Coating-free anti-adhesion absorbent pad and production process thereof

A production process and anti-adhesion technology, applied in non-adhesive dressings, medical science, dressings, etc., can solve problems such as unreasonable structure and wound adhesion, and achieve the effects of avoiding secondary damage, good absorbency, and good moisture retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

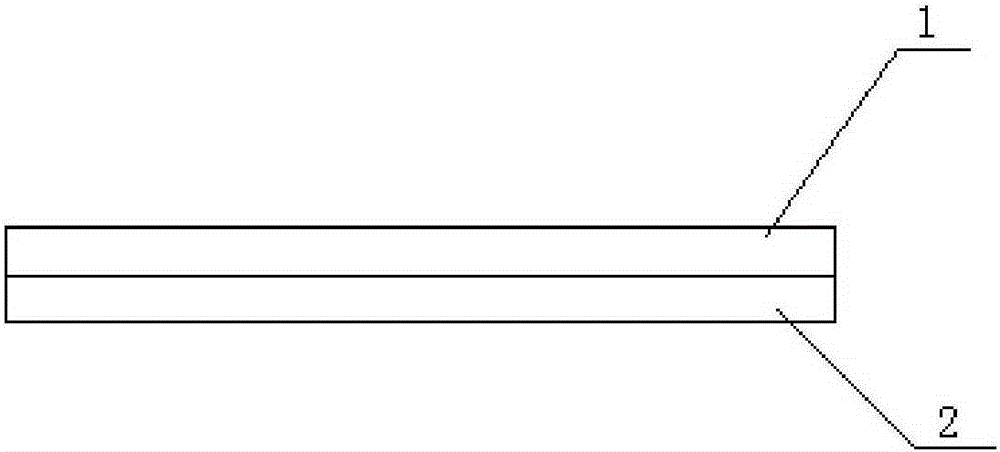

[0026] like figure 1 The non-coating anti-adhesion absorbent pad shown includes a non-woven fabric layer 1 on the surface and a functional fabric layer 2 in contact with the skin. The non-woven fabric layer 1 is made of non-woven fabric, and the functional fabric layer 2 is made of non-toxic grade polyethylene functional fibers. The grammage of the non-woven fabric layer 1 is 50g / ㎡, and the grammage of the functional fabric layer 2 is 20g / ㎡. The thickness of the non-woven fabric layer 1 is 5 mm, and the thickness of the functional fabric layer 2 is 3 mm. The surface of the functional fabric layer 2 is provided with several ventilation holes.

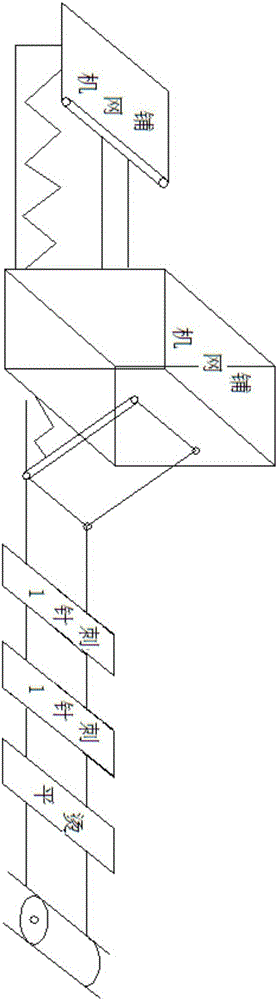

[0027] like figure 2 The production process of the above-mentioned a kind of film-free anti-adhesion absorbent pad shown includes the following steps:

[0028] (1) Preparation of non-woven fabric layer: the mixed fiber mixed with 30 parts by weight of viscose fiber and 20 parts by weight of superabsorbent fiber is sequentially opene...

Embodiment 2

[0033] like figure 1 The non-coating anti-adhesion absorbent pad shown includes a non-woven fabric layer 1 on the surface and a functional fabric layer 2 in contact with the skin. The non-woven fabric layer 1 is made of non-woven fabric, and the functional fabric layer 2 is made of non-toxic grade polyethylene functional fibers. The grammage of the non-woven fabric layer 1 is 200g / ㎡, and the grammage of the functional fabric layer 2 is 50g / ㎡. The thickness of the non-woven fabric layer 1 is 30mm, and the thickness of the functional fabric layer 2 is 10mm. The surface of the functional fabric layer 2 is provided with several ventilation holes.

[0034] like figure 2 The production process of the above-mentioned a kind of film-free anti-adhesion absorbent pad shown includes the following steps:

[0035] (1) Preparation of non-woven fabric layer: the mixed fiber mixed with 120 parts by weight of viscose fiber and 70 parts by weight of superabsorbent fiber is successively ope...

Embodiment 3

[0040] like figure 1 The non-coating anti-adhesion absorbent pad shown includes a non-woven fabric layer 1 on the surface and a functional fabric layer 2 in contact with the skin. The non-woven fabric layer 1 is made of non-woven fabric, and the functional fabric layer 2 is made of non-toxic grade polyethylene functional fiber. The grammage of the non-woven fabric layer 1 is 120g / ㎡, and the grammage of the functional fabric layer 2 is 35g / ㎡. The thickness of the non-woven fabric layer 1 is 18mm, and the thickness of the functional fabric layer 2 is 6mm. The surface of the functional fabric layer 2 is provided with several ventilation holes.

[0041] like figure 2 The production process of the above-mentioned a kind of film-free anti-adhesion absorbent pad shown includes the following steps:

[0042] (1) Preparation of non-woven fabric layer: the mixed fiber mixed with 75 parts by weight of viscose fiber and 45 parts by weight of superabsorbent fiber is successively opened...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com