Polyamide molding composition as well as preparation method and application thereof

A polyamide molding and composition technology, applied in the field of engineering plastics, can solve the problems of poor air tightness, decreased mechanical strength, and fast crystallization rate of parts, and achieves good air tightness, improved air tightness, and slow crystallization rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

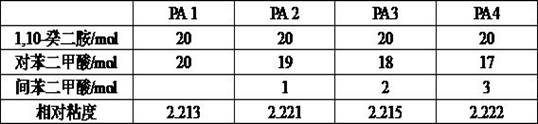

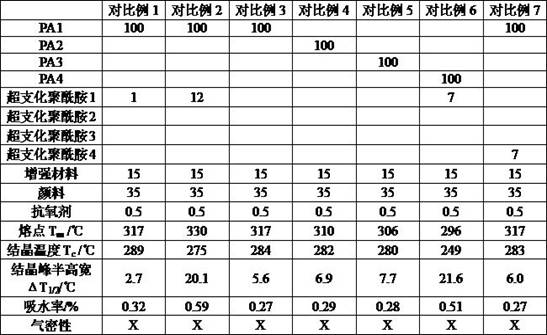

Examples

preparation example Construction

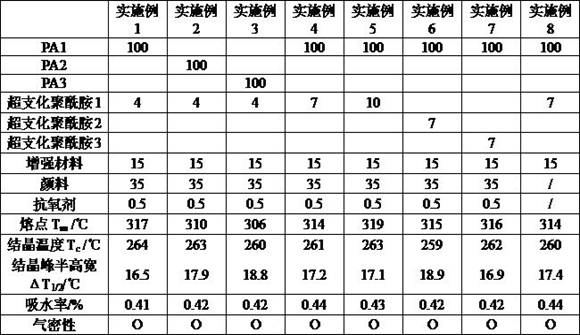

[0037]The preparation method of polyamide resin: add diamine and diacid according to the ratio in Table 1 in the autoclave equipped with magnetic coupling stirring, condenser, gas phase port, feeding port and pressure explosion-proof port; then add benzoic acid, catalyst sodium hypophosphite and deionized water; the amount of benzoic acid is 2.5% of the total amount of diamine and diacid, and the weight of sodium hypophosphite is 0.1% of the weight of other feeds except deionized water, and the weight of deionized water is 30% of the total weight of feed. %; Vacuumize and fill high-purity nitrogen as a protective gas, heat up to 220°C within 2 hours under stirring, stir the reaction mixture for 1 hour, and then raise the temperature of the reactant to 240°C under stirring; react at a constant temperature Continue under constant pressure for 2 hours, keep the pressure constant by removing the formed water, discharge the material after the completion of the reaction, and vacuum d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| crystallization temperature | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com