Patents

Literature

39results about How to "Slow water absorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

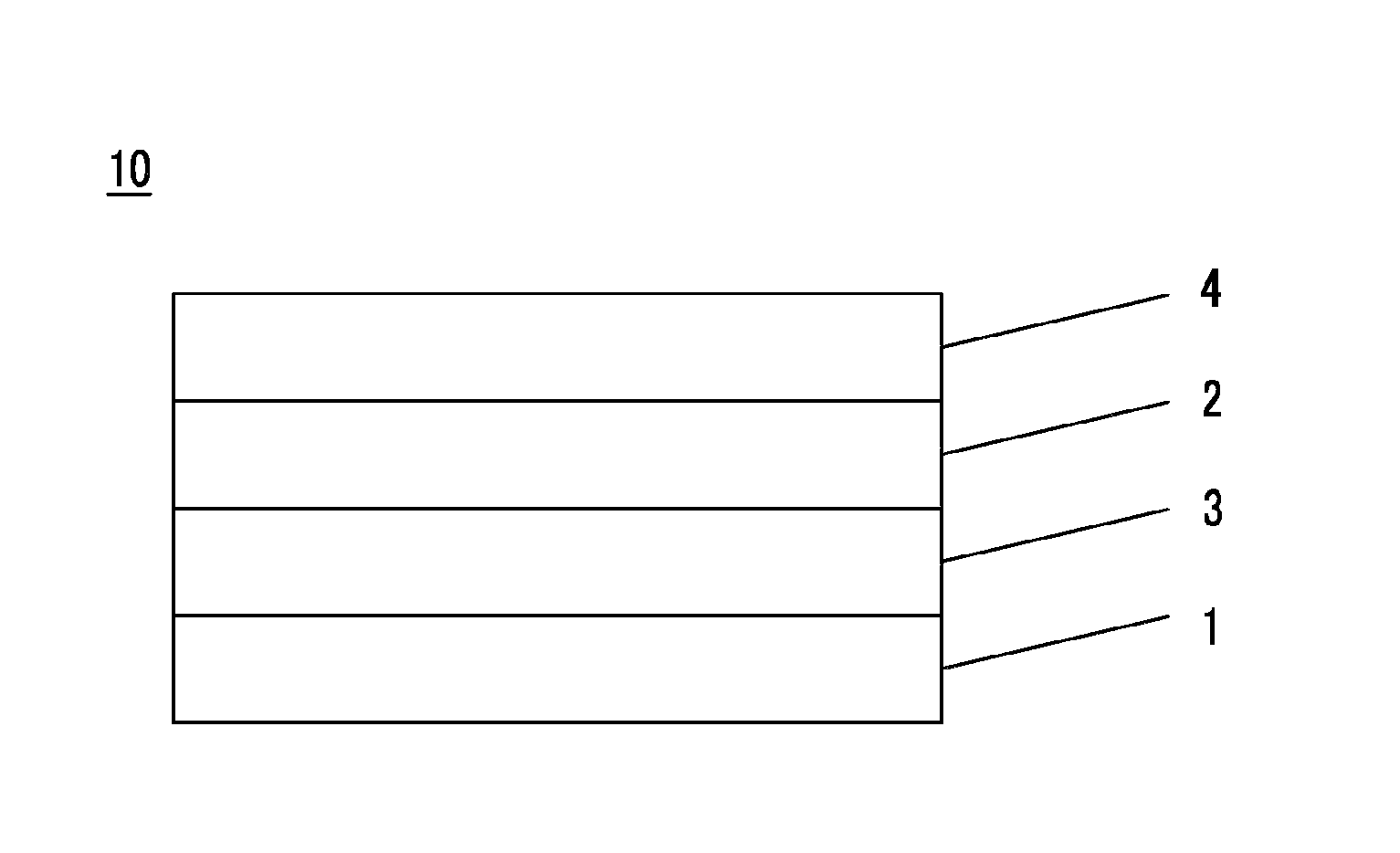

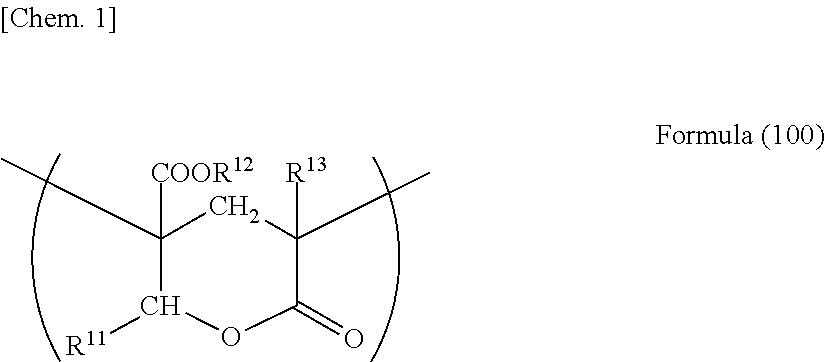

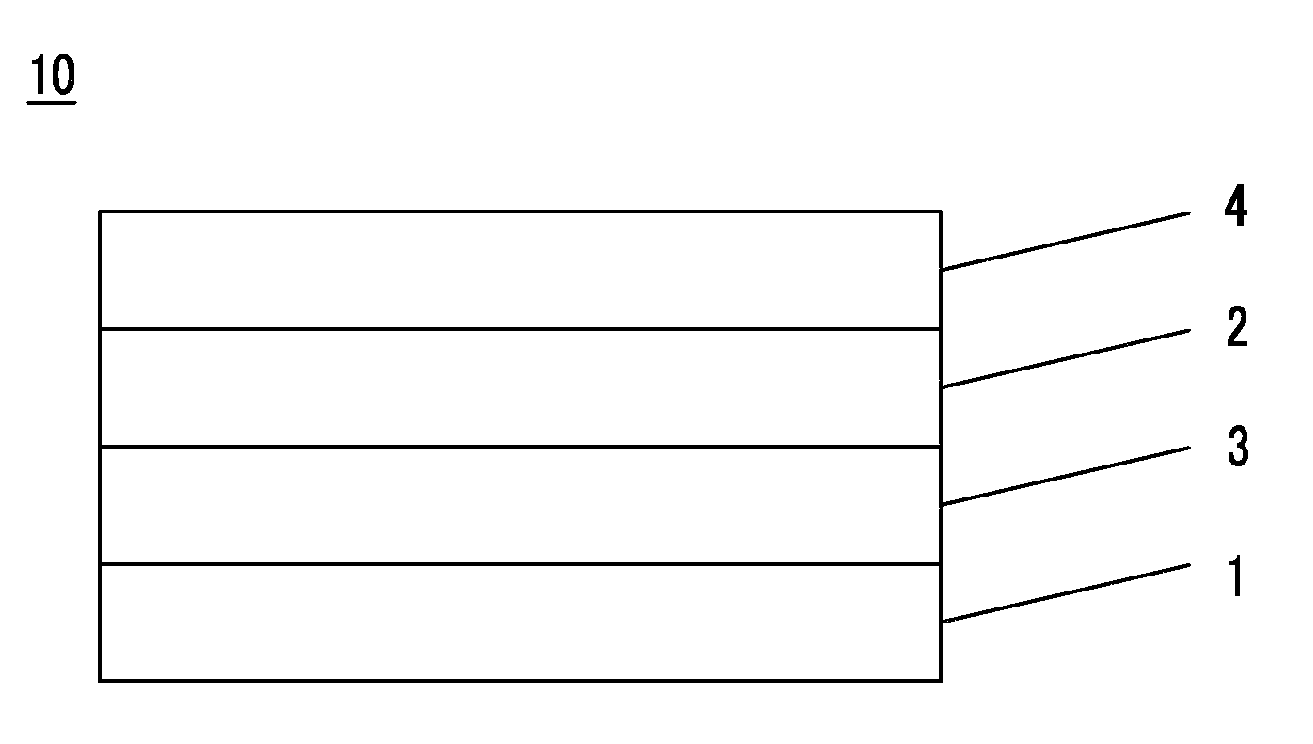

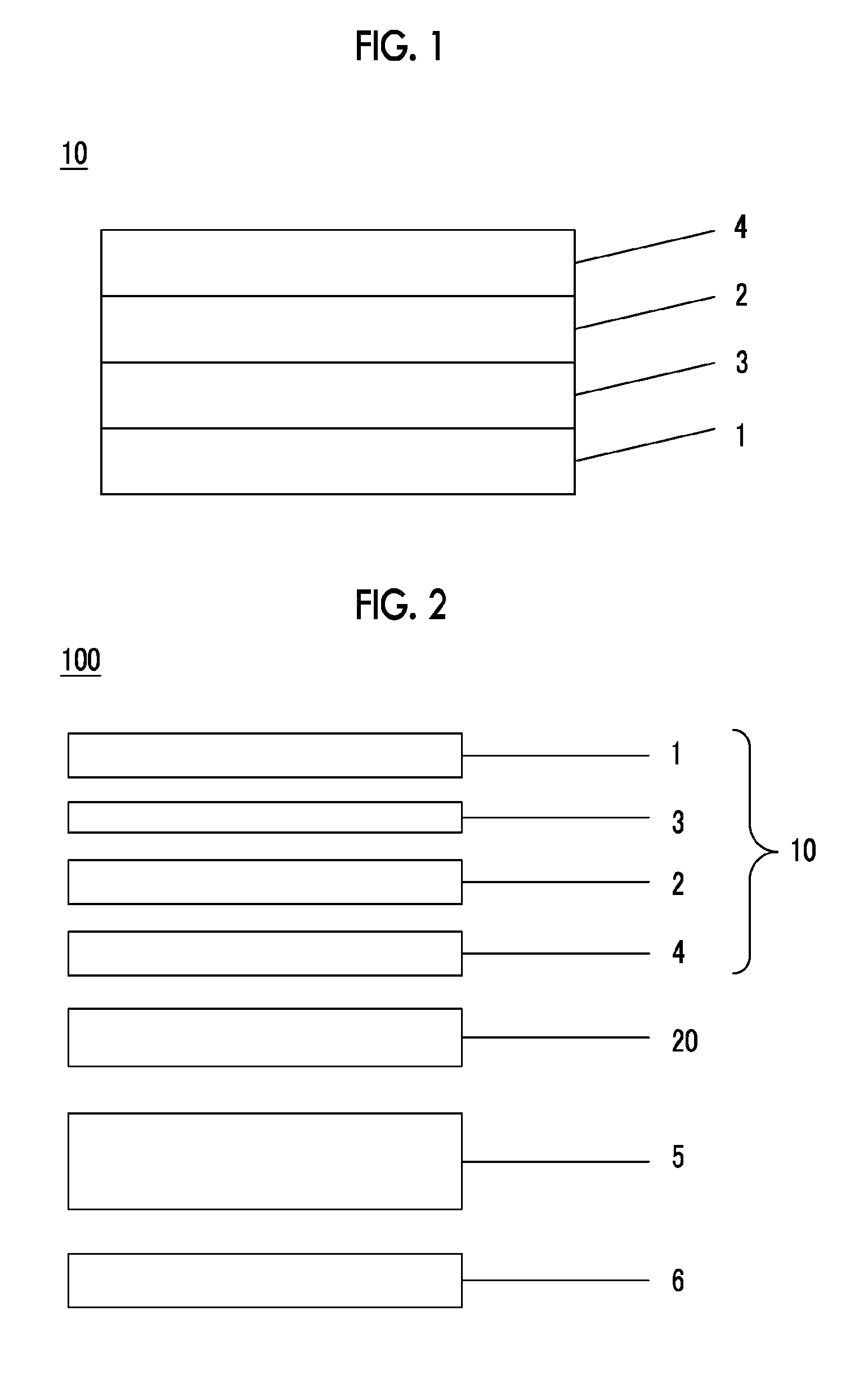

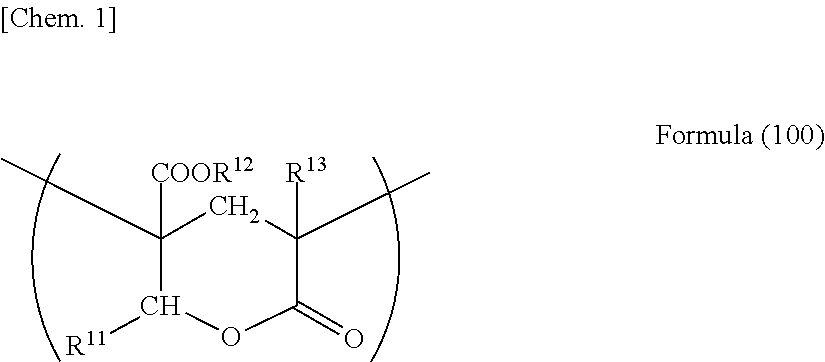

Polarizing plate and liquid crystal display

ActiveUS20140098331A1Suppress light leakageLow moisture permeabilityPolarising elementsNon-linear opticsCelluloseTectorial membrane

A polarizing plate according to the invention includes a first protective film; a polarizer; a second protective film; and an adhesive layer in this order, in which a moisture vapor permeability of the first protective film is less than or equal to 200 g / m2 / 24 hours, the second protective film contains cellulose acylate as a major component, a creep amount of the adhesive layer is less than 100 μm, and a shrinkage force of the polarizing plate in an absorption axis direction thereof which is represented by the following expression (A) is lower than or equal to 2000 N / m. Expression (A) is the Shrinkage Force (N / m) of Polarizing Plate in Absorption Axis Direction=Elastic Modulus (GPa) of Polarizing Plate in Absorption Axis Direction×|Humidity Dimensional Change Rate (%) of Polarizing Plate in Absorption Axis Direction|×Thickness (μm) of Polarizing Plate×10.

Owner:FUJIFILM CORP

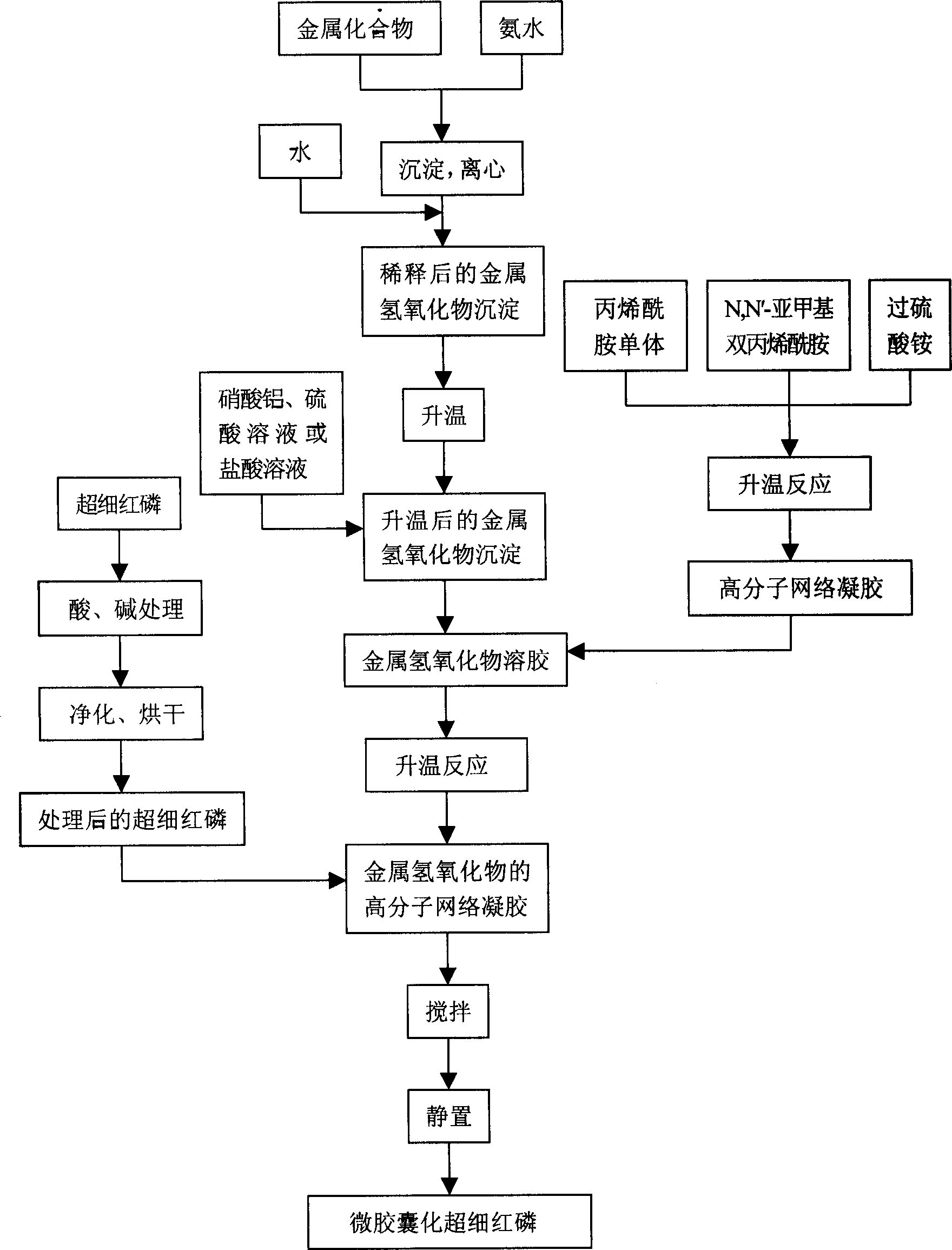

Method for preparing microcapsulated superfine red phosphorus

InactiveCN1775664ASlow water absorptionReduce productionPhosphorus compoundsMolecular networkSodium cyanide

The invention discloses a method for preparing micro-capsulized superfine red phosphorus, boiling the superfine red phosphorus with vitriol, sodium cyanide solution and sodium hydroxide solution, separately, filtering, eliminating impurities, and drying, and storing by sealing; blending and dissolve metal compound, depositing with ammonia, centrifuging and adding water to dilute, raising temperature, dropping in aluminum nitrate, vitriol or HCl and making metal hydroxide sol; mixing propylene acylamide monomers and N, Ní»-methylene dipropylene acylamide with ammonium persulphate, raising temperature and reacting to form high molecular network gel; adding the high molecular network gel into the metal hydroxide sol, raising the temperature and reacting to form high molecular network gel of metal hydroxide, mixing the high molecular network gel of metal hydroxide with the processed superfine red phosphorus, blending and placing still so that the sol takes the red phosphorus as the center to make surface absorption to form gel and coating a layer of colloid membrane on the red phosphorus surface, so as to obtain the micro-capsulized superfine red phosphorus. The advantages of the invention: it improves the stability, invariability and surface activity of the red phosphorus, improving processing property.

Owner:NANJING UNIV OF SCI & TECH

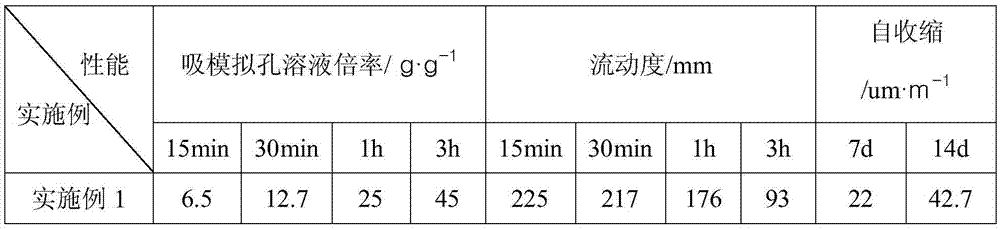

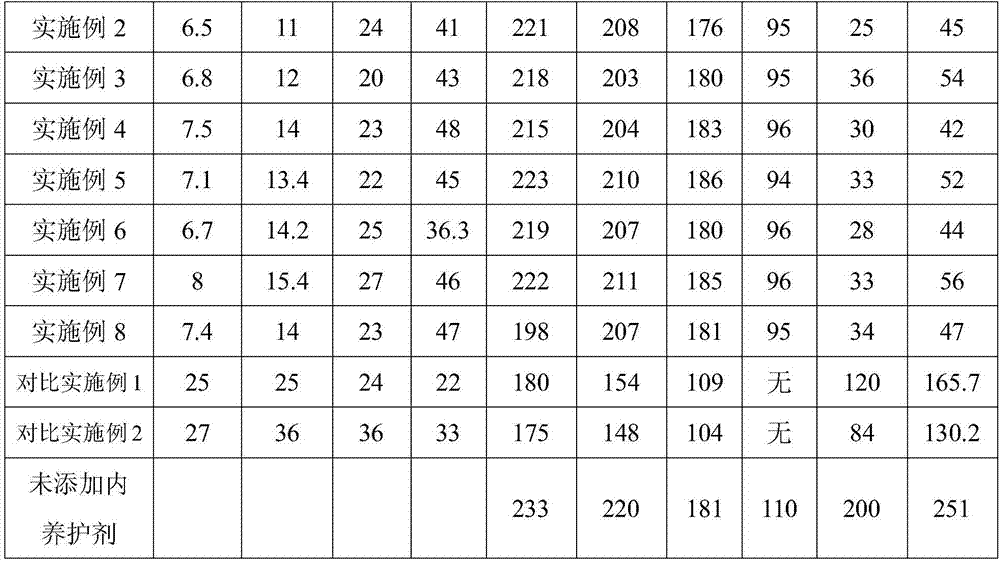

Preparation method of concrete internal curing agent

ActiveCN105439490AImprove early autogenous shrinkage reduction effectSolve the problem of early crackingChemical structureAfter treatment

The invention provides a preparation method of a concrete internal curing agent. The preparation method comprises the following steps: mixing acrylamide, a hydrophobic monomer, ethanol, a crosslinking agent and an initiating agent uniformly, heating until the temperature is 50-70 DEG C, then carrying out reaction for 4-10 hours, and carrying out conventional after treatment on a generated gel to obtain a shell material with a hydrophobic structure; mixing deionized water, acrylic acid and sodium hydroxide uniformly, controlling the neutralization temperature to be lower than 30 DEG C, then sequentially adding a crosslinking agent and an initiating agent, and mixing uniformly to obtain a core solution; and soaking the shell material with the hydrophobic structure in the core solution for 30-60 minutes, putting the shell material after filtration into a drying oven for reaction for 1-3 hours at 60-80 DEG C, and finally carrying out conventional after treatment to obtain the concrete internal curing agent. According to the preparation method, the preparation process is simple and convenient, the chemical structure is easy to control, an outer layer hydrophobic structure of the prepared internal curing agent enables the water absorbing rate to be relatively slow and can significantly reduce the influence of the water absorbing rate on the workability of concrete, and an inner layer hydrophilic structure can improve the early autogenous shrinkage reduction effect to solve the difficult problem of concrete early cracking.

Owner:JIANGSU SOBUTE NEW MATERIALS

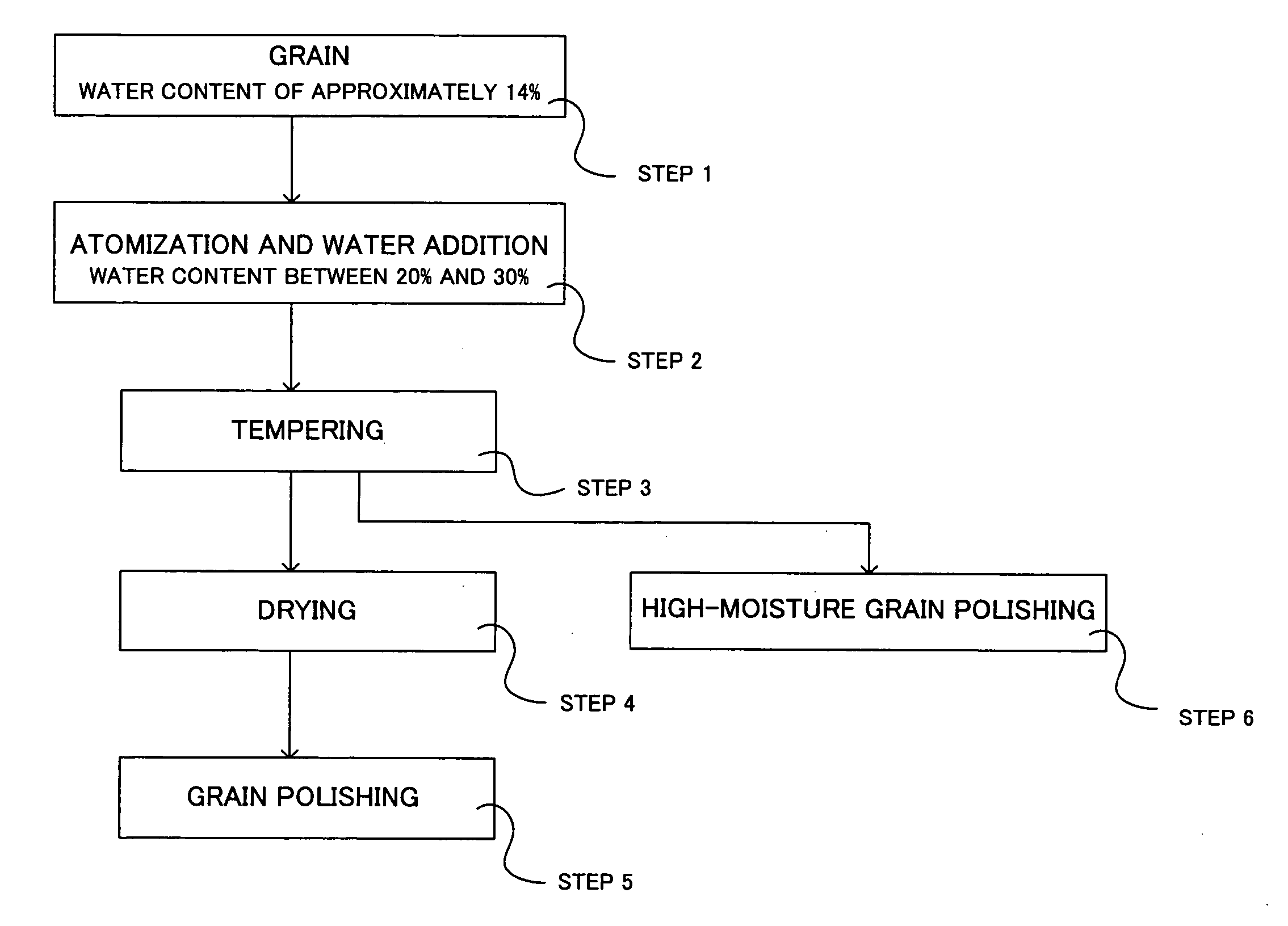

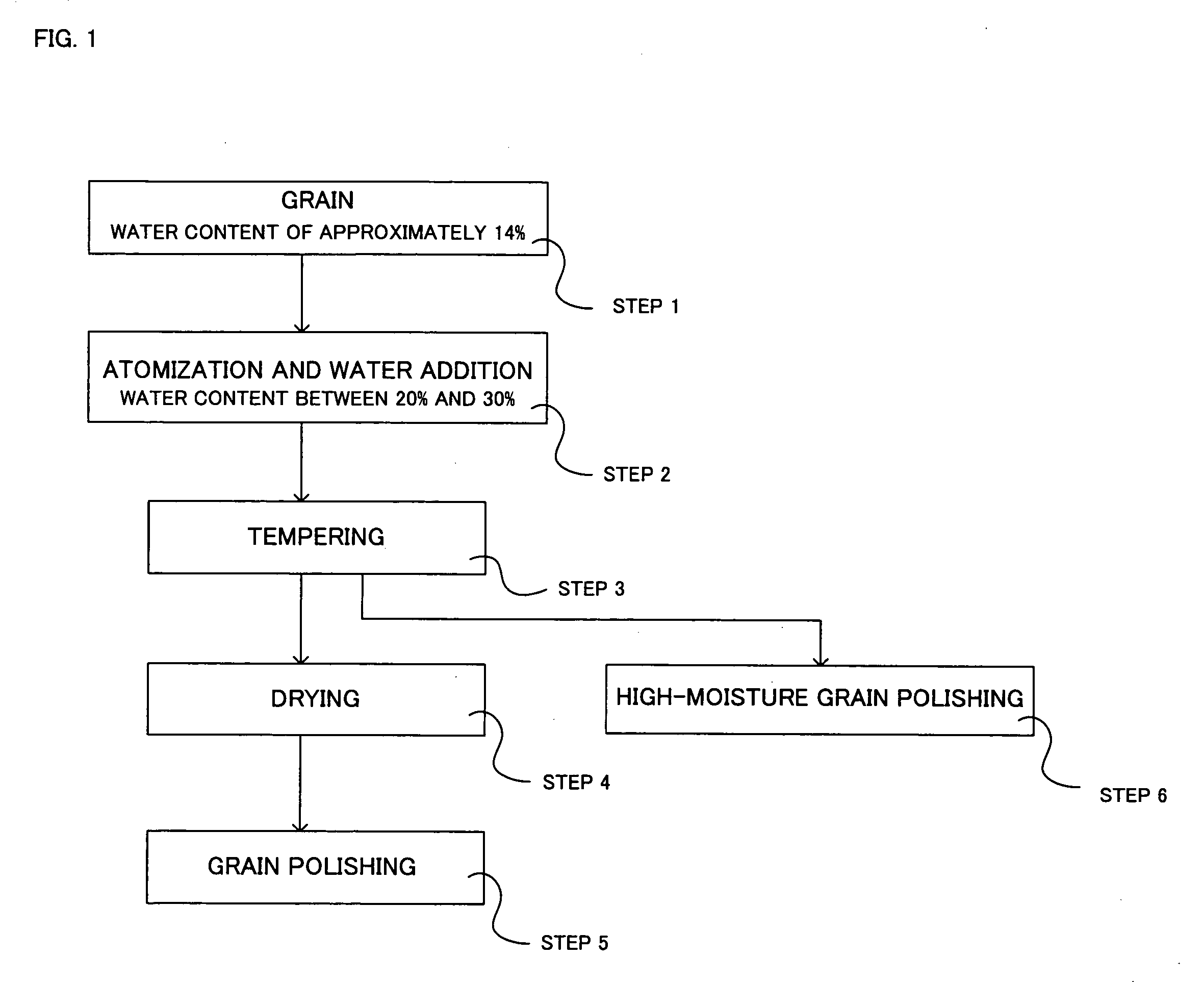

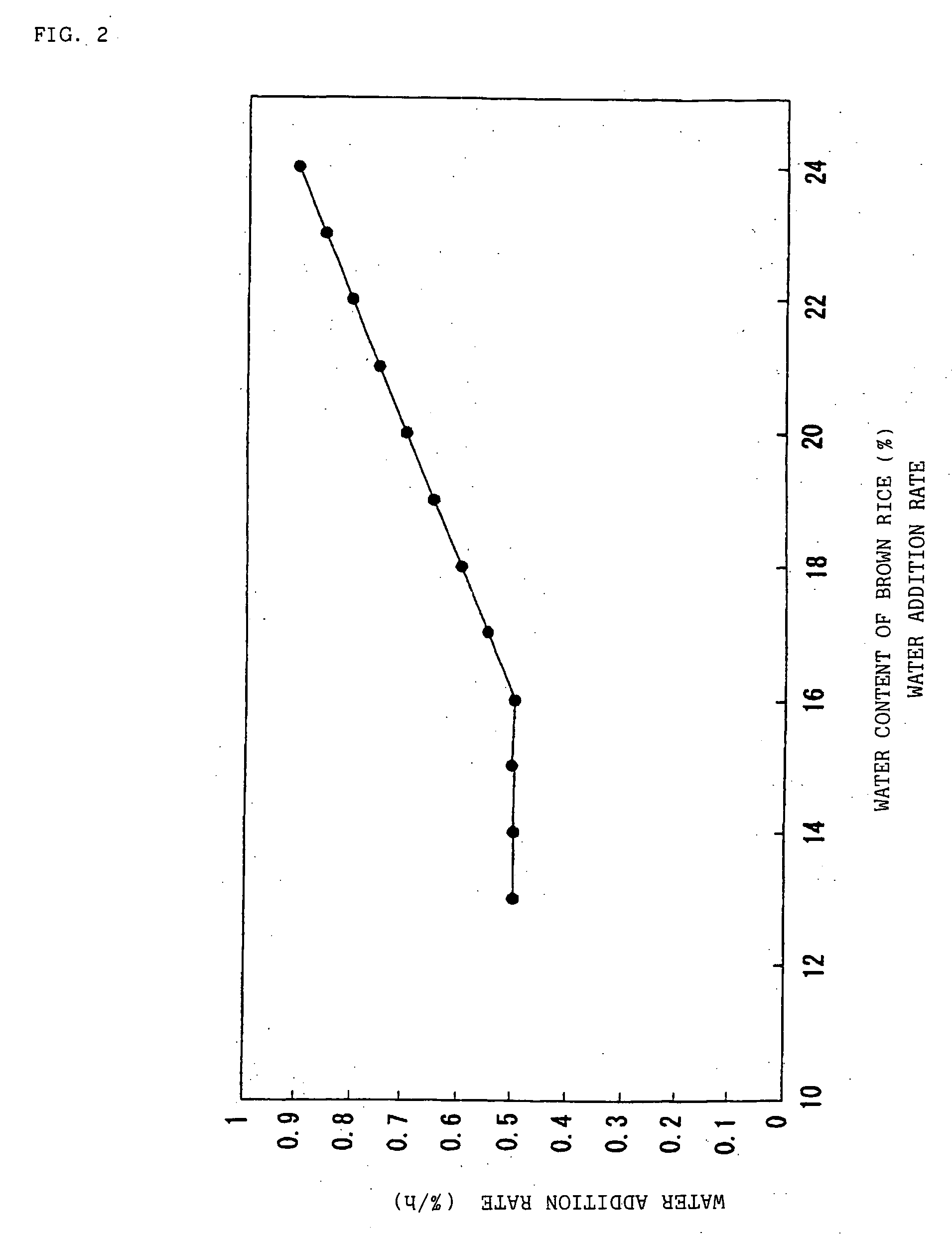

Method for enriching ý-aminobutyric acid and cereal obtained by the method

InactiveUS20060263499A1Denaturation can be suppressedPrevent degradationFood ingredientsMeat/fish preservation by freezing/coolingWater contentAminobutyric acid

Water is slowly added to dry grain having a water content previously adjusted to 10% to 15% at a water addition rate of 0.5% to 2.0% / h, in order to provide a water content of 20% to 30%, and thereafter, the grain is placed into a tank, followed by tempering for 2 to 15 hours.

Owner:SATAKE CORP +1

Method for preparing easily-machined polyether type thermoplastic polyurethane elastomer

The invention discloses a method for preparing easily-machined polyether type thermoplastic polyurethane elastomer (TPU). The method comprises the following steps: 1) adding polyether polyhydric alcohol, an antioxidant and a catalyst into a reaction kettle for fusion, mixing and dehydration for later use; 2) respectively filling three components, namely, the polyether polyhydric alcohol, a dihydric alcohol chain extender and diisocyanate into a double-screw rod extruder for reaction through a high-precision gear pump; and 3) respectively adding solid higher alkane wax and higher fatty amine into the double-screw rod extruder by using a high-precision loss-in-weight in the middle of the double-screw rod extruder, fusing and mixing with polyurethane elastomer melt, and chopping under water to obtain easily-machined polyether type thermoplastic polyurethane elastomer grains. By adopting the method disclosed by the invention, the drying requirement is lowered (a dehumidification drying machine is not needed) when the easily-machined polyether type thermoplastic polyurethane elastomer is subjected to extrusion machining, and the surface smoothness degree of the product and the product extrusion stability are improved.

Owner:奥斯汀新材料(张家港)有限公司

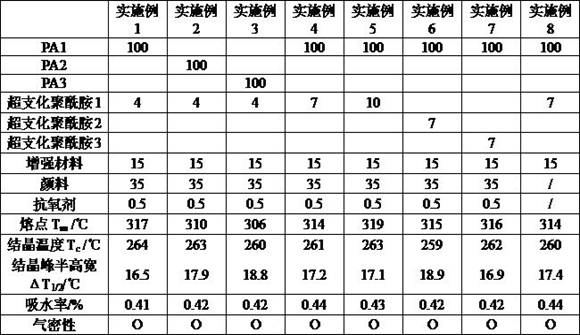

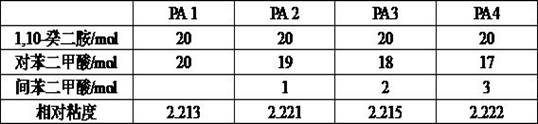

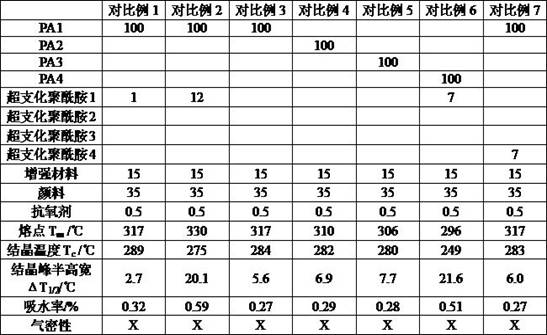

Polyamide molding composition as well as preparation method and application thereof

The invention discloses a polyamide molding composition as well as a preparation method and application thereof. The polyamide molding composition comprises the following components: 100 parts of polyamide resin; 4-10 parts of hyperbranched polyamide; 0-100 parts of a reinforcing filler; the polyamide resin is selected from any one of PA10T or PA10T / 10I. The polyamide molding composition with low crystallization temperature, low crystallization speed and low water absorption is prepared by adding a specific amount of amino-terminated hyperbranched polyamide into a polyamide material. The polyamide molding composition disclosed by the invention can delay the cooling rate of a material in a mold and improve the mold filling fluidity of the material under the condition of cold mold forming with multiple mold cavities, so that the material can better copy the mold structure, the problems of insufficient injection and insufficient glue are avoided, the air tightness of a workpiece is further improved, the method is suitable for the field of LED display screen reflection supports.

Owner:KINGFA SCI & TECH CO LTD +1

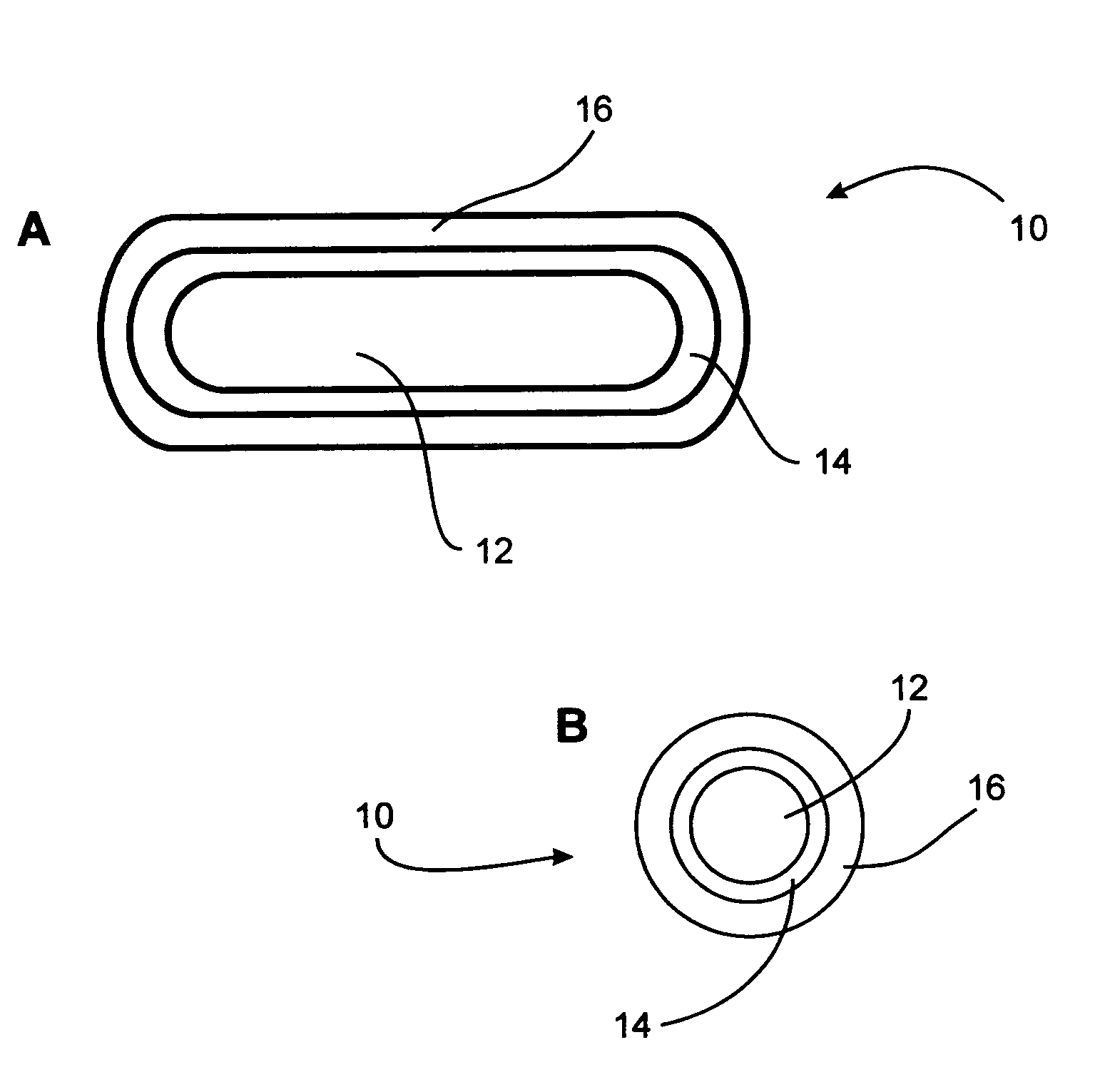

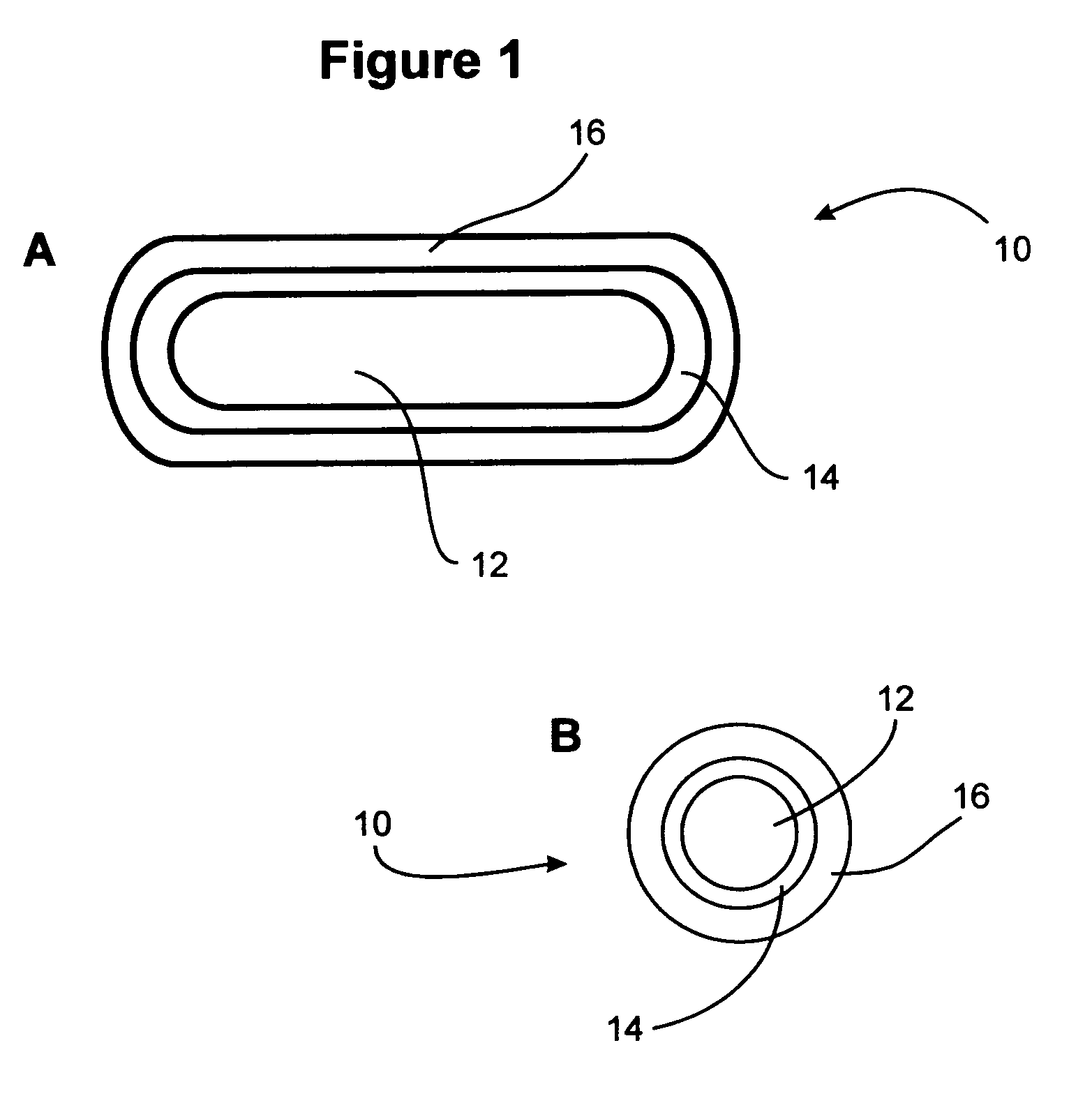

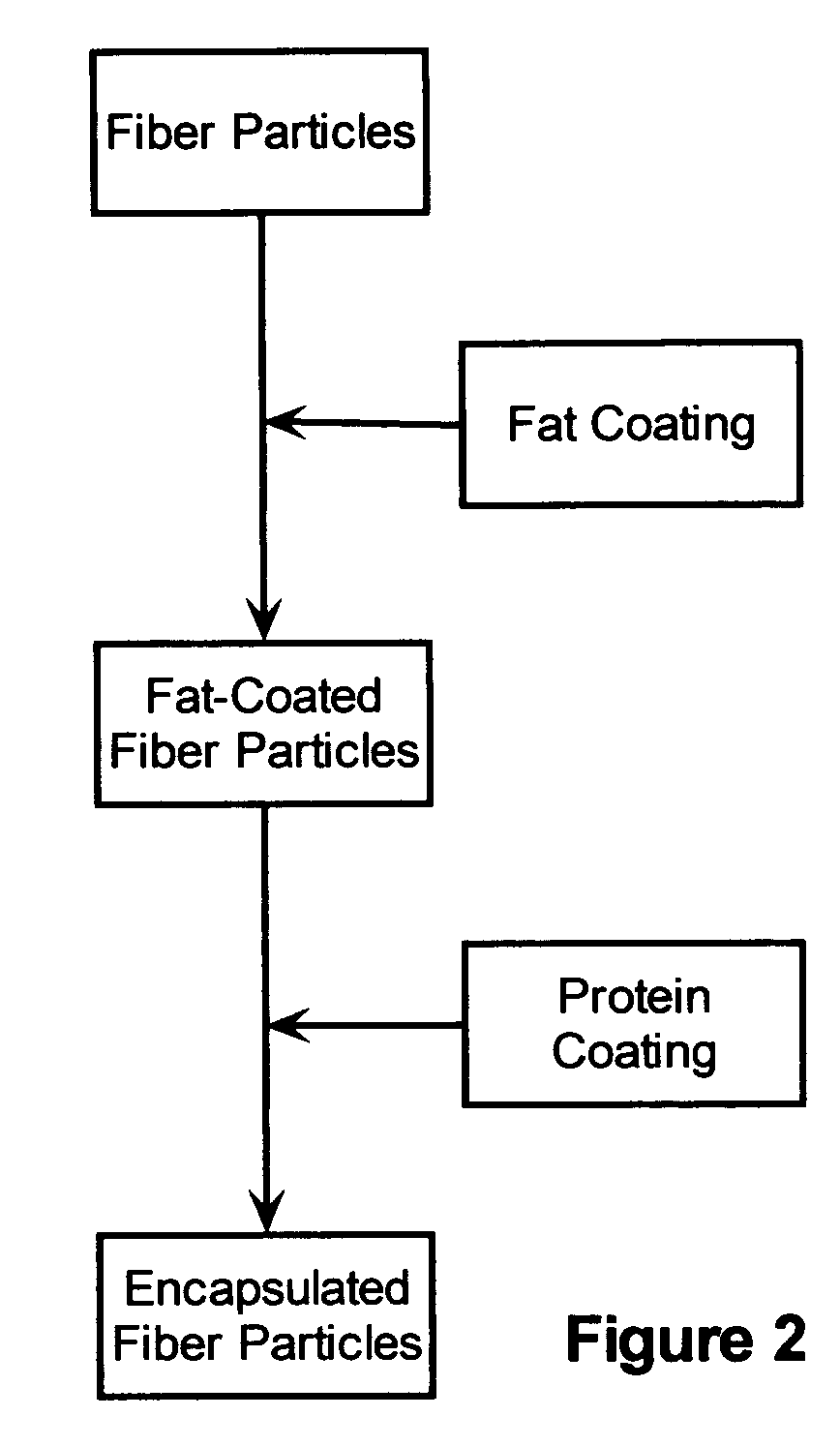

Delivery system for low calorie bulking agents

InactiveUS7981453B2Swelling of the edible fiber) can be effectively delayedNormal digestive processes beginDough treatmentLipidic food ingredientsFiberFiller Excipient

The present invention generally relates to low calorie bulking agents (e.g., cellulose, starch, bran, glucans, hydrocolloids, and the like) coated with a lipid compound to form a base or inner layer and thereafter encapsulating the fiber / lipid complex within a protein compound as an outer layer. In effect, the present invention provides a delivery system for edible fibers wherein the moisture absorption by the edible fibers can be controlled. Using the encapsulated fiber of this invention, the absorption of water by the edible fiber (and thus the swelling of the edible fiber) can be effectively delayed until the encapsulated fiber reaches the stomach and normal digestive processes begin.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

Preparation method of fruit and vegetable crisps

InactiveCN107692117AReduce the rate of water absorptionSlow water absorptionFruits/vegetable preservation by coatingFruits/vegetable preservation by dehydrationChemistryDried fruits

The invention discloses a preparation method of fruit and vegetable crisps. The preparation method comprises the following steps of performing film painting treatment on fruit and vegetable blanks after being subjected to vacuum freezing and drying with a film painting solution which is prepared in advance, and performing drying after film painting, so as to obtain the fruit and vegetable crisps.Compared with the prior art, the preparation method has the beneficial effects that the method for performing film painting treatment on the fruit and vegetable blanks after being subjected to vacuumfreezing and drying is used, so that the effect of slowing the moisture absorption rate of the fruit and vegetable crisps can be realized; a film painting layer is used for packing the fruit and vegetable crisps, and the fruit and vegetable crisps are separated from air, so that moisture regain time is slow, the texture of the fruit and vegetable crisps is not liable to soften, and the texture ismaintained; and thereof, the shelf life of the frozen-fried fruit and vegetable crisps is prolonged. The fruit and vegetable crisps disclosed by the invention are subjected to film painting treatment,and film painting on the surface has the protective effect, so that the moisture absorption is not liable to cause, and the business application value of the frozen-dried fruits and vegetables is greatly increased.

Owner:SERICULTURE & AGRI FOOD RES INST GUANGDONG ACAD OF AGRI SCI

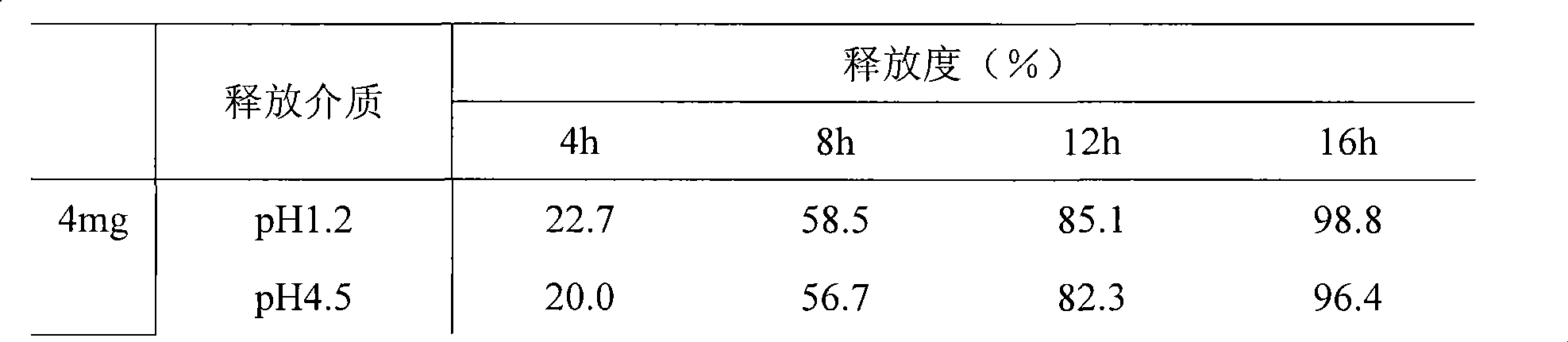

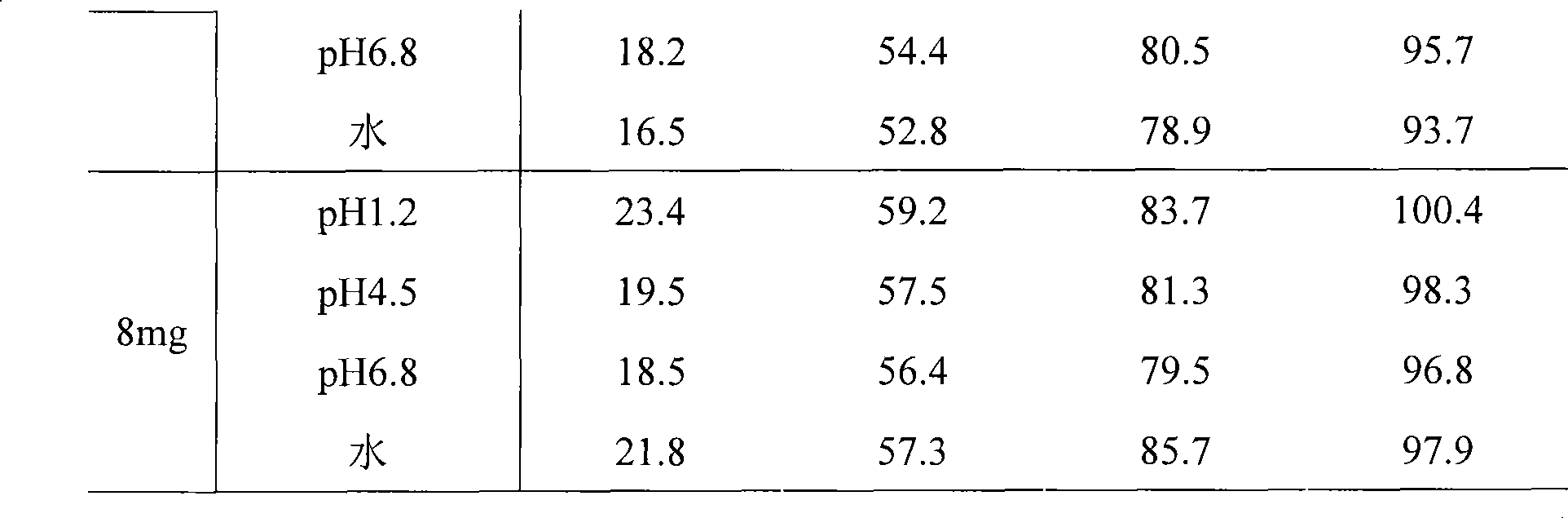

Controlled release preparation containing doxazosin or salt thereof and preparation method thereof

ActiveCN101439026AImprove thermal stabilityControlled release purpose is goodOrganic active ingredientsPharmaceutical non-active ingredientsWater insolubleDoxazosin

The invention provides a controlled release preparation for doxazosin or salts thereof, wherein, the controlled release preparation comprises a drug containing layer and a boosting layer which have the weight ratio of 1 : 0.5 to 3. The drug containing layer comprises the doxazosin or salts thereof and a carrier, and the carrier is vinylpyrrolidone polymers which occupy 40 percent and 99 percent of the weight of the drug containing layer; the boosting layer at least comprises permeability promoting polymers occupying 10 percent to 80 percent of the weight of the boosting layer, 10 percent to 80 percent water insoluble polymers and 3 percent to 60 percent osmotic pressure accelerators; a controllable speed release drug of the doxazosin or the salts which can be accepted by the doxazosin in pharmacy causes the preparation to achieve the purpose that the doxazosin or the salts which can be accepted by the doxazosin in pharmacy can be released within about 24 h through once drug feeding daily.

Owner:OCEAN STAR INT

Method for making high water absorption resin

The invention provides a method for manufacturing a water absorbing resin in a stable manufacturing mode; the method adds a polymerization reaction initiator into water-soluble unsaturated monomers for carrying out polymerization reaction so as to generate an opaque aqueous solution of unsaturated monomers or prepare the water absorbing resin under the polymerization reaction temperature of hydrogel. The obtained water absorbing resin is characterized by good physical property expression and low content of soluble compositions.

Owner:FORMOSA PLASTICS CORP

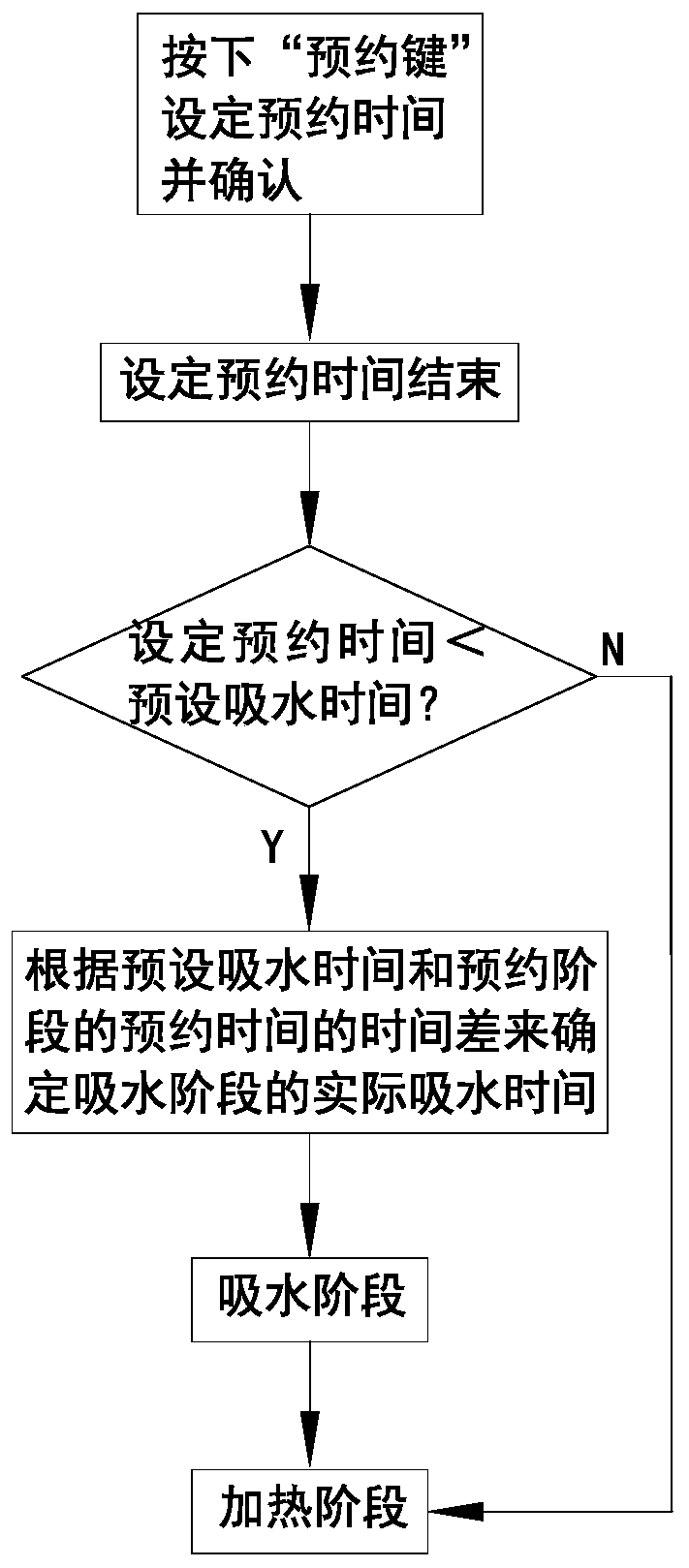

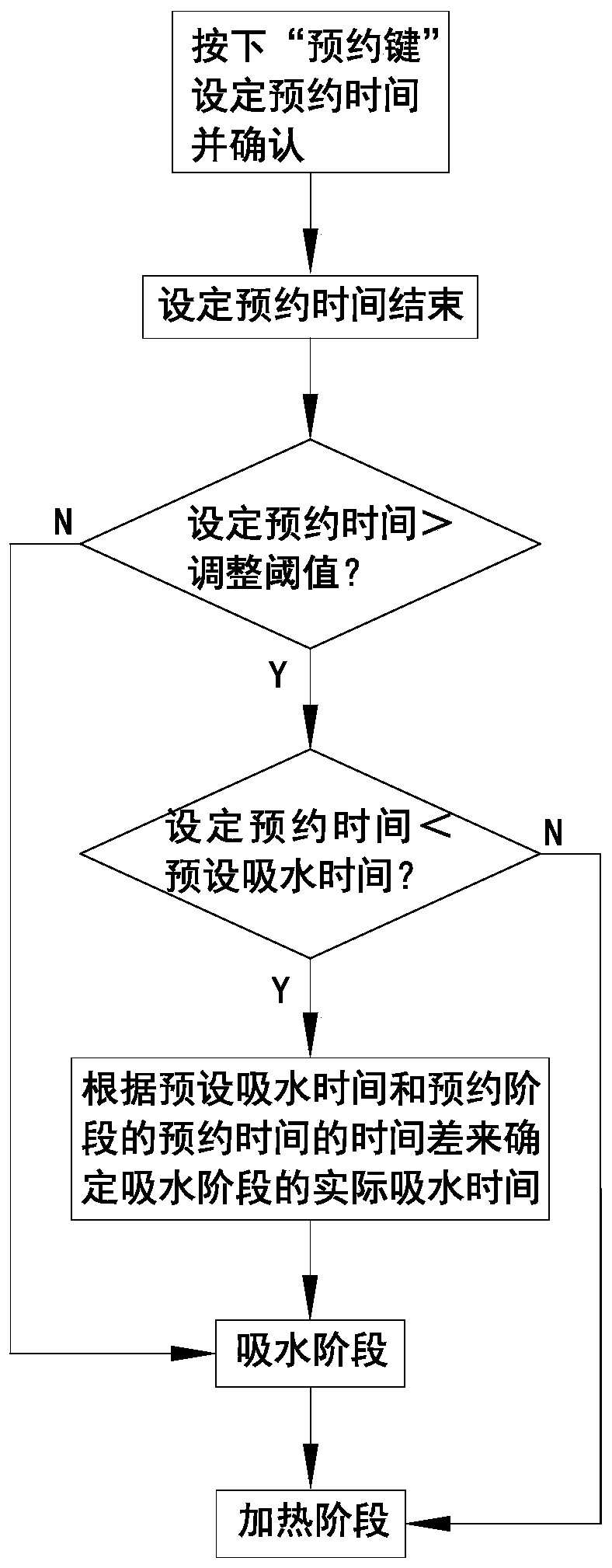

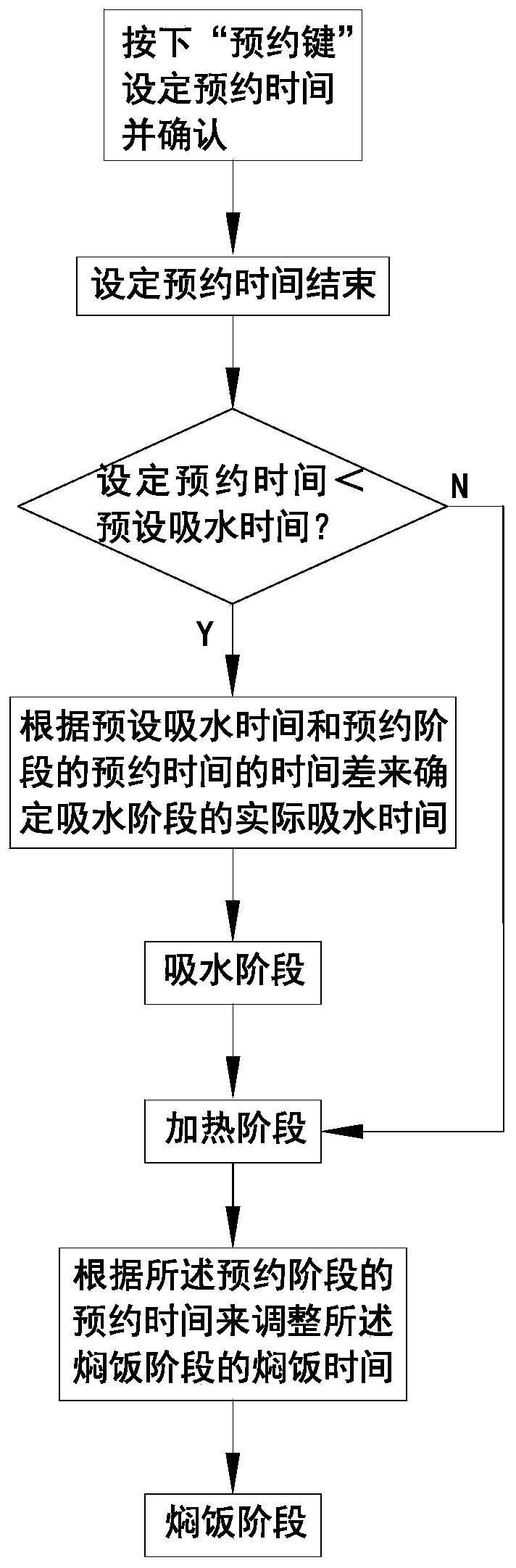

Reserved cooking method of cooking utensil

PendingCN111166194APrevent water absorptionImprove experienceTime-controlled ignitorsProcess engineeringCooking methods

The invention, which belongs to the technical field of kitchen cooking utensil control, discloses an reserved cooking method of a cooking utensil, thereby solvinga problem that in the prior art, excessive water absorption of rice grains is easily caused when the cooking utensil cooks rice under a reserved cooking function. The reserved cooking method comprises a reservation stage and a cooking stage including a water absorption stage and a heating stage. After the cooking utensil enters the cooking stage, the actual water absorption time of the water absorption stage is adjusted according to preset water absorption time and the reservation time of the reservation stage. The water absorption stage is no longer carried out according to the solidification time of the programbut is automatically adjusted according to the reservation time of the reservation stage, so that the excessive water absorption of rice grains in the water absorption stage in the reservation cooking function is avoided.

Owner:JOYOUNG CO LTD

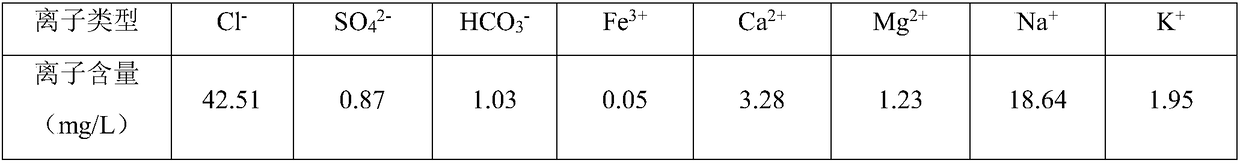

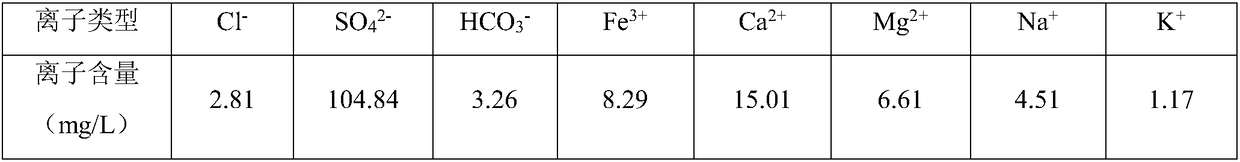

Black shale soluble salt extracting method

The invention discloses a black shale soluble salt extracting method which comprises the following steps: (1) preparing black shale into a centimeter-level block sample in any shape; (2) utilizing a vacuum drying box to dry the sample and weighing; (3) adding distilled water and an organic reducing agent acetone oxime into a container to make a water solution be in strong reducing environment (anEh value is lower than -200mV); (4) completely immersing the shale block sample into the water solution in the step (3) and utilizing an oxidizing and reducing potentiometer and a conductivity meter to respectively monitor the Eh value and conductivity of the water solution in real time; (5) controlling the adding amount of the acetone oxime in an extracting experiment process to make the water solution keep the strong reducing environment (the Eh value is smaller than -200mV); (6) obtaining an extracting solution containing the black shale soluble salt when a conductivity value of the water solution does not increase any more. By means of the black shale soluble salt extracting method disclosed by the invention, mineral oxidization and dissolution in a soluble salt extracting process areeffectively avoided, and the soluble salt is prevented from being lost in a sample preparing process; thus, accurate black shale soluble salt ion composition data can be obtained.

Owner:SOUTHWEST PETROLEUM UNIV

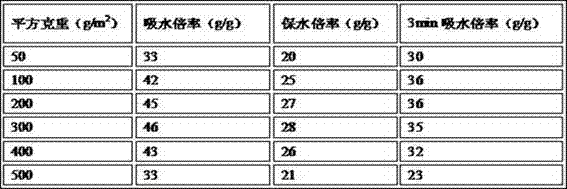

Preparation method of high water absorption composite body

InactiveCN107245875AParticle size controllableReduce absorption rateFibre typesUltrasonic/sonic fibre treatmentIn situ polymerizationMicrowave

The present invention discloses a preparation method of a high water absorption composite body. The preparation method comprises: carrying out plasma etching treatment on an ES fiber hot air nonwoven fabric to produce a defective active catalytic site, adhering a high water absorption polymerization liquid to the ES fibers in an ultrasonic spraying manner, and carrying out in situ polymerization cross-linking on the surface of the hot air nonwoven fabric in a microwave reaction heating manner to form high water absorption resin particles so as to prepare the high water absorption composite body. The high water absorption composite body of the present invention is mainly used in paper diaper, sanitary napkin, products for incontinence, pet urine pads, and other absorption core bodies.

Owner:FUJIAN HENGAN HLDG CO LTD +2

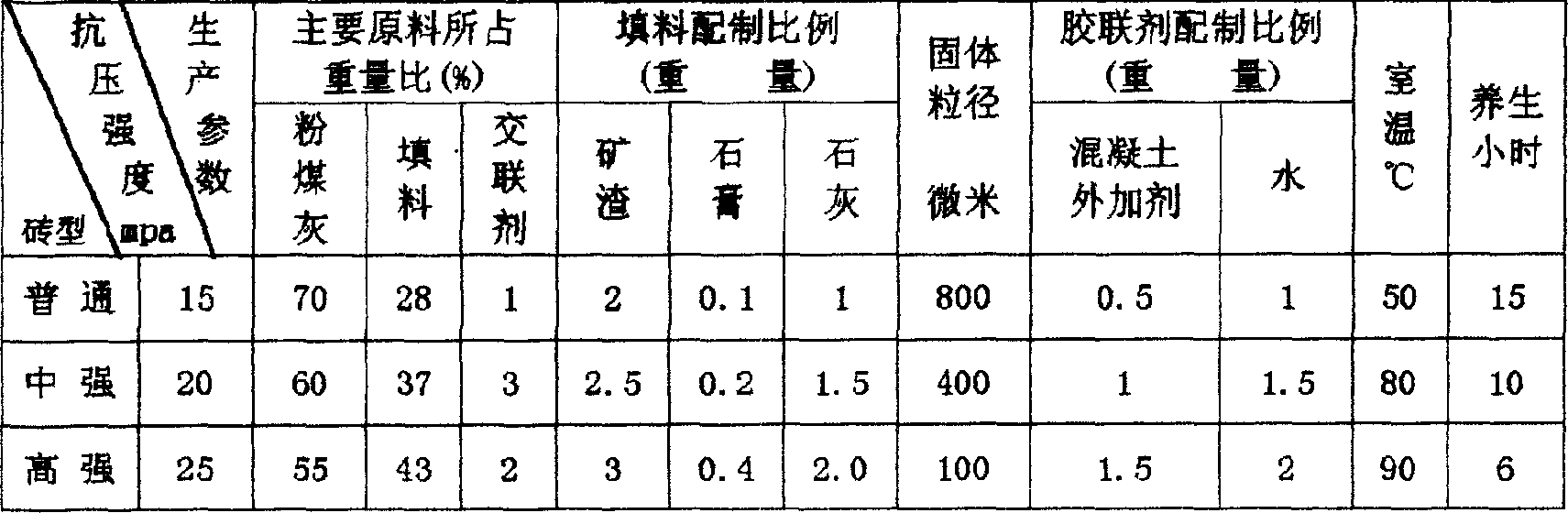

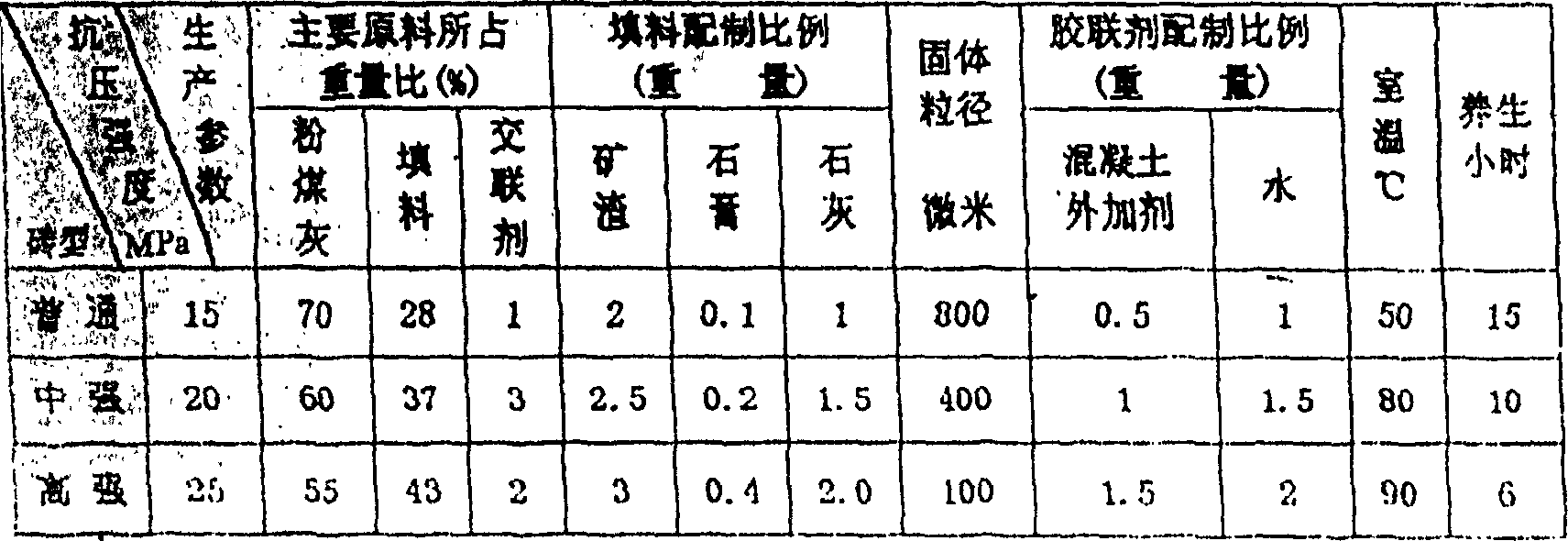

Method for producing flyash brick

A powdered coal ash brick with high compression strength and no shrinking and cracking is proportionally made up of powdered coal ash, slags, gypsum, lime, and the mixture of concrete additive and water through pulverizing, proportional mixing, adding said mixture as cross-linking agent, die pressing and curing.

Owner:时跃明

Chlorine dioxide slow-release particle sterilization disinfectant and preparation method thereof

InactiveCN112120020AAvoid it happening againAvoid pollutionBiocideDisinfectantsSodium bicarbonateActive agent

The invention discloses a chlorine dioxide slow-release particle sterilization disinfectant and a preparation method thereof. The chlorine dioxide slow-release particle sterilization disinfectant is prepared from the following components in percentage by mass: 40% of self-made citric acid; 20% of sodium chlorite; 17.5% of a drying agent sodium chloride; 5% of sodium bicarbonate; 5% of a sustained-release agent sodium cyclamate; 2% of an activator; 0.1% of essence; 0.05% of a fluorine-containing surfactant; 10.35% of a filler sodium sulfate; the preparation method comprises the following steps:firstly, preparing citric acid, secondly, weighing the components, and uniformly mixing the weighed citric acid, activating agent, fluorine-containing active agent, filler sodium sulfate and drying agent sodium chloride to prepare a composite material for loading the acidifying agent on the adsorbent; and adding the weighed sustained-release agent sodium cyclamate into the prepared composite material to prepare a sustained-release agent carrier, finally, uniformly mixing the weighed sodium chlorite and sodium bicarbonate, adding the mixture into the sustained-release agent carrier, and uniformly mixing to obtain the product. The disinfectant has the advantages of uniform , low-speed and effective release of chlorine dioxide gas.

Owner:任建军

Method for producing flyash brick

InactiveCN1313409CSimple methodMaterials are readily availableSolid waste managementCross-linkPolymer science

A powdered coal ash brick with high compression strength and no shrinking and cracking is proportionally made up of powdered coal ash, slags, gypsum, lime, and the mixture of concrete additive and water through pulverizing, proportional mixing, adding said mixture as cross-linking agent, die pressing and curing.

Owner:时跃明

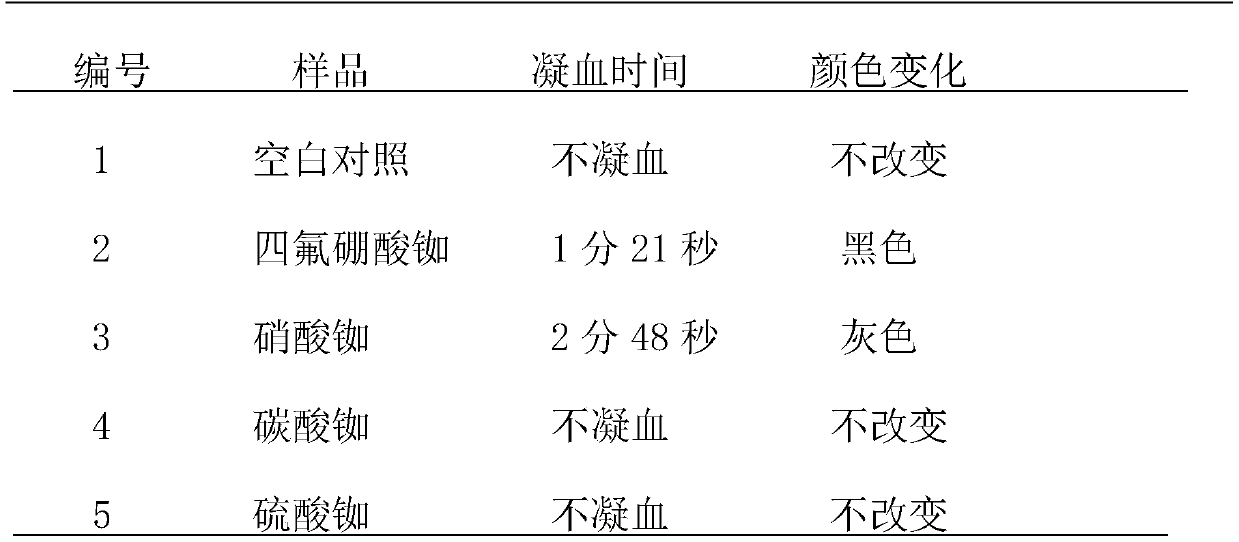

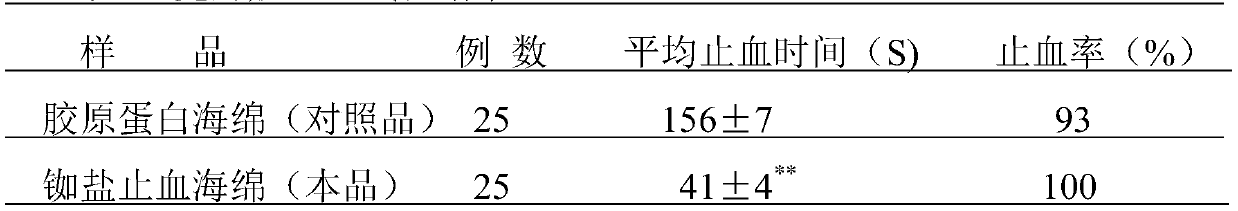

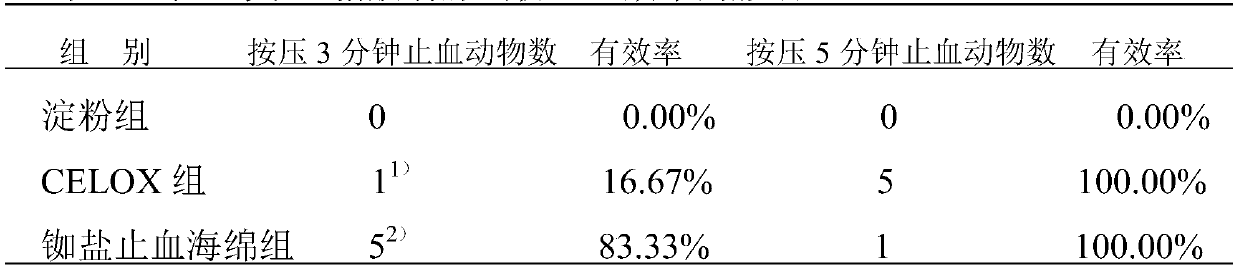

Rubidium salt hemostatic sponge and application thereof

PendingCN110368518AGood tissue adhesionNon-immunogenicSurgical adhesivesPharmaceutical delivery mechanismSide effectWhole body

The invention provides a rubidium salt hemostatic sponge and application thereof. The rubidium salt hemostatic sponge comprises rubidium salt, collagen and a plasticizer, and the mass ratio of the rubidium salt, the collagen and the plasticizer is (1-8): 100: (1-5). The rubidium salt hemostatic sponge provided by the invention can be used as a trauma emergency hemostatic material, has good tissueadhesion, can rapidly stop bleeding and promote tissue healing, has no immunogenicity, sterility, no toxicity and no stimulation, has good biocompatibility and absorbability and degradability, and hasno side effect on the body. Meanwhile, the hemostatic wound protection bandage is simple to operate and convenient to use, is suitable for hemostasis of gunshot wounds and explosive wounds of all parts of the chest and abdomen and the whole body, and can also be conveniently used for hemostasis of special parts, such as neck, armpit and groin, of limb joints where a tourniquet is difficult to use.

Owner:易杨华

Concrete curing agent containing modified pina fibers as well as manufacturing method and application of concrete curing agent

The invention discloses a concrete curing agent containing modified pina fibers as well as a manufacturing method and application of the concrete curing agent. The concrete curing agent is prepared from the following components in percentage by mass: 25 percent to 32 percent of the modified pina fibers, 48 percent to 55 percent of styrene-acrylic emulsion, 2.3 percent to 2.7 percent of dibutyl diformate, 0.45 percent to 0.78 percent of a fluorocarbon modified polyacrylate leveling agent, 0.12 percent to 0.18 percent of an organic silicon de-foaming agent, 0.18 percent to 0.22 percent of tributyl phosphate and the balance of water, wherein the modified pina fibers are prepared from pina fibers, silica sol, concentrated hydrochloric acid, nano calcium oxide and vinyl trimethoxy silane. The concrete curing agent with high water retention rate and anti-cracking and shrinkage reducing effect is obtained through the following steps: taking the modified pina fibers and water which is one half of the mass of a formula amount at the ratios, and uniformly mixing to obtain a first mixed solution; weighing the other components at the ratios, and uniformly mixing to obtain a second mixed solution; combining the first mixed solution and the second mixed solution, and sufficiently and uniformly stirring to obtain the product.

Owner:安徽阳光水泥有限公司

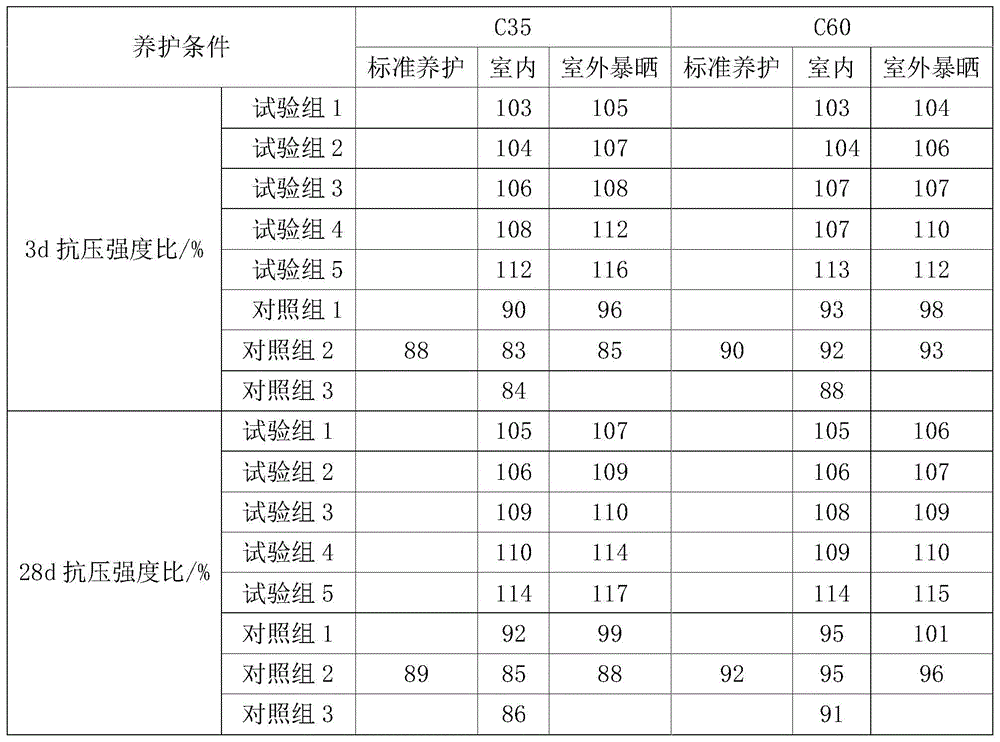

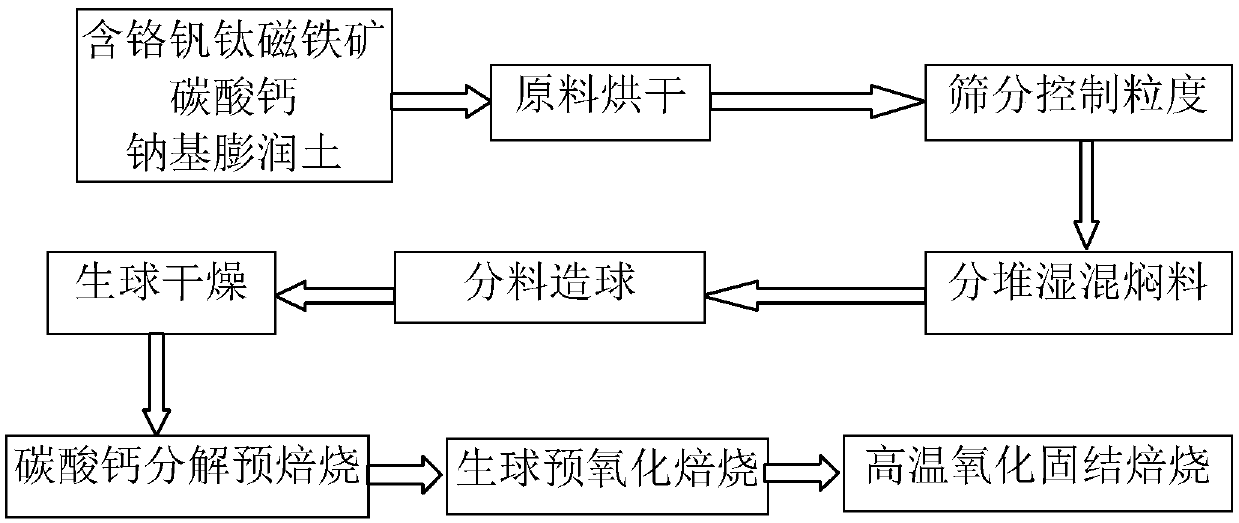

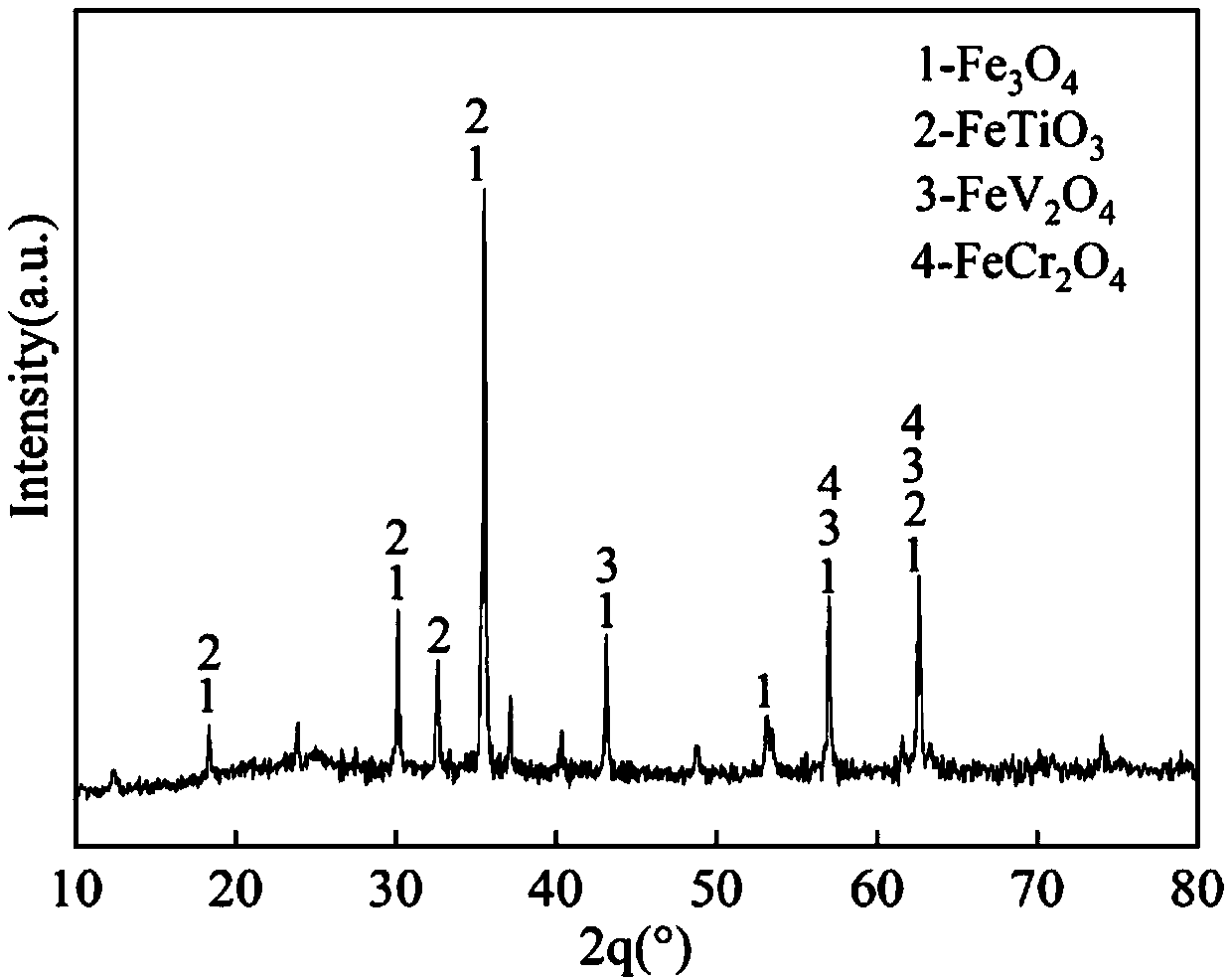

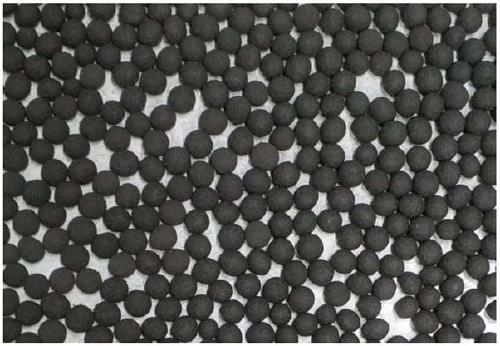

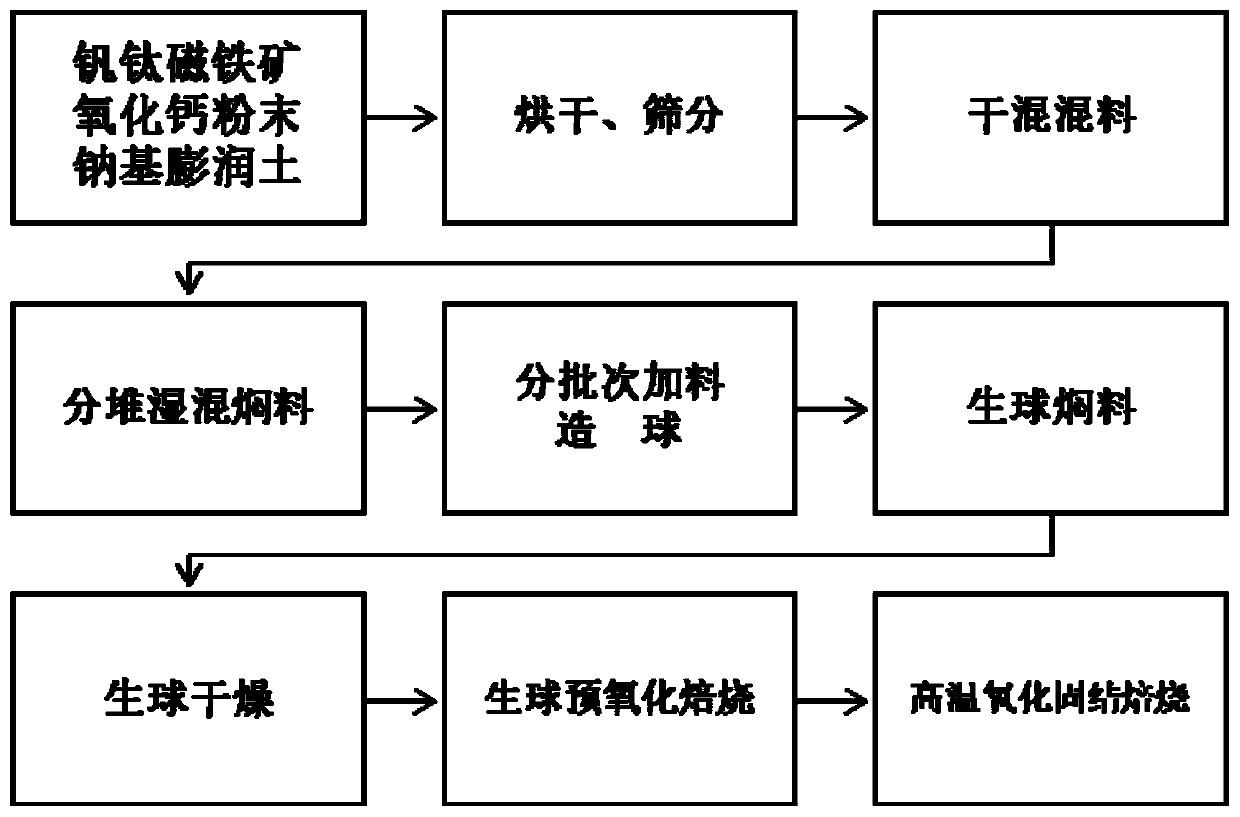

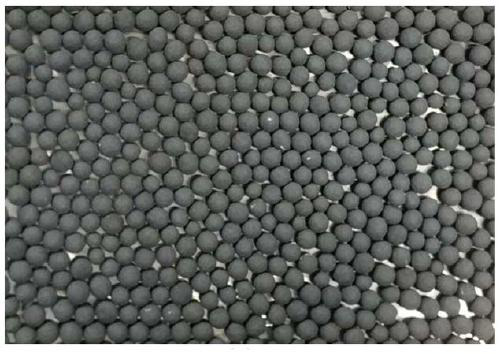

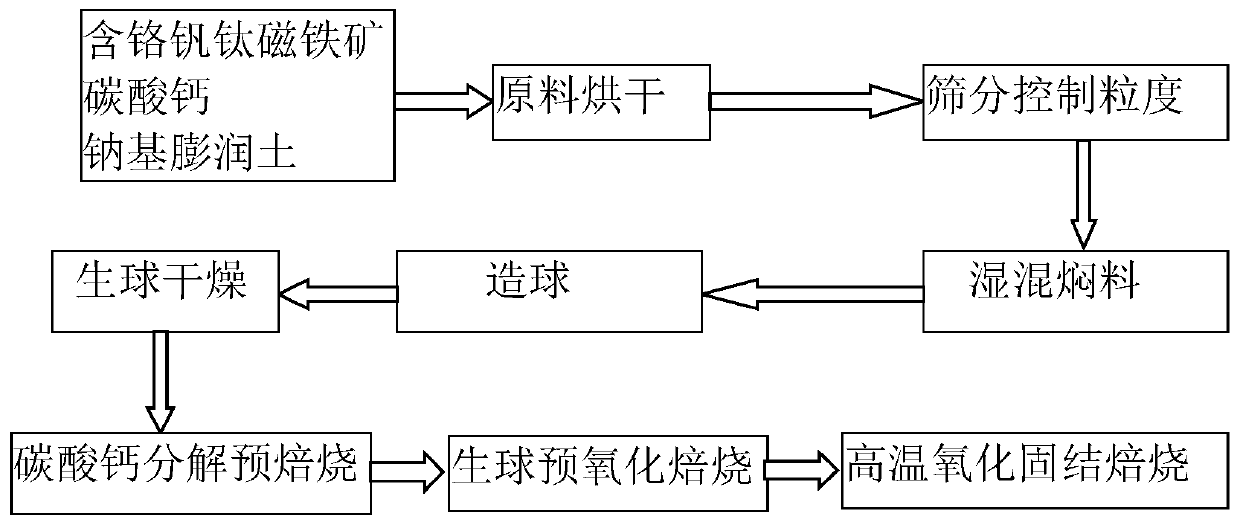

Method of preparing high-alkalinity chromium-containing all-vanadium titaniferous pellets by adding calcium carbonate

The invention relates to a method of preparing high-alkalinity chromium-containing all-vanadium titaniferous pellets by adding calcium carbonate. The method comprises the following steps that S1, batching is performed, calcium carbonate and sodium-based bentonite ingredients are added into red-lattice chromium-containing vanadium titano-magnetite; S2, the mixture is divided into two parts, the first part of the mixture material is added with 3-4% of water by mass, the second part of the mixture material is added with the 6-8% of the water by mass, and wet mixing and leaving the materials to stand to ferment are performed correspondingly; and S3, material dividing and pelletizing are performed, pelletizing is performed on a disk pelletizer with revolving speed of 30-45 r / min, the water spraying amount is controlled to be 1-2 ml / 10 g of mineral aggregates, and the water adding and material feeding are performed per 30-100 seconds at intervals; the first part of mineral aggregates are used for pelletizing in the forming period of a master ball, and the second part of ore material aggregates are used for pelletizing in the growth period of the mother ball; S4, drying is performed; S5,the calcium carbonate is decomposed, pre-oxidated and pre-roasted, the calcium carbonate is decomposed and pre-roasted firstly at the temperature of 900-950 DEG C, and then insufficient amount of airis introduced into a furnace for pre-oxidation and pre-roasting; and S6, high-temperature oxidation consolidation roasting is performed, the incremental air is introduced into the furnace at the temperature of 1250-1300 DEG C to perform the high-temperature oxidation consolidation roasting, after sintering is completed, cooling is performed to prepare the high-alkalinity chromium-containing all-vanadium titaniferous pellets.

Owner:NORTHEASTERN UNIV LIAONING

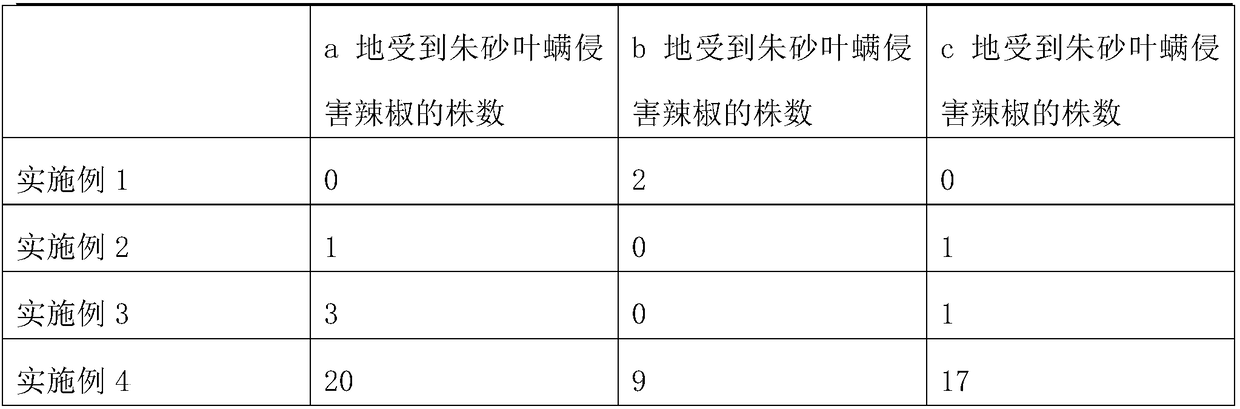

Insect resistance planting method for chili

InactiveCN108934821AIncrease vitalitySlow water absorptionPlant protectionSeed immunisationAlcoholPesticide residue

The invention discloses an insect resistance planting method for chili, and belongs to the technical field of chili. The method comprises the following steps that step one, chili seeds are soaked in apotassium manganite solution, ultrasonic waves are utilized for conducting ultrasonic treatment, then the chili seeds are placed in warm water for soaking, and finally the chili seeds are subjected to pregermination until the seeds sprout; step two, the seeds sprouting are sowed in soil; step three, a miscellaneous fertilizer and a compound fertilizer are applied for a long term in the chili plant growing period; step four, in May and June, tuberous roots of white hellebore and seeds of milfoil are smashed and mixed, then the mixture of white hellebore and milfoil is laid beside chili seedlings, ethyl alcohol is sprayed on the mixture, the mixture is cover with film, and after 5-7 days, the mulching film is uncovered. The prevention and control method solves the problem that the chili isdamaged by tetranychuscinnabarinus, it is not necessary to spray pesticide on the chili, and it is avoided that the amount of pesticide residues remaining on the chili is high, and after eating, the human health is influenced.

Owner:遵义天旺华胜种植有限公司

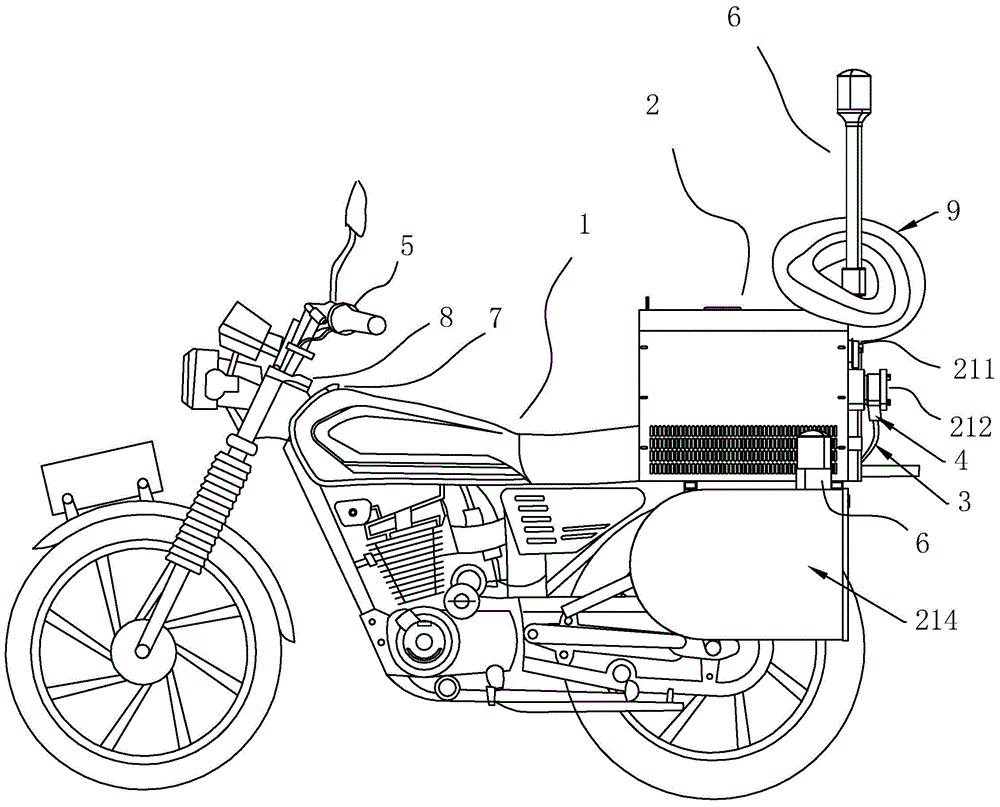

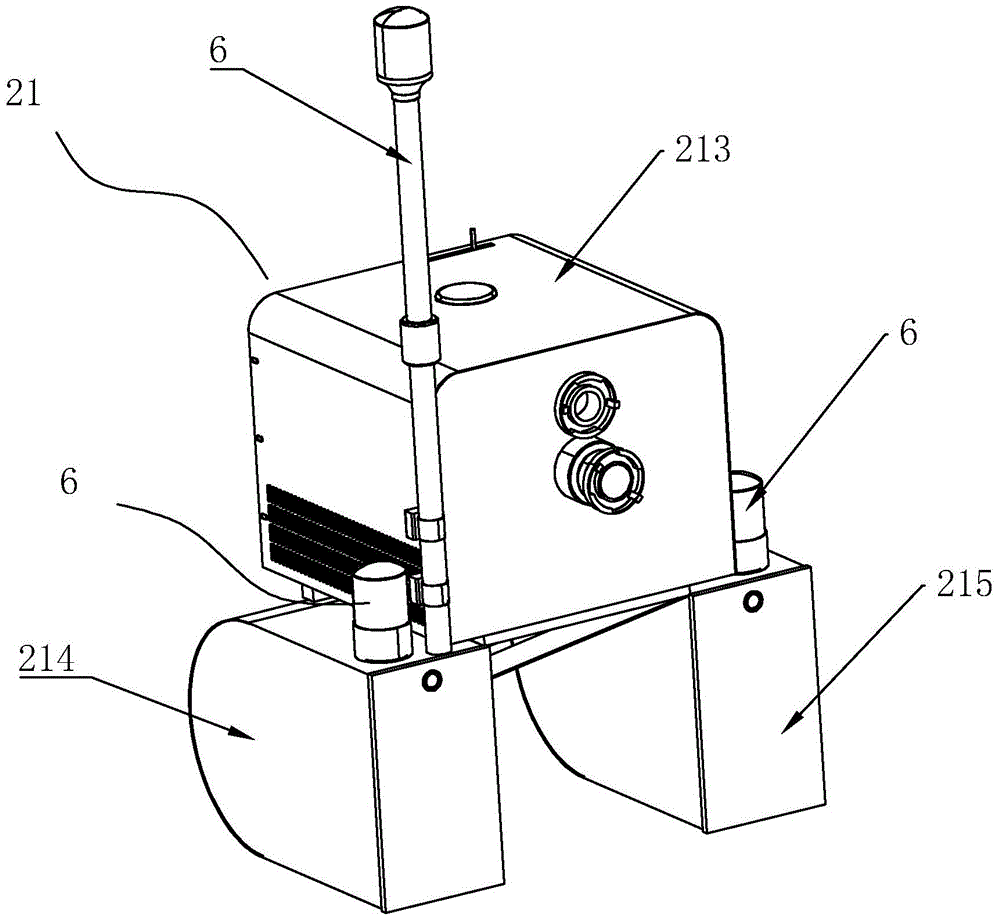

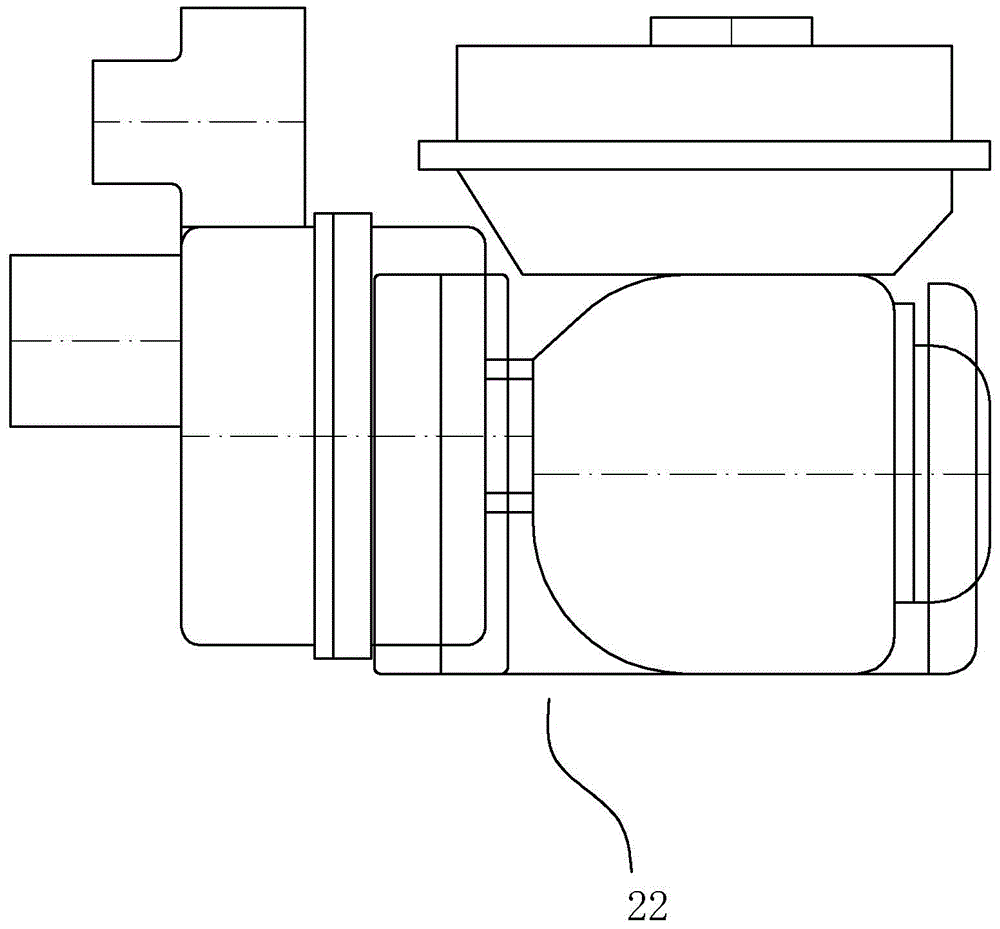

Small multi-functional motorcycle

InactiveCN104906728AExtension of timeImprove water absorption speedFire rescueInlet valveEngineering

The invention discloses a small multi-functional motorcycle. The small multi-functional motorcycle comprises a motorcycle body and a fire extinguishing system, the fire extinguishing system comprises a water supply unit fixed on the motorcycle body, a high-pressure self-sucking pump arranged in the water supply unit, and a straightway pump fixed on the water supply unit, the water inlet of the high-pressure self-sucking pump is connected with a spray pipe joint on the water supply unit while the water outlet is connected with a water inlet joint on the water supply unit, the water outlet of the straightway pump is connected with a high-pressure water pipe, the high-pressure water pipe is connected with the water inlet of the high-pressure self-sucking pump through an inlet valve, and the water inlet of the straightway pump is connected with a straightway pump water pipe. The small multi-functional motorcycle is smart, convenient to use, convenient to run on a narrow road and fast in pumping speed.

Owner:CHINA ONEPOWER ELECTRIC CO LTD

Polarizing plate and liquid crystal display

ActiveUS9013656B2Suppress light leakageLow moisture permeabilityPolarising elementsNon-linear opticsTectorial membraneCellulose

Owner:FUJIFILM CORP

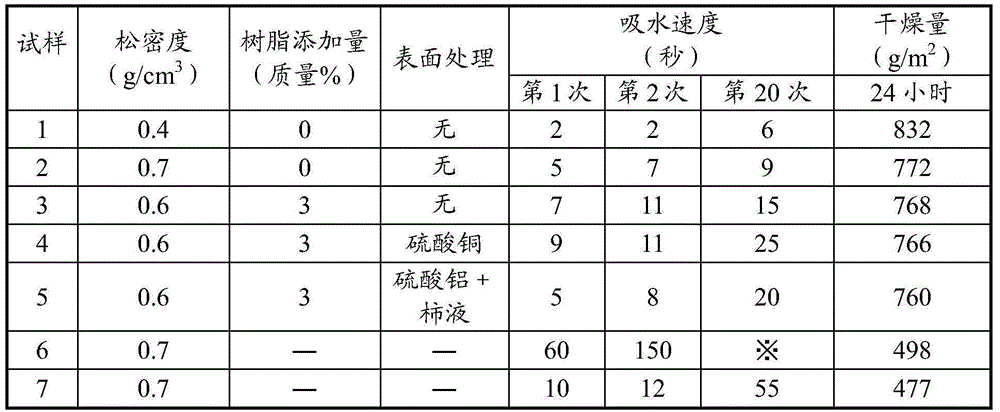

Manufacturing method of foot drying pad

InactiveCN106510524AImprove water absorptionFast water absorptionDomestic applicationsCalcium silicateContinuous use

The invention provides a manufacturing method of a foot drying pad which is high in water absorbing speed and high in drying speed and cannot become declined in water absorbing speed after continuously used. According to the manufacturing method of the foot drying pad provided by the invention, the foot drying pad is constituted by an inorganic substance molding plate, and the method comprises the following steps: 1, stirring raw material slurry consisting of a calcareous raw material, a siliceous raw material and water, and simultaneously, conducting a hydrothermal reaction, so that waterborne slurry containing calcium silicate secondary particles is obtained; and 2, dehydrating and forming the waterborne slurry obtained in the step 1, so that the inorganic substance molding plate is obtained. The foot drying pad manufactured by the manufacturing method comprises the inorganic substance molding plate which is formed by the calcium silicate crystallized secondary particles and / or a compressive deformation substance of the secondary particles, and the bulk density of the inorganic substance molding plate is 0.2-0.7g / cm3.

Owner:日本怡饰丽新株式会社

Processing method for rice with good eating taste

The invention discloses a rice processing method with good edible taste, which comprises the steps of: using the difference in aerodynamic properties of the rice and impurities to perform winnowing to remove the impurities mixed in the rice to achieve the purpose of purifying the rice; The selected rice is subjected to the treatment of removing the husk, and the hulled matter is removed to obtain the hulled rice, which includes brown rice, rice husk and bran; for the rice feed obtained in step (2), the The whitening room is used for rice milling, and the finished rice is obtained from the output. The whitening room includes a roller, a rice sieve and a rice polishing room to realize the combination of rice milling and rice polishing. Through the above method, the rice processing method with good eating taste of the present invention can ensure that the degree of fatty acid oxidation of the rice is low, the water absorption speed is slow in the process of making rice, and the obtained rice has good appearance, high freshness, good eating quality and good taste.

Owner:太仓市绿苗农场专业合作社

A method for preparing high-basic chromium-vanadium-titanium pellets by using calcium oxide

The invention relates to a method for preparing high-alkalinity chromium-containing vanadium-titanium pellets by using calcium oxide. The method is to batch raw materials including vanadium-titanium magnetite and additives calcium oxide powder and sodium bentonite so that the alkalinity is 1.8 ~2.1, dry and dry mix the materials respectively; divide the mixed mineral materials into two parts evenly, add 3~4% water of the total mass of raw materials to the first part, and add 6~4% of the total mass of raw materials to the second part 8% water, mix evenly, seal and let stand; when making balls, use the first part of the mineral powder during the cue ball forming period, and the second part of the mineral powder for the long term when the cue ball grows. Spray before the cue ball grows. The amount of water is controlled at 1ml / 10g mineral powder ~ 2ml / 10g mineral powder to prevent adhesion between the cue balls, and the interval between each water addition and feeding is 40 to 90 seconds, so that the diameter of the produced pellets is within 8mm ~ 12mm; Carry out green pellet stewing, drying, pre-oxidation roasting, and secondary high-temperature oxidation roasting to obtain high-alkalinity chromium-containing vanadium-titanium pellets.

Owner:NORTHEASTERN UNIV LIAONING

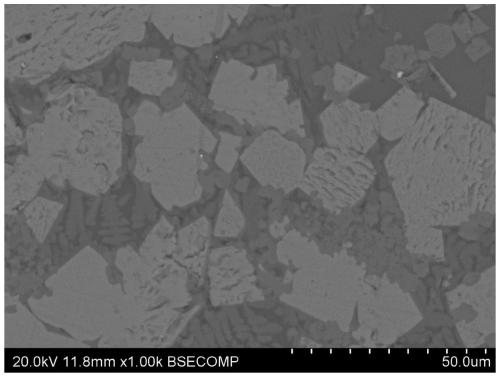

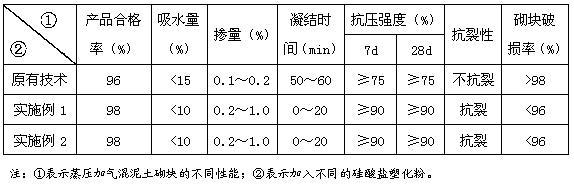

Silicate plasticizing powder

The invention relates to the autoclaved aerated concrete block field, and discloses a silicate plasticizing powder enabling autoclaved aerated concrete blocks to have the characteristics of high product qualification rate, slow block water absorption and high compressive strength. The silicate plasticizing powder comprises a carrier, an anionic surfactant and a setting accelerator; the anionic surfactant comprises a first anionic surfactant and a second anionic surfactant; the mass of the first anionic surfactant is 14.0-0.25% of the mass of the carrier; the mass of the second anionic surfactant is 11.0-0.25% of the mass of the carrier; and the setting accelerator is 5%-0 of the mass of the carrier. The application of the above technical scheme in the embodiment of the invention makes the silicate plasticizing powder have the properties of negative ions, micro-bubbles and colloidal polar molecules, so the silicate plasticizing powder enables the autoclaved aerated concrete blocks to have the characteristics of high product qualification rate, slow block water absorption and high compressive strength.

Owner:黄琪耀 +1

Controlled release preparation containing doxazosin or salt thereof and preparation method thereof

ActiveCN101439026BShort time lagQuick effectOrganic active ingredientsPill deliveryWater insolubleDoxazosin

The invention provides a controlled release preparation for doxazosin or salts thereof, wherein, the controlled release preparation comprises a drug containing layer and a boosting layer which have the weight ratio of 1 : 0.5 to 3. The drug containing layer comprises the doxazosin or salts thereof and a carrier, and the carrier is vinylpyrrolidone polymers which occupy 40 percent and 99 percent of the weight of the drug containing layer; the boosting layer at least comprises permeability promoting polymers occupying 10 percent to 80 percent of the weight of the boosting layer, 10 percent to 80 percent water insoluble polymers and 3 percent to 60 percent osmotic pressure accelerators; a controllable speed release drug of the doxazosin or the salts which can be accepted by the doxazosin in pharmacy causes the preparation to achieve the purpose that the doxazosin or the salts which can be accepted by the doxazosin in pharmacy can be released within about 24 h through once drug feeding daily.

Owner:OCEAN STAR INT

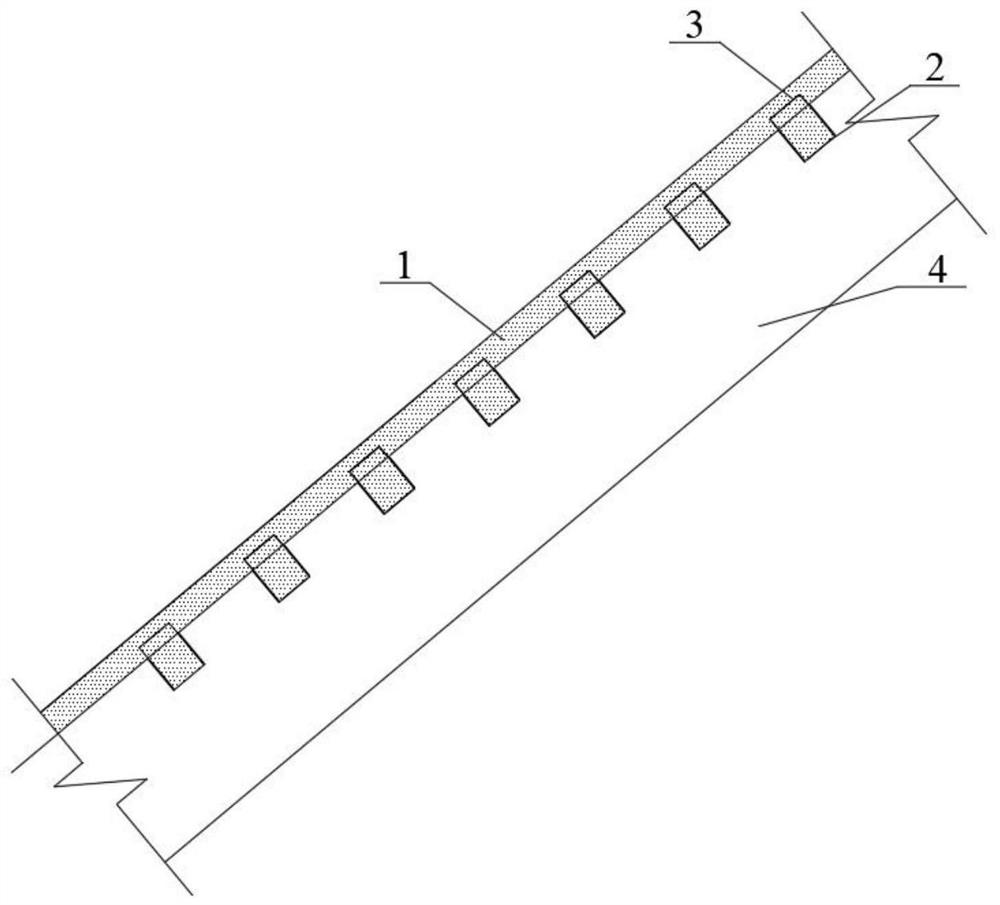

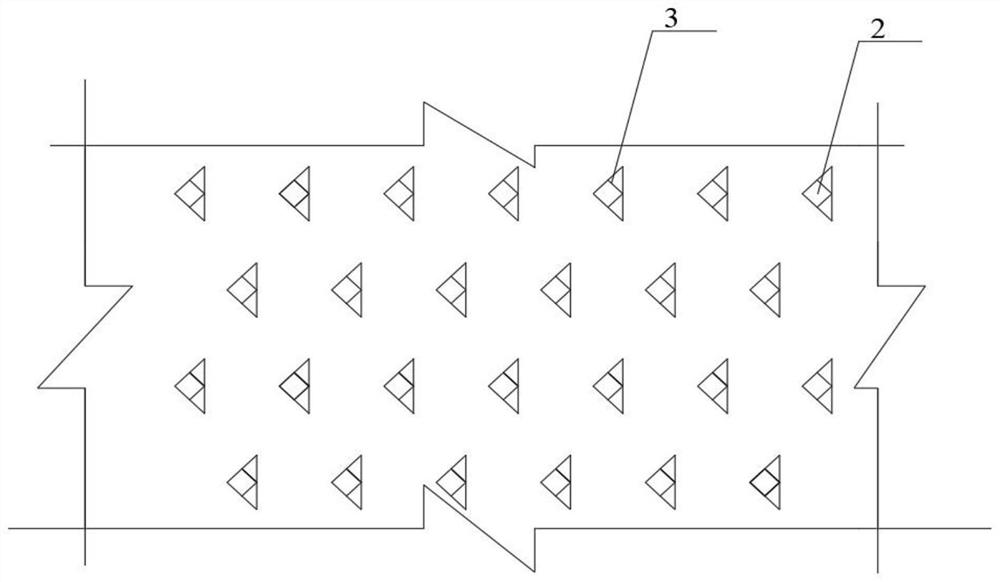

An ecological slope protection method based on straw reinforced soil substrate

The invention discloses an ecological slope protection method based on straw reinforced soil substrate. Including straw-reinforced soil substrate, plant seeds and civil grids, straw-reinforced soil substrate includes main materials and auxiliary materials, the main materials include straw and ordinary loess, the two are mixed with water to form straw-reinforced soil, and auxiliary materials include Trichoderma , potassium salt, trace element fertilizer, lime, polyvinyl alcohol powder, wherein the straw is soaked in polyvinyl alcohol solution for a period of time. Slope protection method: first level the slope surface, excavate holes in the soil layer on the slope surface, insert a part of the cage-shaped geogrid into the hole, and fill it with straw-reinforced soil substrate, cover the slope surface and the surface of the civil grid A mixture of straw-reinforced soil substrate and pure plant seeds completes the construction of the slope protection substrate. The invention can effectively recycle waste straw, reduce environmental pollution, and simultaneously improve the current situation of poor stability of the base material of ecological slope protection and barren soil of the base material. The method has low cost and wide application prospect.

Owner:HUBEI UNIV OF TECH

Artificial cell membrane coating microcarrier for cell culture and preparation method thereof

InactiveCN109055294AGood biocompatibilitySlow water absorptionMicrocarriersGeneral culture methodsChemistryPhosphorylcholine

The invention provides an artificial cell membrane coating microcarrier for cell culture and a preparation method thereof. The microcarrier provided by the invention takes konjac glucomannan microspheres as a matrix, and an artificial cell membrane coating microsphere is made by a biomimetic new material. The preparation method of the microcarrier comprises the following steps: respectively washing the matrix microspheres with petroleum ether and absolute ethyl alcohol, and drying for later use; dissolving 2-methacryloyloxyethyl phosphate choline (MPC) and n-butyl methacrylate in ethanol, polymerizing into an artificial cell membrane material under the effect of an initiator azodiisobutyronitrile (AIBN), diluting to 2 percent concentration for later use; adding the washed konjac glucomannan microspheres to an artificial cell membrane ethanol solution and soaking, and drying by a rotary evaporator in a vacuum, thus obtaining a microcarrier product. The artificial cell membrane materialcovers the surface of the microcarrier evenly and is connected firmly, has the advantages of avirulence, good cell adhesion, degradability, capability of easily eluting cells without adhesion, and thelike, the cost of the prepared microcarrier is low, the production process is simple, and the period is shorter, thus being beneficial for industrial production.

Owner:苏州怡彼得生物技术有限公司

A method for preparing self-fluxing pellets of medium-low alkalinity chromium-containing all-vanadium-titanium

The invention relates to a method for preparing medium-low alkalinity chromium-containing all-vanadium titanium self-fluxing pellets, which includes the steps: S1: Ingredients: adding calcium carbonate and sodium bentonite to red grid chromium-containing vanadium titanium magnetite; Prepare a mixture with medium and low alkalinity; S2: Wet mixed stew material: add water not exceeding 7% of the mass of the mixture, mix evenly, and then let it stand to make the humidity distribution uniform; S3: Ball making: Make it in a disc The ball machine is used to make balls at a speed of 30r / min-45r / min. During the cue ball forming period, the water spray volume is controlled at 1-2ml / 10g of mineral material to fully roll and compact the mineral material; during the cue ball growth period, increase Spray the amount of water to make pellets with a diameter of 6mm-13mm; S4: Dry the green balls; S5: Place the green balls in the furnace and raise the temperature to 900℃-950℃ for calcium carbonate decomposition and pre-baking; while maintaining heat, Insufficient air is introduced into the furnace for pre-oxidation roasting, and the roasting time is 10min-20min; S6: High-temperature oxidation consolidation roasting: Injecting incremental air into the furnace at 1250℃-1300℃ to increase the oxidizing atmosphere, and perform high-temperature oxidation After consolidation and roasting, and then cooling to room temperature, medium-low basicity chromium-containing all-vanadium-titanium self-fluxing pellets are obtained.

Owner:NORTHEASTERN UNIV LIAONING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com