Anti-sticking polypropylene composite material and preparation method thereof

A composite material, polypropylene technology, applied in the field of preparation of the polypropylene composite material, can solve problems such as migration and polypropylene incompatibility, and achieve the effects of low cost, excellent oil filling, and excellent physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

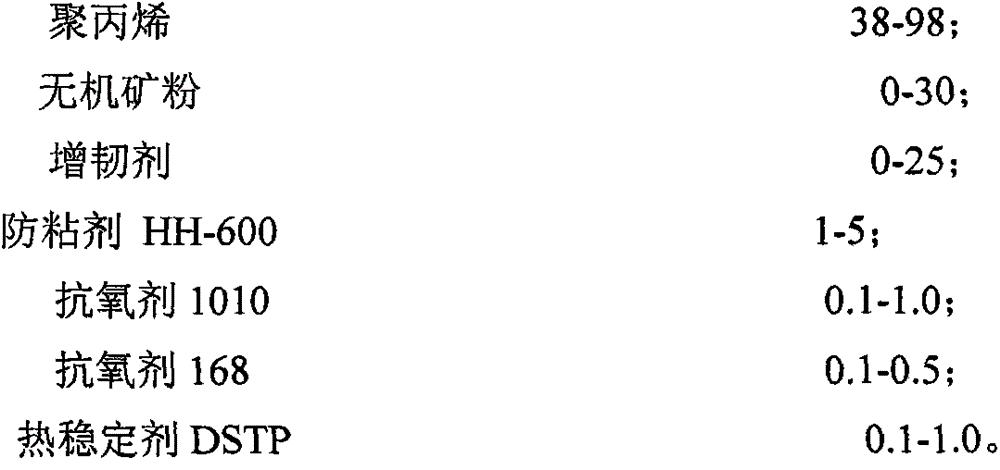

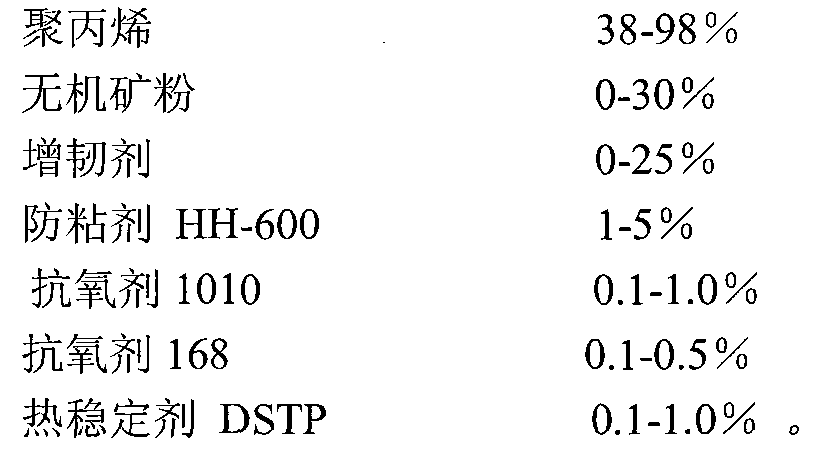

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with experiment, technical solution of the present invention is described in further detail:

[0030] Requirements for the materials used in this experiment: Polypropylene is homopolymerized and copolymerized polypropylene with different fluidity. The comonomer of copolymerized polypropylene is usually ethylene, and its content is in the range of 4-10mol%. The melt flow of polypropylene is Rate (230 ℃ * 2.16kg) is 5-50g / 10min, is more commonly used as 5-30g / 10min, and the inorganic ore powder used in this experiment is talcum powder, and its particle size range is 1-10 micron; The binder is layered hydrotalcite HH-600, which is a powder substance with strong alkalinity and a maximum heat resistance temperature of about 600°C. During the heating process, the ordered layered structure of the oxide is destroyed, and the surface area increases. Increased pore volume. The toughening agent POE is produced by Exxon Mobil Corporation, the trade name is 537...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com