into a gas flue. The liquid ammonia method SNCR nitrate removal system suitable for the circulating fluidized bed boiler achieves the purpose of removing nitric oxide in smoke by directly using the gas ammonia, has the advantages of being stable, efficient, low in running cost, simple to control, and high in automatic degree, and can be widely used for nitric oxide removal of the smoke of the circulating fluidized bed boiler used in industries of the electricity industry, the energy and chemical industry and the like.

Owner:HUANENG CLEAN ENERGY RES INST

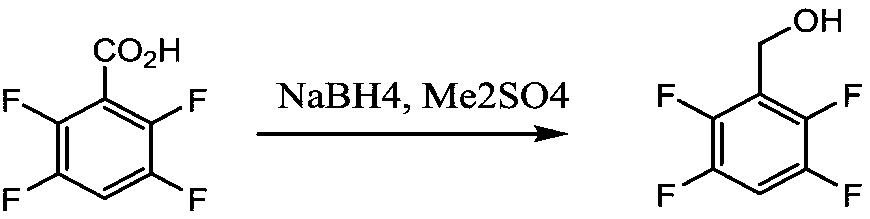

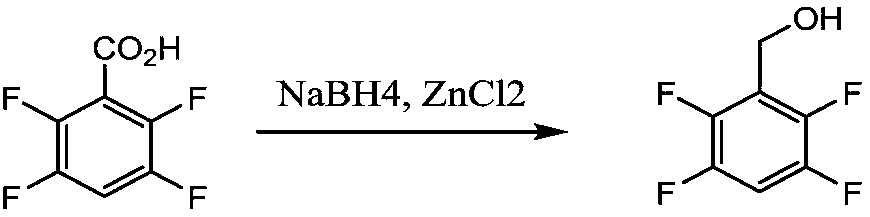

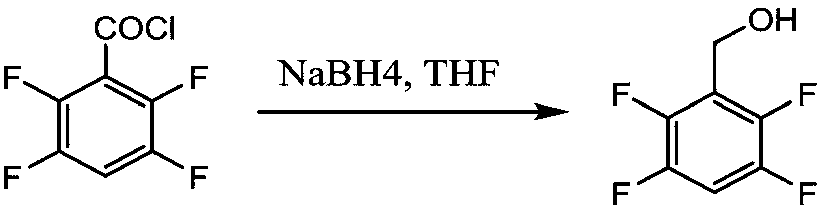

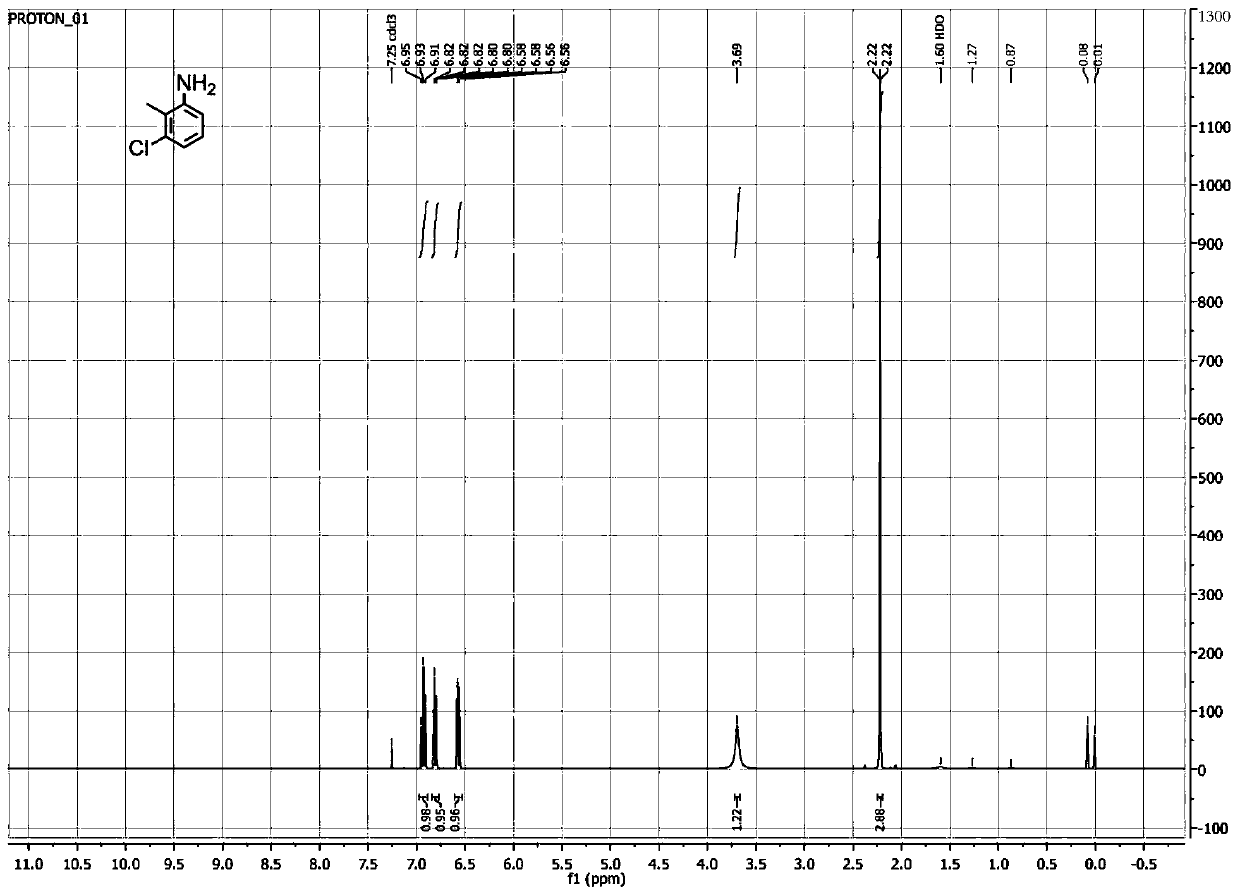

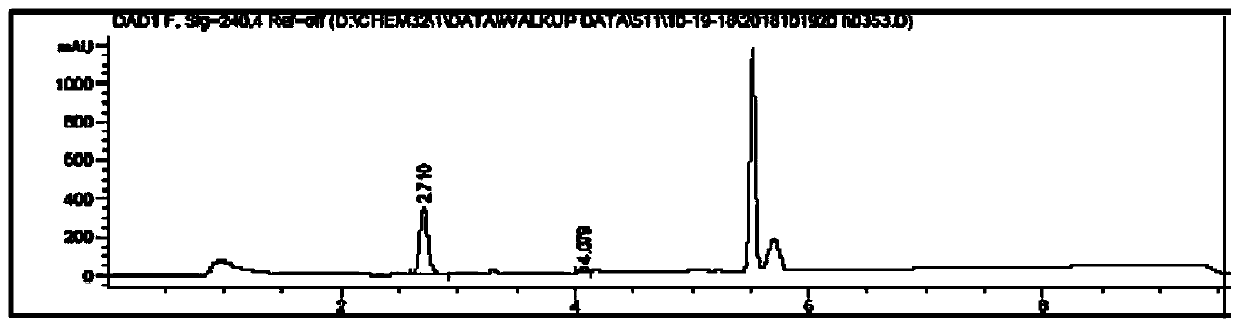

Preparation method of tetrafluorobenzene methanol

ActiveCN109293478AHigh activityFast reduction reactionOrganic compound preparationHydroxy compound preparationOrganic synthesisSodium borohydride

Belonging to the technical field of organic synthesis, the invention discloses a preparation method of tetrafluorobenzene methanol. The method includes: reacting tetrafluorobenzoic acid with thionyl chloride to produce tetrafluorobenzoyl chloride, then taking tetrafluorobenzoyl chloride as the raw material, and conducting reduction in water with sodium borohydride activated by an ether solvent toobtain tetrafluorobenzene methanol. According to the invention, the ether solvent and sodium borohydride are subjected to complexing to activate sodium borohydride, water is adopted as the solvent forreduction, the reaction yield is high, the reductant sodium borohydride can complete the reaction at a catalytic amount, and the reaction process is greener and more environmentally friendly.

Owner:DALIAN QIKAI MEDICAL TECH

Magnesium smelting technique by microwave heating

The invention discloses a magnesium smelting technique by microwave heating and relates to the field of magnesium smelting techniques. The upper end of the round wall of a furnace body is connected with an expander by bricklaying through a refractory material, and the lower end of the round wall of the furnace body is fixed with a tray; the expander is movably connected with a support in a sliding manner; the lower end of a microporous ceramic tube is fixed with the tray while the upper end of the microporous ceramic tube is fixed with the support; the furnace body is fixed with a microwave generator and a shell; the shell is fixed with an upper flange and a lower flange; a gaseous magnesium collecting chamber is formed by the wall of the furnace body above the support, an upper convergent section of the shell and the inner side of the upper flange; a gaseous magnesium outlet tube is penetrated from the gaseous magnesium collecting chamber and then is fixed with the furnace body and the shell; a slag chamber is formed by the wall of the furnace body below the tray, a lower convergent section of the shell and the inner side of the lower flange; a magnesium ball is put in the microporous ceramic tube; slag is put in the slag chamber; the power of the microwave generator is 1-500KW, the frequency of the microwave generator is 300-3000MHz, the temperature of the microwave generator is 1200-1350 DEG C, and the smelting time is 15-60 minutes; the magnesium ball is acquired by roasting dolomite to acquire magnesium oxide and calcium oxide and then mixing silicon iron and fluorite with magnesium oxide and calcium oxide. The magnesium smelting technique by microwave heating is used for smelting magnesium, which is a microwave new energy heating technology.

Owner:于洪喜

Vacuum smelting method of zinc oxide ore

ActiveCN108642303AReduce reduction smelting temperatureReduce energy consumptionCatalytic oxidationMicrowave irradiation

The invention provides a vacuum smelting method of zinc oxide ore. The vacuum smelting method comprises the steps of mounting vacuum microwave smelting equipment and conducting smelting operation. Byutilizing the characteristics that the melting boiling point of metal zinc in a vacuum state is greatly reduced and a zinc oxide material can absorb microwave radiation to produce instantaneous high temperature and catalyze reduction reaction of zinc oxide after mixing carbon powder, the method reduces the reduction smelting temperature of zinc oxide and can uniformly do the reduction reaction from the inner part of a granulating briquette together inside and outside, and no heat conduction process exists. Meanwhile, when microwaves radiate in a vacuum, no energy loss exists, and the microwaves can be quickly absorbed by zinc oxide particles. Thus, the method can perform low-energy high-efficiency smelting.

Owner:GUIZHOU HONGDA ENVIRONMENTAL PROTECTION TECHNOLOGY CO LTD

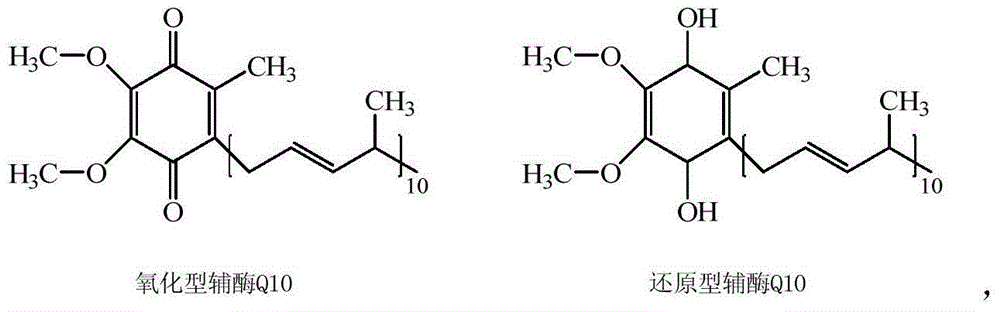

Preparation method for reductive coenzyme Q10

InactiveCN104892370AAdequate responseRapid responseOrganic chemistryOrganic compound preparationElectrolysisSynthesis methods

The invention discloses a method for preparing reductive coenzyme Q10 from oxidative coenzyme Q10. In most conventional production processes for reductive coenzyme Q10, iron powder, zinc dust and sodium hydrosulfite are employed and are all solids, reduction reaction is heterogeneous phase reaction, so workshop operation is inconvenient and reaction time is long. According to the method provided by the invention, oxidative coenzyme Q10 is used as a raw material, stannous chloride is used as a reducing agent, a small amount of acid is added drop by drop so as to control a reaction system to be weakly acidic, continuous stirring reaction is carried out in a solvent at 50 to 70 DEG C, then nitrogen is introduced for protection, and purifying and crystallization are carried out after completion of the reaction so as to obtain the reductive coenzyme Q10 with a purity of no less than 95%; and the stannous chloride is recovered through electrolysis after completion of the reaction, obtained stannous chloride is reused for reduction of coenzyme Q10, so reutilization and continuous reaction are realized. The reductive coenzyme Q10 prepared in the invention has high purity and is safe and reliable; and the reducing agent is regenerable and reusable, so the method is environment-friendly and is a green coenzyme Q10 synthesis method.

Owner:ZHEJIANG NHU CO LTD

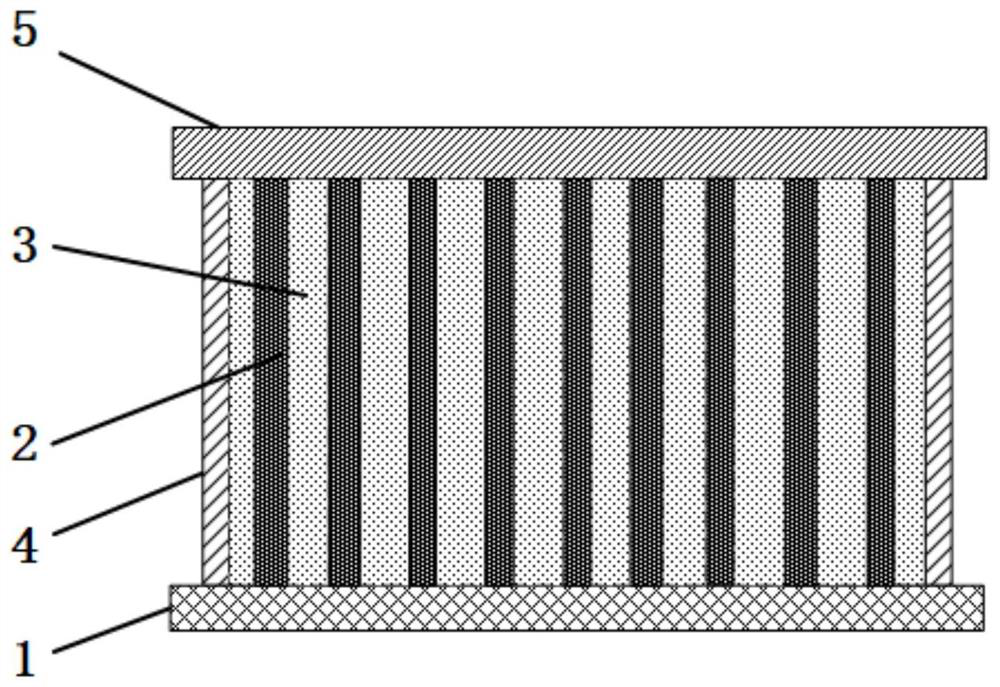

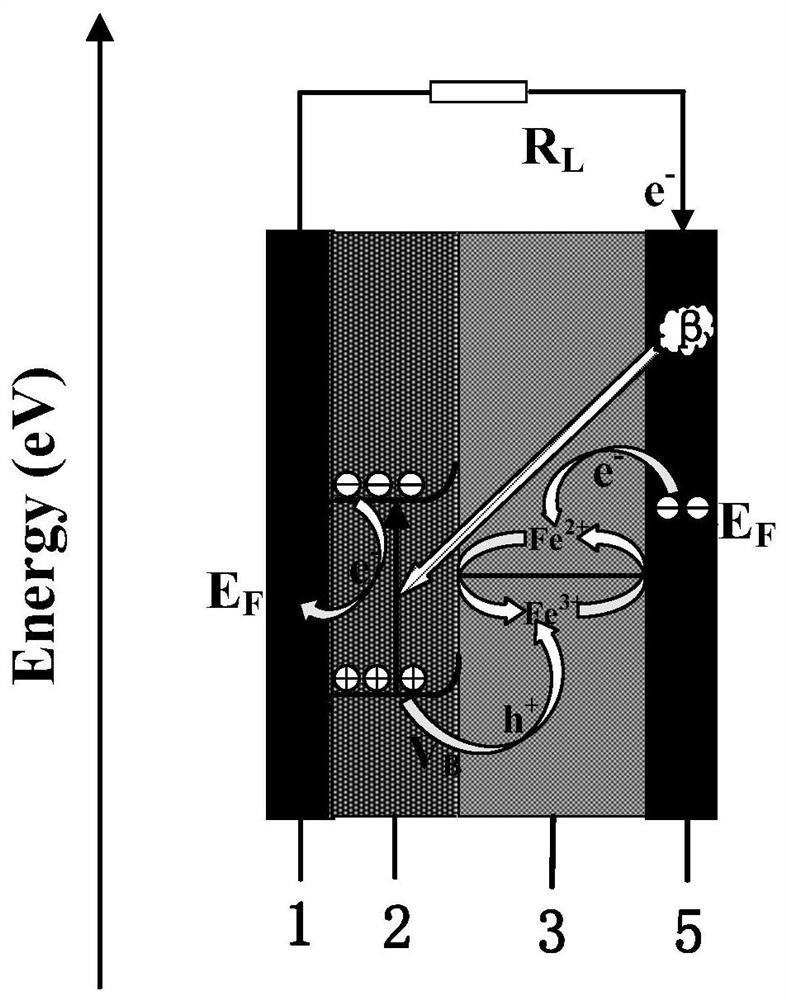

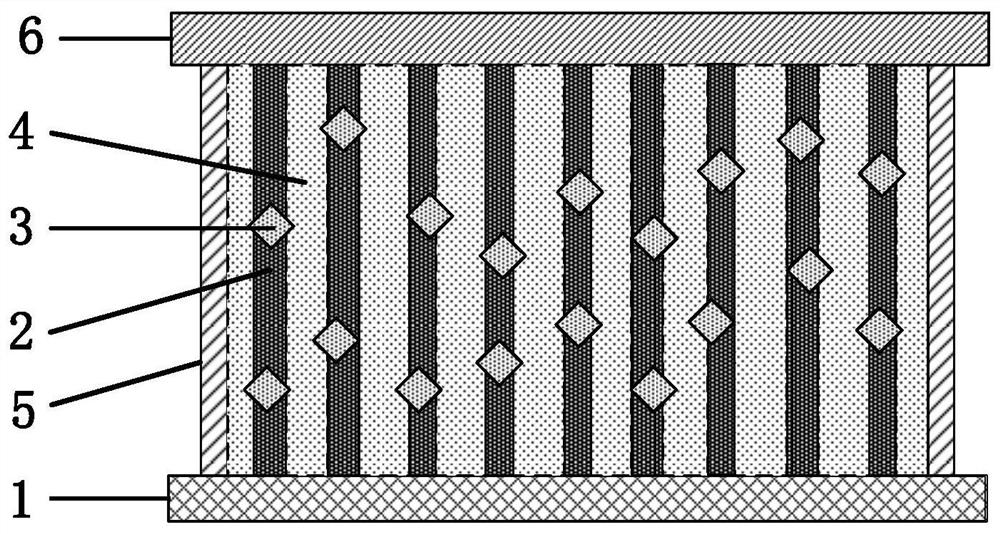

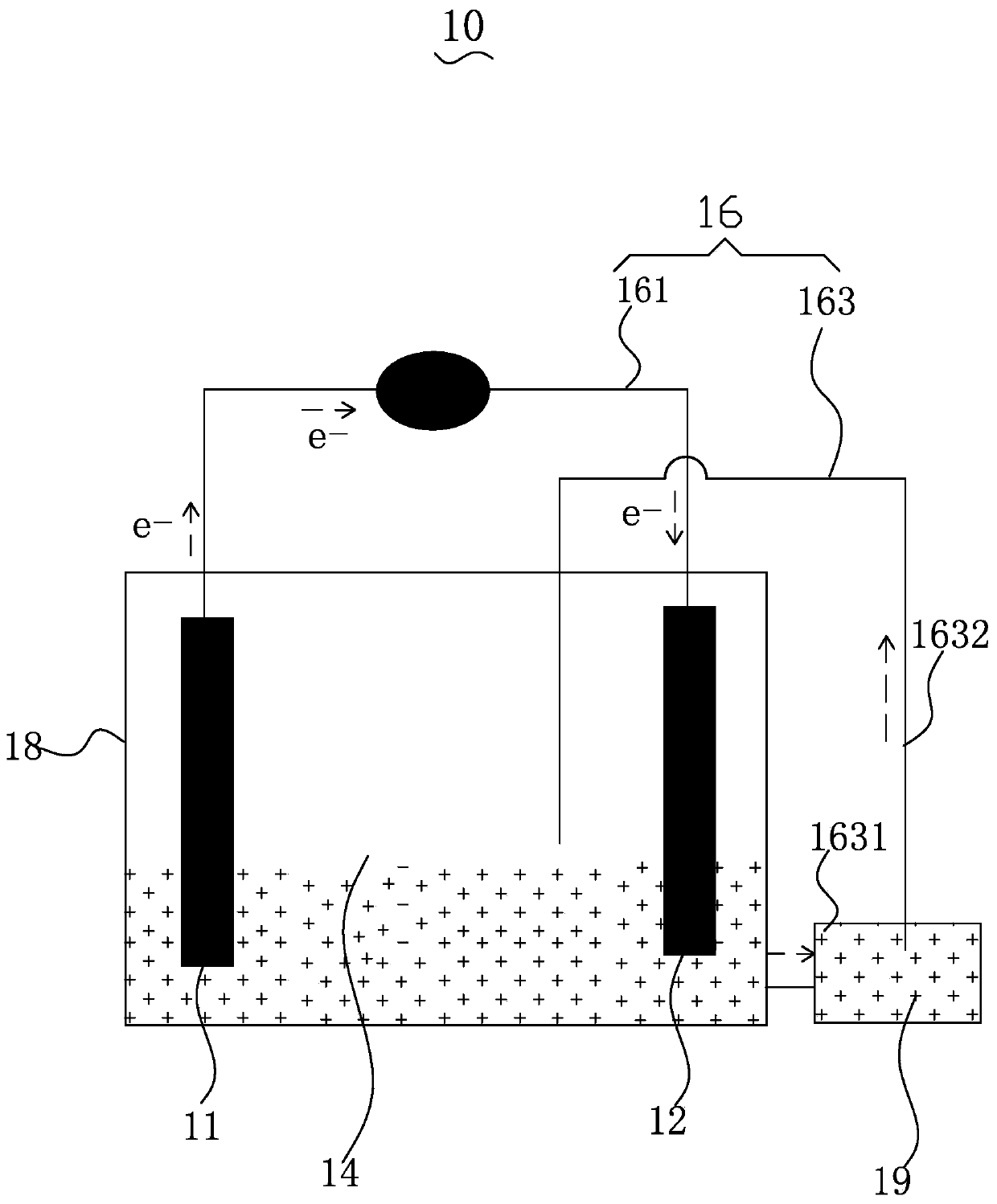

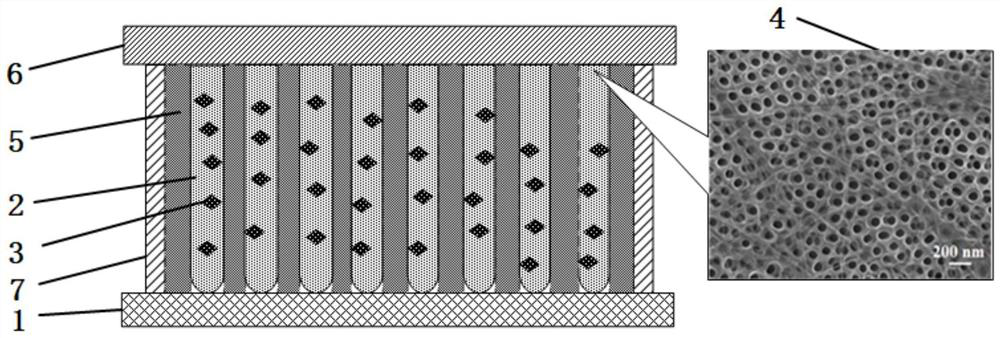

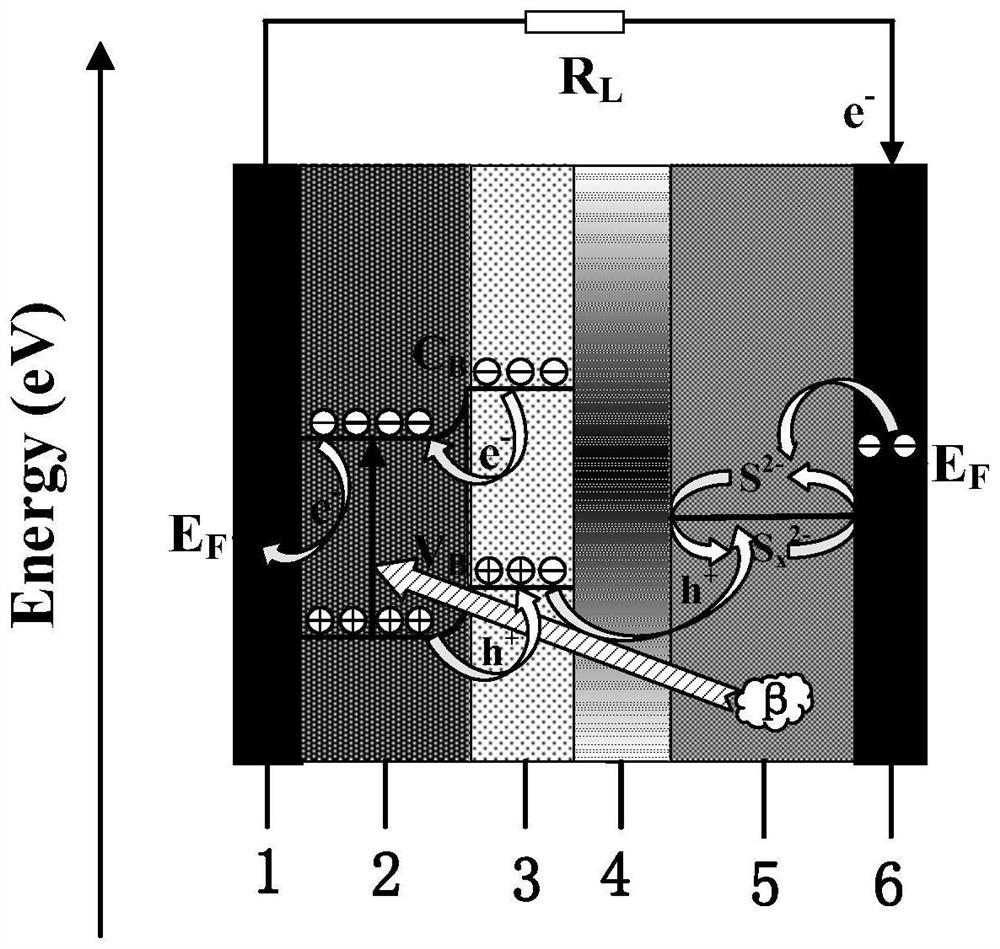

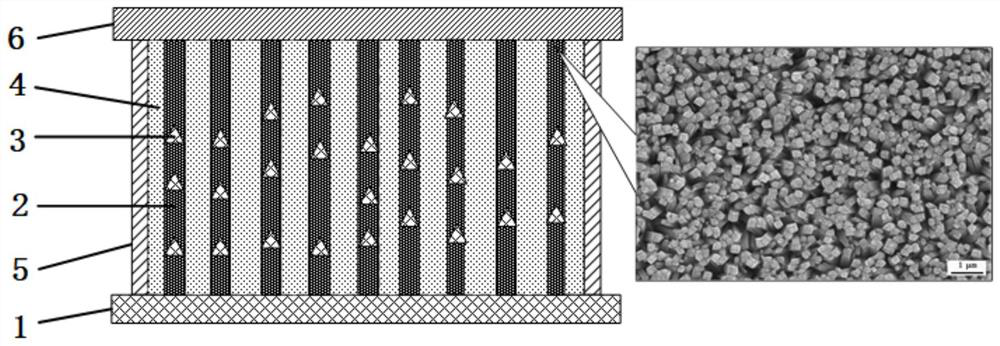

Radioactive three-dimensional nano-structure radiovolt electrochemical cell

PendingCN112750548AReduced service lifeImprove compound rateRadiation electrical energyHeterojunctionRadio isotopes

The invention relates to a radioactive three-dimensional nano-structure radiovolt electrochemical cell which comprises an anode, a cathode and electrolyte filling between the anode and the cathode, the anode is composed of a substrate electrode and a semiconductor three-dimensional nano-structure integrated on the surface of the substrate electrode, and at least one of the substrate electrode, the semiconductor structure and the cathode has radioactivity. The substrate electrode can be a radialized substrate electrode in which stable elements are replaced by radioactive isotopes of the same type; the semiconductors can be radialized semiconductors after stable elements are replaced by radioactive isotopes of the same type; the cathode can be a radialized cathode in which stable elements are replaced by radioactive isotopes of the same type. Rays generated by the radioactive isotope comprise alpha particles and beta particles, the alpha particles and the beta particles interact with a semiconductor to generate a large number of electron-hole pairs, holes and electrolyte are subjected to an oxidation reaction under the action of a built-in electric field formed by the solid-liquid heterostructure and migrate to the cathode, electrons are transferred to the cathode through an external circuit and subjected to a reduction reaction with the electrolyte, and a closed loop is formed to generate output current.

Owner:XIAMEN UNIV

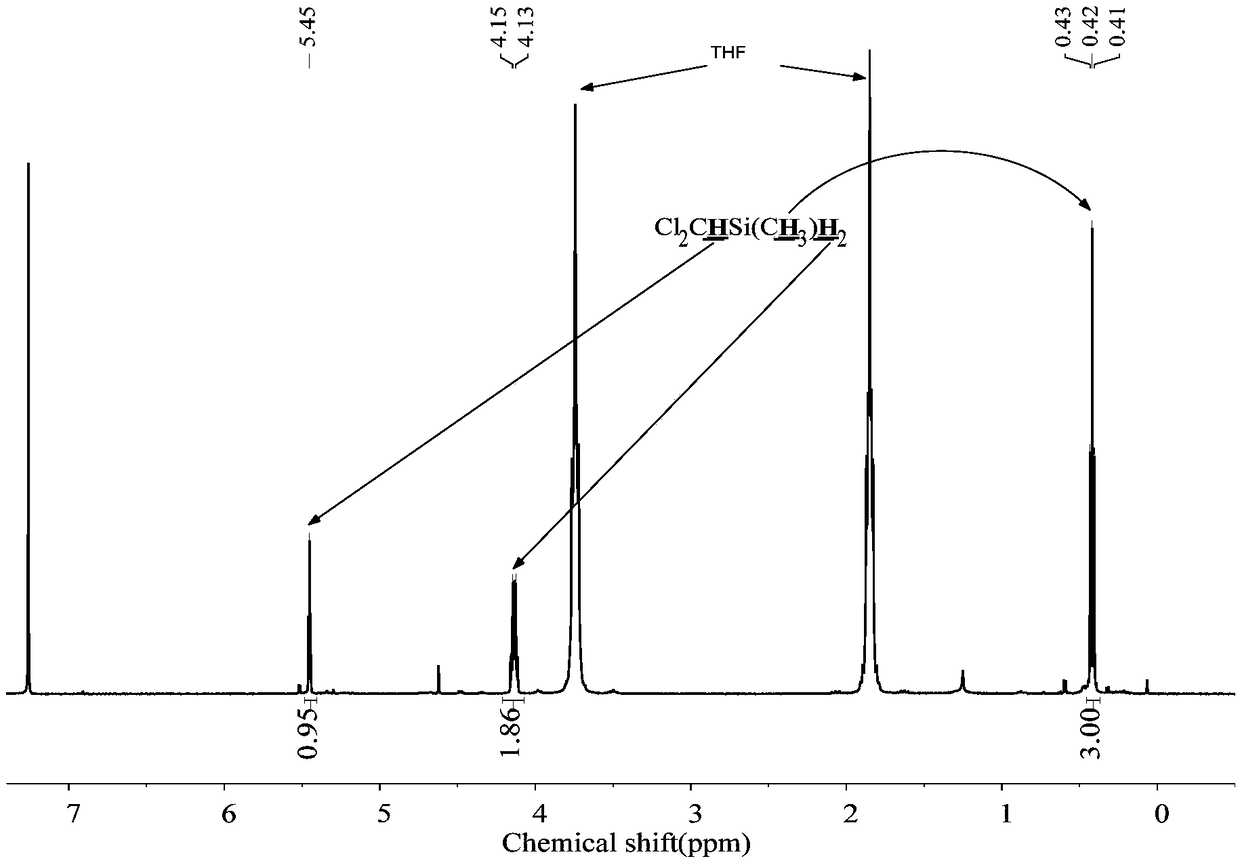

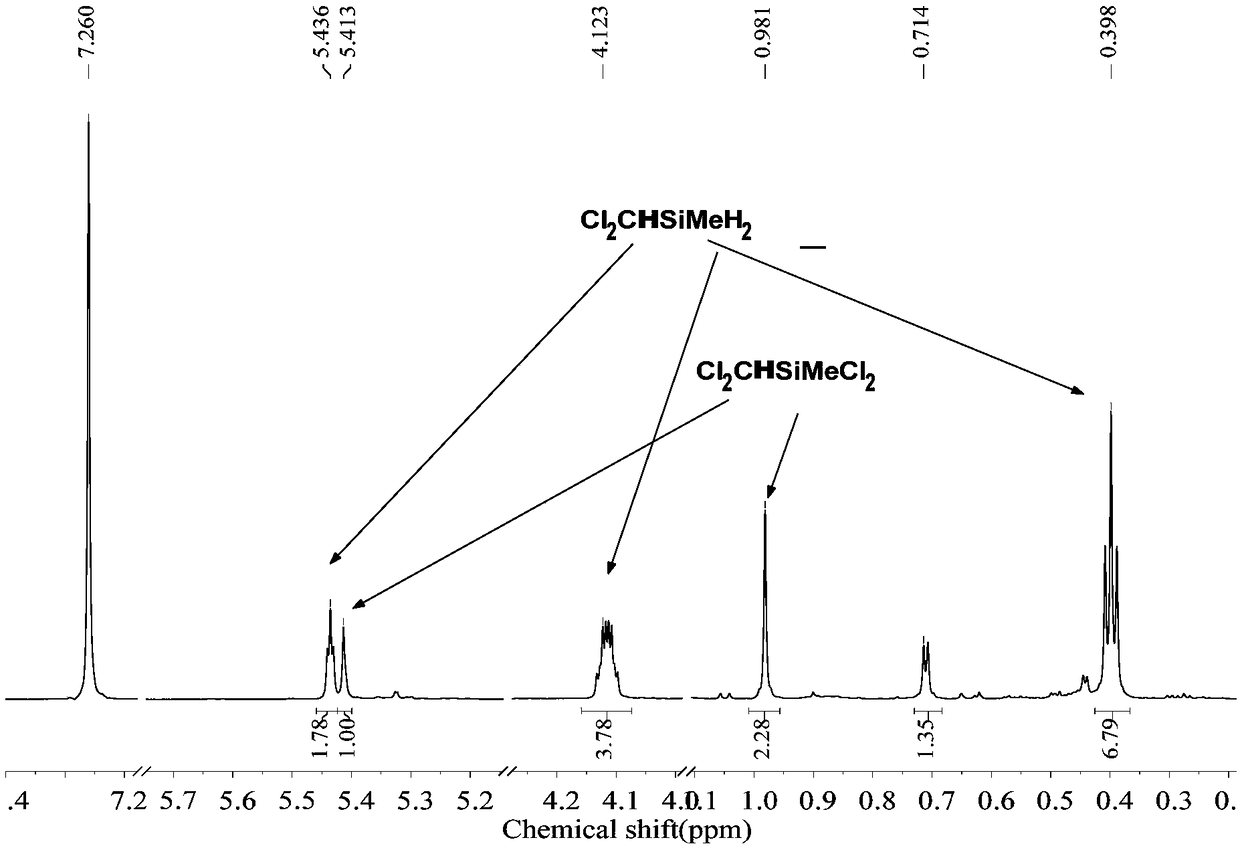

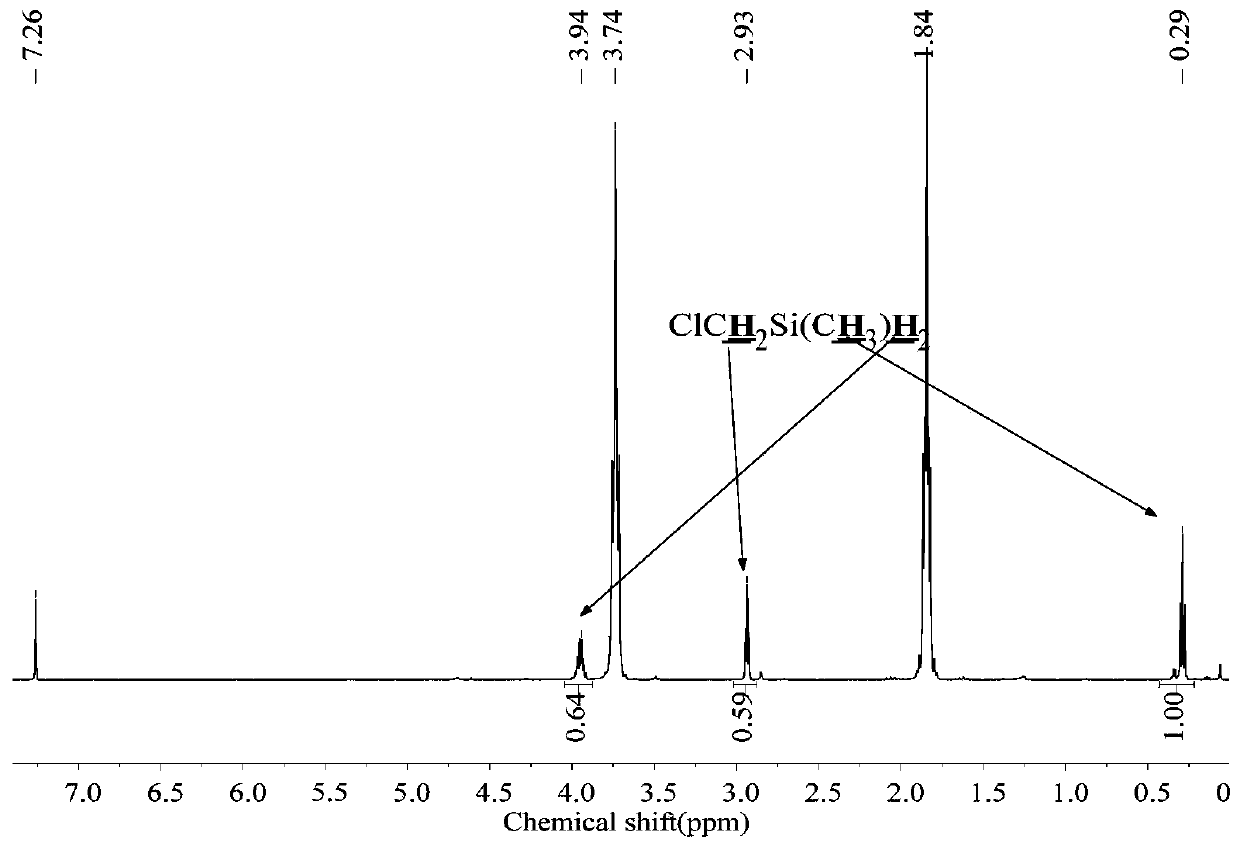

A kind of method of lithium hydride selective reduction chloroalkyl chlorosilane

ActiveCN108530477BAchieve restorationEfficient reductionGroup 4/14 element organic compoundsSelective reductionEther solvent

The invention discloses a method used for selective reduction of chlorine alkylchlorosilane with lithium hydride, and belongs to the technical field of chlorine alkylchlorosilane reduction. The methodis capable of solving a problem in the prior art that it is impossible to prepare chlorine alkyl hydrosilane through rapid high efficiency selective reduction of chlorine alkylchlorosilane. Accordingto the method, in an ether solvent, under the effect of a catalyst, lithium hydride is taken as a reducing agent, chlorine alkylchlorosilane is reduced into chlorine alkyl hydrosilane; a borane, a hydroboron, or lithium aluminium hydride is taken as a catalyst; the molar ratio of the catalyst to lithium hydride is controlled to be 1:41-100000. The method can also used for preparation of chlorinealkyl hydrosilane through reduction of chlorine alkylchlorosilane.

Owner:INST OF CHEM CHINESE ACAD OF SCI

A kind of preparation method of chloroalkyl hydrosilane

The invention discloses a preparation method of chloride alkyl hydrogen silane, belongs to the technical field of reduction of the chloride alkylchlorosilane, and solves the problem that in the priorart, the chloride alkyl hydrogen silane cannot be prepared through selective reduction of the chloride alkyl chlorosilane. In an ether solvent, under the catalysis of a catalyst, LiH is adopted as a reducing agent, the chloride alkyl chlorosilane is reduced to the chloride alkyl hydrogen silane; the catalyst is boron hydride, borohydride or lithium aluminum hydride. The preparation method can be used for preparing the chloride alkyl hydrogen silane.

Owner:INST OF CHEM CHINESE ACAD OF SCI

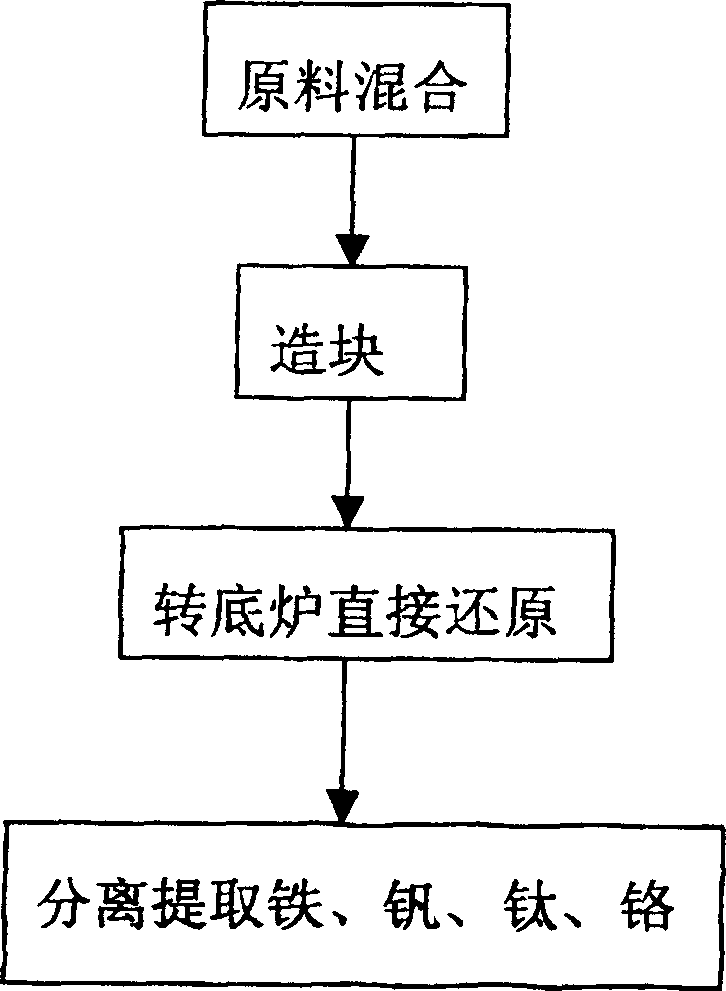

Method for separating and extracting metal element from varadium-titanium magnetite

InactiveCN1264993CFast reduction reactionShort recovery timeRecycling and recovery technologiesProcess efficiency improvementSlagAdhesive

The technological process of separating and extracting metal elements from V-Ti iron ore includes the steps of: agglomerating ore powder of mixing V-Ti iron ore powder, reductant, additives and adhesive, pressing the mixture into 10-25 mm diameter agglomerates and drying at 80-90 deg.c; reducing inside one bottom rotating furnace to obtain metal products; smelting the metal products in an electric furnace to obtain molten iron and V-Ti slag component, and smelting the V-Ti slag component to obtain V-Cr oxide and Ti slag as the material for producing titanium while. The present invention has high reduction temperature, fast reduction speed, short reduction time, high production efficiency, high metal and V-Ti recovering rate and less environmental pollution.

Owner:SICHUAN LOMON MINING & METALLURGY

Highly selective catalytic fuel cell based on mixed liquid and application thereof

The invention relates to the technical field of fuel cells, and in particular to a highly selective catalytic fuel cell based on mixed liquid and application thereof. The highly selective catalytic fuel cell based on mixed liquid includes a battery body, an oxidation electrode, a reduction electrode and a circuit system, the battery body is formed with a reaction chamber used for receiving a fuelsolution, and the oxidation electrode and the reduction electrode are arranged in the reaction chamber, the oxidation electrode catalyzes the fuel solution to generate the oxidation reaction, the reduction electrode catalyzes the oxidation reaction of the fuel solution, and the electrons generated by the oxidation electrode are transmitted to the reduction electrode through the circuit system. Inthe invention, a proton exchange membrane is not required for isolation of the reaction chamber so as to simplify the battery structure, reduce the battery weight and improve the catalytic efficiency.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Method for preparing nano molybdenum disulfide with fullerene structure

The invention discloses a method for preparing nano molybdenum disulphide with a fullerene structure. The method comprises the following steps sequentially: by using industrial molybdenum trioxide as raw material, argon as carrier gas and hydrogen as reducing agent, molybdenum dioxide nano particle is generated by gas-phase reaction; the nano molybdenum disulphide and elemental sulfur are reactedunder the condition of high temperature self-pressurization to produce powder material of the nano molybdenum disulphide with the fullerene structure; the molybdenum dioxide is nano particle generated directly by the reaction of the molybdenum trioxide after gasification under 700 to 1,000 DEG C with the hydrogen under 400 to 950 DEG C; the molybdenum disulphide with the fullerene structure is compound molybdenum disulphide by the self-pressurization reaction of the nano molybdenum dioxide and elemental sulfur in a vessel under 500 to 950 DEG C. The method for preparing the nano molybdenum disulphide with the fullerene structure has the advantages of simple process, high production efficiency, low cost of the raw material and product and short reaction time and the method can easily control the size of the molybdenum dioxide nano particle.

Owner:CHANGAN UNIV

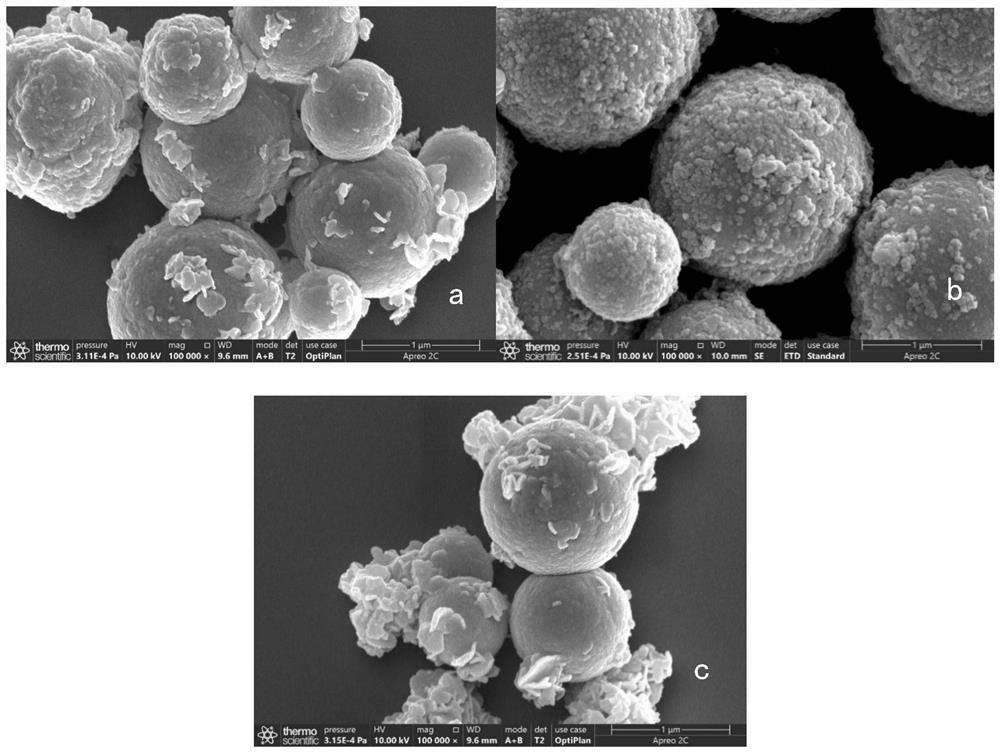

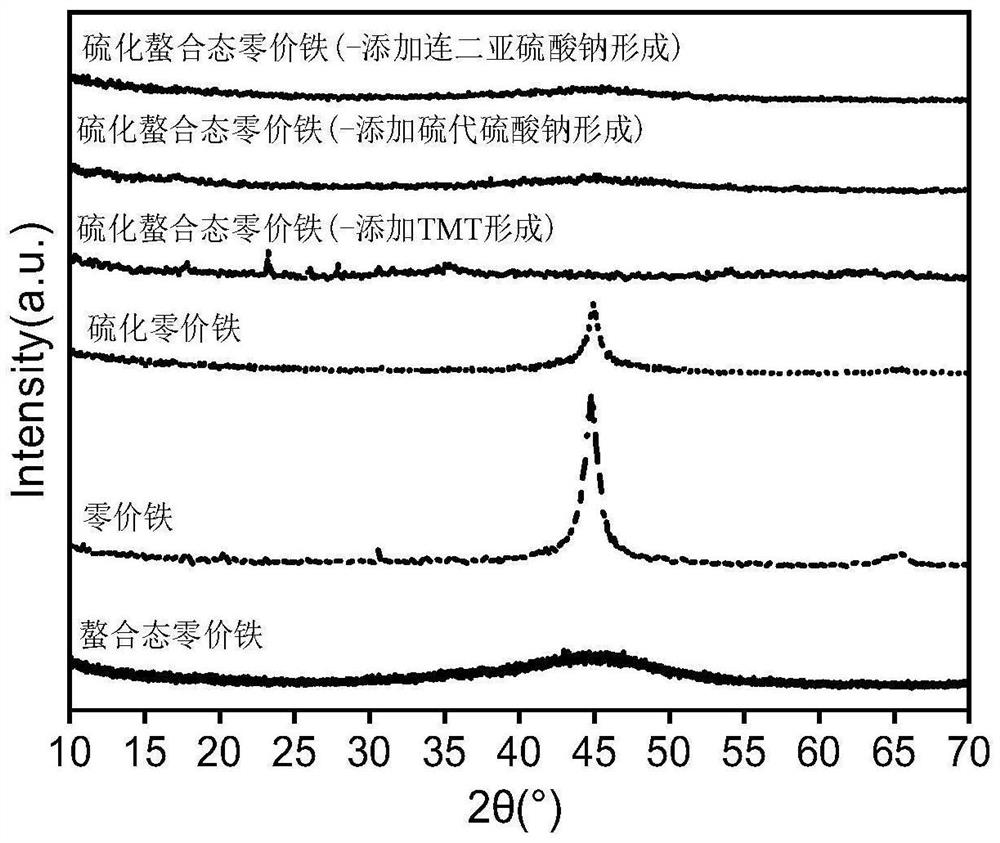

Vulcanized chelated zero-valent iron as well as preparation method and application thereof

ActiveCN114162953AEasy to provideImprove adsorption capacityWater contaminantsWater/sewage treatment by reductionFerrous sulfate ironSulfate

The invention discloses vulcanized chelated zero-valent iron as well as a preparation method and application thereof, belongs to the technical field of heavy metal pollution remediation, and solves the technical problems that traditional zero-valent iron is easy to agglomerate and an iron oxide film is high in resistance. According to the sulfurized chelated zero-valent iron disclosed by the invention, ferrous ions are chelated by adopting a nitrogen-containing compound, a NaBH4 solution is added into a mixed solution to form the chelated zero-valent iron, then the chelated zero-valent iron is sulfurized by adopting a sulfurizing agent, and finally the amorphous sulfurized chelated zero-valent iron is formed. The chelating-state zero-valent iron can provide electrons more easily, the agglomeration problem is effectively solved, in the preparation process, ferrous sulfate is used for wrapping the chelating-state zero-valent iron particles with a layer of iron sulfide film, the defects of a traditional zero-valent iron material are overcome, and therefore the material has very wide application prospects.

Owner:XI AN JIAOTONG UNIV

A method and device for producing direct reduced iron

ActiveCN107779536BReduce the temperatureLower requirementShaft furnaceProcess efficiency improvementChemical reactionShaft furnace

The invention relates to a microwave shaft furnace direct reduction process adopting pellets and coal powder. According to the process, direct reduced iron is produced from raw material pellets and external matched material coal powder in a continuous microwave shaft furnace, selection heating, rapid heating, volume heating, activated metallurgical chemical reaction and other features of the microwave are fully utilized, gasification of fixed carbon is accelerated, and iron oxide is further reduced, so that the reduction temperature is lowered and the reaction time is shortened. The coal powder can serve as both a reducing agent and a heating element in the process, a gas-solid-heat exchange step is simplified, energy is saved and emission is reduced. The process contains low free oxygen content, and can produce CO with high purity of 95% or above; and the process is compact in structure, high in metallization degree, which is 94-98%, low in carbon content, which is less than 0.2%, andis low in quality requirements on coal powder, thereby being an environment-friendly iron making process.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

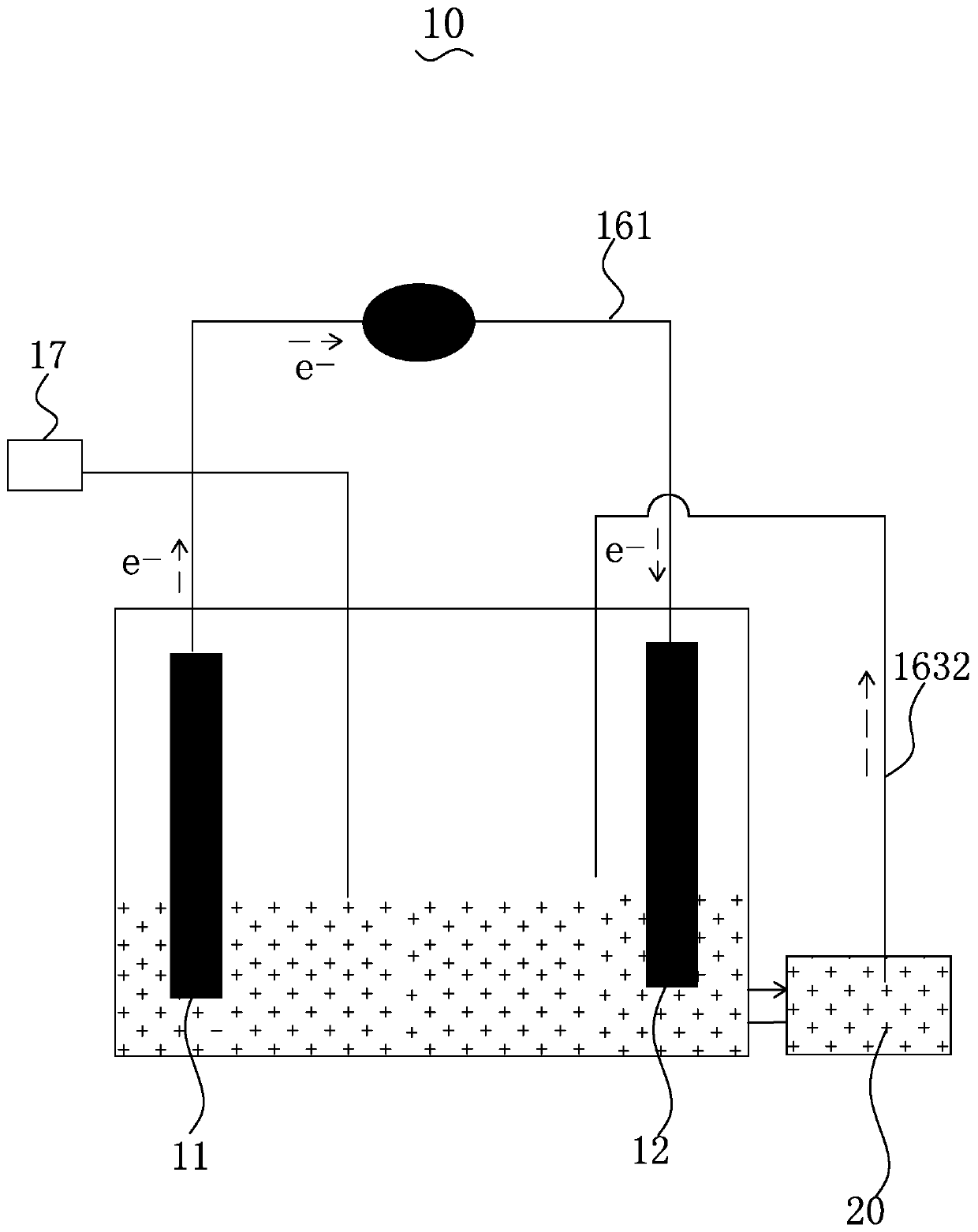

Radiovolt electrochemical radioisotope battery

PendingCN112750547ALarge specific surface areaIncrease contact areaRadiation electrical energyElectron holeSemiconductor

The invention provides a radiovolt electrochemical radioisotope battery which comprises an anode composed of a substrate electrode and a semiconductor three-dimensional nano structure integrated on the surface of the substrate electrode, a cathode and a radioactive electrolyte filling in the three-dimensional nano space structure of the anode, the radioactivity of the radioactive electrolyte is obtained by replacing one or more stable elements in the electrolyte with radioactive isotopes of the same type, and rays generated by the radioactive isotopes comprise at least one of alpha particles and beta particles; the radioactive isotope has a half-life period of more than 5 years, and the average energy of radiation particles is not higher than 250keV. Rays generated by the radioactive electrolyte interact with the three-dimensional nanostructure of the anode semiconductor to generate a large number of electron-hole pairs, holes and the electrolyte are subjected to an oxidation reaction under the action of a built-in electric field formed by the solid-liquid heterostructure and migrate to the cathode, and electrons are transferred to the cathode through an external circuit to be subjected to a reduction reaction with the electrolyte, and a closed loop is formed to generate an output current.

Owner:XIAMEN UNIV

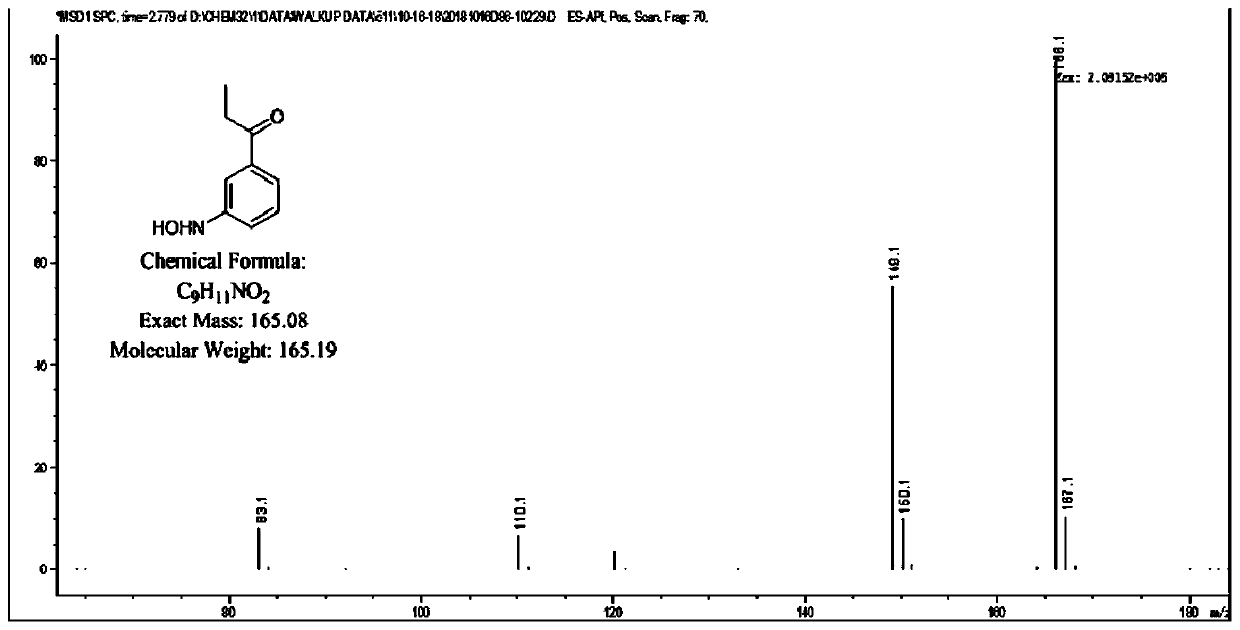

Method for reducing nitrocompound through biocatalysis

PendingCN111118076AEasy to operateWide substrate applicabilityFermentationHydroxylamine compoundNitro compound

The invention provides a method for reducing nitrocompound through biocatalysis. A coenzyme is used as a hydrogen donor, olefin reductase is used as a catalyst, the nitrocompound is subjected to catalytic reduction, and a hydroxylamine compound or an amine compound is generated. The method for reducing the nitrocompound through biocatalysis provided by the invention replaces a conventional methodfor chemically reducing the nitrocompound which is complex, dangerous and polluted in product extraction, the olefin reductase which can be obtained through purchase from the market or prepared by oneself is used as the catalyst, and a quick, simple and effective scheme for reducing the nitrocompound by a biocatalysis method can be established; and the nitrocompound is reduced into the stable hydroxylamine compound or the amine compound, the method has broad substrate applicability, and a high-flux and rapid nitroreduction reaction can be realized.

Owner:PORTON FINE CHEM

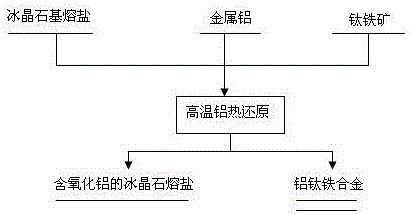

A kind of method for preparing al-ti-fe alloy by thermite reduction of ilmenite in cryolite-based molten salt

The invention belongs to the field of metal smelting and extraction, and particularly relates to a method for preparing Al-Ti-Fe alloy by thermite reduction of ilmenite in cryolite-based molten salt. The present invention uses metallic aluminum as a reducing agent, performs thermite reduction of ilmenite in a cryolite-based molten salt medium at 930-985°C for 0.5-6 hours, and then separates the alloy and molten salt to obtain Al-Ti-Fe alloy and Al2O3-rich cryolite-based molten salt, in which the Al-Ti-Fe alloy contains 59.44~83.55% Al, 12.42~36.62% Ti, 0.41~9.03% Fe, and 0.87~2.68% Si by weight. Compared with the existing technology of directly reducing solid ilmenite with liquid aluminum, the reaction temperature required by the present invention is greatly lowered, energy consumption is reduced, metal aluminum is not lost, and the alloy product obtained by the reduction has high purity.

Owner:NORTHEASTERN UNIV LIAONING

Gas-based reduction method and system for granular iron ore and application

PendingCN113373273AReduce chance of stickingSmall reduction reaction rateHydrogenRotary drum furnacesCo2 removalSteam reforming

The invention provides a gas-based reduction method and system for granular iron ore and application, and relates to the technical field of smelting. According to the gas-based reduction method, pure oxygen and high-calorific-value fuel gas are not needed, natural gas is used as a raw material, compressed natural gas is converted into hydrogen-rich gas through desulfurization, steam reforming, shift reaction, first dehydration treatment and first CO2 removal treatment, the hydrogen-rich gas is preheated to be in countercurrent contact with the granular iron ore with a specific particle size and a specific preheating temperature to conduct a reduction reaction so as to prepare the granular directly reduced iron; and due to the fact that the particle size of the granular iron ore is small, the reduction reaction speed at the same temperature is higher than that of traditional pellets, other binders and sintering processes do not need to be introduced, pollution is greatly reduced, meanwhile, the granular iron ore at the specific preheating temperature and the hydrogen-rich gas are directly subjected to the reduction reaction, and the reduction reaction at low temperature is realized by utilizing the heat of the granular iron ore and the hydrogen-rich gas.

Owner:北京金博威科技有限公司

High-efficiency preparation method of rare-earth fluoride nanoparticle

InactiveCN103073046ASmall sizeImprove stabilityMaterial nanotechnologyRare earth metal compoundsRare earth ionsPhotoelectric conversion

The invention relates to an organic preparation method of a multifunctional nano-material and especially relates to a high-efficiency preparation method of a rare-earth fluoride nanoparticle. The rare-earth fluoride nanoparticle obtained by the high-efficiency preparation method has a core-shell structure and high photoelectric conversion performances and anti-wear performances. The high-efficiency preparation method of the rare-earth fluoride nanoparticles comprises that trivalent rare earth ions are reduced spontaneously by a hyperbranched polymer in a normal-temperature aqueous solution so that the rare-earth fluoride nanoparticle is produced. The rare-earth fluoride nanoparticle has a core-shell structure composed of a nanoparticle and a hyperbranched compound wrapping the nanoparticle. The reaction system is arranged in an ultrasonic field so that reaction time is reduced and a reaction rate is improved.

Owner:JIANGSU UNIV

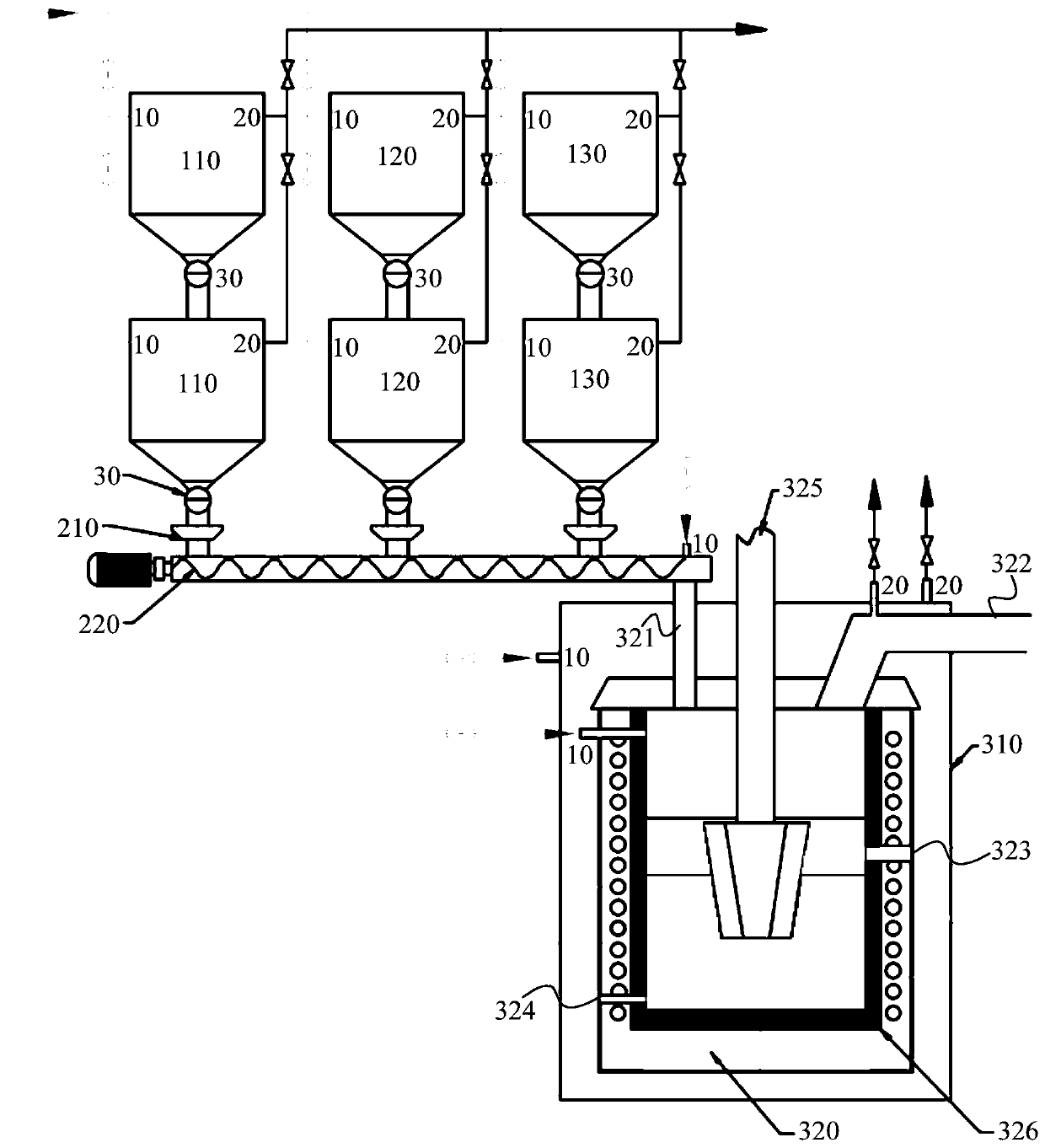

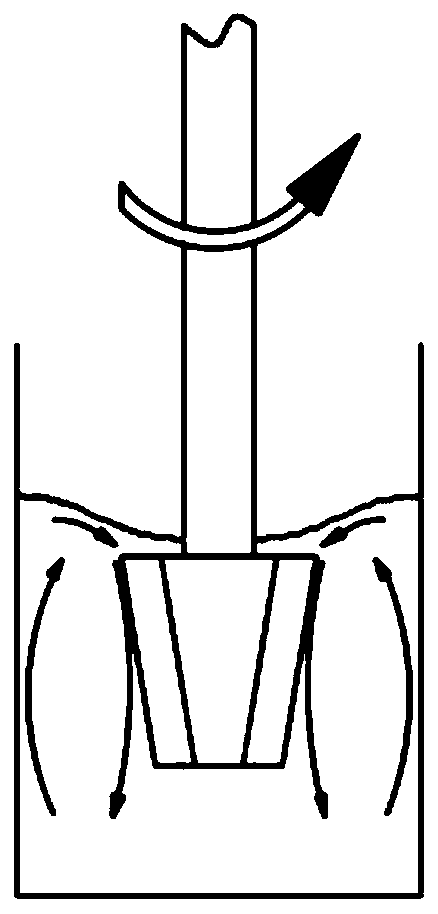

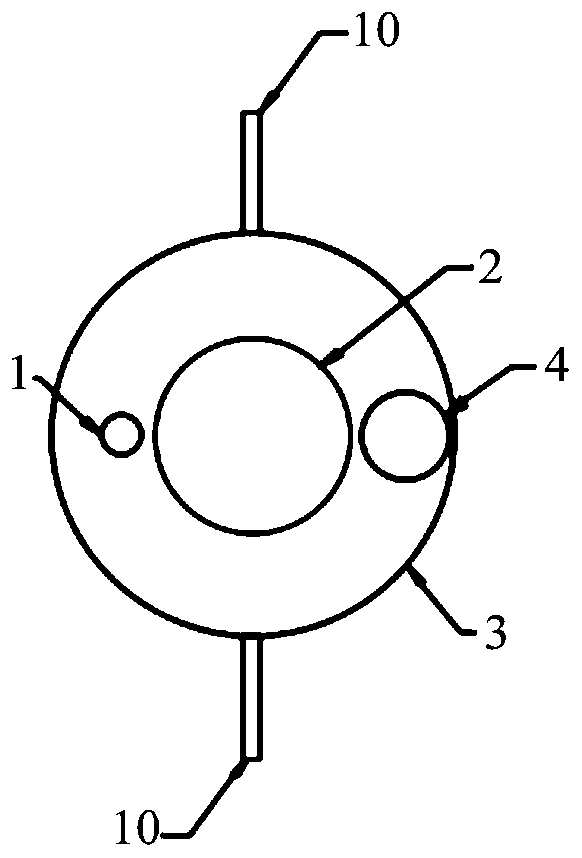

System and method of induction heating liquid mixing continuous magnesium production

PendingCN111270088AReduce the burden onReduce power consumptionProcess efficiency improvementChemistryScrew conveyor

The invention discloses a system and method of induction heating liquid mixing continuous magnesium production. The system comprises a silicon iron raw material bin, a magnesium ore raw material bin,a flux raw material bin, a feeding mechanism and a smelting mechanism. Each raw material bin is provided with an inert gas inlet and a vacuuming port. The smelting mechanism comprises an airtight chamber and an induction furnace. The induction furnace is arranged in the airtight chamber. A feeding pipeline and an exhaust gas pipeline are arranged on the top of the induction furnace. The feeding pipeline extends out of the airtight chamber and is connected with a screw conveyer. The exhaust gas pipeline extends out of the airtight chamber. A slag outlet and an iron outlet are arranged on the side on the induction furnace. The induction furnace is further provided with a stirring paddle. The airtight chamber is provided with an inert gas inlet on the side wall. The induction furnace is provided with an inert gas inlet on the side wall. The airtight chamber is provided with a vacuuming port on the top wall. The exhaust gas pipeline is provided with a vacuuming port. According to the system of induction heating liquid mixing continuous magnesium production, because the negative micro-pressure operation or normal-pressure operation is adopted, continuous feeding and discharging can be implemented, continuous production of the metal magnesium is implemented, and the production cost is reduced; and splashing can be effectively reduced, the quantity of soot is effectively reduced, thequality of original magnesium is improved, and the stable running state of equipment is improved.

Owner:CHINA ENFI ENGINEERING CORPORATION +1

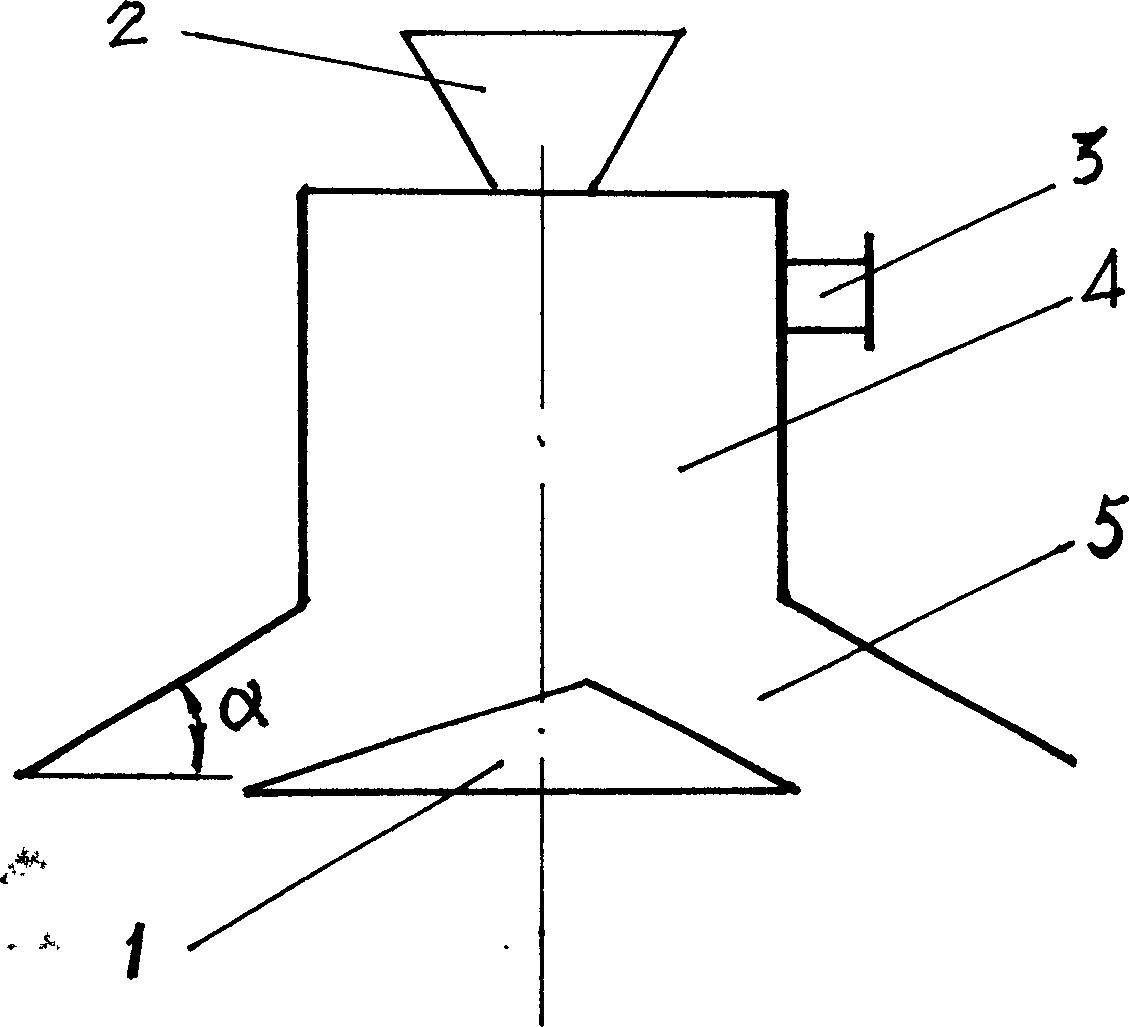

High-strength, low cost and wide coal kind gas producer

InactiveCN1435469AStrong penetrating powerIncreased chance of properly oriented collisionsCombustible gas productionHigh intensityProcess engineering

A gas generator is disclosed. Its features are high gasifying intensity (1600-1800 kg / sq.m.hr), broad spectrum of raw materials including soft coal, hard coal, coal gangue and combustible solid, and low cost.

Owner:陈科正

Preparation method of rhodium metal nanoparticles

PendingCN112439900AEasy to prepareSmall particle sizeMaterial nanotechnologyTransportation and packagingPhysical chemistryAnalytical chemistry

The invention relates to a preparation method of rhodium metal nanoparticles. The preparation method comprises the following steps: carrying out plasma glow discharge treatment on a rhodium-containingsolution and assistant mixed solution to reduce rhodium ions in the mixed solution into the rhodium metal nanoparticles. According to the method, rhodium ions in the rhodium-containing solution are reduced by adopting a plasma glow discharge method, so that introduction of a reducing reagent is avoided, and the method is environment-friendly. Moreover, the preparation method provided by the invention is simple and can be carried out at normal temperature and normal pressure. In addition, the rhodium metal nanoparticles prepared by the preparation method provided by the invention are small inparticle size, high in purity and uniform in granularity, and have a wide application prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing nonferrous metal by micro mist thermal recovery

A method for preparing nonferrous metal by micro mist thermal recovery belongs to the metallurgy field. The process steps are as follows: reactant is prepared according to chemometry of reduction reaction; solid reactant is processed into powder and homogenous mixing is carried out; and reduction material is made into blocks by pressing and then placed into a reducing furnace for carrying out vacuum reduction reaction, so as to obtain metal; wherein reactant material powder with the diameter of 10-10000nm accounts for 90-100wt% of the total reactant material in the grain distribution of the reactant material powder. The invention is a metal preparation method with high resource and energy utilization and can be applicable to preparation of nonferrous metal such as magnesium, calcium, strontium, lithium and the like.

Owner:CHONGQING UNIV

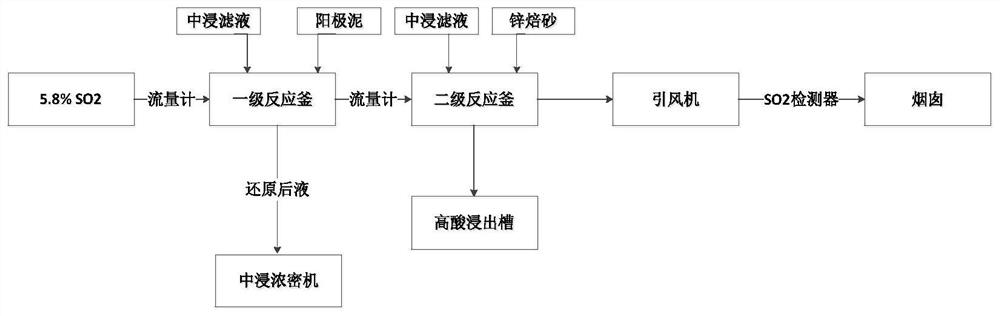

Method for efficiently recycling manganese in zinc anode mud in short process

PendingCN113802016AFast reduction reactionShort reaction timePhotography auxillary processesProcess efficiency improvementSulfur dioxideFlue gas

The invention discloses a method for efficiently recycling manganese in zinc anode mud in a short process. The method comprises the following specific steps of: primary size mixing: uniformly mixing and stirring zinc calcine neutral leaching liquid of a zinc smelting system and the zinc anode mud; primary reduction reaction: feeding ore pulp into a primary reduction reaction kettle, and enabling sulfur dioxide-containing flue gas obtained by the zinc smelting system to be in contact reaction with the ore pulp; and after the reaction is finished, merging obtained supernatant A into a medium leaching thickening system, and enabling the supernatant A to enter a zinc electrolysis system after purification for supplementing Mn < 2+ > in the zinc electrolysis system; secondary size mixing: uniformly mixing and stirring the zinc calcine neutral leaching liquid and zinc calcine of the zinc smelting system; secondary absorption reaction: introducing the ore pulp obtained by secondary size mixing and tail gas subjected to the primary reduction reaction into a secondary reaction kettle for reduction absorption to obtain absorption ore pulp B, and directly merging the absorption ore pulp B into a high-acid leaching system. According to the method disclosed by the invention, manganese dioxide in the zinc anode mud is reduced by utilizing sulfur dioxide produced by a zinc smelting and roasting acid plant, and the reduced liquid is merged into the leaching system to maintain the Mn < 2+ > balance of the system.

Owner:新疆紫金有色金属有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com