Method for preparing microcapsulated superfine red phosphorus

A technology of microencapsulation and red phosphorus, applied in chemical instruments and methods, inorganic chemistry, phosphorus compounds, etc., can solve the problem of large phosphine release, weak surface adhesion of red phosphorus, and combination of coating layer and red phosphorus It can reduce the amount of PH3, stabilize the powder, and improve the strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

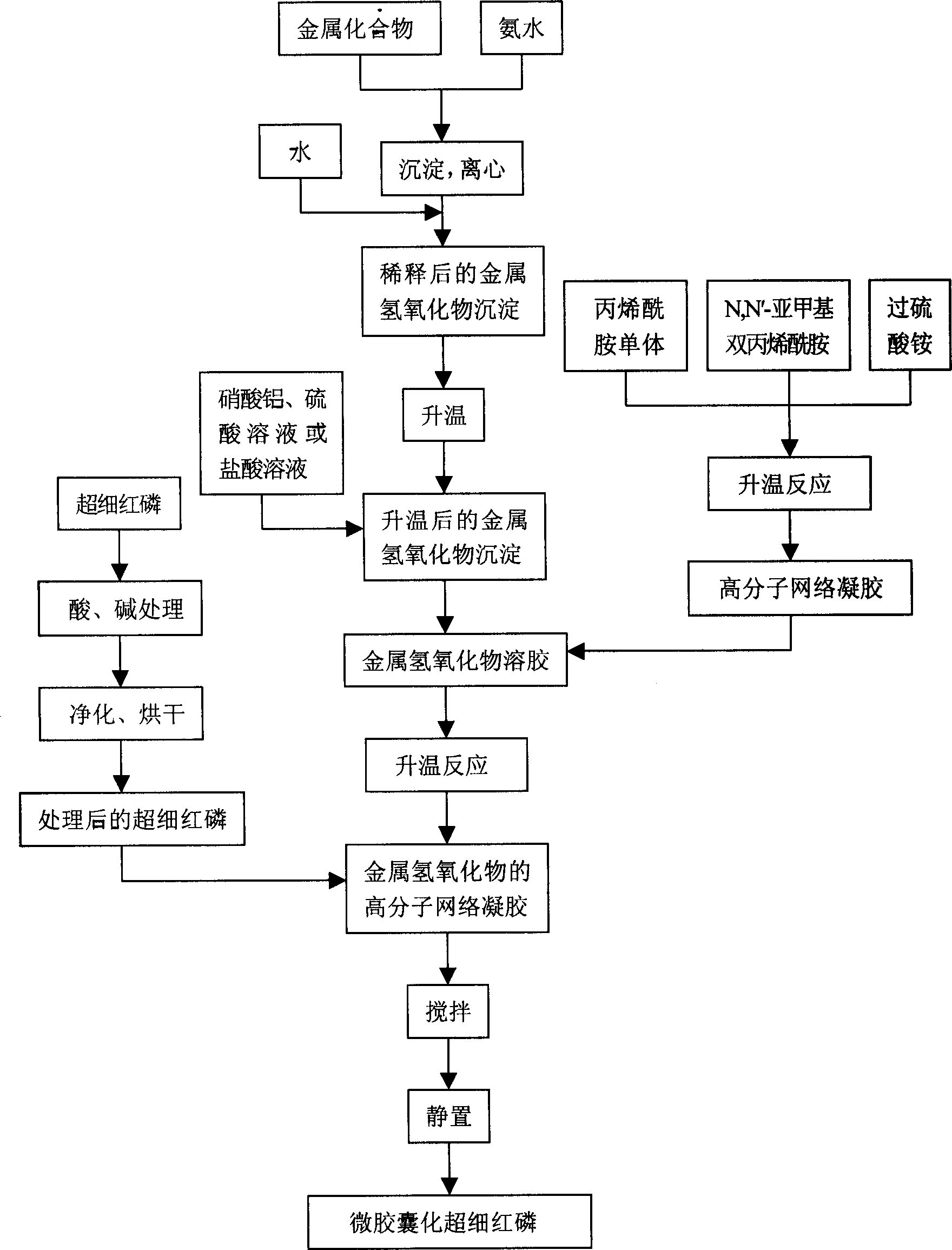

[0024] In conjunction with accompanying drawing, the preparation method of microencapsulated ultrafine red phosphorus of the present invention comprises the following steps:

[0025] 1.1 Boil 2-200μm ultra-fine red phosphorus with sulfuric acid solution, filter, and wash with water, then boil with sodium cyanide and sodium hydroxide solution, filter, wash with water, remove impurities in the raw material, dry and seal for storage;

[0026] 1.2 Stir and dissolve the metal compound, precipitate with ammonia water, dilute with water after centrifugal precipitation, raise the temperature, add aluminum nitrate, sulfuric acid solution or hydrochloric acid solution dropwise, and obtain the metal hydroxide sol;

[0027] 1.3 Mix acrylamide monomer, N,N'-methylenebisacrylamide network agent and ammonium persulfate initiator, and heat up to react to form a polymer network gel;

[0028] 1.4 Add the polymer network gel to the sol of the metal hydroxide synthesized in step 1.2, and heat up ...

Embodiment 1

[0031] Embodiment 1: the preparation method of microencapsulated ultrafine red phosphorus of the present invention, comprises the following steps:

[0032] The first step, weigh 10.0g ultrafine red phosphorus (average particle size 14μm), boil with 30ml 5% sulfuric acid solution for 5-6h, filter, wash 3-4 times with 50ml deionized water, and then wash with 30ml 5% sodium cyanide Boil with 30ml of 1.5% sodium hydroxide solution for 1-2 hours, filter, wash with 50ml of deionized water for 3-4 times to remove trace impurities of iron and copper in the raw material, dry in vacuum at 70-80°C for 24-30 hours, cool and store in In a sealed and dry jar, 9.9 g of purified red phosphorus was obtained.

[0033] In the second step, weigh 4.5g of Al(NO 3 ) 3 9H 2 O, add 30ml of water and stir to dissolve, precipitate with ammonia water and adjust the pH to 8-9, after centrifugal precipitation, wash with 100ml of deionized water for 3-4 times, control the temperature at 70°C and drop int...

Embodiment 2

[0044] Embodiment 2: the preparation method of microencapsulated ultrafine red phosphorus of the present invention, comprises the following steps:

[0045] The first step, weigh 10.0g ultrafine red phosphorus (average particle size 5μm), boil with 30ml 5% sulfuric acid solution for 5-6h, filter, wash 3-4 times with 50ml deionized water, and then wash with 30ml 5% sodium cyanide Boil with 30ml of 1.5% sodium hydroxide solution for 1-2 hours, filter, wash with 50ml of deionized water for 3-4 times to remove trace iron and copper impurities in raw materials, vacuum dry at 70-80°C for 24-30 hours, cool and store In a sealed and dry jar, 9.8 g of purified red phosphorus was obtained.

[0046] The second step, weigh 1.5g AlCl 3 , add 30ml of water and stir to dissolve, precipitate with ammonia water and adjust the pH to 8-9, after centrifugation, add 100ml of deionized water to the precipitate to dilute, control the temperature at 75 ° C with 10% aluminum nitrate solution dropwise ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com