Patents

Literature

33results about How to "Reduce chance of sticking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Soybean milk preparing method of soybean milk grinder

InactiveCN101744057AIncrease temperatureSpeed up thermal motionBeverage vesselsMilk substitutesSlurrySoybean meal

The invention relates to a soybean milk preparing method of a soybean milk grinder. The soybean milk preparing method comprises the following steps that: (a) a motor drives a smashing cutter to stir the soybean milk for t1 seconds so as to produce appropriate foam; (b) a heating device is started to heat water and a material until the mixture is going to leak out; and (c) the motor drives the smashing cutter to smash the mixture to prepare the soybean milk and boil the soybean milk by heating. The method is characterized in that: in order to replenish the foam and prevent the material from becoming adhesive in the heating process of stage (b), the soybean milk is stirred for t3 seconds every after a time interval of t2. The soybean milk preparing method stirs the soybean milk for 5 to 10 seconds before starting heating, so most of the material does not produce too mush foam and only anti-leaking requirement is basically met. In the heating process, the soybean milk is stirred once after a certain period of time to replenish the foam and prevent the material from being adhered to the bottom of the soybean milk grinder after being heated for a long time. Therefore, the disadvantages in the soybean milk preparing method in the prior art are overcome better.

Owner:JOYOUNG CO LTD

Degreasing and reeling method of cold rolled titanium strip coil before annealing

The invention provides a degreasing and reeling method of a cold rolled titanium strip coil before annealing, which comprises the processes of cold rolling, degreasing, vacuum annealing or cover-type annealing. Under the condition that the rolling emulsion concentration is 0.8-2.5%, the temperature is 40-50 DEG C, the deformation rate in the process of rolling is 20-80% and the pass deformation rate is 3-10%, the strip coil is carried out 5-19 passes rolling to the target thickness, and is degreased and cleaned, different unit tension are used for reeling by aiming at different positions of cold rolled titanium strip coil when degreasing, the titanium stripe after reeling is packed and sent to a vacuum furnace or a bell furnace for heat treatment. According to the invention, the bonding rate of cold rolled titanium strip coil after vacuum annealing or cover-type annealing is substantially reduced, the problems of rolling, open coiling and scattered rolling can be avoided when the strip coil uses small unit tension for reeling.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

Method for breeding sturgeons

InactiveCN108541632AImprove hatchabilityReduce adhesionClimate change adaptationPisciculture and aquariaBroodstockSemen

The invention discloses a method for breeding sturgeons, and belongs to the technical field of sturgeons breeding. The method comprises the steps that step 1, sturgeon parent fish with excellent shapes and characters is selected, the parent fish is put into a breeding pond for split-pond breeding 1-2 years before egg / sperm retrieval, sand covers the bottom of the breeding pond, the sand is coveredwith a filter net, cobblestones with the thickness of 2-3 cm are laid on the filter net, and submerged plants and shrimps and crabs are put into the breeding pond; step 2, when gonadogenesis of the parent fish reaches IV period, leuteinizing hormone releasing hormone is adopted to perform drug hasten parturition on the parent fish, the using amount is milter 1.2-1.5 microgram per kilogram and raun 2.5-3 microgram per kilogram, and flowing water is adopted in the breeding pond from one month before drug hasten parturition is conducted to the time when egg cells / sperm are collected; step 3, artificial fecundation is conducted on the collected egg cells / sperm, fertilized eggs are put into an incubator to be incubated until seedlings are produced, and the breeding process is completed. By means of the method, the incubation rate and quality of the sturgeons are improved.

Owner:贵州龙源冷水渔业有限公司

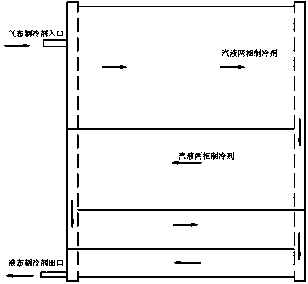

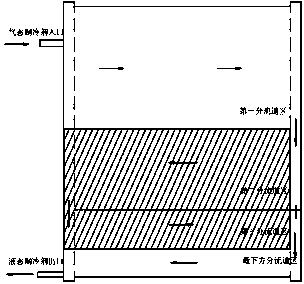

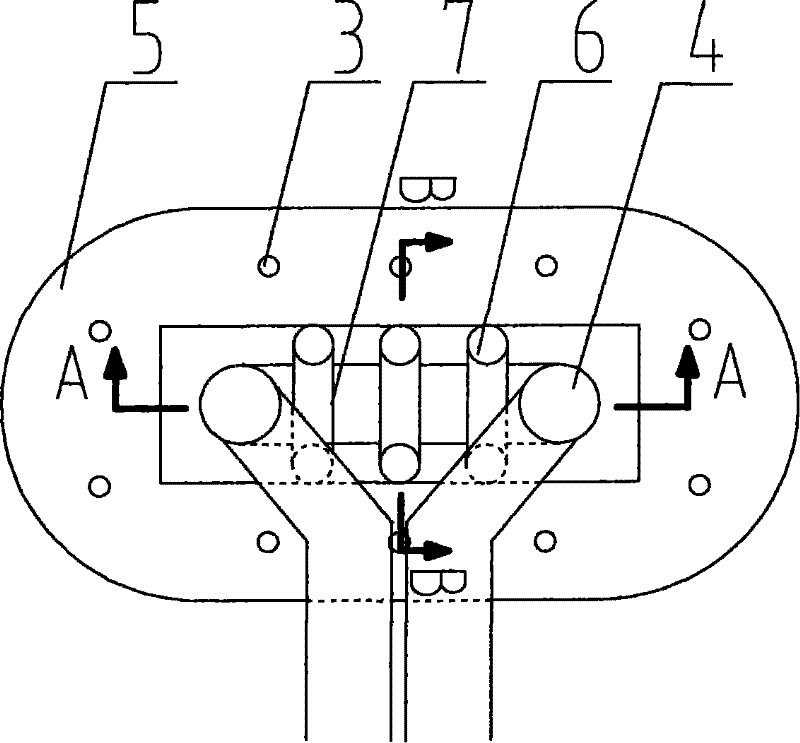

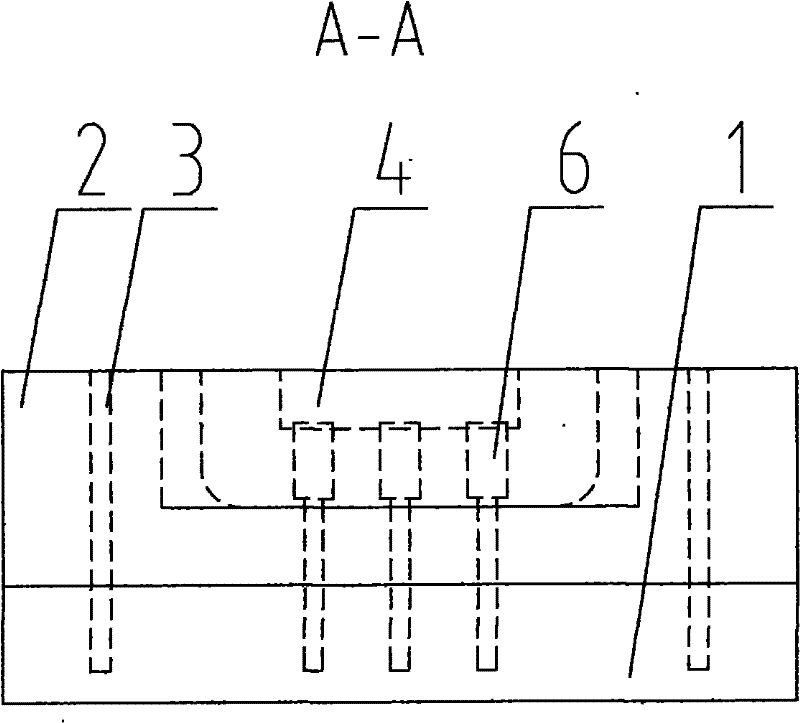

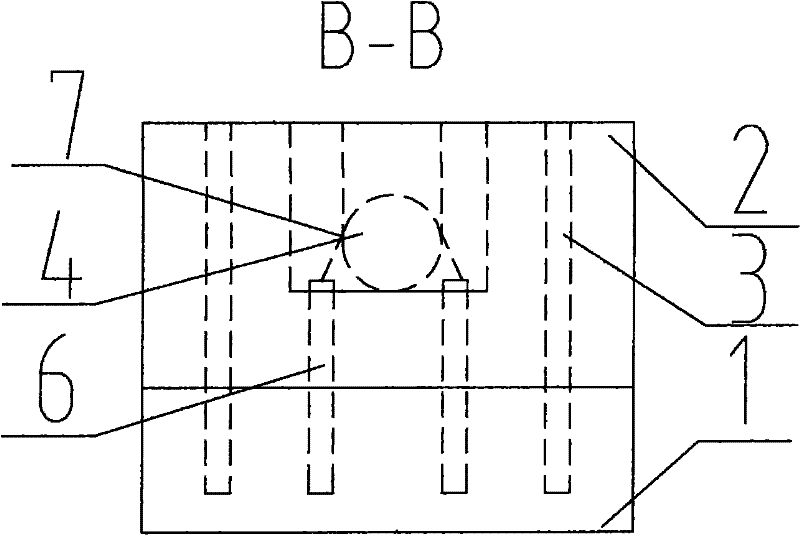

Parallel flow condenser and air conditioner with same

InactiveCN104279798AReduce chance of stickingDirect contact guaranteeEvaporators/condensersEngineeringRefrigerant

The invention provides a parallel flow condenser. Two sides of the condenser are provided with collecting pipes; the collecting pipes are internally provided with multiple spacers used for separating internal runners of the collecting pipes into multiple sub-runner regions; the spacer behind the first sub-runner region is provided with a leak hole. By use of the characteristic that a liquid refrigerant has specific weight greater than that of press machine oil and is collected toward the bottom of the condenser under the action of gravity, each spacer of each collecting pipe of the parallel flow condenser is additionally provided with a flowing hole, and a part of liquid refrigerant and press machine oil can be guided into the rear half part of the condenser, so that the possibility that the liquid refrigerant or press machine oil is attached to the pipe walls of the collecting pipes is reduced, complete direct contact between a gaseous refrigerant and the pipe walls is ensured, and thus the heat exchange efficiency of the middle of the parallel flow condenser is improved. In addition, the invention also provides an air conditioner.

Owner:HAIER GRP CORP +1

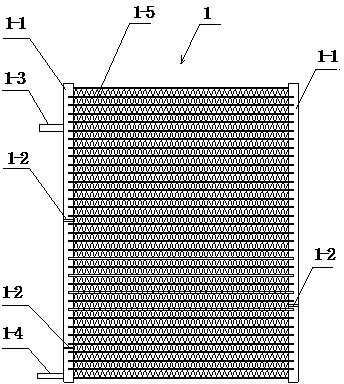

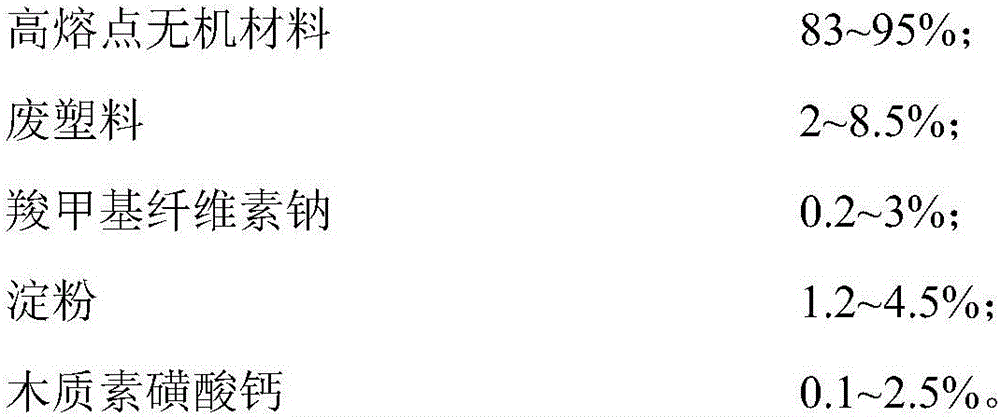

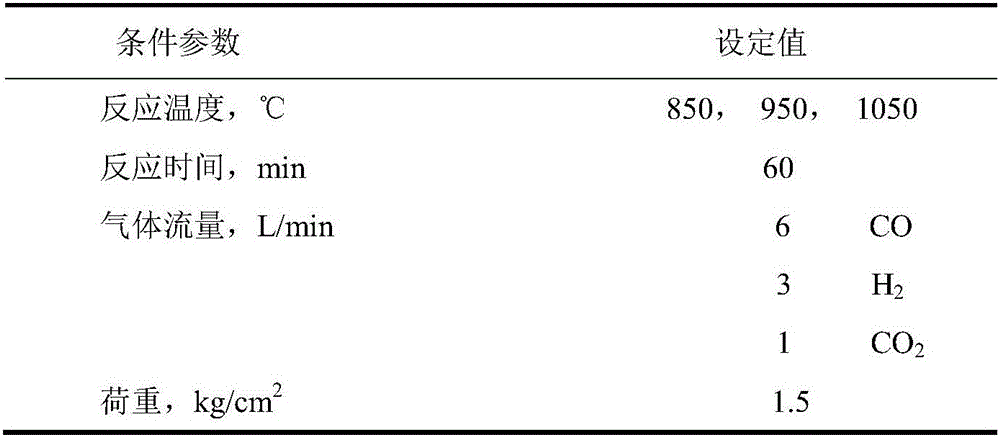

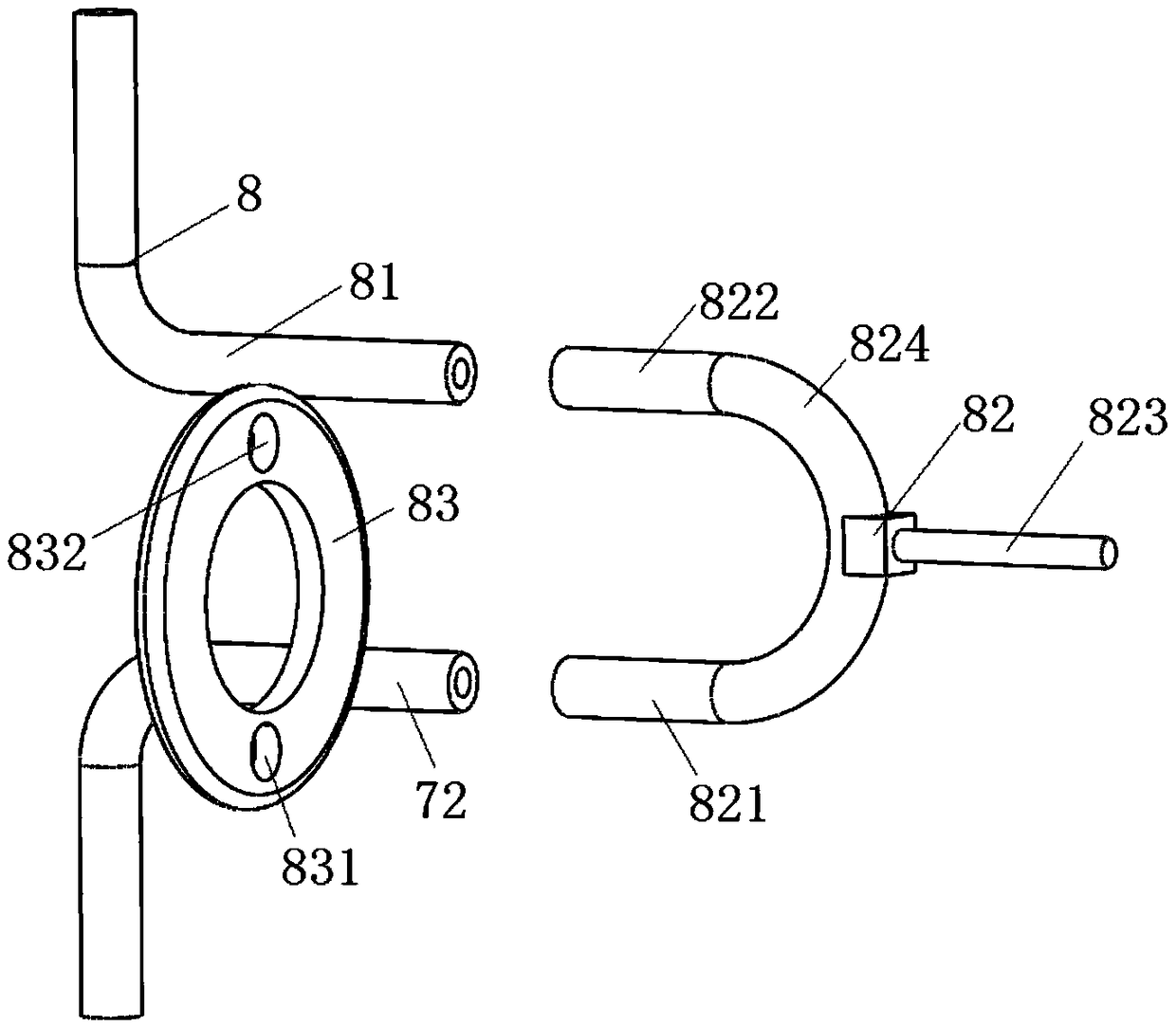

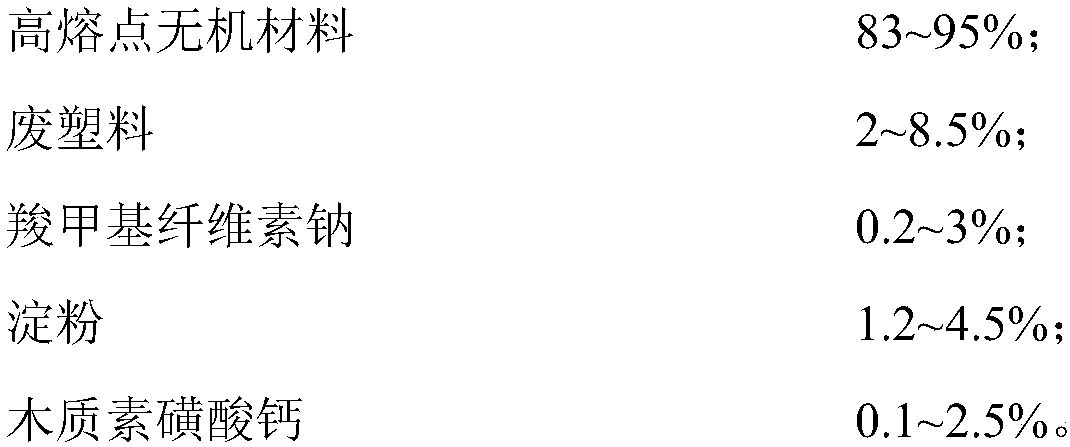

Coating material for restraining excessive bonding during smelting reduction of iron ore pellets and preparation method of coating material

ActiveCN106222350AInhibit excessive bondingFully contactedShaft furnacePre treatmentInorganic materials

The invention discloses a coating material for restraining excessive bonding during smelting reduction of iron ore pellets and a preparation method of the coating material, and belongs to the technical field of smelting reduction ironmaking. The coating material comprises, by weight, 83%-95% of high-melting-point inorganic materials, 2%-8.5% of waste plastic, 0.2%-3% of sodium carboxymethylcellulose, 1.2%-4.5% of starch and 0.1%-2.5% of calcium lignosulphonate. The preparation method of the coating material comprises the following steps of pretreatment of the coating raw materials, preparation of the coating material, smearing of the coating material and drying. The coating material provided by the invention can effectively restrain excessive bonding between the iron ore pellets in the pre-reduction process of a smelting-reduction ironmaking technique, the coating material and the iron ore pellets are firmly bonded, and a coating can be effectively prevented from cracking and falling; and meanwhile, it is guaranteed that the metallization ratio of reduction products is high.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Method for restoring steep slopes of mining area by mechanical spraying of lime neutralizing sludge slag

InactiveCN109041691AReduce viscosityAvoid churnAgriculture gas emission reductionBroadcast seedersEcological environmentSludge

The invention relates to a method for restoring steep slopes of a mining area by mechanical spraying of lime neutralizing sludge slag. The method comprises the following steps and conditions of addingtailing slag into the lime neutralizing sludge slag, mechanically stirring according to a mass ratio of 100:(70 to 300), and uniformly mixing, so as to obtain a mixed material a; adding an organic fertilizer, a composite fertilizer and grass seeds into the mixed material a, mechanically stirring according to a mass ratio of 100:(2 to 6):(0.1 to 0.3), and uniformly mixing, so as to obtain a mixedmaterial b; screening the mixed material b by a vibration screen, grading the coarse and fine materials, enabling the material under the screen to fall into a material bin of a spraying machine, and using as a dry powder mechanical spraying material; enabling a pipeline and pressure air flow to convey the spraying material to perform dry powder mechanical spraying on the area requiring ecologicalrestoration; covering a nonwoven fabric onto the sprayed area, and performing proper servicing management on the area according to the local climate environment. The method has the advantages that theneutralizing sludge slag can be applied to the dry powder mechanical spraying, the 'guest soil' material is protected, the loss of water and soil is prevented, the energy-saving and consumption-decreasing effects are realized, the method is suitable for the rooting, germinating and later fertilizer applying and caring of the plant grass seeds, the ecological environment benefit is good, and the like; the method is suitable for being applied into the field of ecological restoration of the mine areas.

Owner:ZIJIN MINING GROUP +1

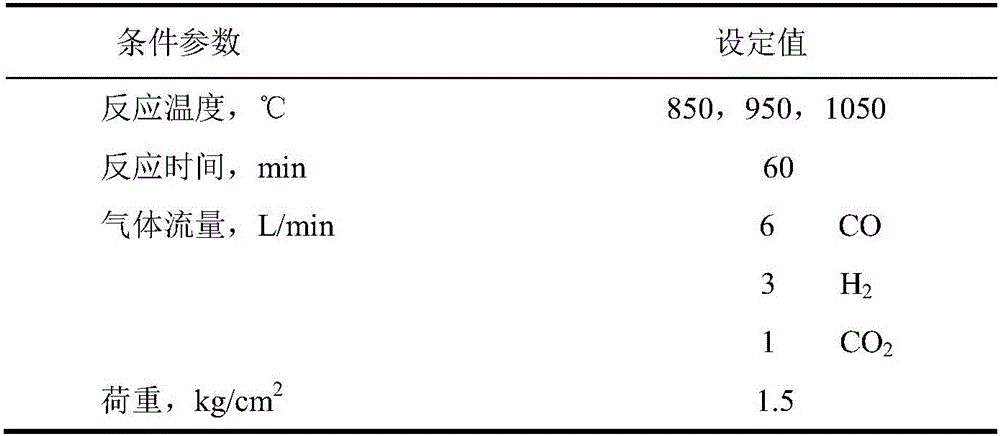

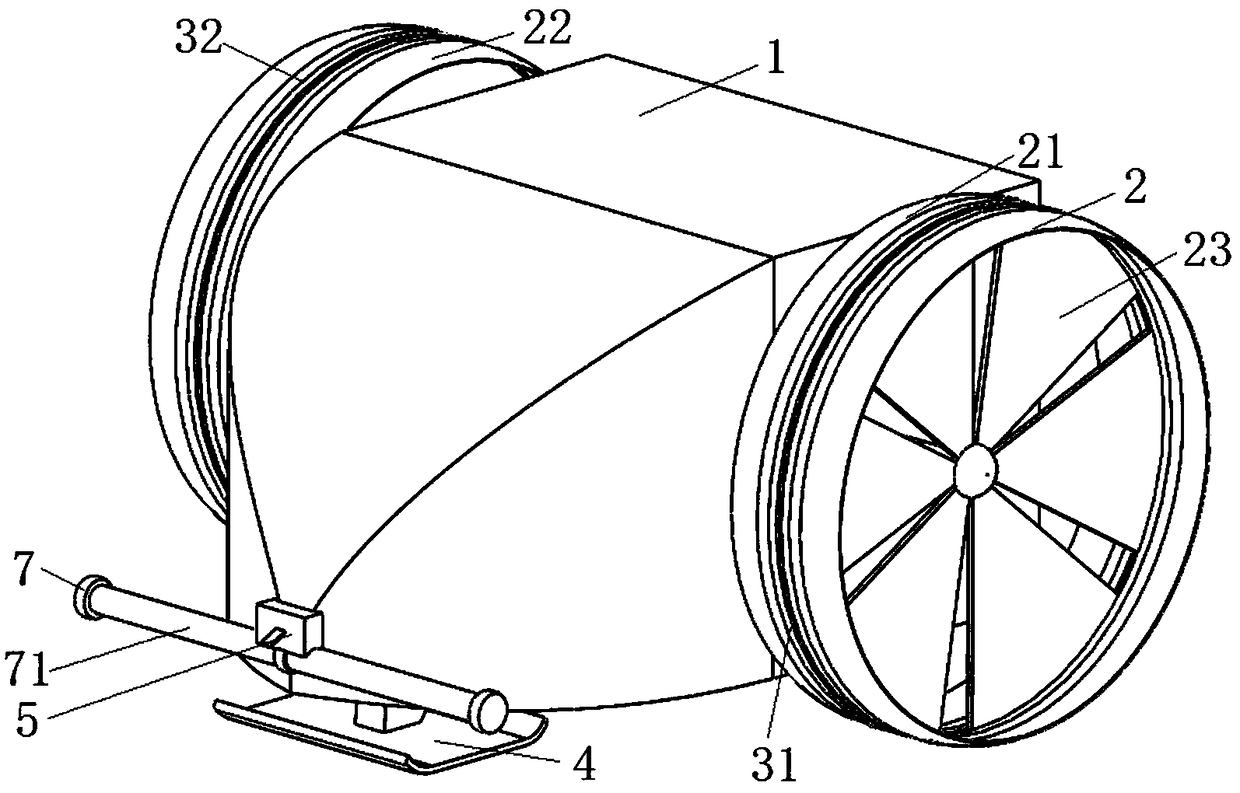

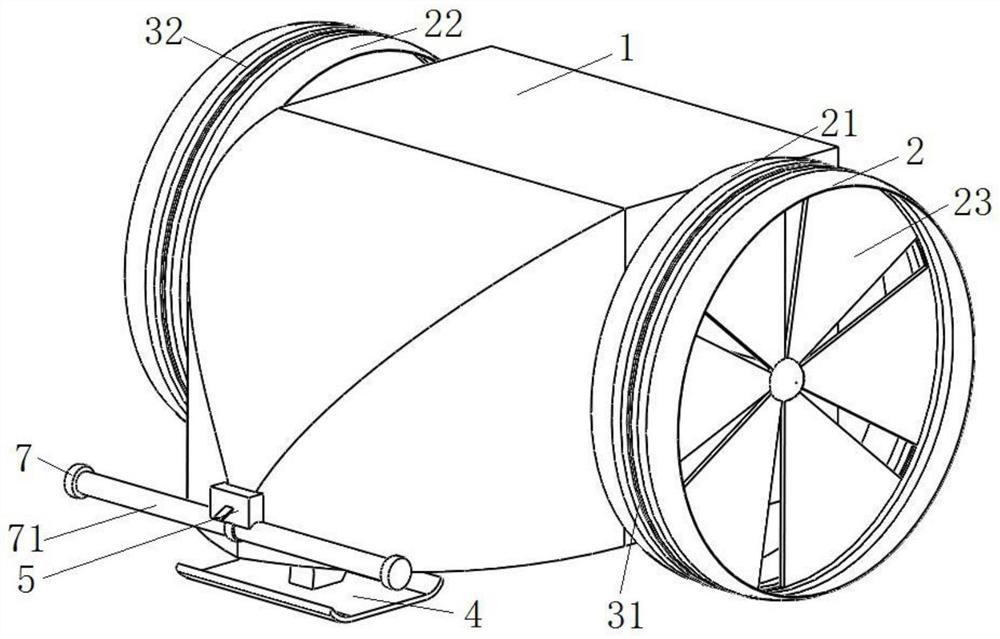

Dredging device for aquaculture fish pond and working method thereof

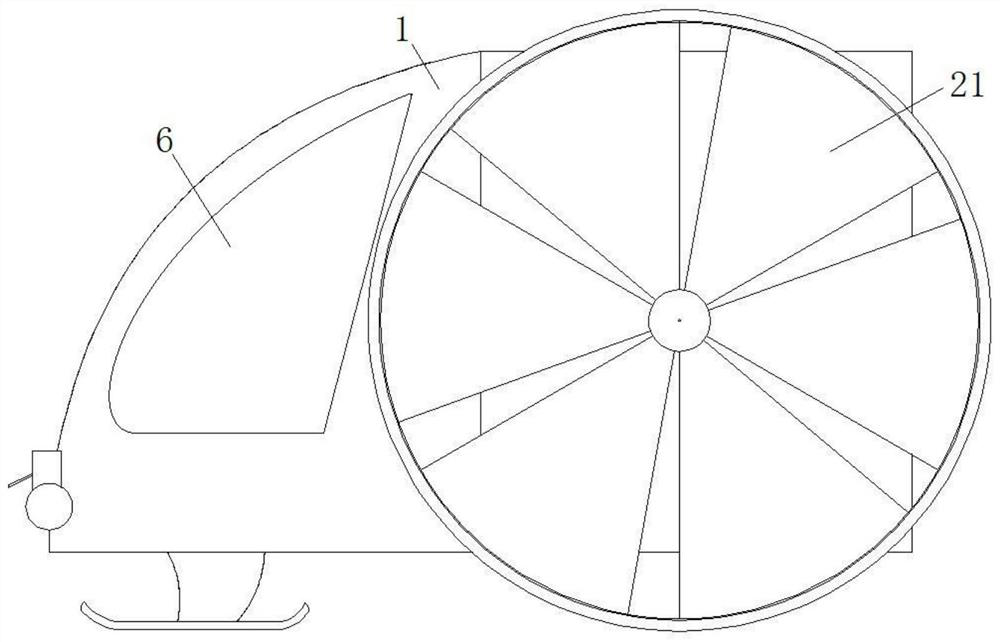

The invention discloses a dredging device for an aquaculture fish pond. The dredging device for the aquaculture fish pond comprises a vehicle body and wheels. The wheels are mounted on both sides of the vehicle body. The wheels include a first wheel and a second wheel. The first wheel is arranged on the left side of the moving direction of the dredging device. The second wheel is arranged on the right side of the moving direction of the dredging device. The wheels are provided with air bags. The bottom of the vehicle body is provided with a sliding plate. A balance cavity is formed in the front end of the inside the vehicle body. The front end of the vehicle body is provided with a pollution absorbing device. A jet-flow device is installed on the pollution absorbing device. The inside of the vehicle body is also provided with a transfer device. The steering of the underwater is more smoothly by the fit of the wheels and the air bags. The weight of the front end of the vehicle body canbe dynamically controlled by the fit of sliding plate and the balance cavity, and it is guaranteed that the front end of the vehicle cannot sink into the mud when moving. The jet-flow device is used to jet high-pressure water, so that the sludge can be effectively dispersed from pond bottom. The transfer device can effectively break up the sludge in the sewage.

Owner:嘉兴金旅燕科技有限公司

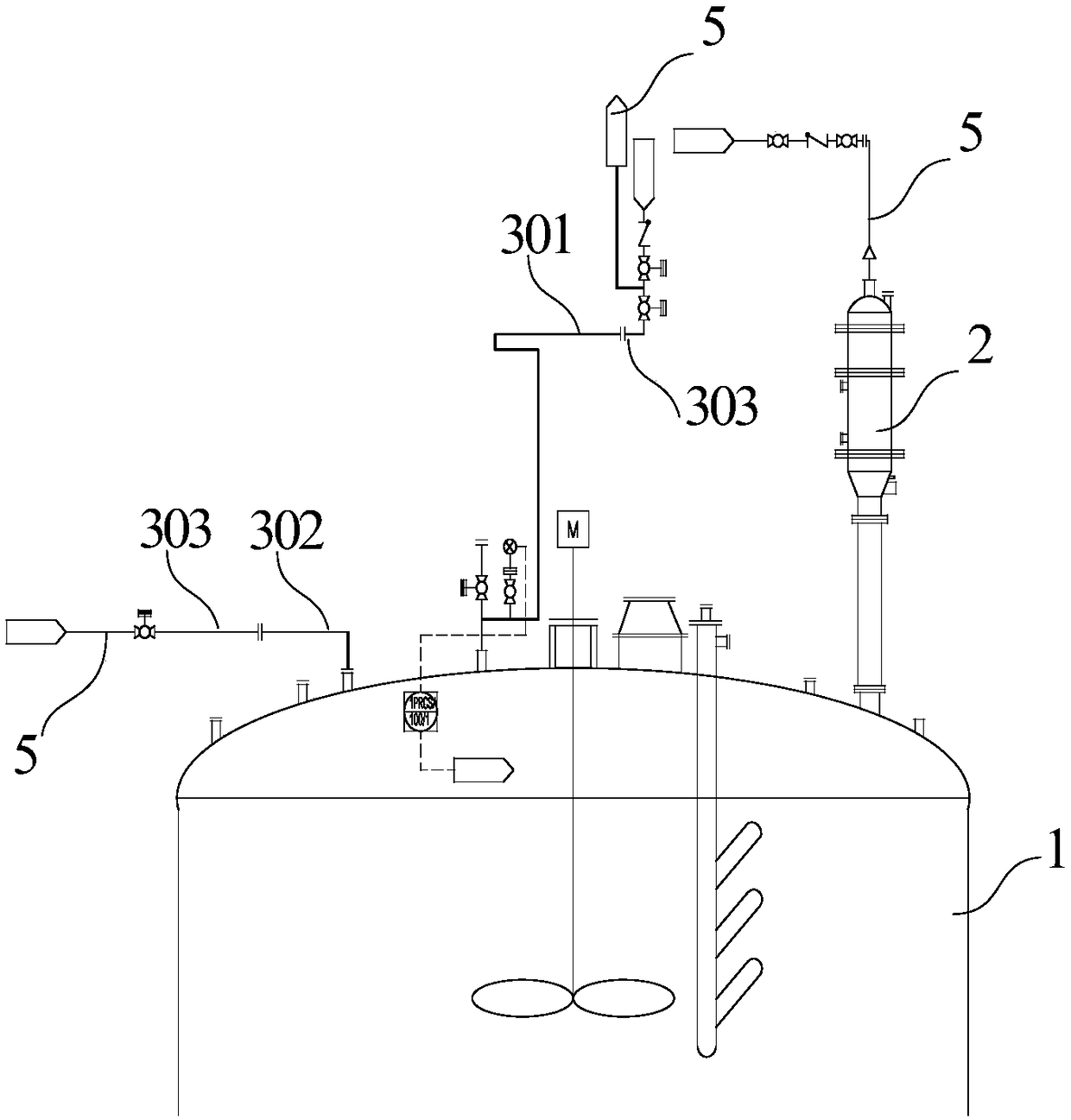

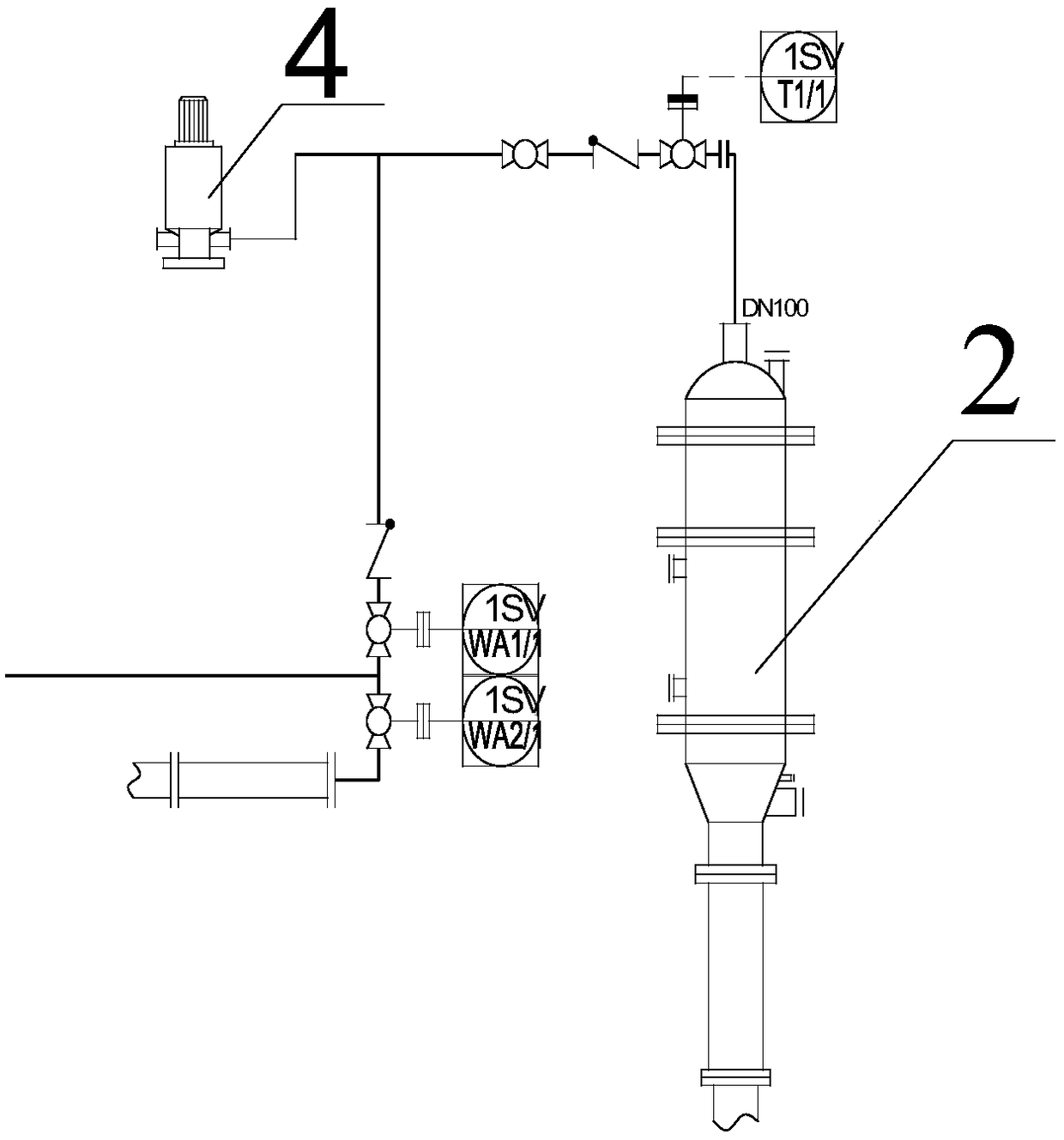

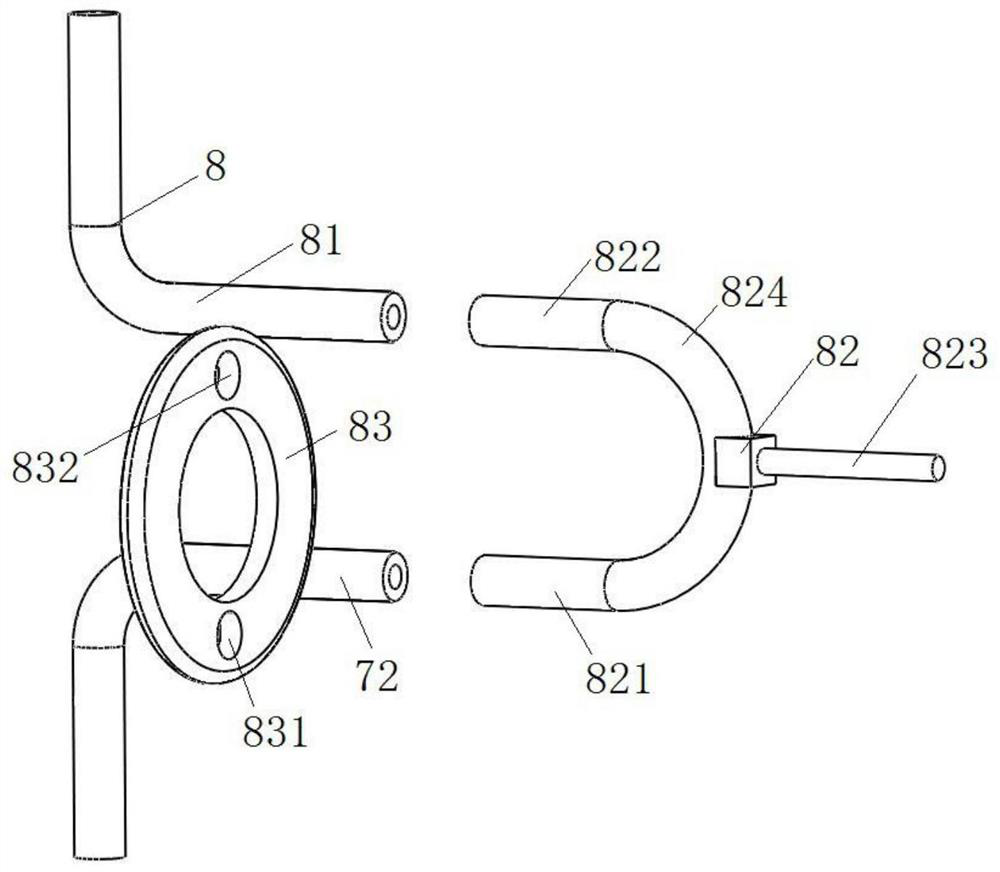

Automatic flushing device and method for paste resin polymerization kettle

PendingCN109226139AIncrease profitReduce labor intensityHollow article cleaningChemical/physical/physico-chemical stationary reactorsEngineeringHigh pressure water

The invention provides an automatic flushing device and method for a paste resin polymerization kettle. The device comprises a multistage centrifugal pump and a high-pressure water pipe. The multistage centrifugal pump is arranged on a pipeline of the high-pressure water pipe, a polymerization kettle condenser is located at the top of the polymerization kettle and is in a row tube type, circulation cooling water is placed in a shell side, and incoagulable vinyl chloride monomer is placed in a pipe side; the water outlet end of the high-pressure water pipe is arranged at the top in the condenser and is opposite to the pipe side. The automatic flushing device for the paste resin polymerization kettle is characterized in that the polymerization kettle condenser is provided with a spray nozzleand is automatically flushed, a flange of the tail end of a polymerization kettle pressure horizontal pipe is additionally provided with a flushing water port, and it is guaranteed that the horizontal pipe is flushed. Through program control, after a polymerization reaction is completed, a large amount of foam still exists in the sections of the pressure horizontal pipe and the condenser row tube, flushing water is used for successfully flushing the foam to prevent the foam from generating autopolymer, and the bonding probability of the autopolymer is lowered.

Owner:ORDOS JUNZHENG ENERGY CHEM

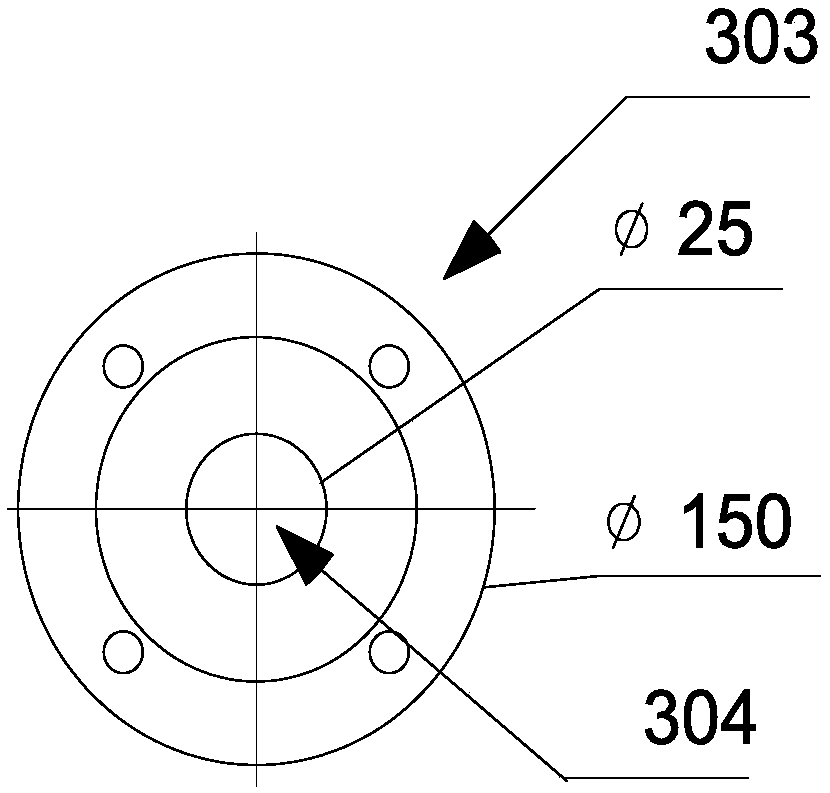

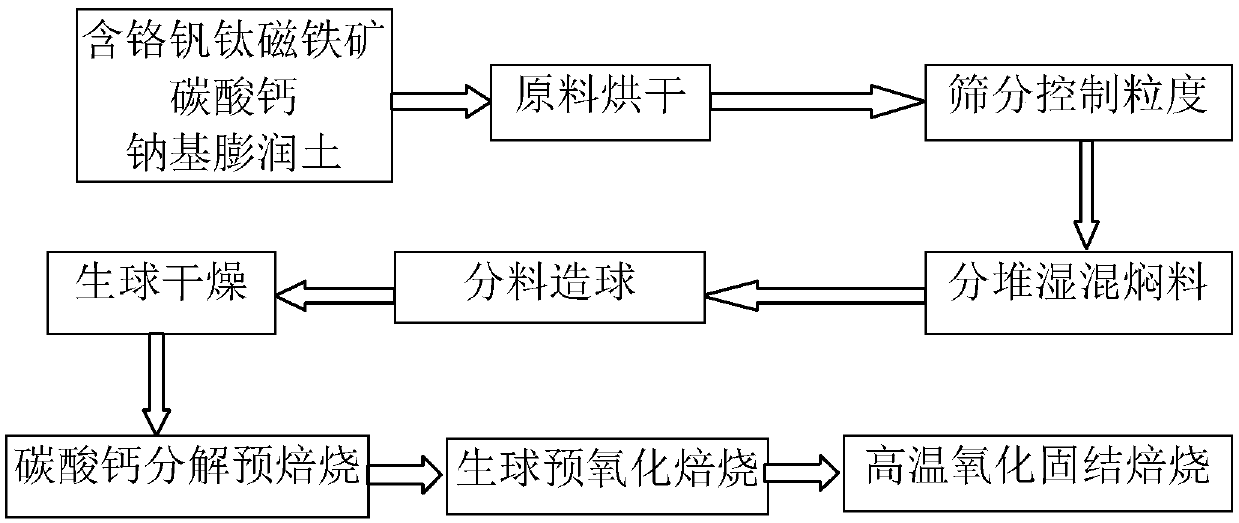

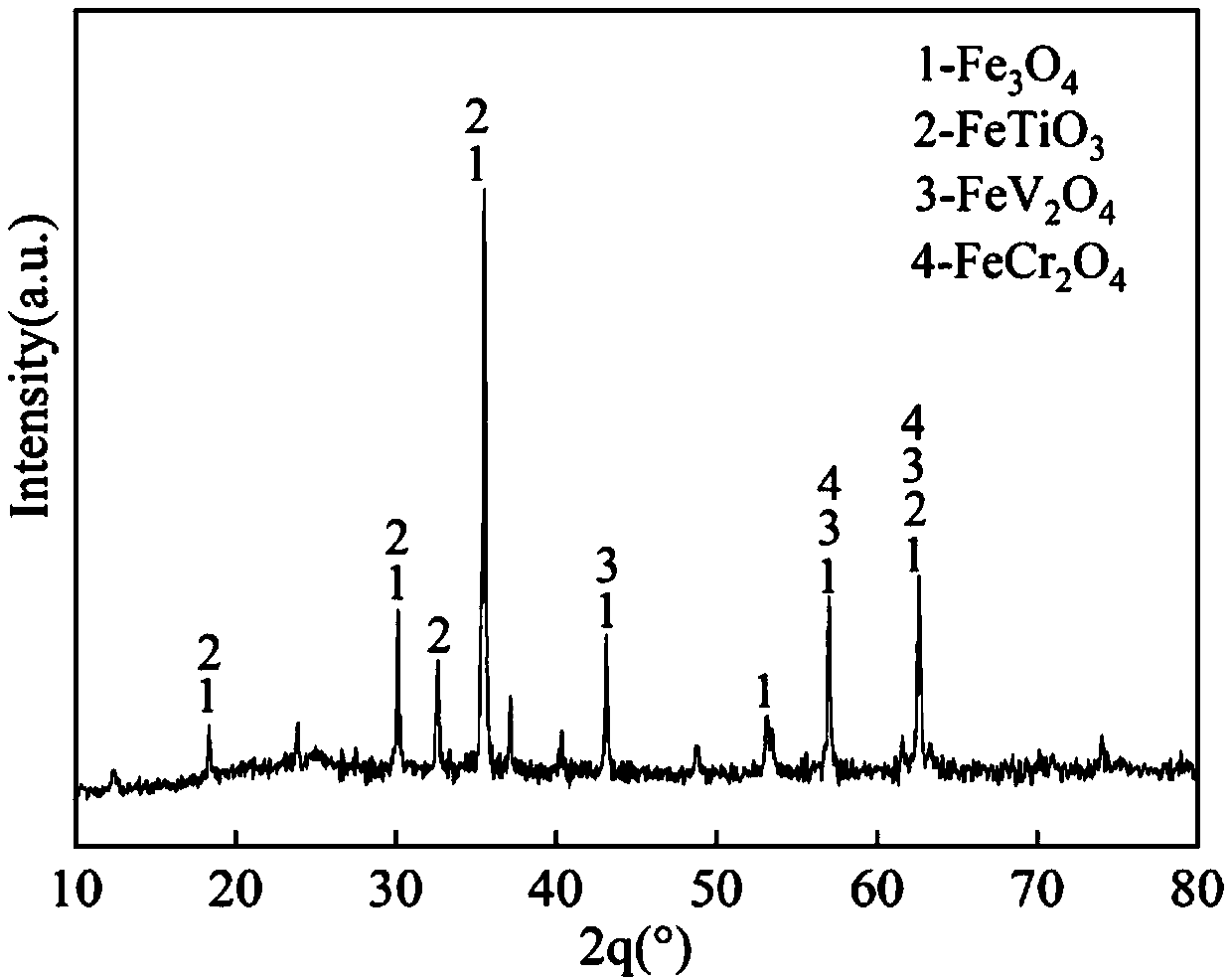

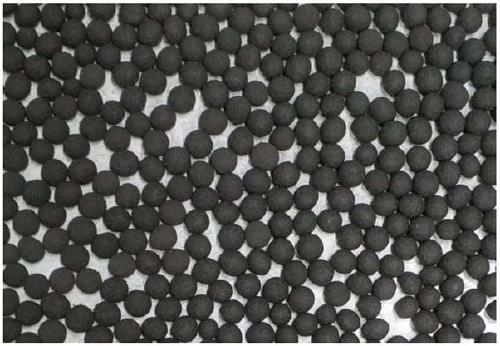

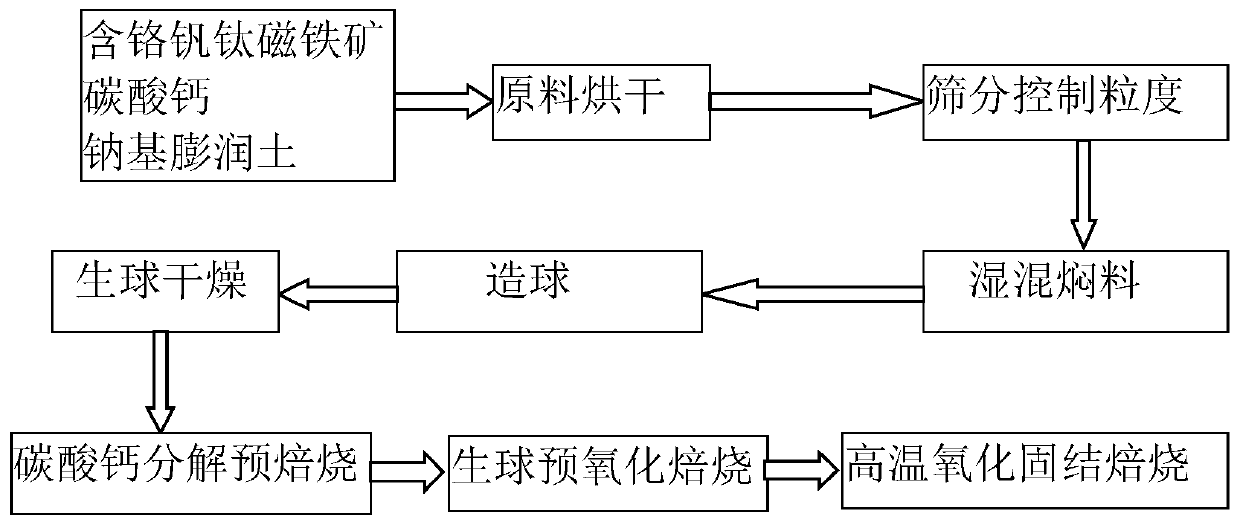

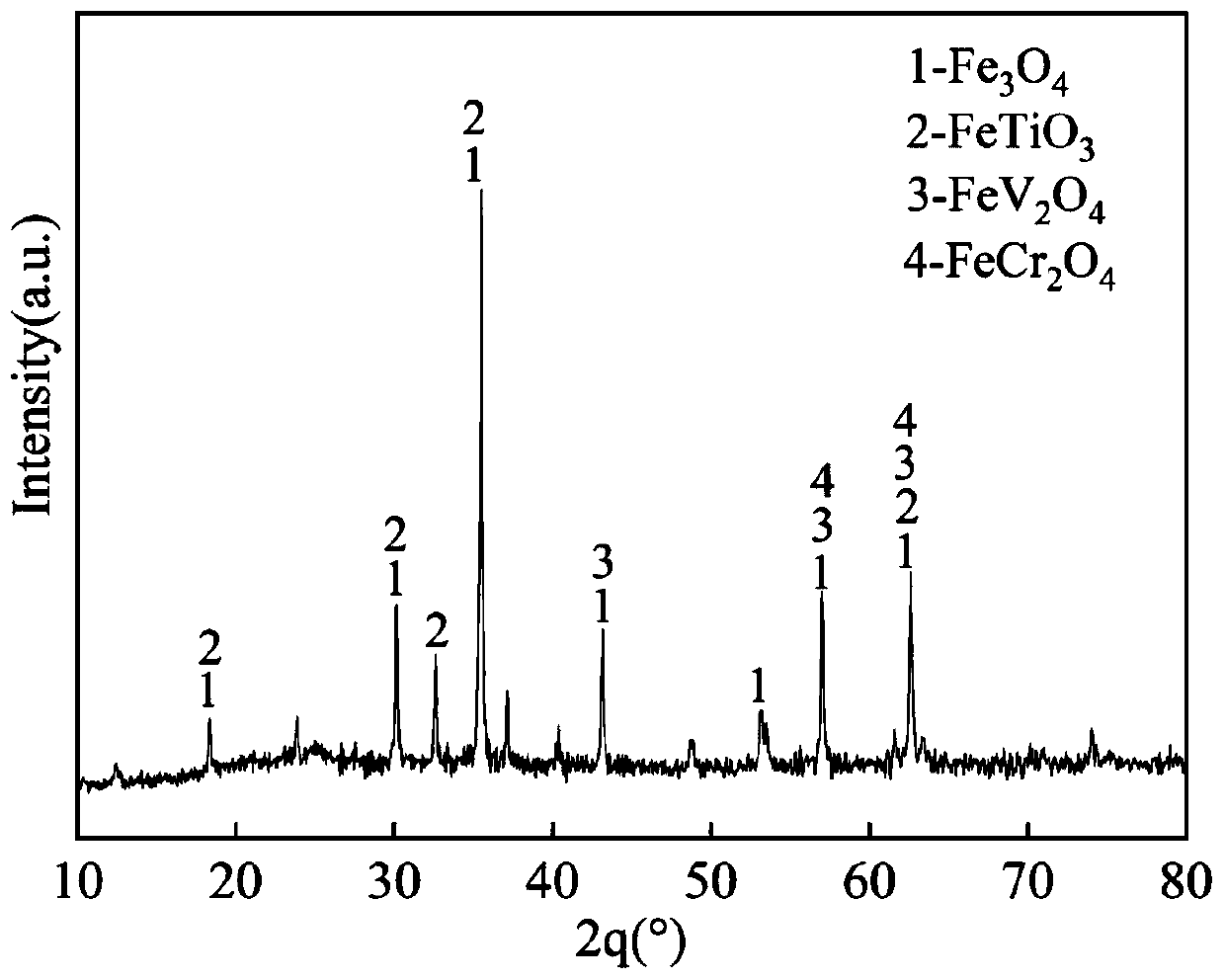

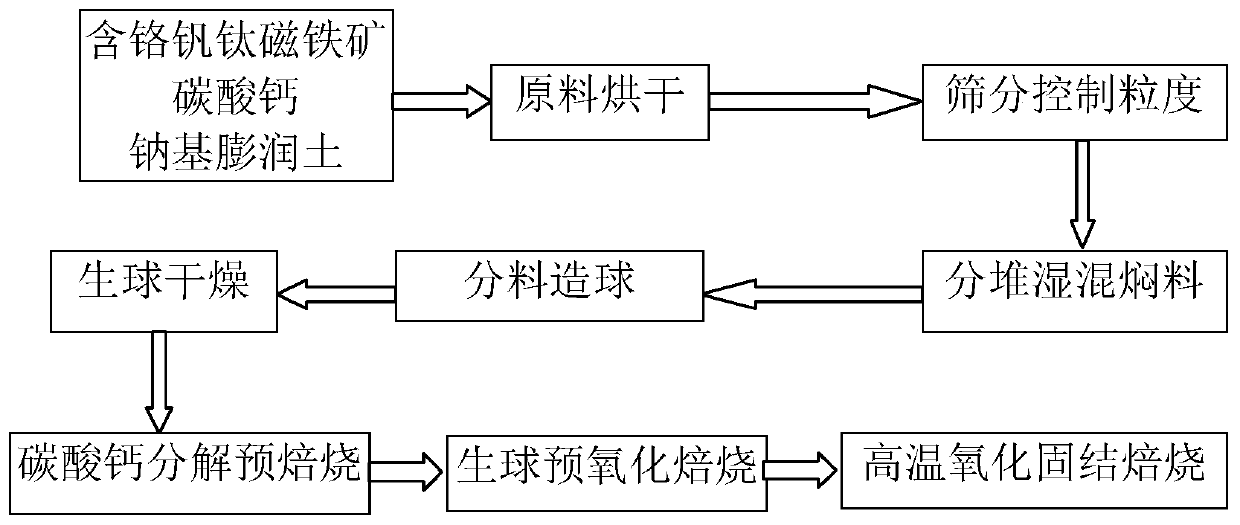

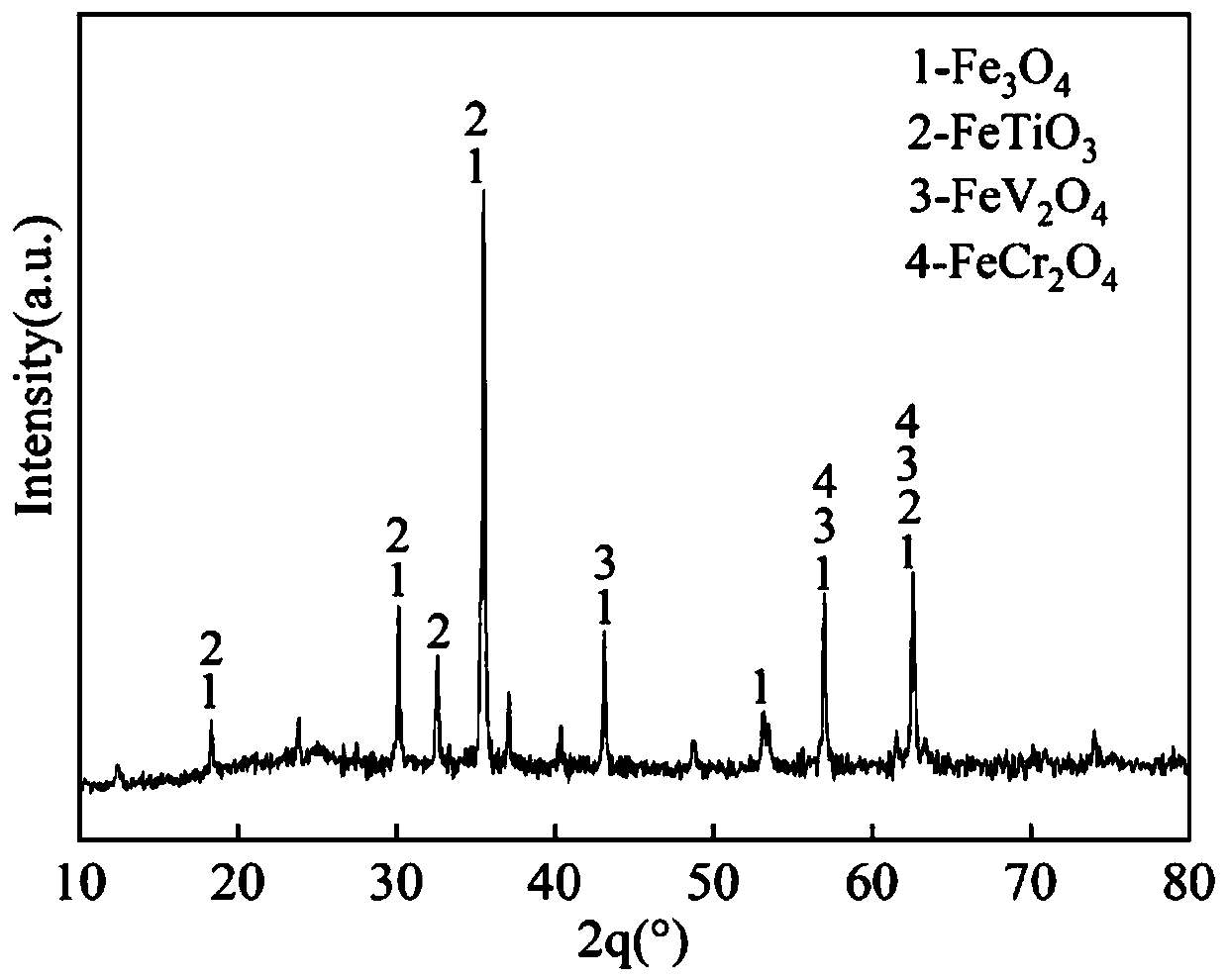

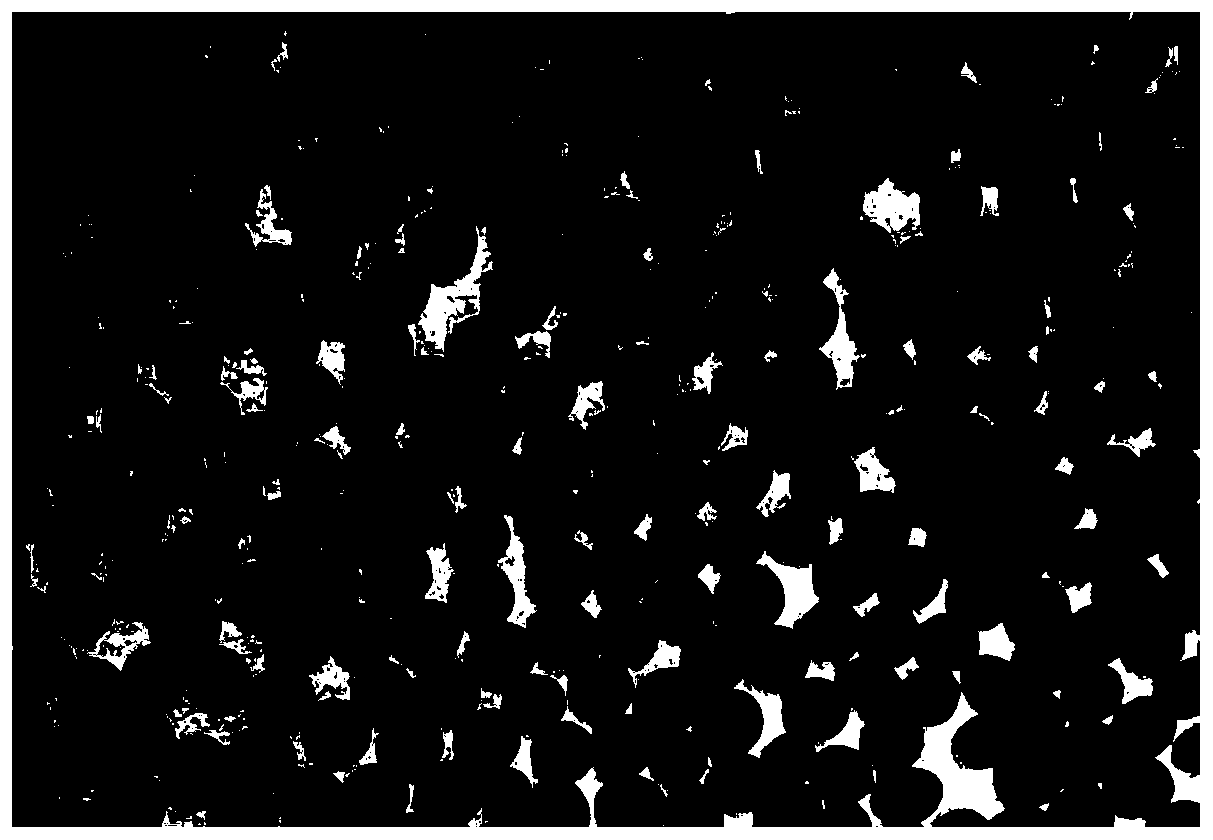

Method of preparing high-alkalinity chromium-containing all-vanadium titaniferous pellets by adding calcium carbonate

The invention relates to a method of preparing high-alkalinity chromium-containing all-vanadium titaniferous pellets by adding calcium carbonate. The method comprises the following steps that S1, batching is performed, calcium carbonate and sodium-based bentonite ingredients are added into red-lattice chromium-containing vanadium titano-magnetite; S2, the mixture is divided into two parts, the first part of the mixture material is added with 3-4% of water by mass, the second part of the mixture material is added with the 6-8% of the water by mass, and wet mixing and leaving the materials to stand to ferment are performed correspondingly; and S3, material dividing and pelletizing are performed, pelletizing is performed on a disk pelletizer with revolving speed of 30-45 r / min, the water spraying amount is controlled to be 1-2 ml / 10 g of mineral aggregates, and the water adding and material feeding are performed per 30-100 seconds at intervals; the first part of mineral aggregates are used for pelletizing in the forming period of a master ball, and the second part of ore material aggregates are used for pelletizing in the growth period of the mother ball; S4, drying is performed; S5,the calcium carbonate is decomposed, pre-oxidated and pre-roasted, the calcium carbonate is decomposed and pre-roasted firstly at the temperature of 900-950 DEG C, and then insufficient amount of airis introduced into a furnace for pre-oxidation and pre-roasting; and S6, high-temperature oxidation consolidation roasting is performed, the incremental air is introduced into the furnace at the temperature of 1250-1300 DEG C to perform the high-temperature oxidation consolidation roasting, after sintering is completed, cooling is performed to prepare the high-alkalinity chromium-containing all-vanadium titaniferous pellets.

Owner:NORTHEASTERN UNIV LIAONING

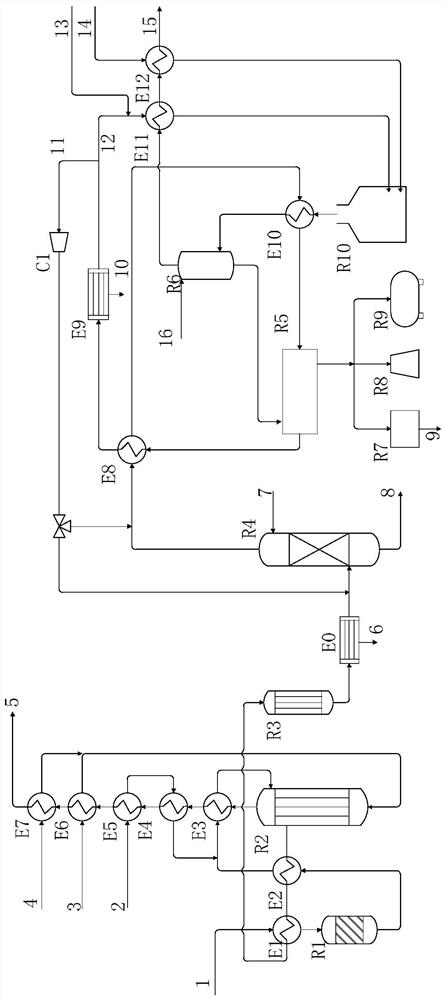

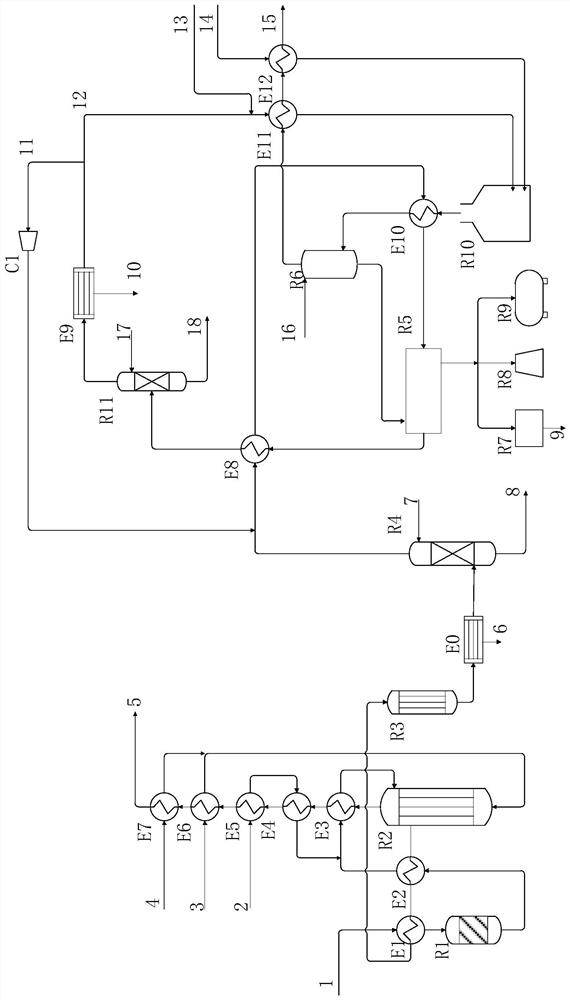

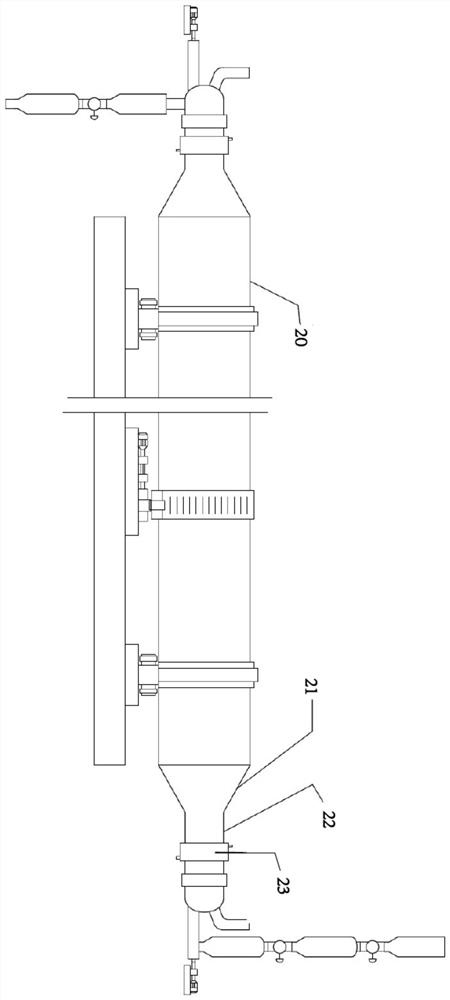

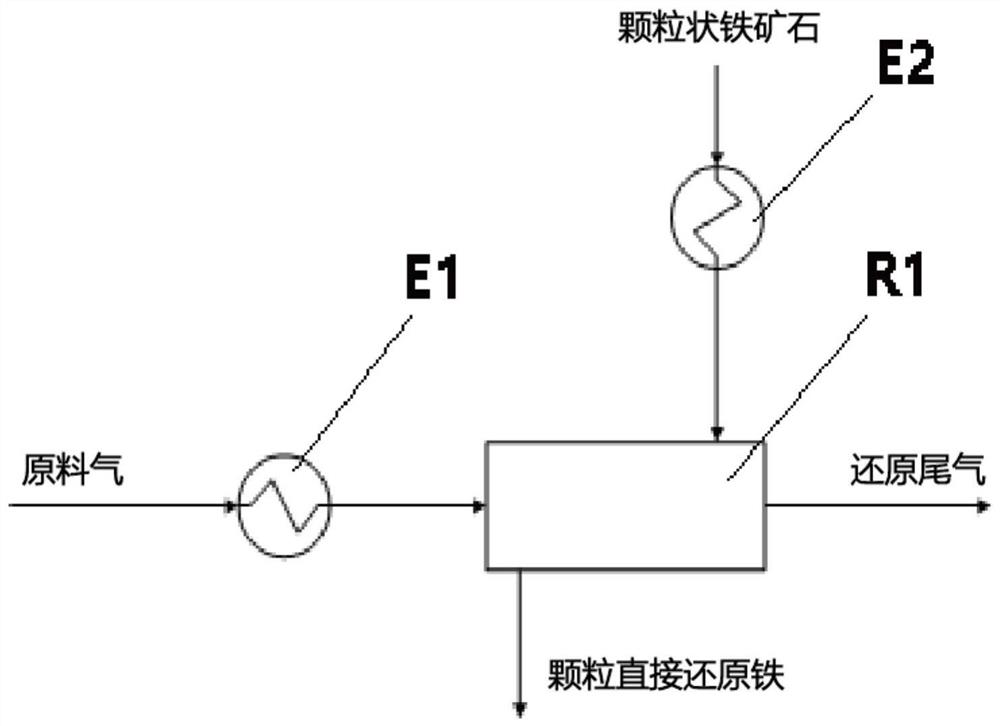

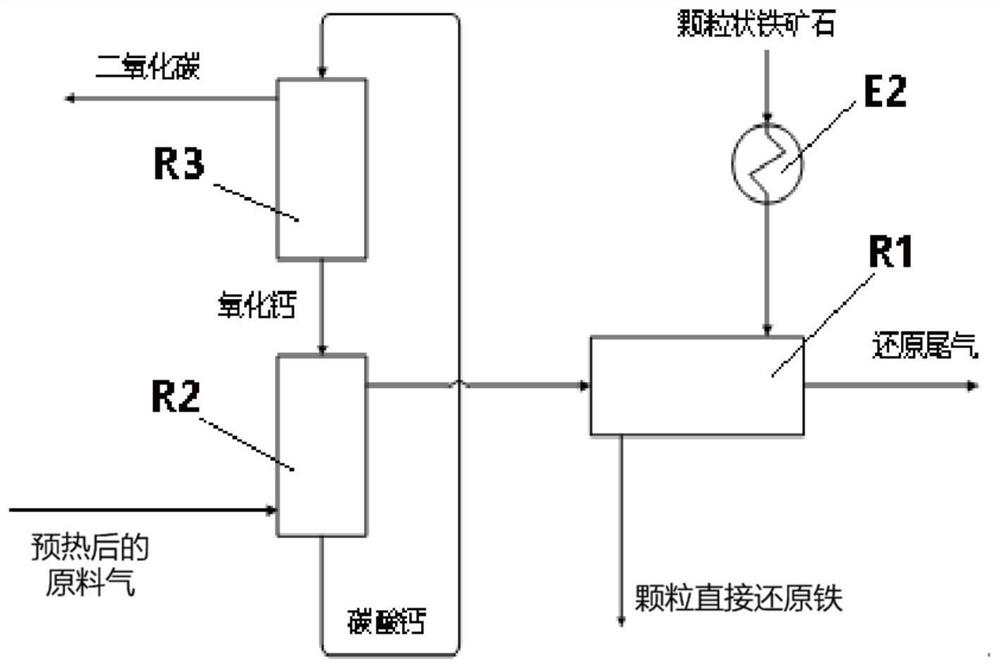

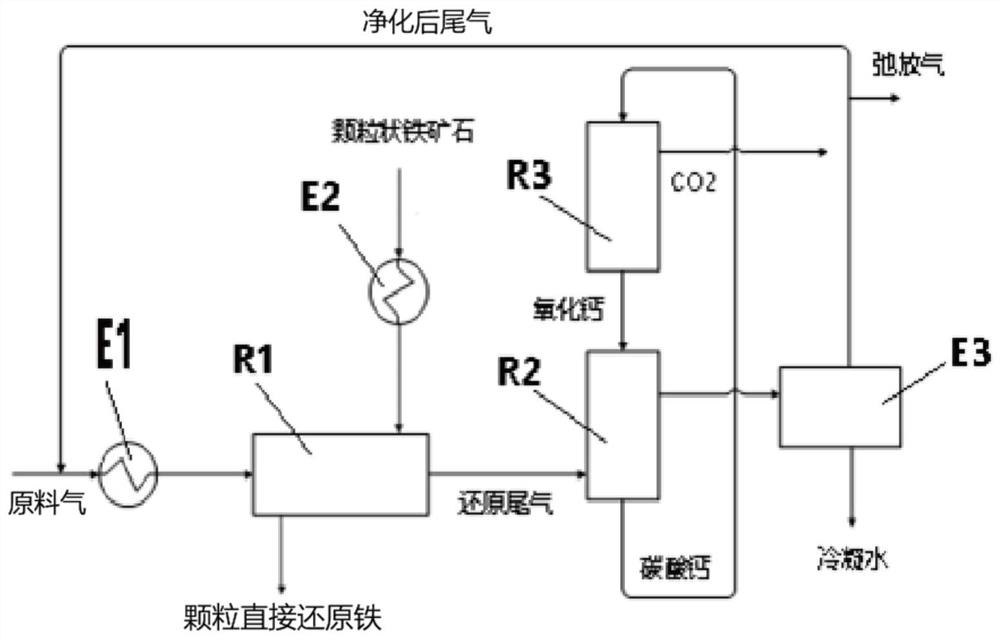

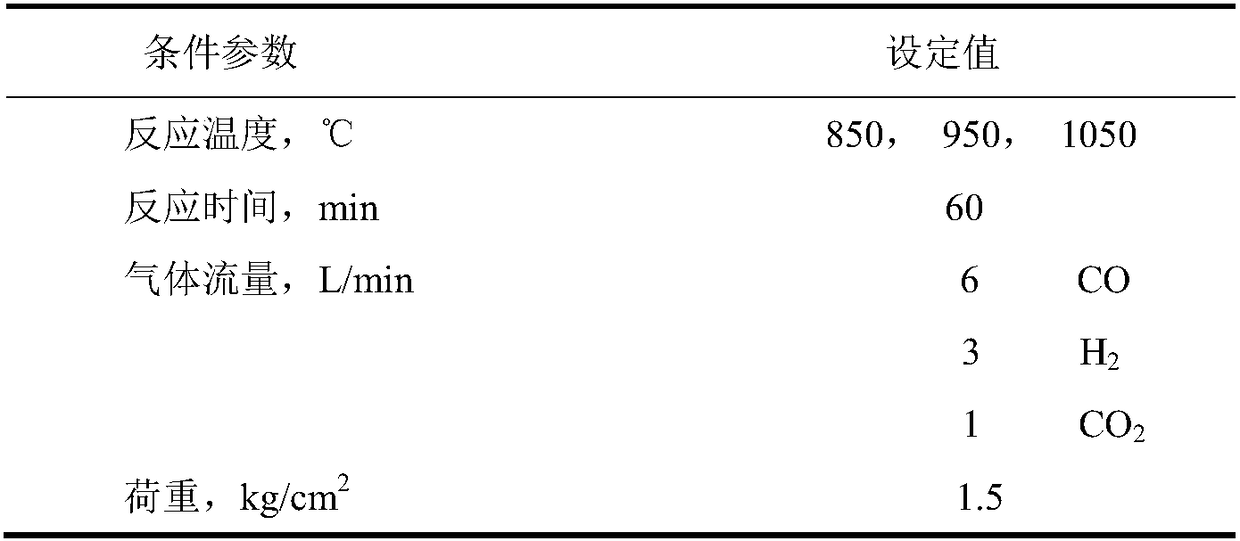

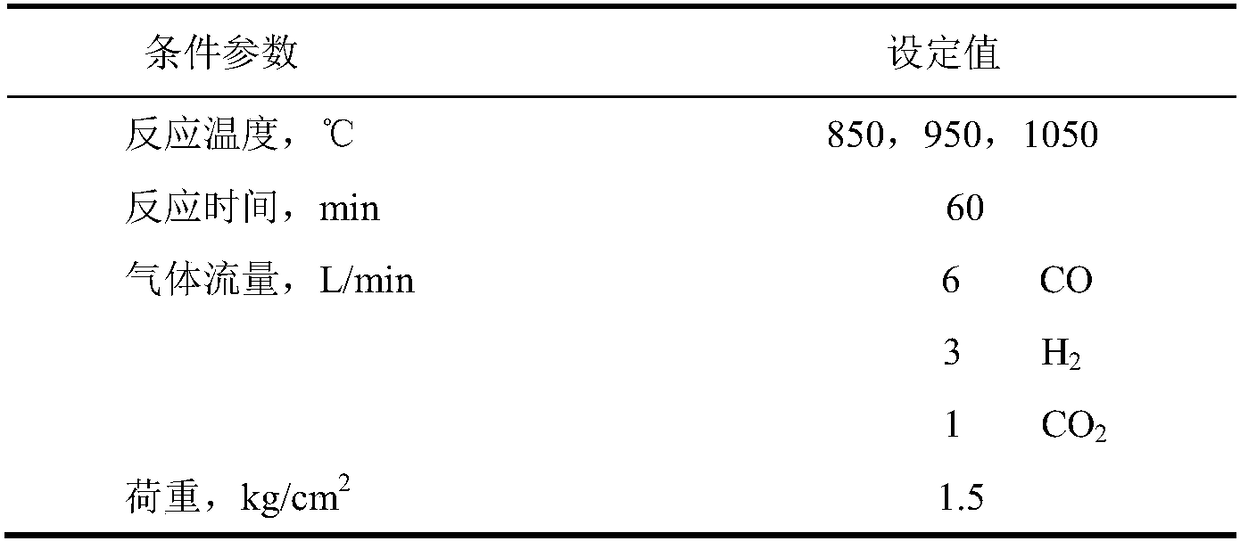

Gas-based reduction method and system for granular iron ore and application

PendingCN113373273AReduce chance of stickingSmall reduction reaction rateHydrogenRotary drum furnacesCo2 removalSteam reforming

The invention provides a gas-based reduction method and system for granular iron ore and application, and relates to the technical field of smelting. According to the gas-based reduction method, pure oxygen and high-calorific-value fuel gas are not needed, natural gas is used as a raw material, compressed natural gas is converted into hydrogen-rich gas through desulfurization, steam reforming, shift reaction, first dehydration treatment and first CO2 removal treatment, the hydrogen-rich gas is preheated to be in countercurrent contact with the granular iron ore with a specific particle size and a specific preheating temperature to conduct a reduction reaction so as to prepare the granular directly reduced iron; and due to the fact that the particle size of the granular iron ore is small, the reduction reaction speed at the same temperature is higher than that of traditional pellets, other binders and sintering processes do not need to be introduced, pollution is greatly reduced, meanwhile, the granular iron ore at the specific preheating temperature and the hydrogen-rich gas are directly subjected to the reduction reaction, and the reduction reaction at low temperature is realized by utilizing the heat of the granular iron ore and the hydrogen-rich gas.

Owner:北京金博威科技有限公司

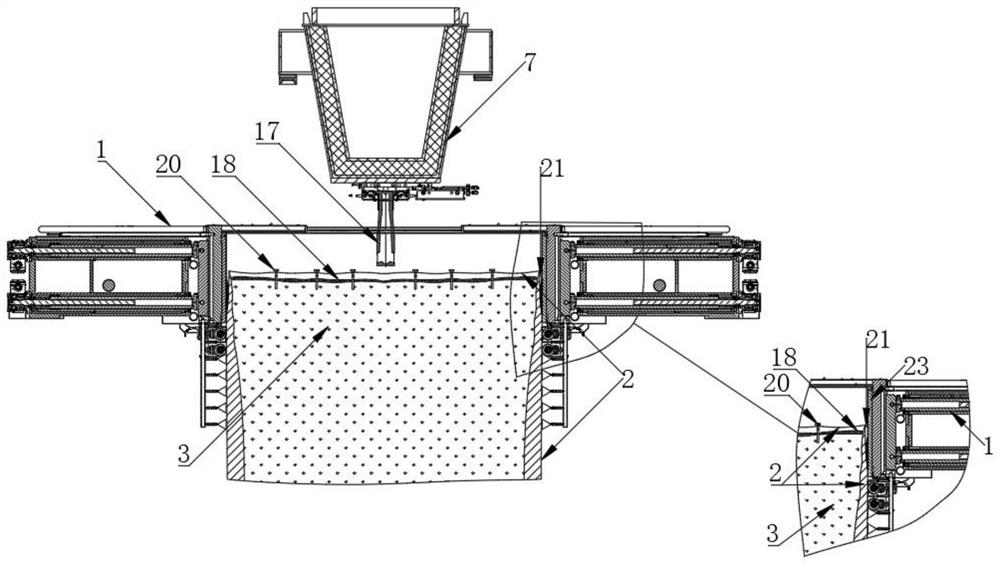

Method for rapidly replacing online tundish of ultra-wide thin slab continuous casting machine

The invention discloses a method for quickly replacing an online tundish of an ultra-wide thin slab continuous casting machine, which comprises the following specific steps: before replacing the tundish, controlling the thickness of a covering slag layer in a crystallizer, cleaning sintered slag blocks in the covering slag layer, and cleaning up covering slag strips attached to the wall of the crystallizer; before the tundish is replaced and after the steel ladle is closed, along with continuous descending of molten steel in the old tundish, the pulling speed is controlled to descend, and secondary cooling water weak cooling control is carried out in the pulling speed control process; after the tundish is replaced, the pulling speed is controlled to be increased, and secondary cooling water is controlled to be normally cooled; the first preheating position new tundish and the pouring position old tundish are switched by starting the first tundish trolley and the second tundish trolley, meanwhile, the first tundish trolley is driven to the pouring position from the first preheating position, the method is suitable for a continuous casting machine, and rapid and safe replacement of the ultra-wide sheet billet tundish can be effectively achieved through the method.

Owner:ANYANG IRON & STEEL

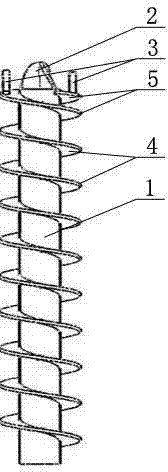

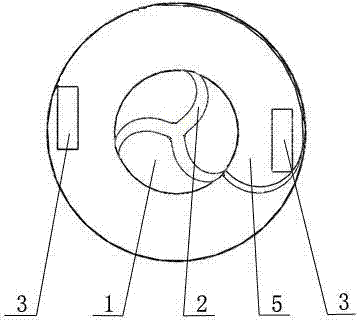

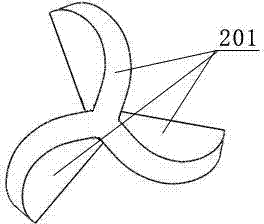

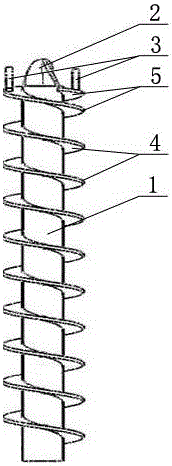

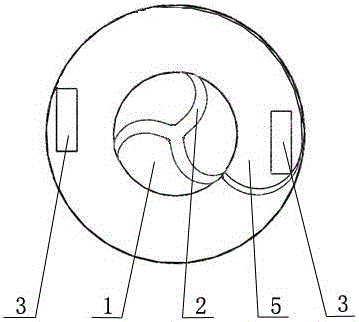

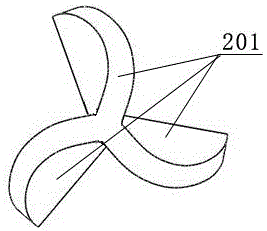

Drill bit of variable-curvature screw pile driver

The invention provides a drill bit of a variable-curvature screw pile driver. The drill bit comprises a drill stem, a drill point, a screw blade and a drill pick; the curved surfaces of the two sides of the drill pick are an inner soil contacting curved surface and an outer soil contacting curved surface, respectively; the profile curve of the inner soil contacting curved surface of the longitudinal section of the drill pick and the profile curve of the outer soil contacting curved surface of the same conform to different equations, respectively; the drill point is composed of three drill point base bodies which are symmetrical to each other about the center of circle of an end face, going into soil, of the drill stem. The drill bit of the variable-curvature screw pile driver has the advantages that the equation curves adopted by the drill bit are optimized based on tests, the bionic curves applied to the inner and outer soil contacting curved surfaces are derived from cock toe soil contacting curved surfaces, the inner and outer soil contacting profile curves of the cock toes have excellent soil resistance reduction and desorption capability, and once the structures are applied to the drill pick part of the drill bit of the pile driver, the pile driver is enabled to have excellent soil excavation capability, and meanwhile, the soil resistance to the drill bit is also reduced, and therefore, the service life of the drill bit can be prolonged and the working efficiency of the drill bit can be improved.

Owner:HENAN UNIV OF SCI & TECH

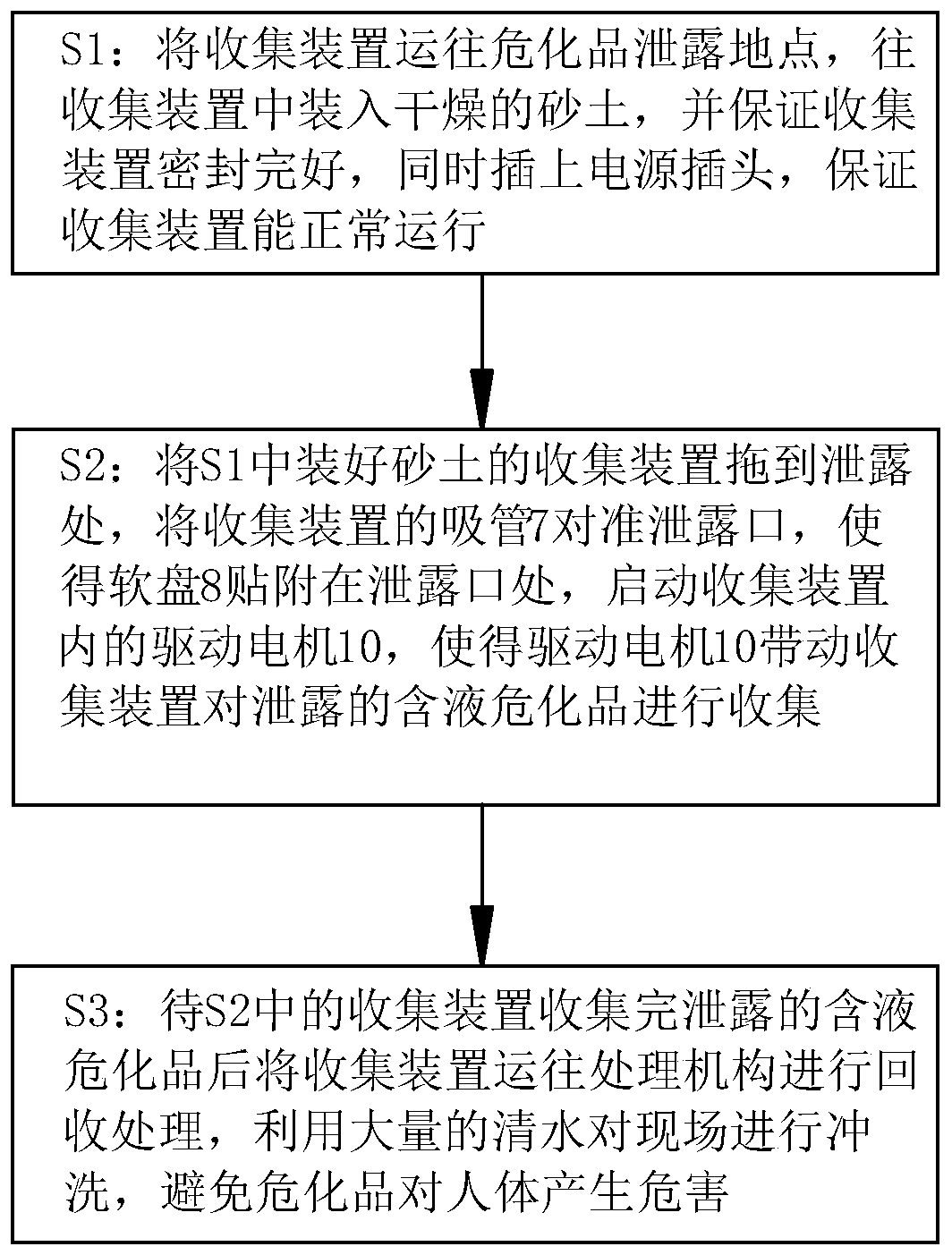

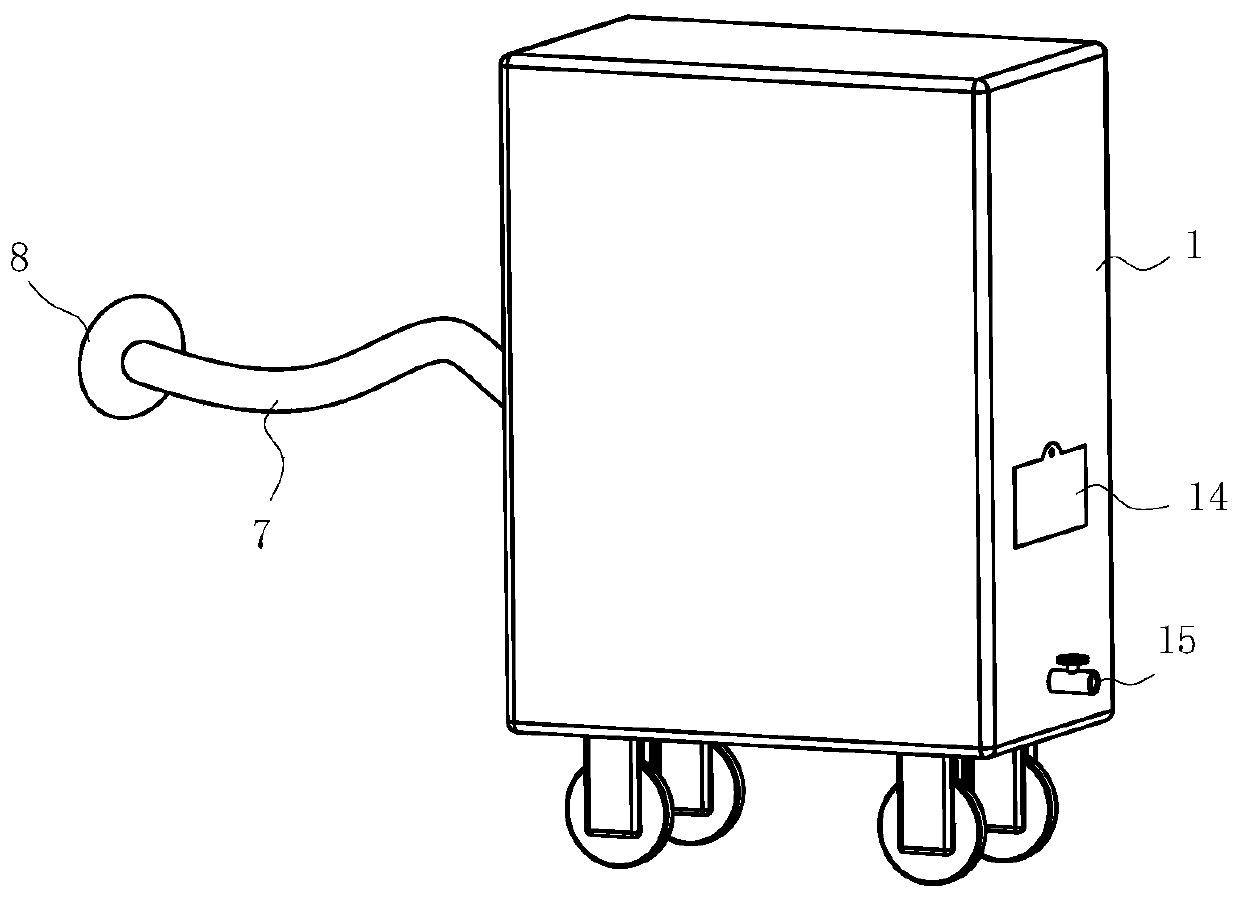

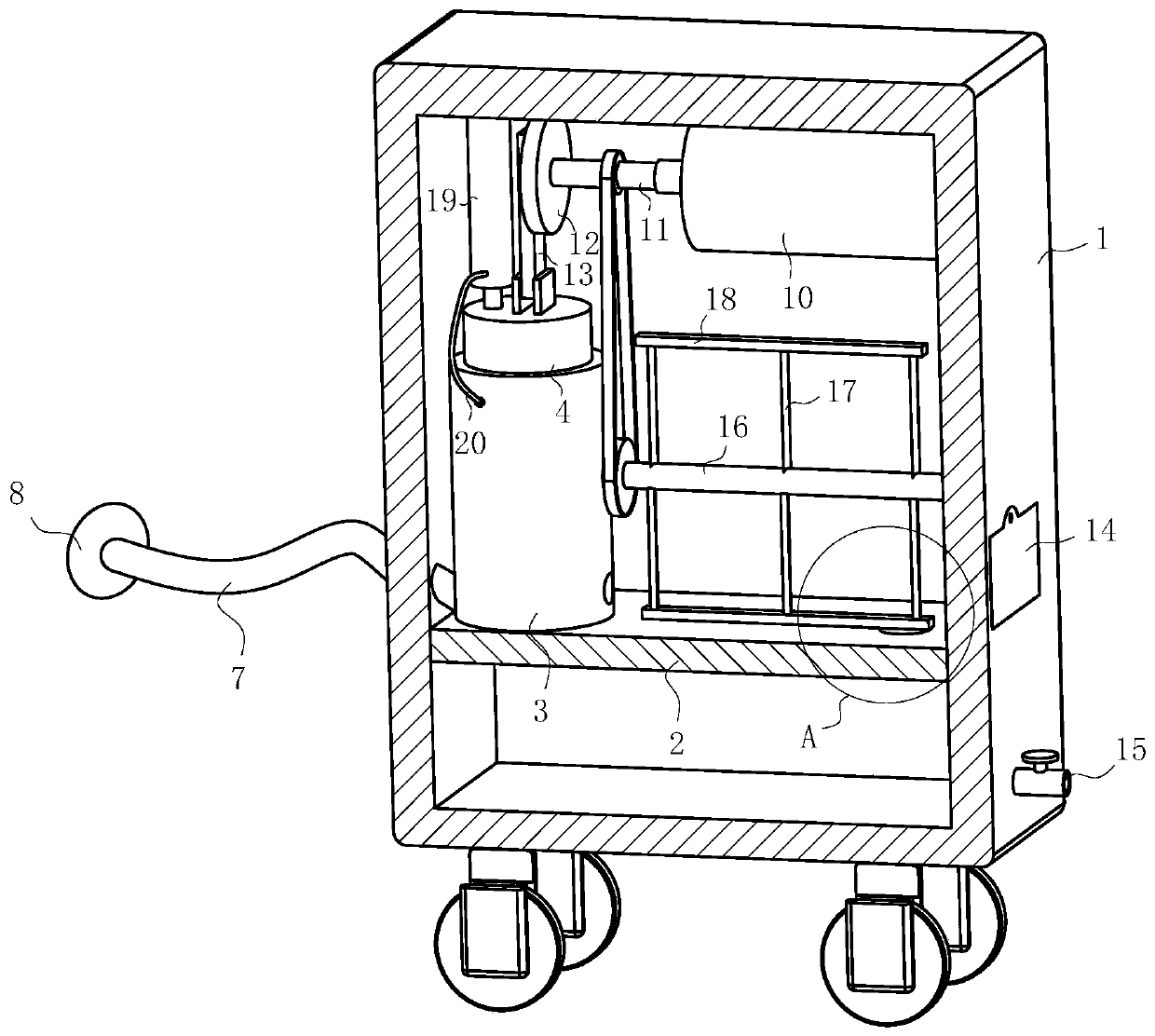

Liquid-containing hazardous chemical substance treatment method

InactiveCN111422528AImprove processing efficiencyExpand the scope of processingRefuse receptaclesStrawEnvironmental engineering

The invention belongs to the technical field of hazardous chemical substance treatment, and particularly relates to a liquid-containing hazardous chemical substance treatment method. A collection device used in the method comprises a box, a partition plate is arranged at the bottom of an inner cavity of the box body, the upper space of the box body is used for storing sandy soil, a sleeve is fixedto the top end of the partition plate, a piston is movably mounted within the sleeve, the bottom of the sleeve is provided with a first hole and a second hole, a first one-way valve is fixed in the first hole, a second one-way valve is fixed in the first hole, a straw is fixed at the first hole, the straw extends to the outside of the box body, and a soft disc is fixed to the free end of the straw. A third hole is formed in the partition plate, the third hole is formed in the end, far away from the sleeve, of the partition plate, and a third one-way valve is fixed in the third hole. Accordingto the method, leaked liquid-containing hazardous chemical substances are collected through the arrangement of the collection device, liquid can be absorbed, gas hazardous chemical substances also can be absorbed, and therefore the treatment efficiency and the treatment range of the hazardous chemical substances are improved.

Owner:淮南德元化工科技有限公司

Material for inhibiting biological attachment and preparation method thereof

InactiveCN111286119APlay an inhibitory roleImprove water vapor barrier performanceActive agentMechanical equipment

A material for inhibiting biological adhesion at least comprises the preparation raw materials: resin, a functional material and an active material; the functional material at least comprises an antibacterial composition and salt, and the active material at least comprises a nonionic surfactant. The invention further provides an application of the material for inhibiting biological adhesion in thefields of transportation, constructional engineering, mechanical equipment and packaging engineering.

Owner:上海膜益信息科技有限公司

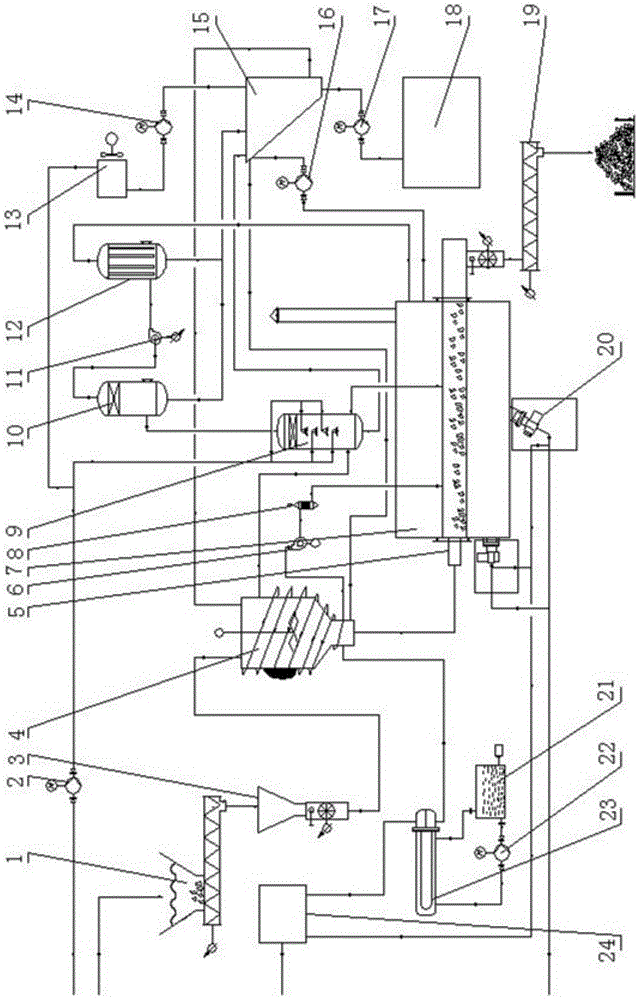

Efficient sludge treatment system

ActiveCN105152503BLow TPH contentReduce viscosityCombination devicesSludge treatment by de-watering/drying/thickeningCombustion chamberOil sludge

The invention discloses an efficient treatment system of oil sludge. The TPH (total petroleum hydrocarbons) content of the oil sludge treated is less than 1%. The oil sludge enters a dryer with a stirrer and an outer heating coil and is subjected together with hydrogen separated by a nitrogen making machine, to heat exchanging via heat transfer oil, a resulting product is subjected with oil sludge directly to convection drying, cracking heat of a thermal desorption unit performs on indirect heating on the oil sludge through the outer heating coil of the dryer, viscosity of the oil sludge is decreased after free water, interstitial water and part of light gases are removed, chances that the oil sludge cake in the heat desorption unit are also slimmed, and long-term running of the thermal desorption unit is guaranteed; the dryer with the stirrer and the outer heating coil uses the cracking heat of the thermal desorption unit, thus energy is saved; gases subjected to oil removal, dust removal and odor removal are used as fuels for a combustor, thus energy is saved; high-hydrogen gas from the dryer with the stirrer and the outer heating coil separates oil and water through bubbles generated by an air flotation machine, oil-water separation is efficient, and the separated oil is used as a fuel for the combustor, thus energy is saved.

Owner:大连爱德摩设备制造有限公司

Desilting device for aquaculture fish pond and working method thereof

ActiveCN108086384BSmooth steeringEffectively disperseMechanical machines/dredgersMarine engineeringSludge

Owner:嘉兴金旅燕科技有限公司

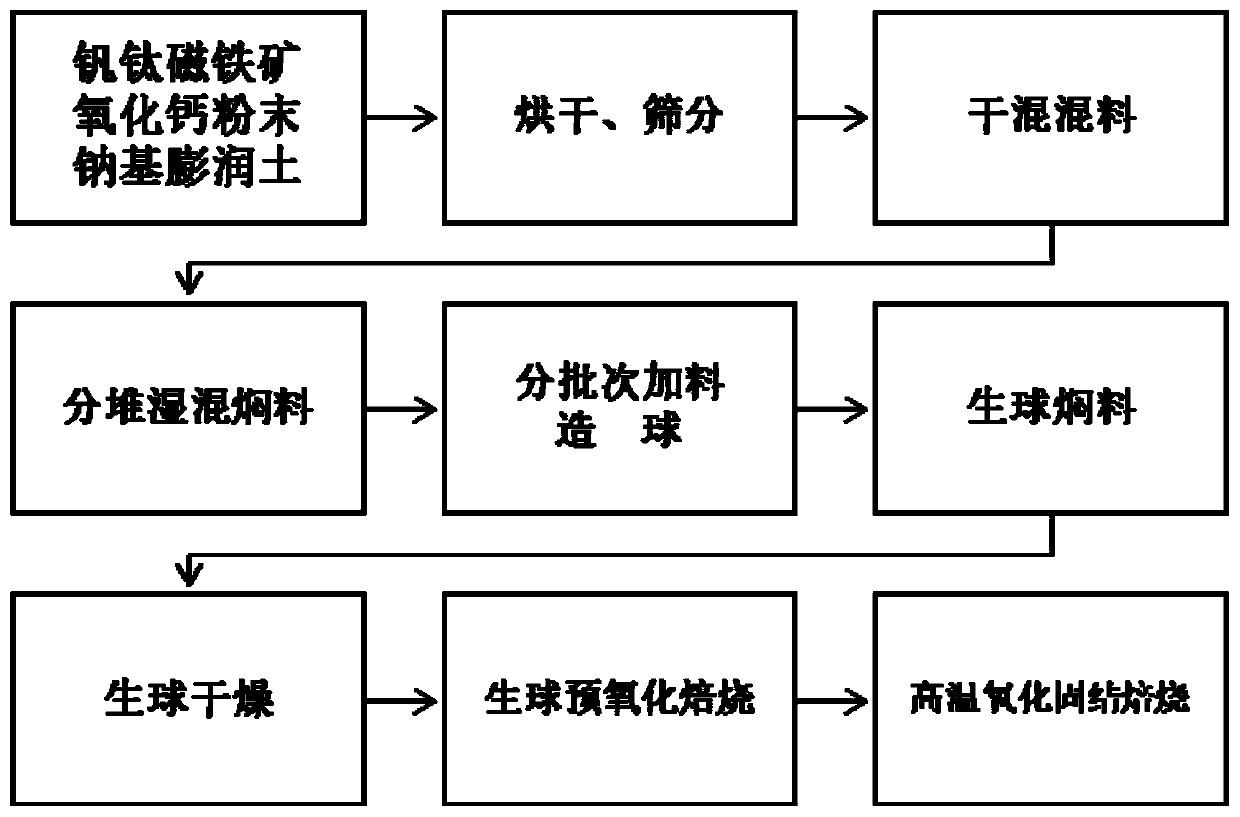

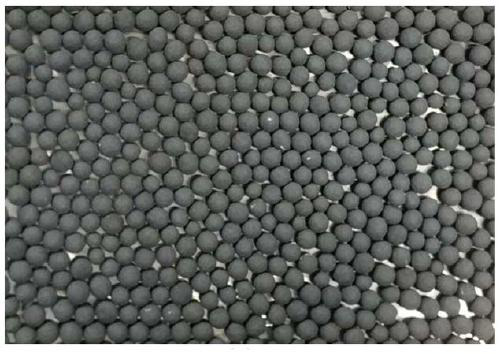

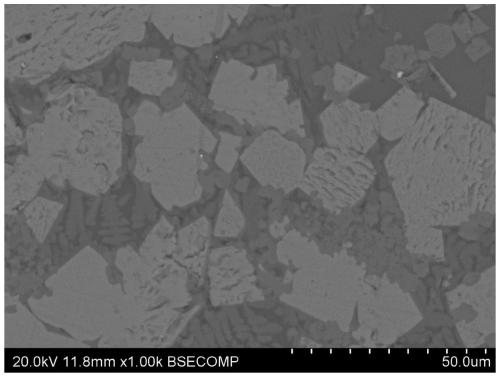

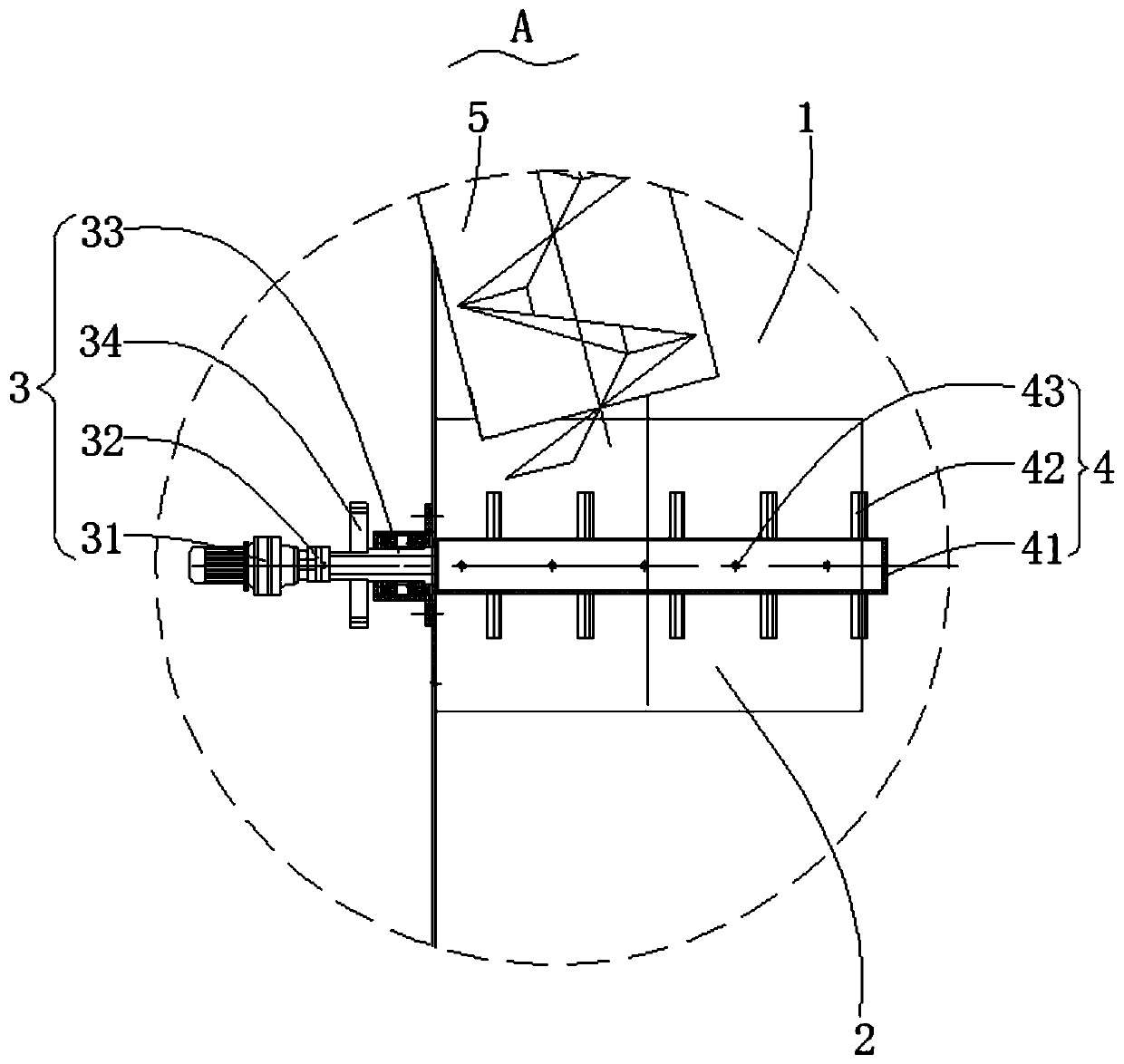

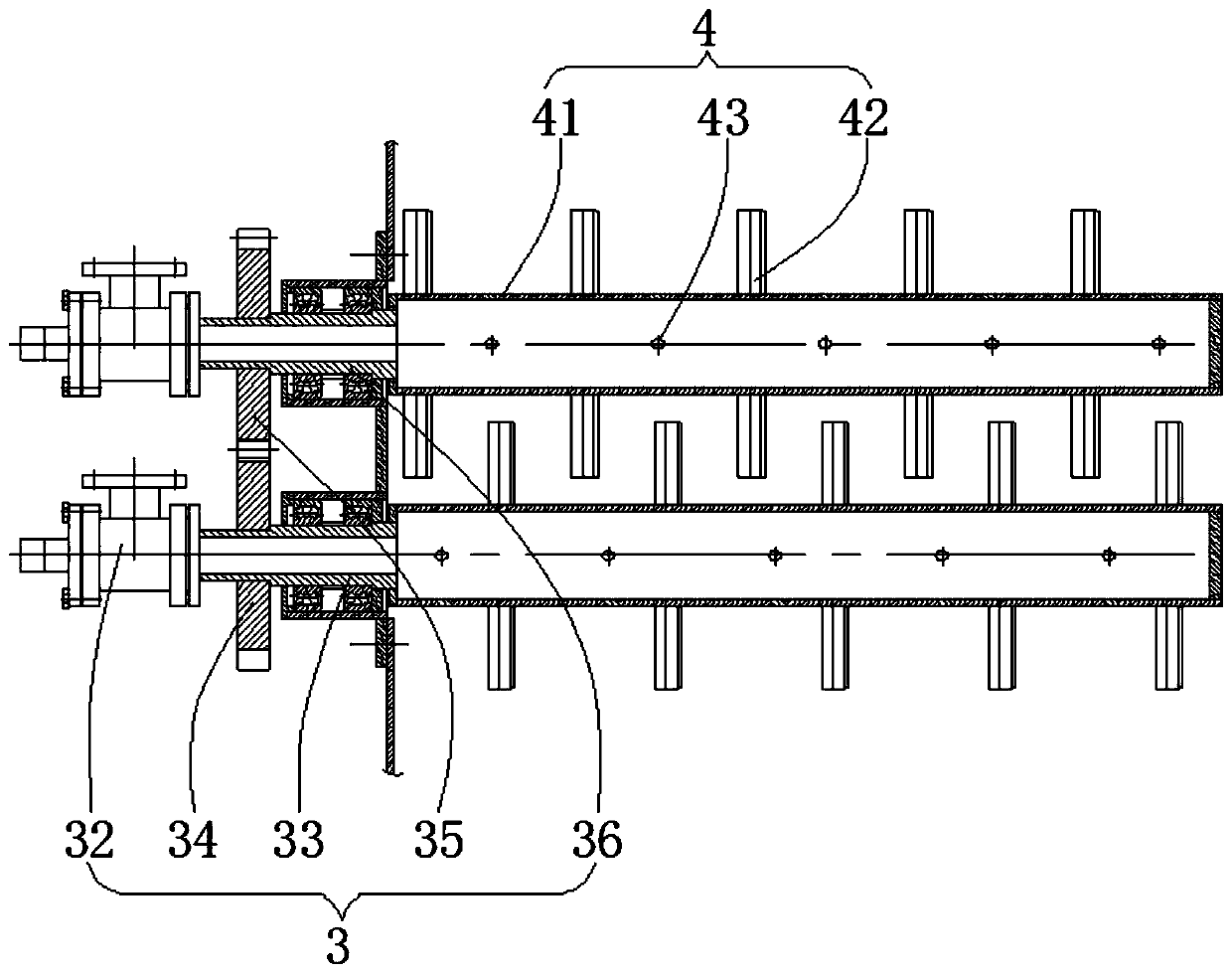

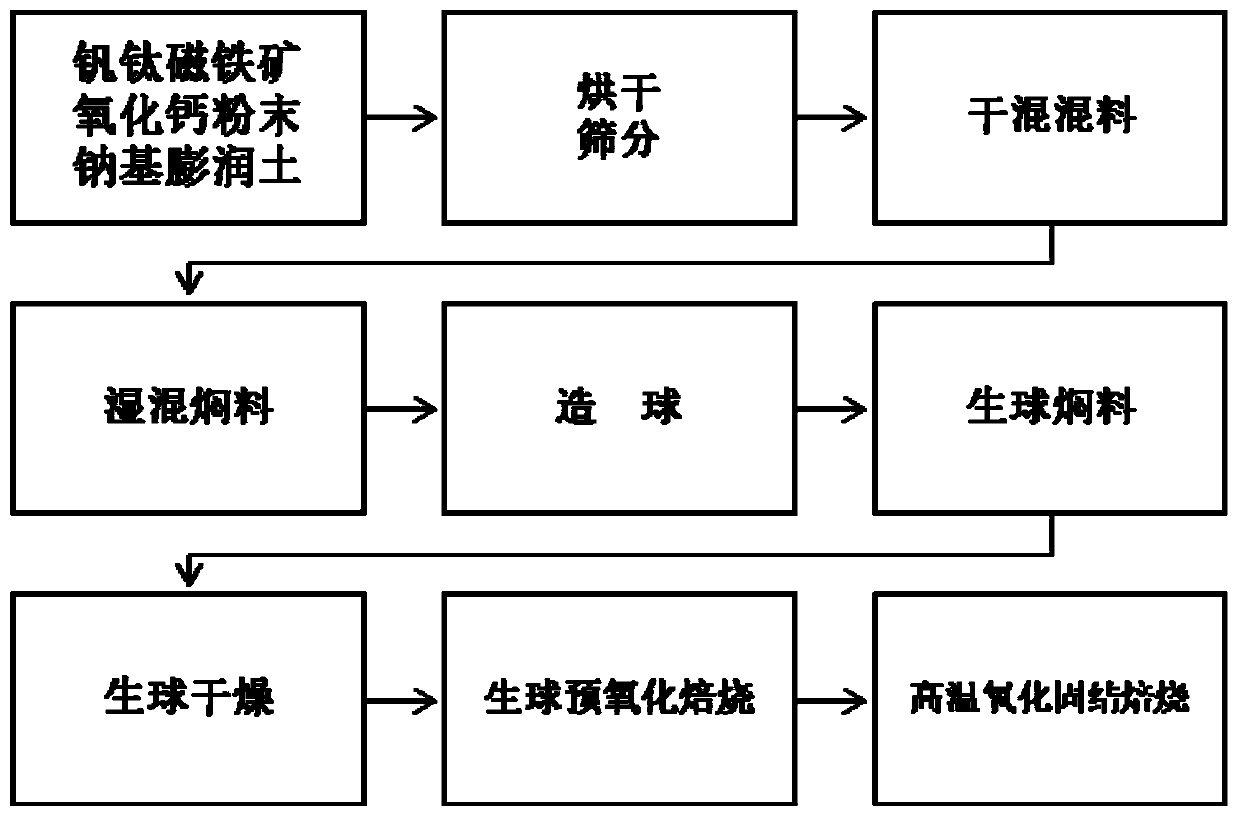

A method for preparing high-basic chromium-vanadium-titanium pellets by using calcium oxide

The invention relates to a method for preparing high-alkalinity chromium-containing vanadium-titanium pellets by using calcium oxide. The method is to batch raw materials including vanadium-titanium magnetite and additives calcium oxide powder and sodium bentonite so that the alkalinity is 1.8 ~2.1, dry and dry mix the materials respectively; divide the mixed mineral materials into two parts evenly, add 3~4% water of the total mass of raw materials to the first part, and add 6~4% of the total mass of raw materials to the second part 8% water, mix evenly, seal and let stand; when making balls, use the first part of the mineral powder during the cue ball forming period, and the second part of the mineral powder for the long term when the cue ball grows. Spray before the cue ball grows. The amount of water is controlled at 1ml / 10g mineral powder ~ 2ml / 10g mineral powder to prevent adhesion between the cue balls, and the interval between each water addition and feeding is 40 to 90 seconds, so that the diameter of the produced pellets is within 8mm ~ 12mm; Carry out green pellet stewing, drying, pre-oxidation roasting, and secondary high-temperature oxidation roasting to obtain high-alkalinity chromium-containing vanadium-titanium pellets.

Owner:NORTHEASTERN UNIV LIAONING

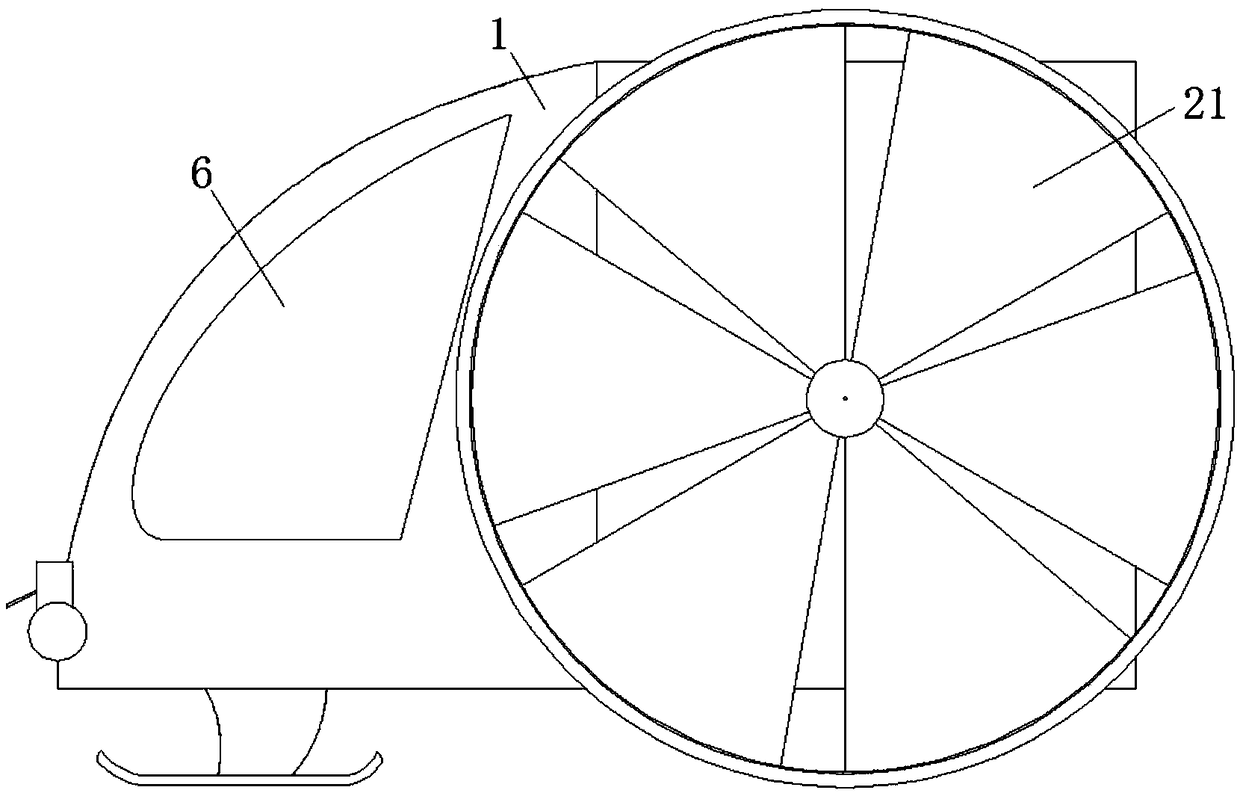

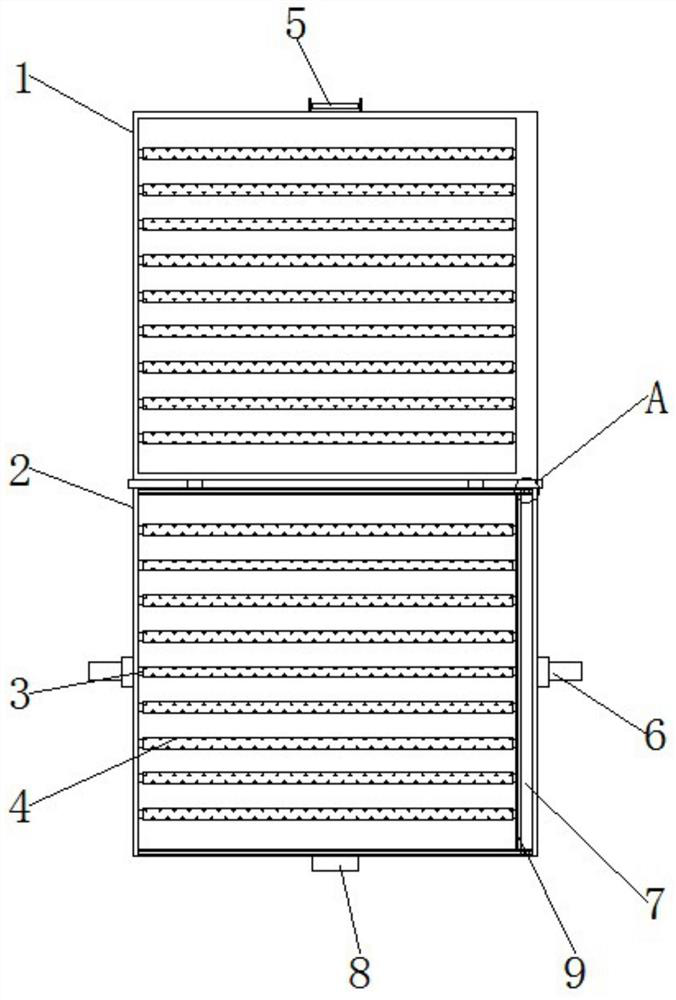

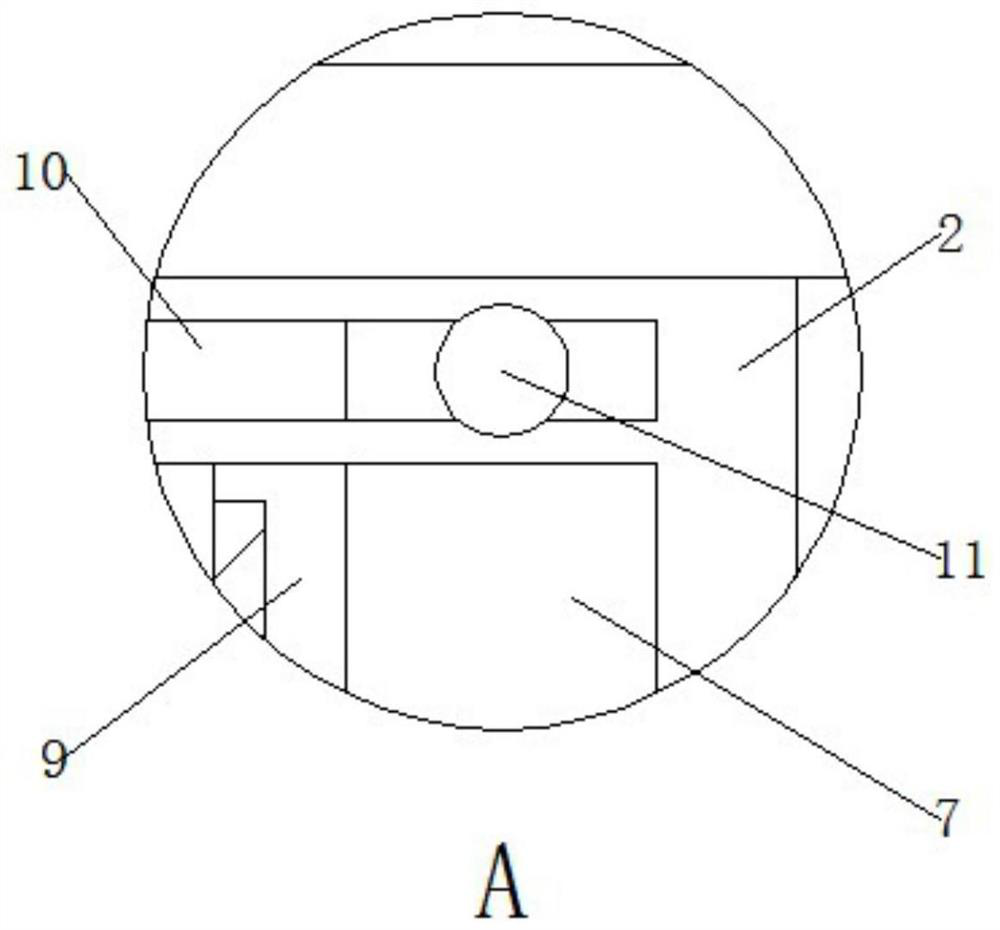

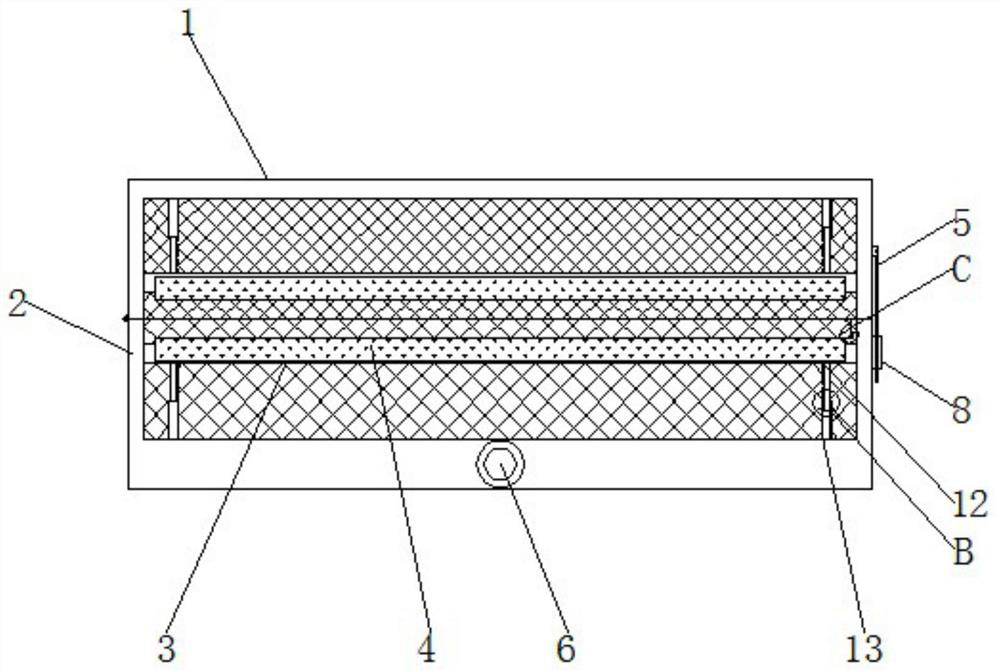

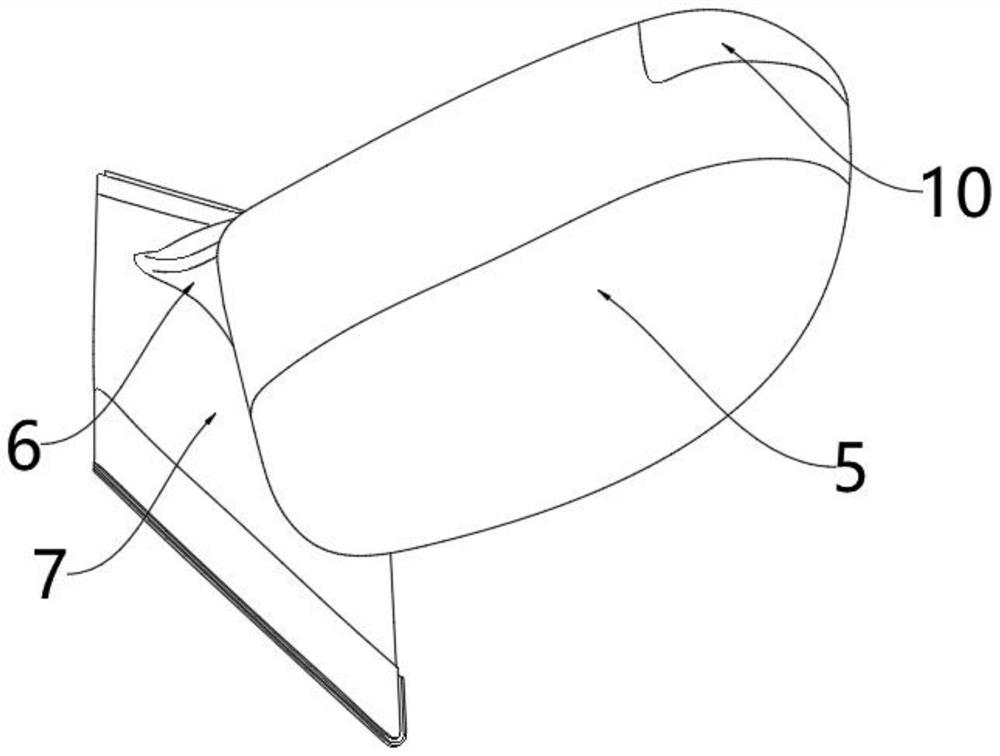

Rotary clamping plate structure for drying of oryzias latipes

PendingCN111981839AGuaranteed supportReduce chance of stickingDrying chambers/containersMeat/fish preservation by dryingPhysicsEngineering

The invention discloses a rotary clamping plate structure for drying of oryzias latipes. The rotary clamping plate structure for drying of the oryzias latipes comprises a lower clamping plate, the inner wall of the lower clamping plate is provided with sleeves, the inner walls of the sleeves are provided with second friction teeth, telescopic rods are arranged at the upper ends of the sleeves in an inserted manner, the outer walls of the telescopic rods are provided with first friction teeth, and the first friction teeth are in contact with the second friction teeth. The upper ends of the telescopic rods are provided with connecting rods, the outer walls of the connecting rods are provided with anti-sticking pads, the front end of the lower clamping plate is rotatably connected with an upper clamping plate, the inner wall of the upper clamping plate is provided with connecting rods and anti-sticking pads, the upper clamping plate is provided with a sleeve ring, and the front and rear ends of the lower clamping plate are provided with rotating shafts. According to the rotary clamping plate structure for drying of the oryzias latipes, by arranging the multiple connecting rods on theinner walls of the upper clamping plate and the lower clamping plate and adjusting the heights of the connecting rods through the telescopic rods and the sleeves, the connecting rods in a proper supporting quantity can be selected according to the size of the oryzias latipes, the probability of sticking is reduced while the supporting strength is guaranteed, and damage of the surfaces of the oryzias latipes is avoided.

Owner:蒋颖婷

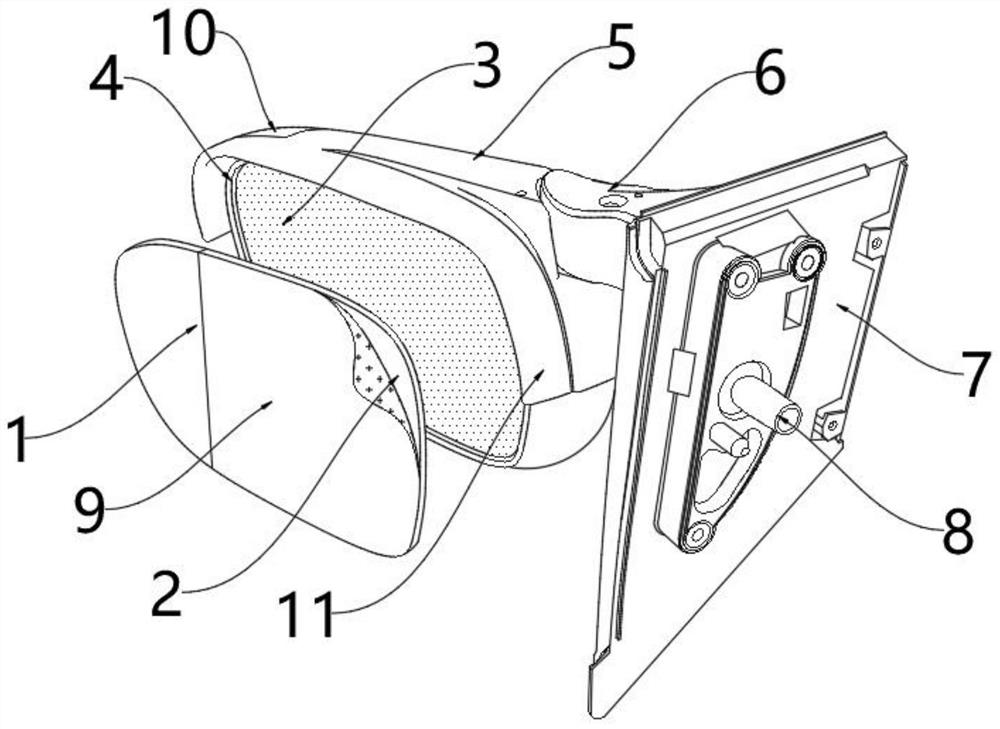

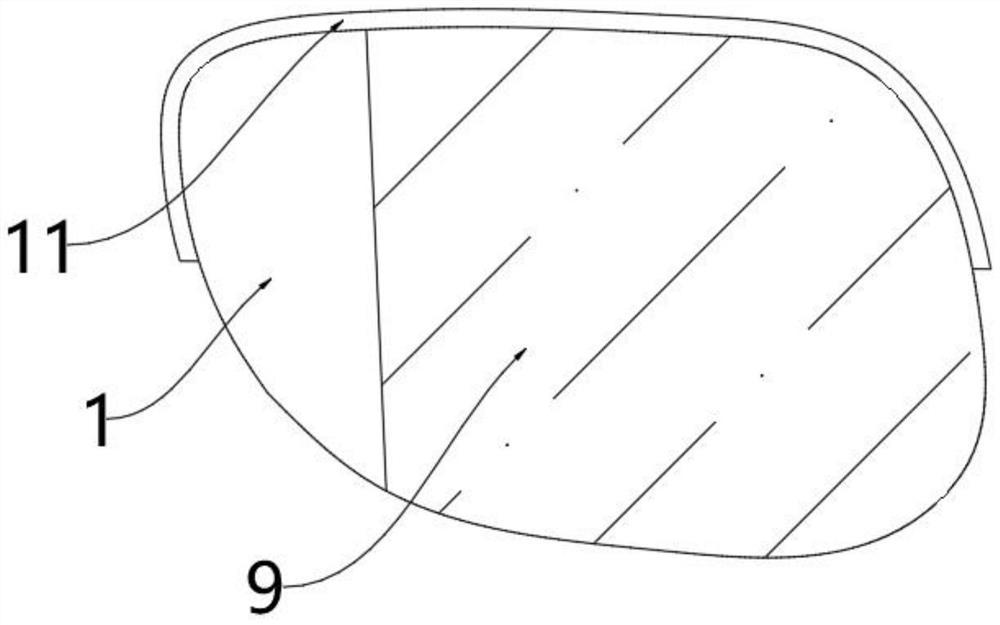

Control system for automobile electronic outside rear-view mirror

PendingCN113895356AReduce chance of stickingImprove securityVehicle cleaningOptical viewingPhysicsRear-view mirror

The invention relates to the technical field of production machinery, and discloses a control system for an automobile electronic outside rear-view mirror, the control system comprises a mounting plate, a first rotating shaft is mounted on the outer surface of the mounting plate, a shell is mounted at the top end of the first rotating shaft, and a rain baffle is fixedly mounted on the outer edge of the shell. A mirror frame is fixedly installed in the shell, a physical mirror surface is clamped in the mirror frame, a display screen is arranged on one side of the physical mirror surface, the outer surface of the physical mirror surface is coated with a hydrophobic film, a heating plate is arranged on the rear end face of the physical mirror surface, and a second rotating shaft is arranged on the rear end face of the heating plate, and a distance sensor and a temperature sensor are arranged in the shell. By arranging the warning lamp and the distance sensor, different kinds of light can be displayed in a grading mode according to the distance between the shell 5 and surrounding vehicles, so that the safety distance between the vehicle and other surrounding vehicles can be visually known, and the safety of vehicle driving is improved.

Owner:安徽光阵光电科技有限公司

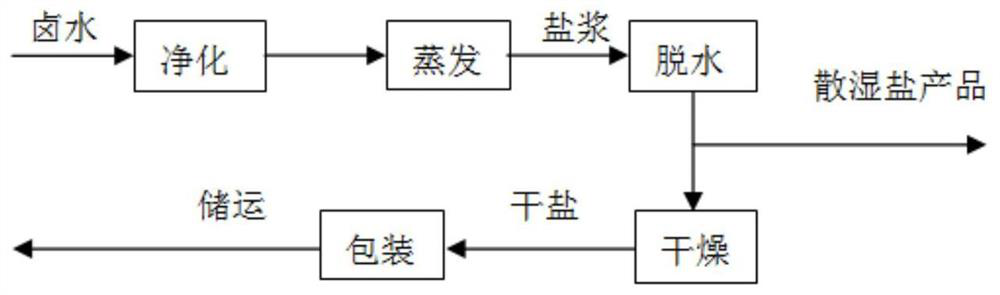

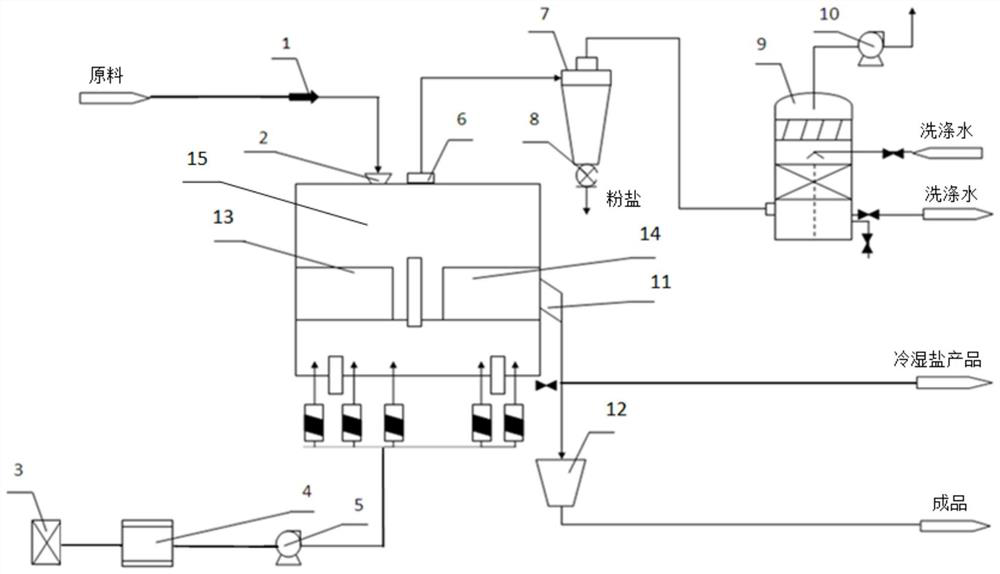

Wet salt cold drying anti-caking device and method

PendingCN113446817AAvoid cakingReduce chance of stickingDrying solid materials with heatGranular material dryingProcess engineeringAir conditioning

The invention discloses a wet salt cold drying device and method for preventing bulk salt products from caking without adding an anti-caking agent. The device comprises a fluidized bed, a material input device, an air conditioner cold dry air device and a tail gas treatment device. An original external heating type fixed boiling fluidized bed is adopted, an external heating device is omitted, a constant-temperature and constant-humidity air conditioner unit cools and dehumidifies environment air, then cold dry air directly cools and dries wet salt, and the salt product caking phenomenon caused by temperature and humidity changes is effectively avoided.

Owner:江苏苏盐井神股份有限公司

A method for preparing self-fluxing pellets of medium-low alkalinity chromium-containing all-vanadium-titanium

The invention relates to a method for preparing medium-low alkalinity chromium-containing all-vanadium titanium self-fluxing pellets, which includes the steps: S1: Ingredients: adding calcium carbonate and sodium bentonite to red grid chromium-containing vanadium titanium magnetite; Prepare a mixture with medium and low alkalinity; S2: Wet mixed stew material: add water not exceeding 7% of the mass of the mixture, mix evenly, and then let it stand to make the humidity distribution uniform; S3: Ball making: Make it in a disc The ball machine is used to make balls at a speed of 30r / min-45r / min. During the cue ball forming period, the water spray volume is controlled at 1-2ml / 10g of mineral material to fully roll and compact the mineral material; during the cue ball growth period, increase Spray the amount of water to make pellets with a diameter of 6mm-13mm; S4: Dry the green balls; S5: Place the green balls in the furnace and raise the temperature to 900℃-950℃ for calcium carbonate decomposition and pre-baking; while maintaining heat, Insufficient air is introduced into the furnace for pre-oxidation roasting, and the roasting time is 10min-20min; S6: High-temperature oxidation consolidation roasting: Injecting incremental air into the furnace at 1250℃-1300℃ to increase the oxidizing atmosphere, and perform high-temperature oxidation After consolidation and roasting, and then cooling to room temperature, medium-low basicity chromium-containing all-vanadium-titanium self-fluxing pellets are obtained.

Owner:NORTHEASTERN UNIV LIAONING

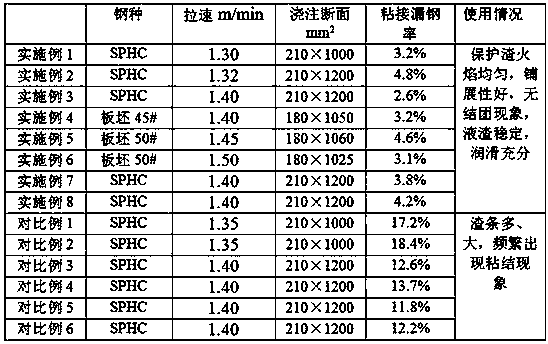

A continuous casting mold powder for reducing bonding breakout and preparation method thereof

ActiveCN106583673BOptimize chemical compositionReduce bonding breakout rateAlkalinityChemical composition

The invention discloses a continuous-casting mold flux for decreasing sticking steel breakouts and a preparation method thereof. The continuous-casting mold flux for decreasing the sticking steel breakouts comprises the following chemical components of, by weight, 32.5-35.5 percent of SiO2, 29.5-31.5 percent of CaO, 1.5-3.0 percent of MgO, 2.2- 3.0 percent of Al2O3, 0.5-1.5 percent of Fe2O3, 11.0-13.0 percent of Na2O, 10.0-12.0 percent of F-, 3.0-4.0 percent of C solid and the balance unavoidable impurity, wherein the binary basicity is 0.87 to 0.93; a melting point is 1050 to 1070 DEG C; and the viscosity below 1300 DEG C is 0.115Pa*S to 0.135Pa*S. In the practical application of the mold flux, a flame in a crystallizer is uniform; the spreadability is better; caking and agglomerating phenomena do not exist; a melt cinder is stable; the lubrication is sufficient; and the rate of the sticking steel breakouts can be decreased to below 5 percent from original 10 to 20 percent.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

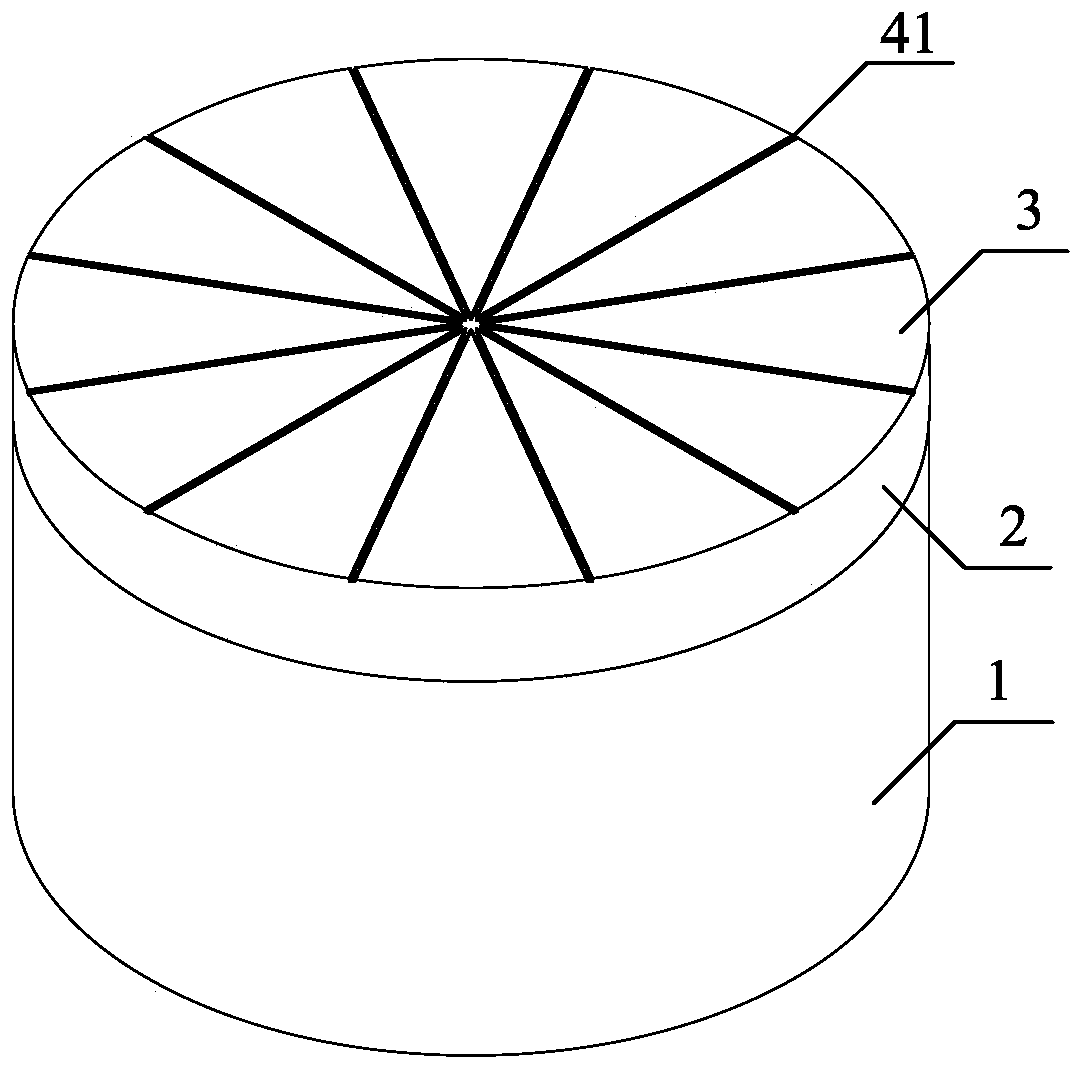

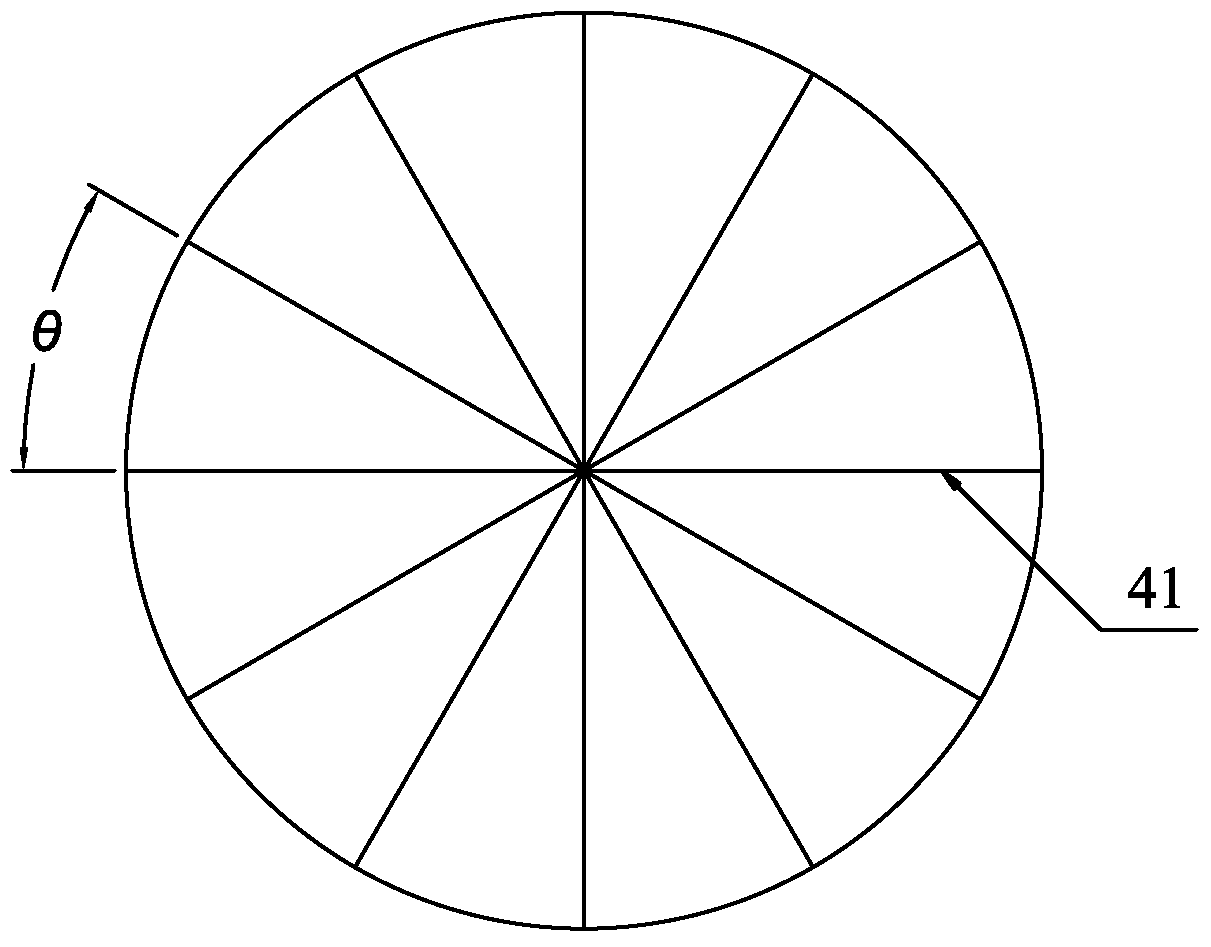

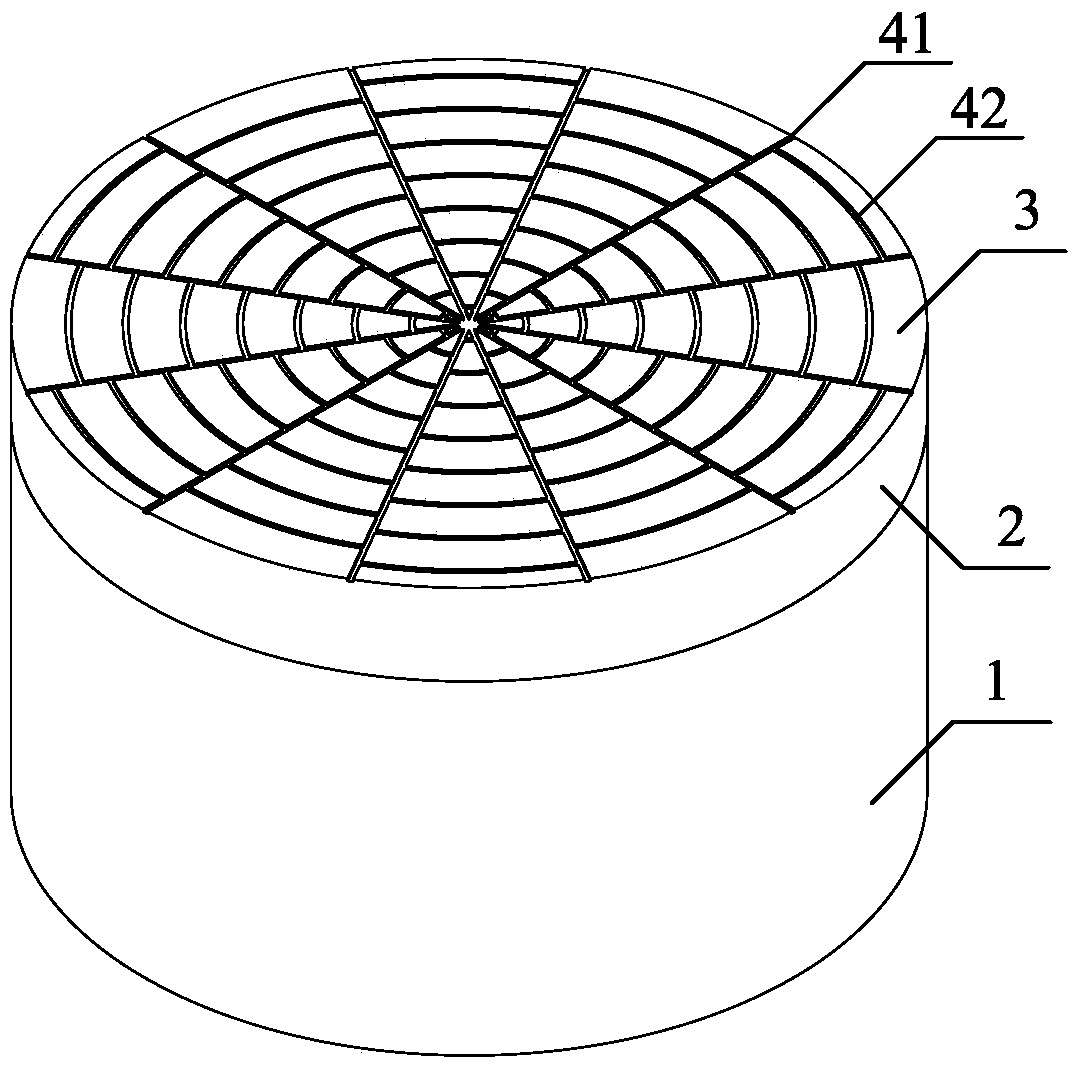

Polycrystalline diamond compact with anti-adhesion properties

The invention discloses a polycrystalline diamond composite sheet with anti-adhesion properties, which comprises a cemented carbide substrate and a polycrystalline diamond layer compounded thereon, and a groove structure is arranged on the blade surface of the polycrystalline diamond layer; the groove The groove structure includes several radial grooves arranged radially along the radial direction of the blade surface, which divide the blade surface into several sectors, and several arc-shaped circumferential grooves connected with the radial grooves , a number of circumferential grooves are concentrically distributed with the center of the blade face as the center of a circle, and the circumferential grooves of adjacent sectors are arranged alternately. The polycrystalline diamond composite sheet with anti-adhesion characteristics of the present invention has a large number of grooves on the blade surface, so that the contact area between the cuttings and the blade surface is small, and the adhesion is reduced; drilling fluid can enter the grooves, lubricate On the face of the composite blade, the cuttings can be carried by the drilling fluid out of the bottom of the well, thus avoiding the adhesion and accumulation of the cuttings in front of the composite blade, fundamentally preventing the formation of the bag of PDC bit.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

A variable curvature screw pile driver drill bit

The invention provides a drill bit of a variable-curvature screw pile driver. The drill bit comprises a drill stem, a drill point, a screw blade and a drill pick; the curved surfaces of the two sides of the drill pick are an inner soil contacting curved surface and an outer soil contacting curved surface, respectively; the profile curve of the inner soil contacting curved surface of the longitudinal section of the drill pick and the profile curve of the outer soil contacting curved surface of the same conform to different equations, respectively; the drill point is composed of three drill point base bodies which are symmetrical to each other about the center of circle of an end face, going into soil, of the drill stem. The drill bit of the variable-curvature screw pile driver has the advantages that the equation curves adopted by the drill bit are optimized based on tests, the bionic curves applied to the inner and outer soil contacting curved surfaces are derived from cock toe soil contacting curved surfaces, the inner and outer soil contacting profile curves of the cock toes have excellent soil resistance reduction and desorption capability, and once the structures are applied to the drill pick part of the drill bit of the pile driver, the pile driver is enabled to have excellent soil excavation capability, and meanwhile, the soil resistance to the drill bit is also reduced, and therefore, the service life of the drill bit can be prolonged and the working efficiency of the drill bit can be improved.

Owner:HENAN UNIV OF SCI & TECH

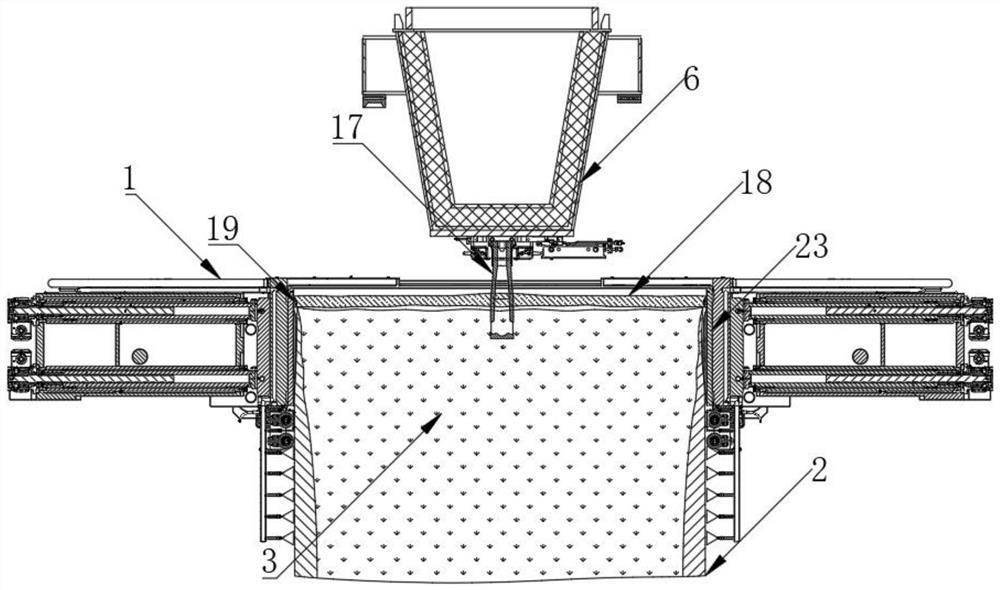

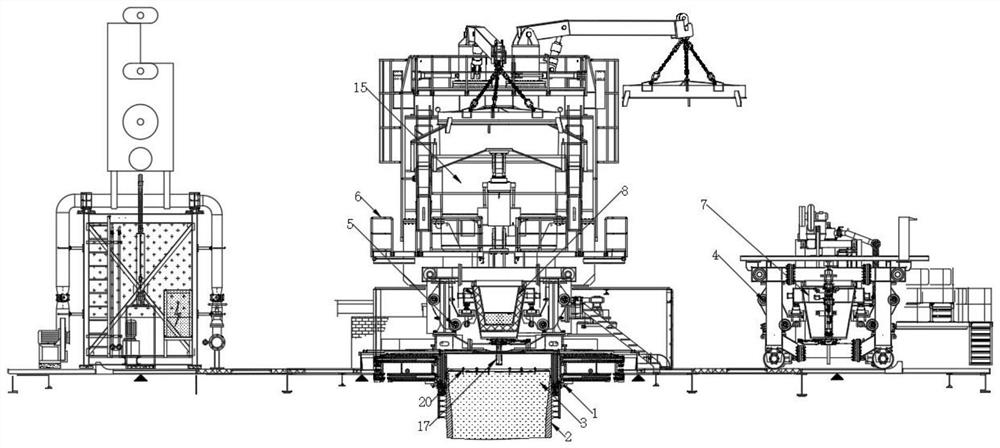

Production method, production system and application of particle direct reduced iron

PendingCN113403441AEmission reductionReduce chance of stickingFluidised-bed furnacesThermodynamicsPhysical chemistry

The invention provides a production method, a production system and an application of particle direct reduced iron, and relates to the technical field of smelting. According to the production method, granular iron ore with a specific particle size and a specific preheating temperature is subjected to countercurrent contact with feed gas at the specific preheating temperature for a reduction reaction, and the granular direct reduced iron is obtained; the particle size of the granular iron ore is small, the reduction reaction speed at the same temperature is higher than that of traditional pellets, other binders and sintering processes do not need to be introduced, energy consumption and pollution are greatly reduced, meanwhile, the granular iron ore at the specific preheating temperature and feed gas are directly subjected to the reduction reaction, the reduction reaction at low temperature is realized by utilizing the heat of the material, and the low-temperature reduction reaction does not need a special high-temperature-resistant material, so that the bonding probability of the particle direct reduced iron in the reduction process is reduced; and the average flow velocity of the specific feed gas is adopted, so that the feed gas can be in full contact with the granular iron ore, and the utilization efficiency of the feed gas is greatly improved.

Owner:北京金博威科技有限公司

Coating material for inhibiting excessive bonding of iron ore pellets in smelting reduction and preparation method thereof

ActiveCN106222350BInhibit excessive bondingFully contactedShaft furnaceCelluloseCarboxymethyl cellulose

The invention discloses a coating material for inhibiting excessive bonding of iron ore pellets in smelting reduction and a preparation method thereof, belonging to the technical field of smelting reduction ironmaking. The coating material of the present invention is composed of the following components in weight percentage: 83-95% of high melting point inorganic materials, 2-8.5% of waste plastics, 0.2%-3% of sodium carboxymethyl cellulose, 1.2%-4.5% of starch, Calcium lignosulfonate 0.1%-2.5%; the preparation method of the coating material of the present invention comprises the following steps: coating raw material pretreatment, coating material preparation, coating material coating and drying. The coating material of the present invention can effectively inhibit the excessive bonding between iron ore pellets in the pre-reduction process of the smelting reduction ironmaking process, and the coating material and the iron ore pellets are closely combined, which can effectively prevent the coating from cracking and falling off, and at the same time ensure The metallization rate of the reduced product is at a high level.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

A method for preparing high-basicity chromium-containing all-vanadium-titanium pellets by adding calcium carbonate

The invention relates to a method for preparing high alkalinity chromium-containing all-vanadium titanium pellets by adding calcium carbonate, which includes the steps: S1: Ingredients: adding calcium carbonate and sodium bentonite ingredients to the red grid chromium-containing vanadium titanium magnetite; S2: Divide the mixture into two parts. Add 3-4% of the mass of water to the first part and 6-8% of the mass of the material to the second part. Wet mix them separately and let them stand for stewing; S3 : Material separation and pelletizing: Make balls on the disc pelletizing machine at a speed of 30‑45r / min. The water spray volume is controlled at 1‑2ml / 10g of mineral material. The interval between adding water and materials is 30s‑100s; during the cue ball forming period, use the third One part of the mineral material is pelletized, and the second part of the mineral material is used for long-term pelletizing in the cue ball; S4: drying; S5: pre-roasting of calcium carbonate decomposition and pre-oxidation: first decompose calcium carbonate at 900℃-950℃ Pre-baking, and then introduce insufficient air into the furnace for pre-oxidation and pre-baking; S6: High-temperature oxidation consolidation roasting: Inject increasing amounts of air into the furnace at 1250℃-1300℃ for high-temperature oxidation consolidation roasting and sintering. After completion, it is cooled to obtain high alkalinity chromium-containing all-vanadium titanium pellets.

Owner:NORTHEASTERN UNIV LIAONING

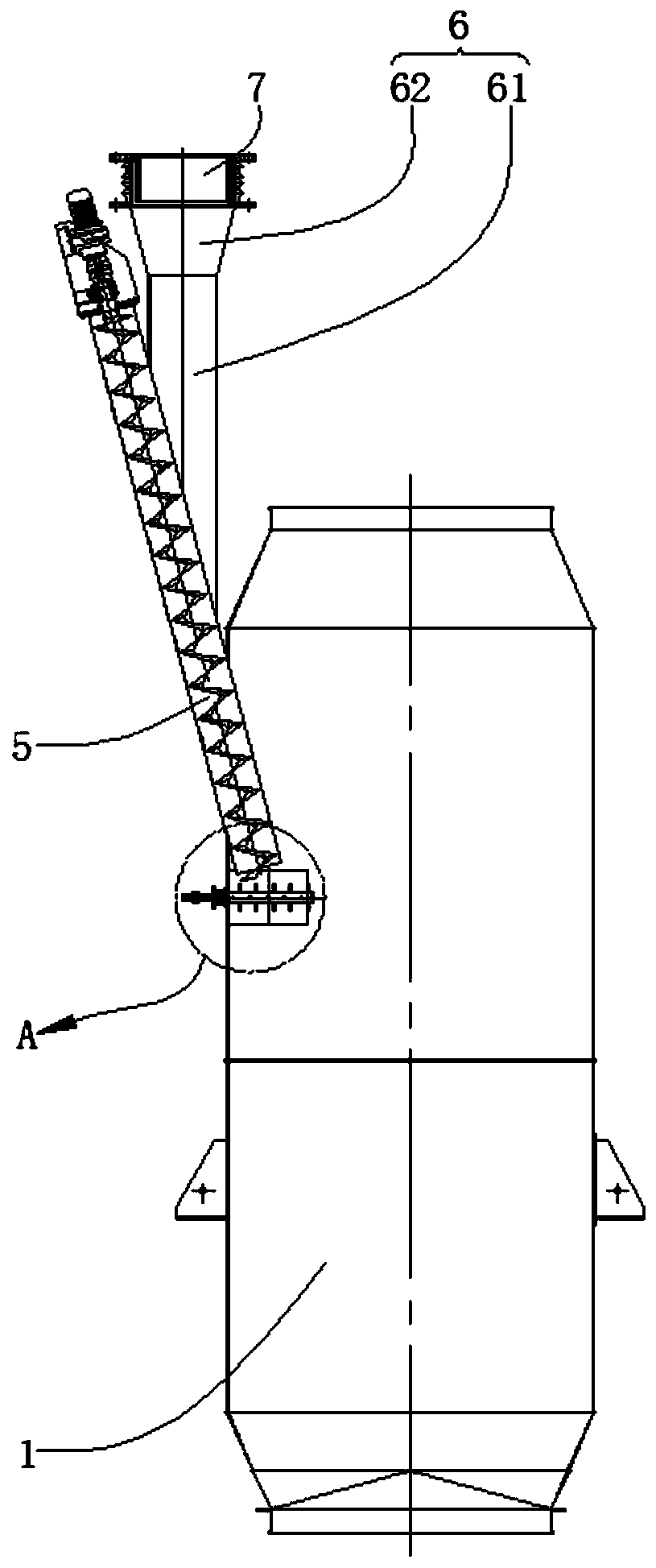

Unloading and scattering drying furnace

PendingCN110411152AImplement join transformationDeceleration circulation linkDrying solid materials with heatHearth type furnacesEngineeringGypsum

The invention provides an unloading and scattering drying furnace which comprises a drying furnace, a tangential air inlet pipe and an unloading device. The tangential air inlet pipe is arranged in the middle section of the drying furnace, a scattering rod device is arranged in a position of an air outlet of the tangential air inlet pipe in the drying furnace, a stirring device is arranged at theoutput end of the scattering rod device, and a conveying pipe is arranged above the stirring device. The bottom of the unloading device is arranged above the conveying pipe. The unloading and scattering drying furnace achieves connection conversion of static equipment and dynamic equipment by means of loop connection of an unloading pipe, drying equipment is directly connected to steam curing equipment, the circulating link of a wet material is reduced, the bonding probability of wet gypsum is reduced, and the efficiency is improved. By means of joint action of jittering and conveying, scattering, blowing and suspended drying, the material is dehydrated quickly, the bonding probability of wet gypsum is reduced, the heat efficiency can be improved by 80%, and industrial production and largescale of capacity are facilitated.

Owner:湖南昌迅科技环保股份有限公司

A method for preparing medium-low alkalinity all-vanadium-titanium self-fluxing pellets by using calcium oxide

The invention relates to a method for preparing medium-low alkalinity all-vanadium-titanium self-fluxing pellets by utilizing calcium oxide. In the method, vanadium-titanium ore powder, calcium oxide powder and sodium bentonite are first dried, and then dry-mixed with water and Mix evenly, seal and let stand; make balls. Before the cue ball grows up, the amount of water sprayed is controlled at 1ml / 10g mineral powder ~ 2ml / 10g mineral powder, and the interval between each water addition and feeding is 45 seconds ~ 90 seconds, so that the mineral The powder is fully rolled and compacted to produce green pellets; the raw pellets are simmered; dried, and then pre-oxidized and roasted; the temperature is raised, and secondary high-temperature oxidation and roasting is performed, and then cooled to obtain medium and low alkalinity High chromium type all-vanadium-titanium self-fluxing pellets. This method solves the problems of low green pellet strength, low compressive strength, high humidity, easy powdering and bursting after drying, and produces medium-low alkalinity high-chromium type all-vanadium-titanium self-fluxing pellets with excellent performance. The prepared pellets meet the requirements for entering the blast furnace, improve the pellet mineralization efficiency, and reduce the cost.

Owner:NORTHEASTERN UNIV LIAONING

Stabilizing device for tin bath hot-end glass strip

The invention discloses a stabilizing device for a tin bath hot-end glass strip, solves the problem of poor transverse stability of the glass strip in the prior art, overcomes the disadvantages of the stabilizing device for the tin bath hot-end glass strip without regional adjustment, reduces accidents, such as loosing of edge of the glass strip and the like and improves the production quality. The adopted technical scheme is that: the structure comprises a base at a lower layer and a graphite device, wherein the graphite device is fixed on the base through a connecting bolt and provided witha groove for holding tin-lead mixed melt; and a cooling device is arranged in the groove of the graphite device. By effectively adjusting the contact condition of the stabilizing device and the tin bath hot-end glass strip, the stability of the tin bath hot-end glass strip is obviously improved, the accidents, such as loosing of edge of the glass strip and the like, are greatly reduced, and the production quality of ultra-thin glass is greatly improved. The stabilizing device has the advantages of simple structure, high practicability and good stabilizing effect.

Owner:北京远大信达科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com