Production method, production system and application of particle direct reduced iron

A production method and production system technology, applied in the field of smelting, can solve the problems of fluidization, low reaction temperature and high energy consumption, and achieve the effects of reducing energy consumption and pollution, simple process flow and low dust emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

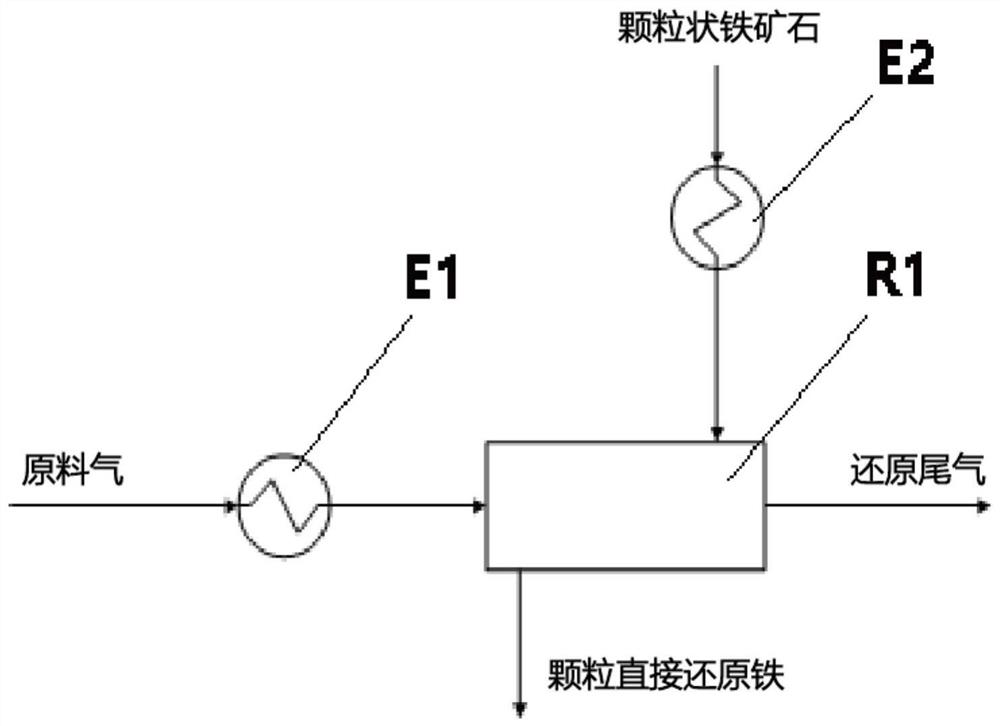

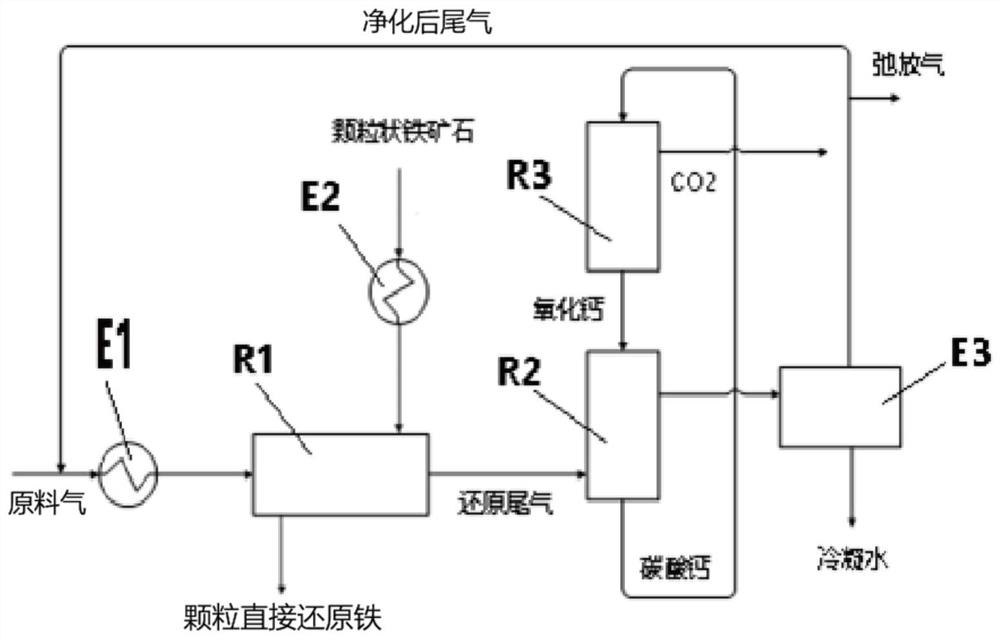

[0109] The present embodiment provides a kind of production method of granular direct reduced iron, comprises the following steps:

[0110] The preheated granular iron ore and the preheated raw material gas are contacted in countercurrent to make a reduction reaction. The reduction reaction pressure is 2.5 MPa, and the reduction reaction time of the granular iron ore is 8 hours to obtain granular direct reduced iron;

[0111] Among them, the chemical composition of granular iron ore is total iron, FeO, SiO 2 , CaO, MgO, Al 2 o 3 , MnO contents are 62.7%, 27.3%, 1.32%, 1.53%, 3.45%, 0.82%, 0.28%, respectively, the granular iron ore particle size is 100-300 mesh (48-150μm, average particle size is 0.105 mm), the temperature of the preheated granular iron ore is 600°C;

[0112] Raw gas composition: H 2 The content is greater than 99.5%, and the temperature of the raw material gas after preheating is 600°C.

[0113] When the raw material gas flows through the bed, the average...

Embodiment 2

[0117] The present embodiment provides a kind of production method of granular direct reduced iron, comprises the following steps:

[0118] The preheated granular iron ore and the preheated raw material gas are contacted in countercurrent to make a reduction reaction. The reduction reaction pressure is 1.2 MPa, and the reduction reaction time of the granular iron ore is 3 hours to obtain granular direct reduced iron;

[0119] Among them, the chemical composition of granular iron ore is total iron, FeO, SiO 2 、Al 2 o 3 , MnO content are 66.2%, 1.4%, 5.2%, 0.43%, 0.06% respectively, the particle size of granular iron ore is 50-200 mesh (75-270μm, average particle size is 0.15mm), after preheating The temperature of granular iron ore is 650°C;

[0120] Raw gas composition: H 2 The content is 90%, N 2 The content is 10%, and the temperature of the preheated feed gas is 550°C.

[0121] When the raw material gas flows through the bed, the average gas flow velocity is 0.09m / s, ...

Embodiment 3

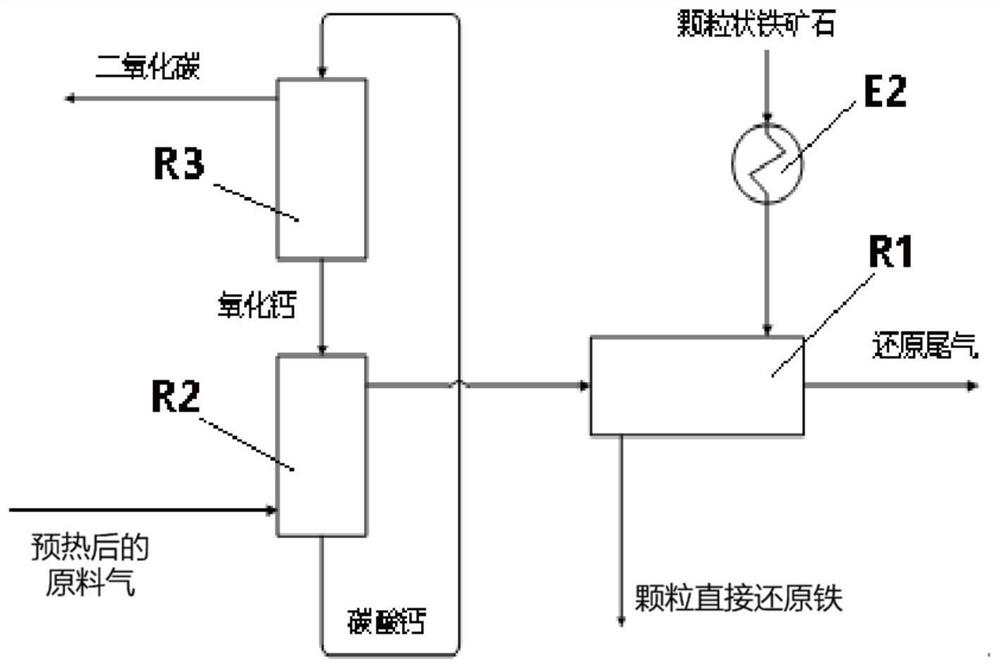

[0125] The present embodiment provides a kind of production method of granular direct reduced iron, comprises the following steps:

[0126] The preheated granular iron ore and the preheated raw material gas are contacted in countercurrent to carry out a reduction reaction. The reduction reaction pressure is 1.0 MPa, and the reduction reaction time of the granular iron ore is 4.5 hours to obtain granular direct reduced iron;

[0127] Among them, the chemical composition of granular iron ore is total iron, FeO, SiO 2 、Al 2 o 3 , MnO contents are 62.67%, 0.59%, 4.52%, 1.59%, 0.26% respectively, the particle size of granular iron ore is 40-100 mesh (150-380μm, average particle size is 0.28mm), after preheating The temperature of granular iron ore is 650°C;

[0128] Raw gas composition: H 2 The content is 75%, the CO content is 8%, the CO 2 Content is 0.5%, N 2 The content is 16.5%, and the temperature of the preheated feed gas is 600°C.

[0129] When the raw material gas fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com