Polycrystalline diamond compact with anti-adhesion properties

A polycrystalline diamond and anti-adhesion technology, which is applied in drilling equipment, earthwork drilling, drill bits, etc., can solve problems such as ineffective control, improve anti-adhesion performance, improve drilling efficiency, and reduce drilling costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

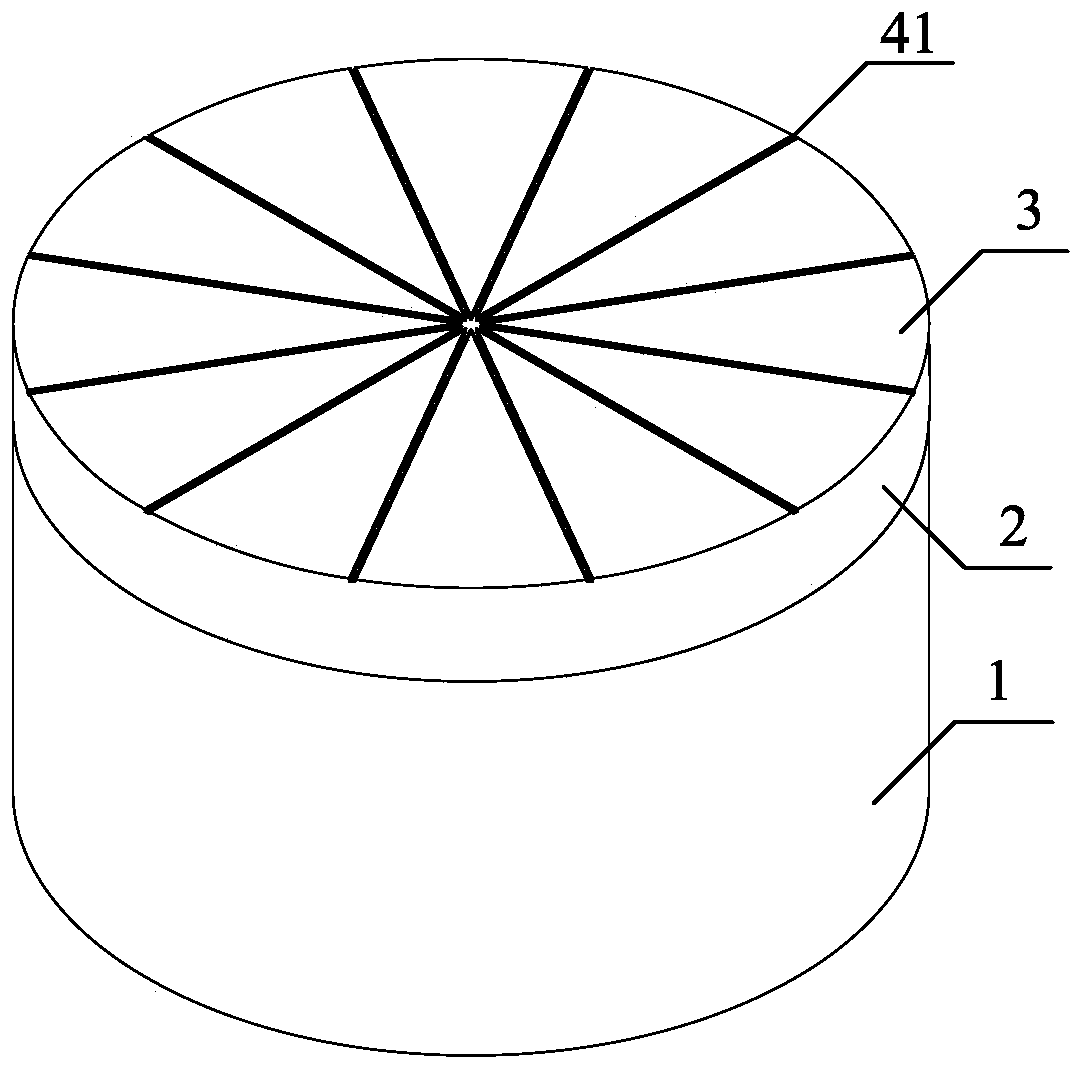

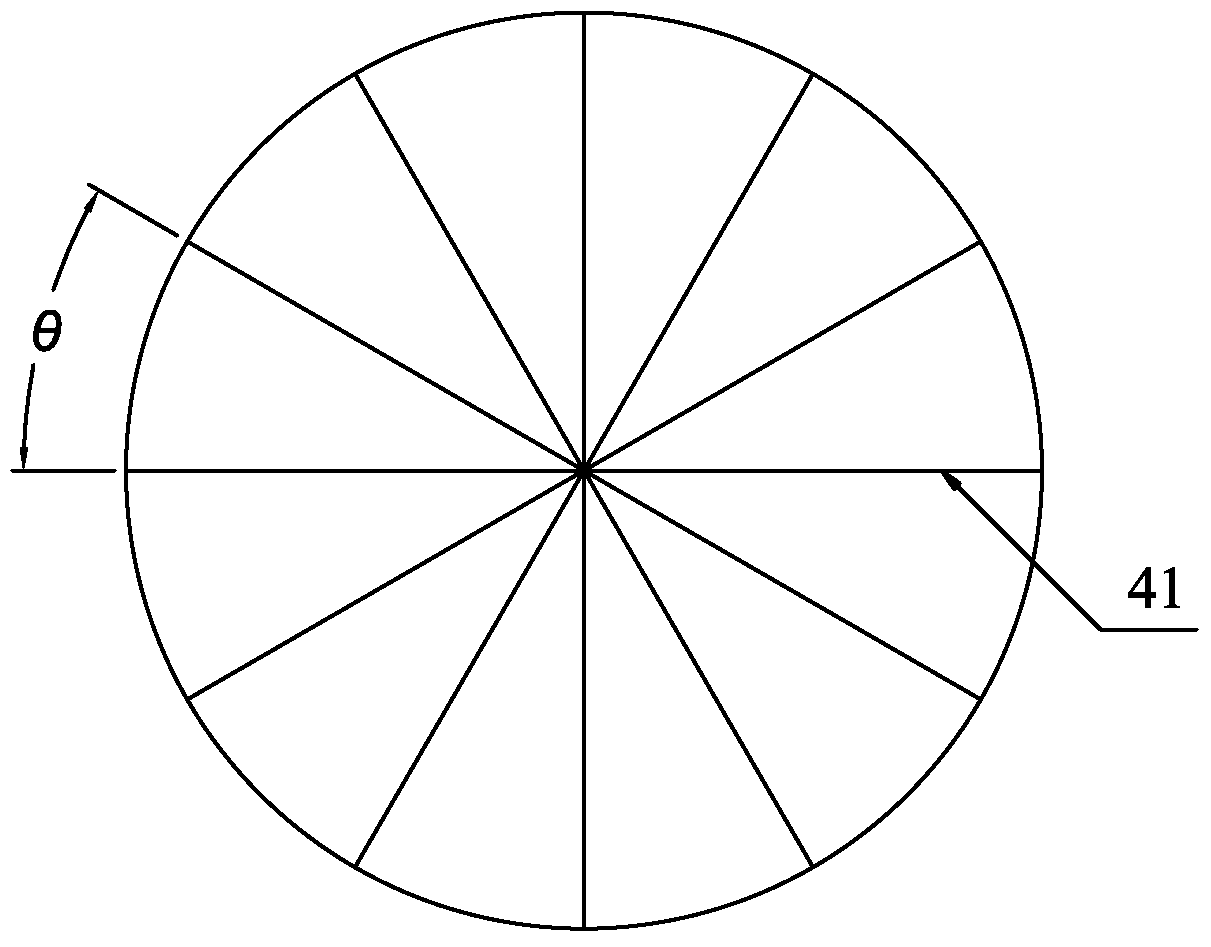

[0026] Such as figure 1 and figure 2 As shown, the polycrystalline diamond compact with anti-adhesive properties of embodiment 1 includes a cemented carbide substrate 1 and a polycrystalline diamond layer 2 compounded on the cemented carbide substrate 1, at the edge of the polycrystalline diamond layer 2 The surface 3 is provided with a groove structure. In this embodiment, the groove structure includes several radial grooves 41, and the several radial grooves 41 are radially arranged along the radial direction of the blade surface 3 starting from the center of the blade surface 3. The blade face 3 is divided into several sectors. Wherein, the included angle between two adjacent radial grooves 41 is θ﹦10-30°, and the figure shows the situation of θ﹦30°.

[0027] Such as Figure 5 , Figure 6 , Figure 7 and Figure 8 As shown, the cross section of the groove can be designed as a rectangle, trapezoid, triangle, arc or other suitable shapes; wherein, the width of the groo...

Embodiment 2

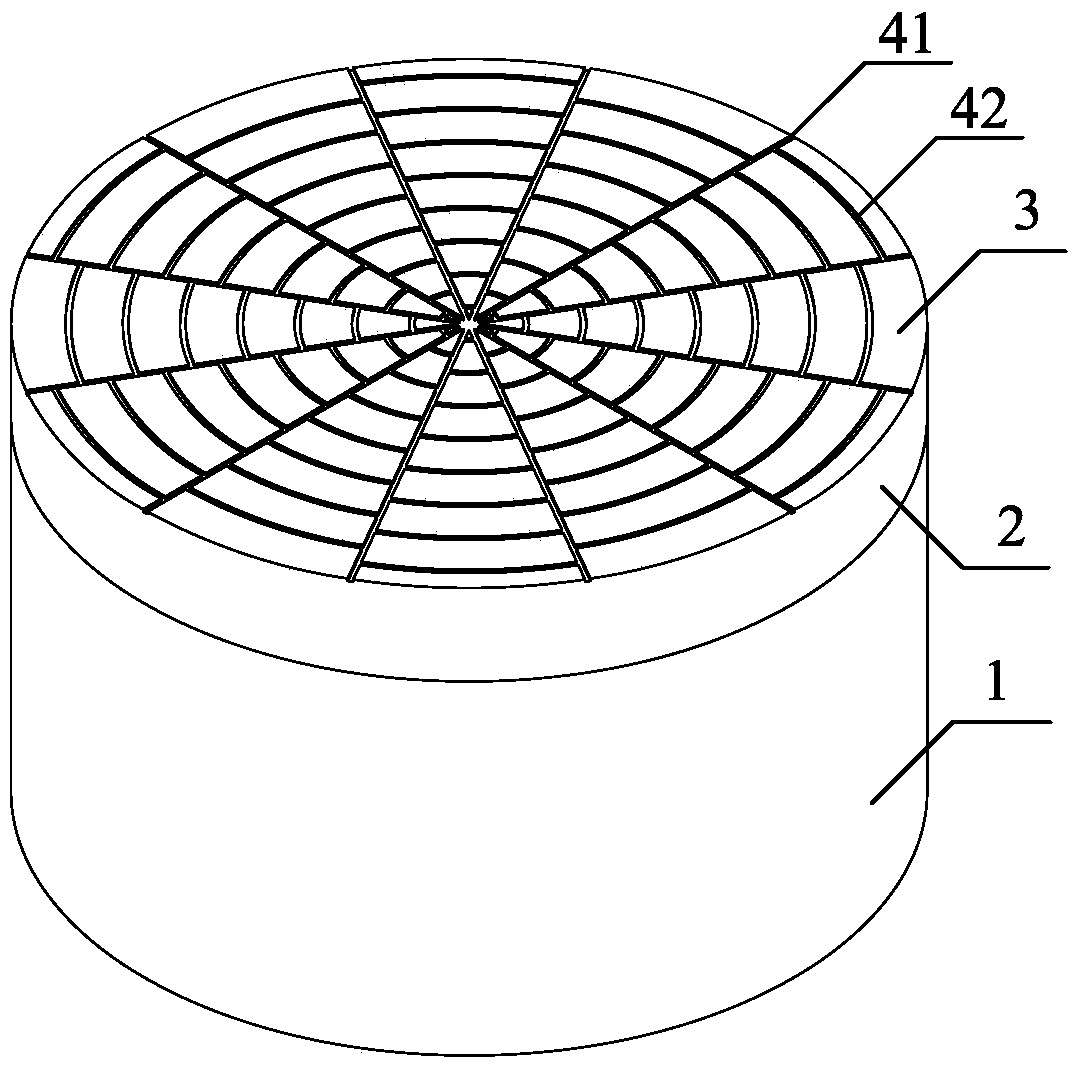

[0029] Such as image 3 and Figure 4 As shown, the polycrystalline diamond composite sheet with anti-adhesion properties of Example 2 is basically the same as Example 1, the difference is that on the basis of Example 1, the groove structure is further optimized, and Example 2 The groove structure in the blade also includes several arc-shaped circumferential grooves 42 communicating with the radial groove 41, and the several circumferential grooves 42 are concentrically distributed with the center of the blade surface 3 as the center. Among them, the circumferential grooves 42 of adjacent sectors are preferably arranged in a staggered manner. Cooperating with the radial grooves 41, the length of the drilling fluid circuitous flow channel can be extended, the storage time of the drilling fluid in the grooves can be extended, and it is beneficial to reduce rock formation. Friction and adhesion between chip and blade surface. Wherein, the distance between two adjacent circumfer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com