Squashed cable duct repairing device

A cable ducting and deflating technology, applied in tubular items, applications, household appliances, etc., can solve the problems of poor impact toughness, poor impact toughness, poor heat dissipation, etc., to achieve excellent weather resistance, low water absorption, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

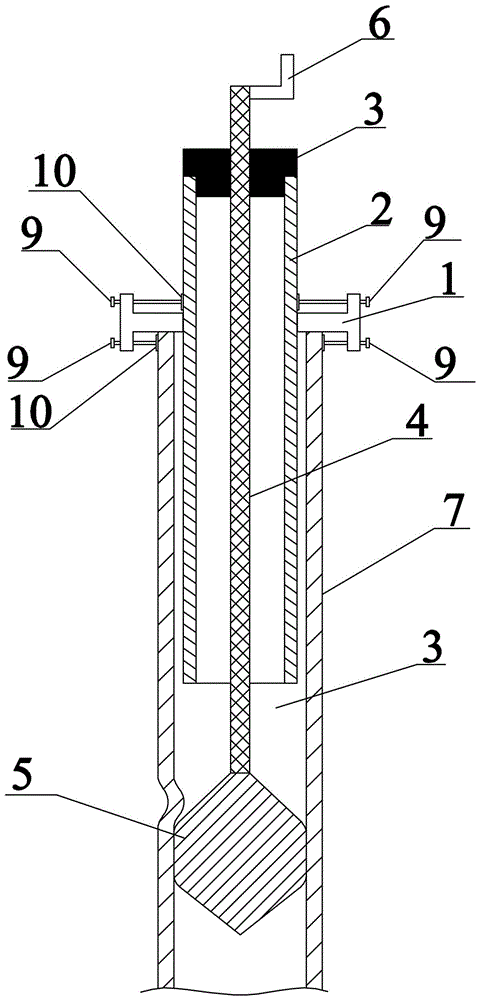

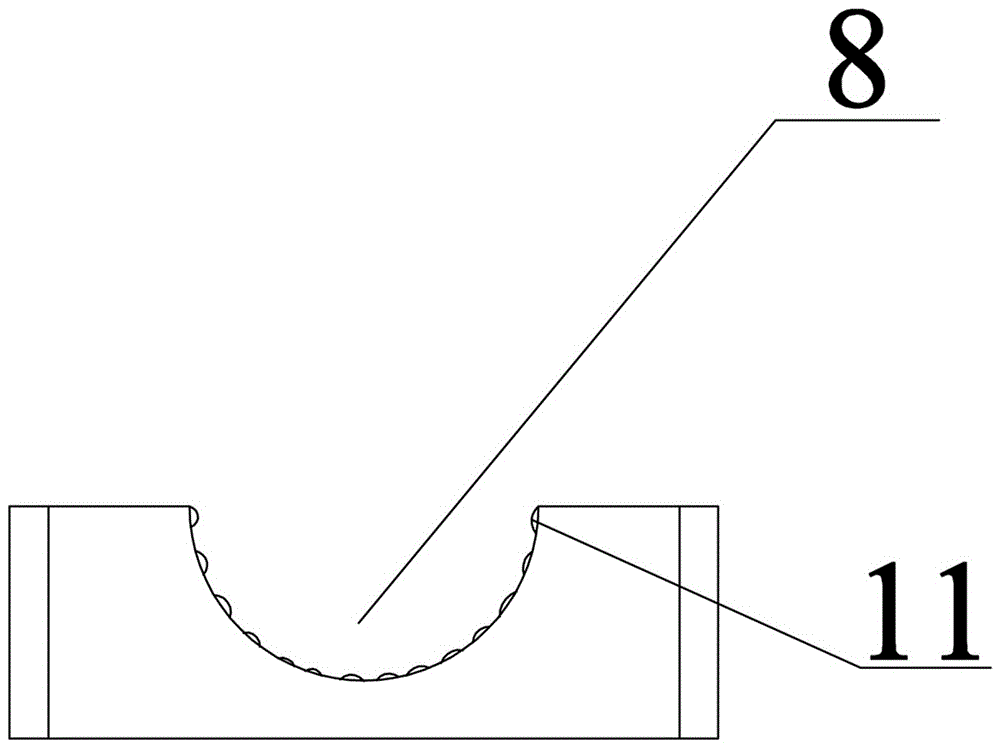

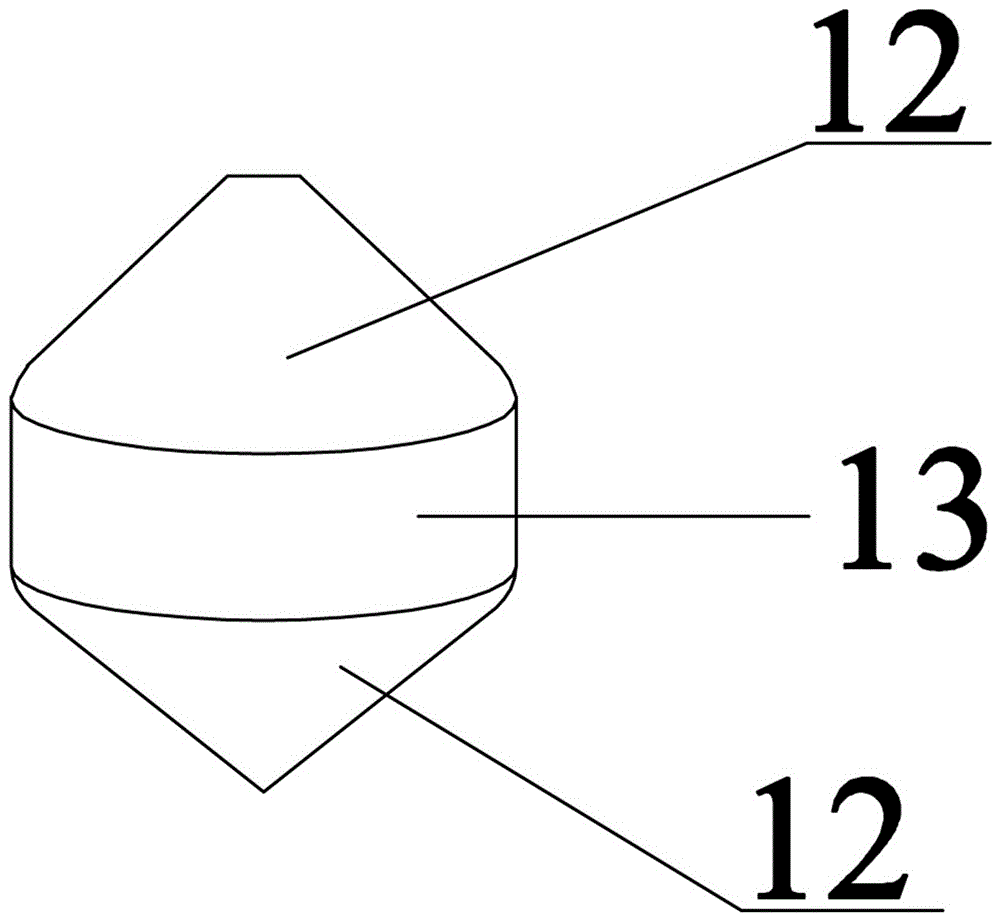

[0032] see Figure 1-3 , a flattened cable pipe repair device, including a fixed seat 1, a support tube 2, a cover 3, a rotating rod 4, a repair head 5 and a rocking handle 6, the fixed seat 1 is arranged outside the cable pipe 7, and the One side of the fixed seat 1 is in contact with the port of the cable pipe 7, the upper end surface of the fixed seat 1 is I-shaped, and the middle part of the upper end surface of the fixed seat 1 is provided with a semicircular groove 8 matching the support tube 2, so that An anti-slip protrusion 11 is provided in the semicircular groove, and two radial jacking screws 9 are arranged on both sides of the fixing seat 1, and tooth plates 10 are provided at the ends of the jacking screws 9, and the The tooth plate 10 is in a concave arc shape, which is consistent with the arc shape of the outer wall of the support pipe 2 or the cable pipe 7. The tooth plate 10 is provided with tooth-shaped teeth facing the cable pipe or support pipe; the suppor...

Embodiment 2

[0039] The structure of the device for repairing the collapsed cable pipes in this implementation is the same as that of Embodiment 1, and will not be repeated.

[0040] see Figure 4 , when the flattened cable pipe repair device of the present invention is used, depressions appear on both sides of the cable pipe 7 at the same time (see Figure 4 ), so that the center line of the support tube 2 of the repair device coincides with the center line of the cable pipe 7, and at the same time make the cone 12 at the end of the repair head 5 of the repair device connected to the screw rod 4 close to the depression, and fix the fixing seat 1 and the jacking wire 9, so that one side of the fixing seat 1 is in contact with the port of the cable tube 7, the support tube 2 is placed in the semicircular groove 8, and the shaking handle 6 drives the rotation rod 4 and the repair head 5 to rotate and move in the direction of the depression , and gradually realize the repair.

[0041] Descr...

Embodiment 3

[0046] The device and method of repairing the collapsed cable pipes in this implementation are the same in structure as in Embodiment 1, and will not be repeated.

[0047] Described cable pipe is made of the following raw materials in parts by weight:

[0048] 50 parts of EPDM rubber, 35 parts of SAN resin, 15 parts of glass fiber, 15 parts of polyhydroxyalkanoate, 6 parts of polyethylene wax, 15 parts of phenyl sulfonate, 20 parts of dioctyl phthalate , 7 parts of dicumyl peroxide and 3 parts of trimethylolpropane trimethacrylate.

[0049] The preparation method of described cable duct comprises the following steps:

[0050] Heat EPDM rubber and SAN resin in an internal mixer to 60°C, masticate for 4 minutes, then add glass fiber, polyhydroxyalkanoate, polyethylene wax, alkyl phenyl sulfonate and diphthalate Mix octyl esters, continue to stir for 6 minutes, finally add dicumyl peroxide and trimethylolpropane trimethacrylate, mix at 90 ° C for 4 minutes, and then send them i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com