Drill bit of variable-curvature screw pile driver

A pile driver, variable curvature technology, applied in construction and other directions, can solve problems such as short life, serious clay, unreasonable structure, etc., to achieve the effect of improving service life and work efficiency, reducing soil resistance, and increasing excavation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

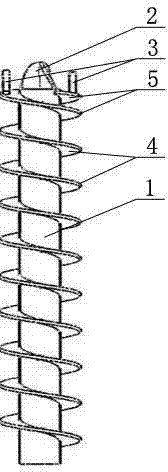

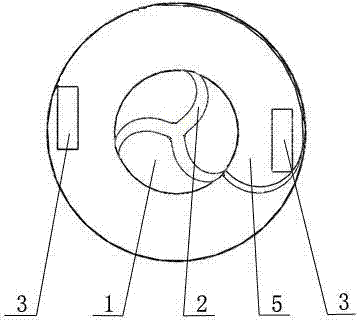

[0022] A variable curvature spiral pile driver bit, such as figure 1 As shown, it includes a cylindrical drill pipe 1, a drill tip 2 arranged at the end of the drill pipe 1 that enters the soil, a helical blade arranged along the outer peripheral surface of the drill pipe 1, and two drill picks fixed at the end of the helical blade that enters the soil. 3.

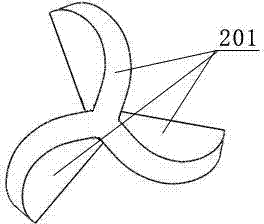

[0023] Wherein, the two drill picks 3 are arranged symmetrically to the central axis of the drill pipe 1, and the two drill picks 3 are all bent toward the central axis of the drill pipe 1, and the two opposite sides of the drill picks 3 are curved surfaces, respectively The inner curved surface 301 that touches the soil and the outer curved surface 302 that bends toward the inner curved surface 301 that touches the soil; the other two opposite sides of the drill pick 3 are vertical planes. The contour curves of the inner soil-touching surface in the section along the vertical plane of the drill pick 3 respectively comply...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com