Artificial cell membrane coating microcarrier for cell culture and preparation method thereof

A cell culture and cell membrane technology, applied in general culture methods, microcarriers, biochemical equipment and methods, etc., to achieve the effect of low price, long-term maintenance of cell activity and function, and uniform coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

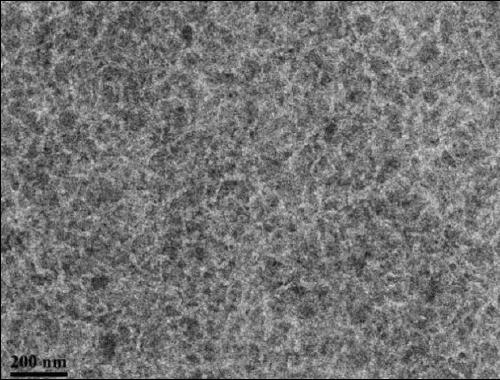

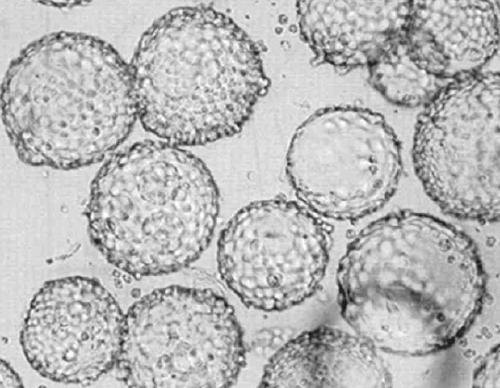

Image

Examples

Embodiment 1

[0026] A preparation method of artificial cell membrane coating microcarriers for cell culture, comprising the steps of:

[0027] 1) Add 100 grams of konjac glucomannan microspheres to 500 ml of petroleum ether, stir and wash, filter with a Buchner funnel, then add to 500 ethanol, stir and wash, filter and dry for later use;

[0028] 2) Dissolve 29.5 g of 2-methacryloyloxyethyl phosphorylcholine (MPC) and 42.6 g of n-butyl methacrylate in 350 ml of ethanol, add 0.4 g of azobisisobutyronitrile (AIBN), Then the reaction system was evacuated with a vacuum pump and then fed with high-purity nitrogen, and this was repeated three times to replace the gas in the reaction system with high-purity nitrogen, wrapped with aluminum foil to avoid light, and then stirred and refluxed for 24 hours. The high-performance liquid phase detection raw material MPC has been basically consumed, stop the reaction, pour it into acetone with vigorous stirring to precipitate after cooling, wash with acet...

Embodiment 2

[0031] A preparation method of artificial cell membrane coating microcarriers for cell culture, comprising the steps of:

[0032] 1) Add 100 grams of konjac glucomannan microspheres to 500 ml of petroleum ether, stir and wash, filter with a Buchner funnel, then add to 500 ethanol, stir and wash, filter and dry for later use;

[0033] 2) Dissolve 29.5 g of 2-methacryloyloxyethyl phosphorylcholine (MPC) and 28.4 g of n-butyl methacrylate in 260 ml of ethanol, add 0.3 g of azobisisobutyronitrile (AIBN), Then the reaction system was evacuated with a vacuum pump and then fed with high-purity nitrogen. Repeatedly, the gas in the reaction system was replaced with high-purity nitrogen. After wrapping it with aluminum foil to avoid light, it was stirred and refluxed for 24 hours. The high-performance liquid phase detection raw material MPC has basically Consumed, stopped the reaction, cooled and poured into vigorously stirred acetone to precipitate, filtered and washed with acetone thr...

Embodiment 3

[0036] A preparation method of artificial cell membrane coating microcarriers for cell culture, comprising the steps of:

[0037] 1) Add 100 grams of konjac glucomannan microspheres to 500 ml of petroleum ether, stir and wash, filter with a Buchner funnel, then add to 500 ethanol, stir and wash, filter and dry for later use;

[0038] 2) Dissolve 29.5 g of 2-methacryloyloxyethyl phosphorylcholine (MPC) and 42.6 g of n-butyl methacrylate in 350 ml of ethanol, add 0.4 g of azobisisobutyronitrile (AIBN), Then the reaction system was evacuated with a vacuum pump and then fed with high-purity nitrogen. Repeatedly, the gas in the reaction system was replaced with high-purity nitrogen. After wrapping it with aluminum foil to avoid light, it was stirred and refluxed for 24 hours. The high-performance liquid phase detection raw material MPC has basically Consumed, stopped the reaction, cooled and poured into vigorously stirred acetone to precipitate, filtered and washed with acetone thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com