Patents

Literature

80results about How to "Reduced chance of reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

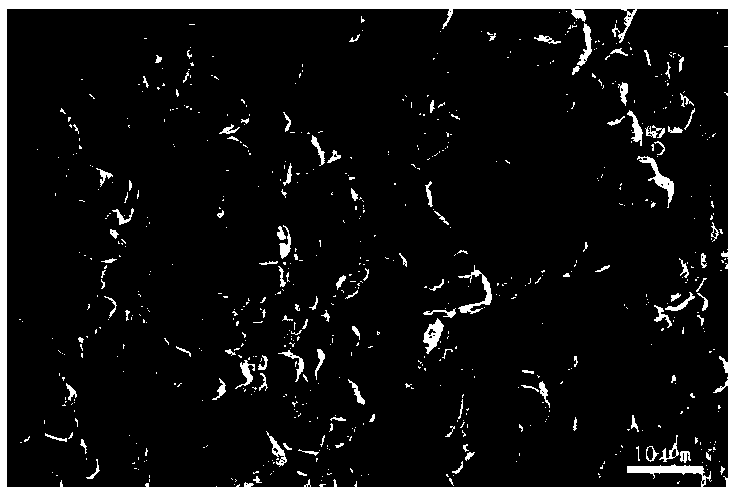

Method for diffusely distributing micro-nano particle reinforced phase in composite material

A method for diffusely distributing a micro-nano particle reinforced phase in a composite material is characterized in that the method comprises the following steps: 1, ball-milling the micro-nano particle reinforced phase and matrix powder by adopting a mechanical ball-milling process in order to improve the wettability of the micro-nano particle enhanced wetting phase and a metal melt; 2, melting the metal melt, adding the molten metal melt to the ball-milled mixed powder, and processing the obtained melt by utilizing an ultrasonic field or an ultrasonic and electromagnetic compound fieldt; and 3, carrying out cooling molding or casting molding to prepared a micro-nano particle reinforced phase diffusely distributed metal matrix composite material. The method realizes the diffusive distribution of one or more of ceramic particles of SiC, WC, Al4C3, B4C, ZrB2, TiB, Al2O3 and AlN in metal materials of aluminum alloy, magnesium alloy and the like, and the high-quality metal matrix composite material with good compactness and uniform performances can be obtained through the method.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

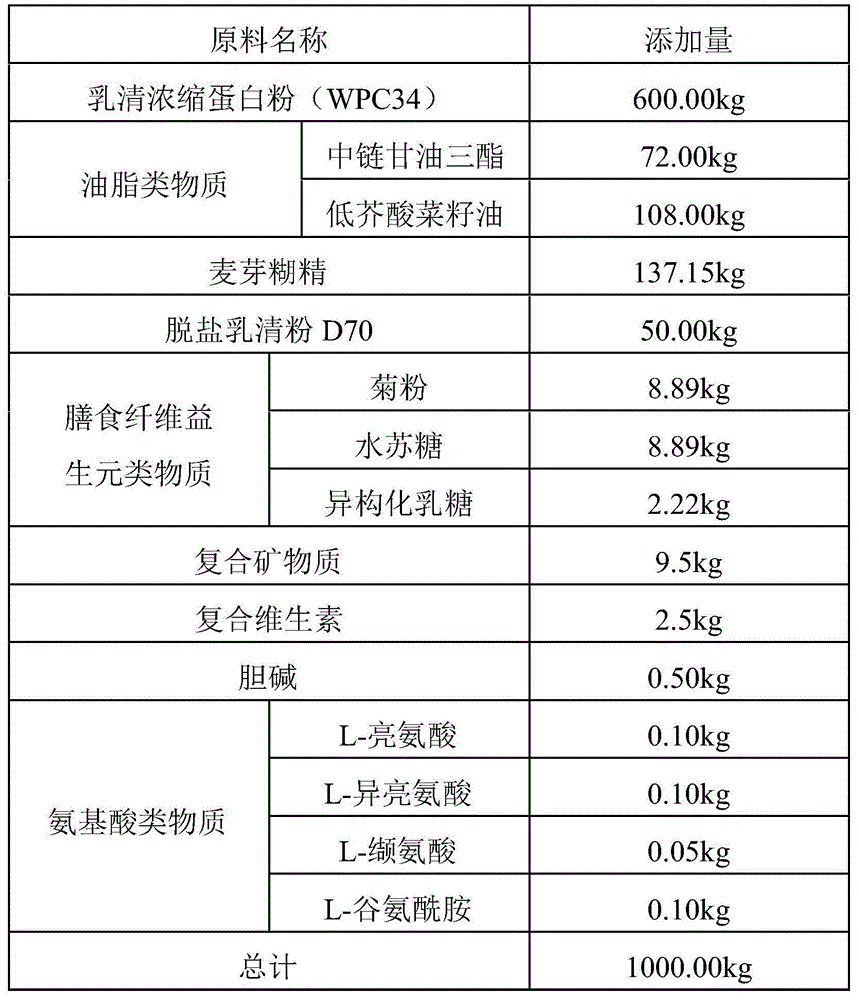

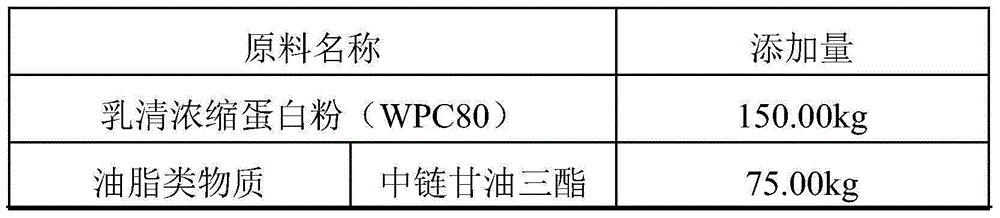

Total-nutritional formula milk powder and preparation method thereof

The invention discloses a total-nutritional formula milk powder, comprising the following components: 15-60% of concentrated whey protein powder, 18-25% of grease substances, 5-25% of desalted whey powder, 0-21% of carbohydrate, 2-12% of dietary fiber prebiotics substances, 0.95-1.4% of compound mineral substances, 0.25-0.45% of multi-vitamins, 0.05-0.10% of choline and 0.035-0.068% of amino acid substances; the preparation method comprises the steps: (1) mixing the concentrated whey protein powder, the desalted whey powder, the carbohydrate, the prebiotics, the choline, the amino acids and water to obtain a solution A; (2) mixing grease and the solution A to obtain a solution B; (3) mixing the multi-vitamins with water to obtain a solution C; (4) mixing the solution C and the solution B to obtain a solution D; (4) dissolving multi-vitamins in water to obtain a solution E; (6) mixing the solution E and the solution D to obtain a solution F; (7) sterilizing, concentrating and drying.

Owner:BRIGHT DAIRY & FOOD

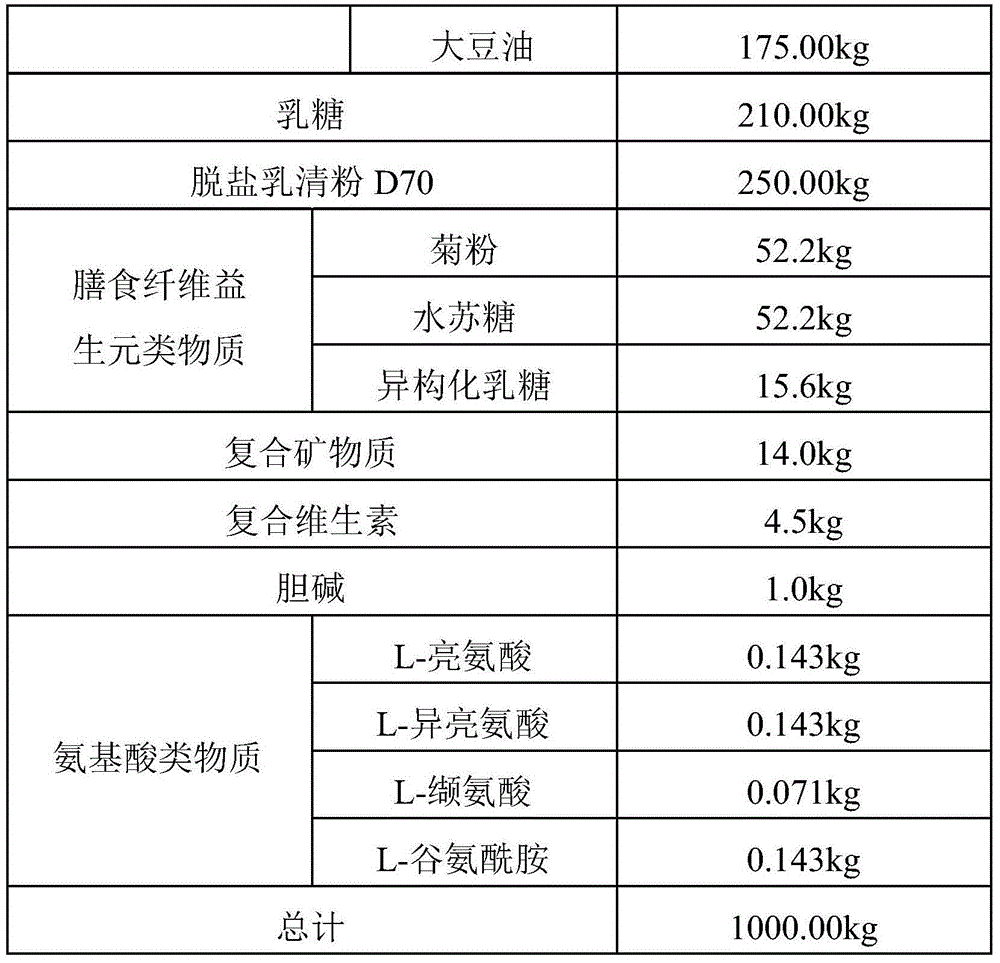

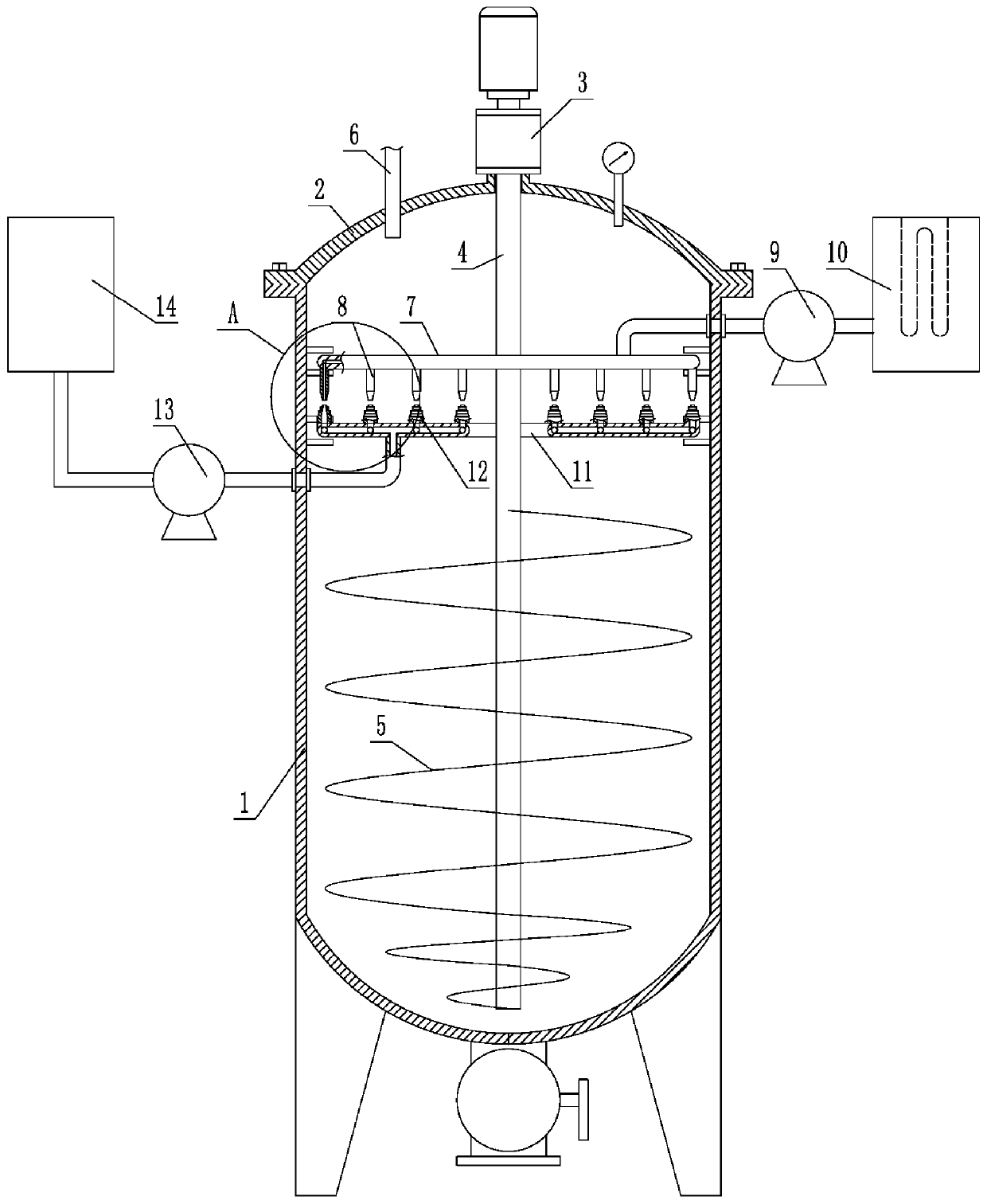

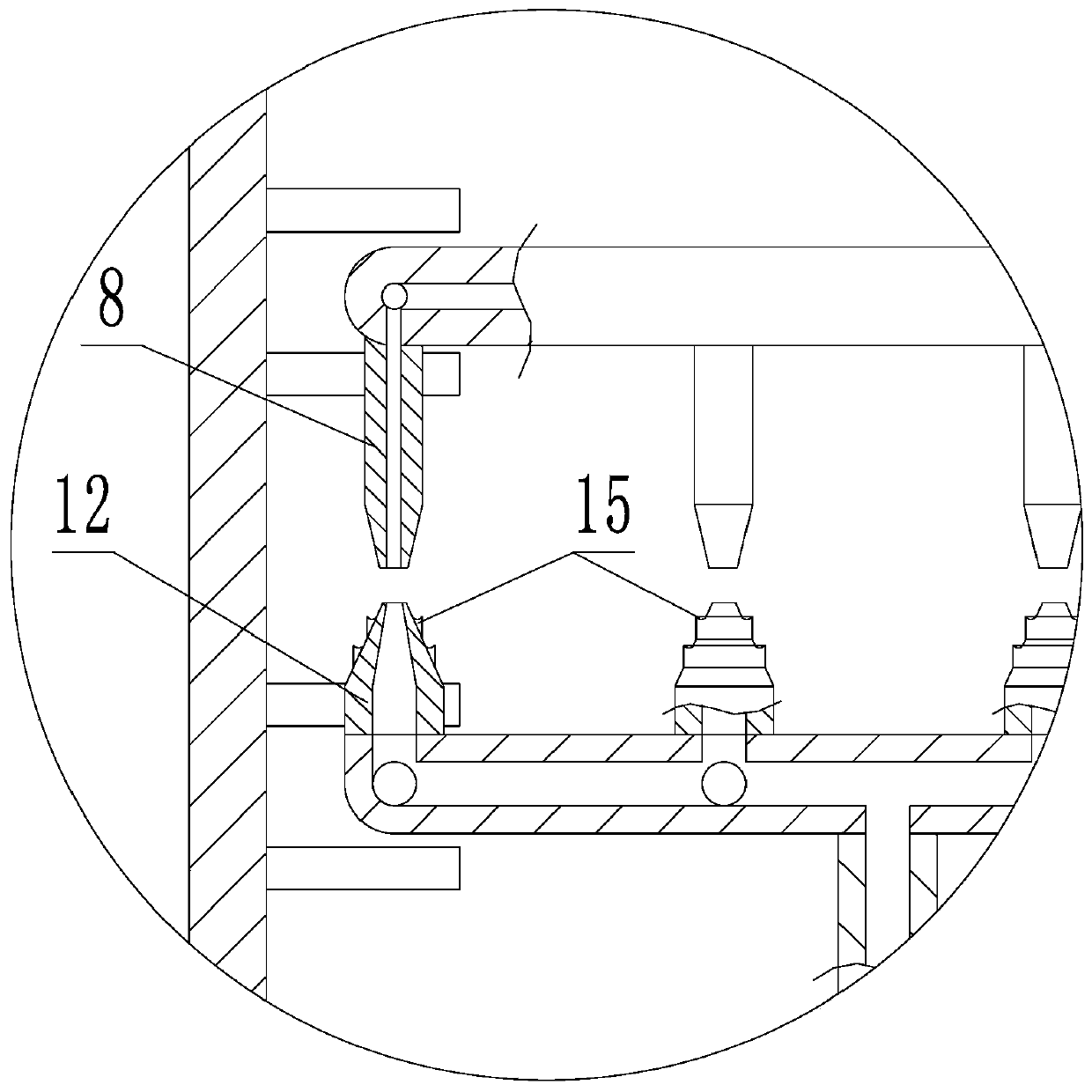

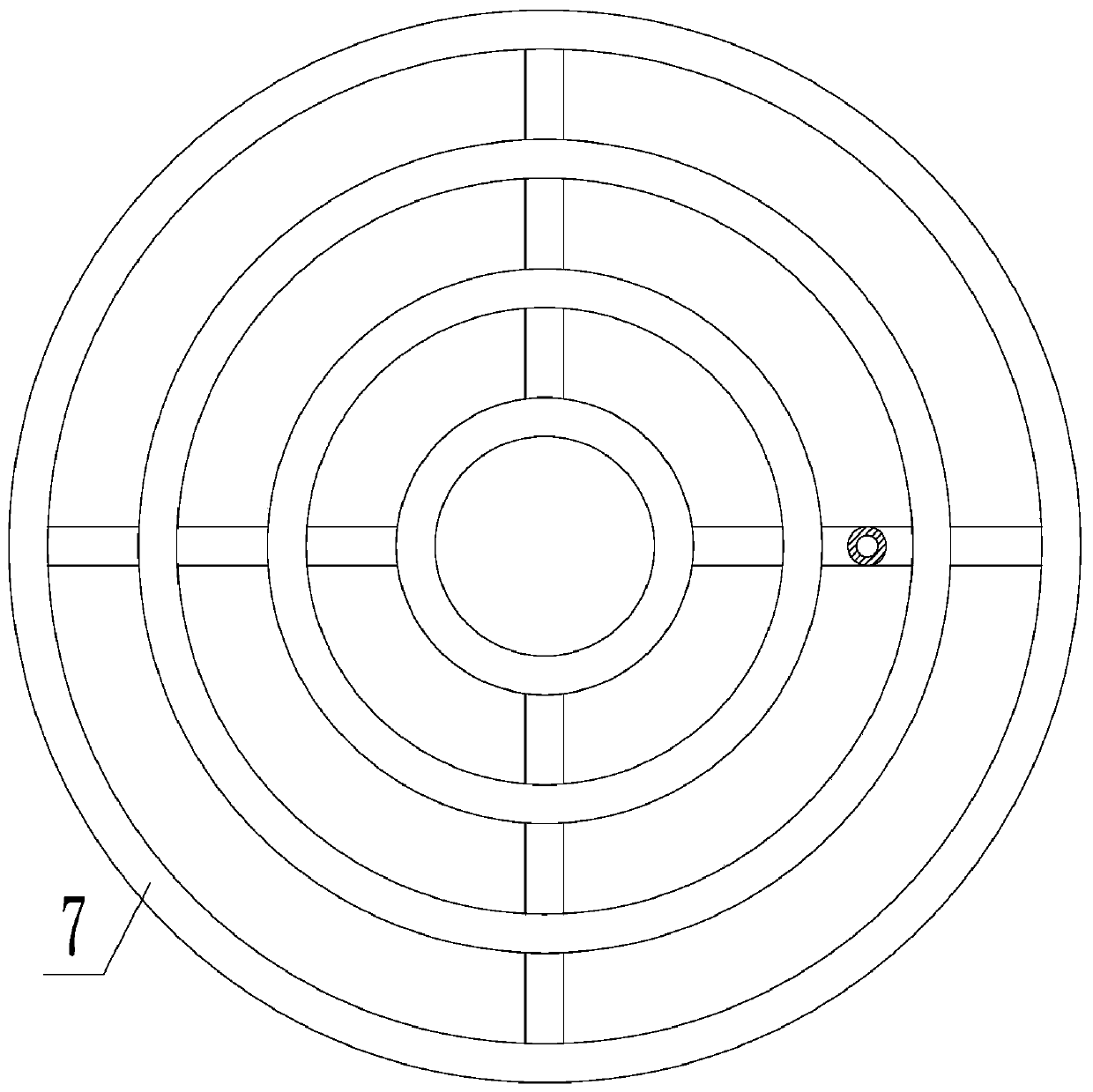

Equipment and method for removing light components through inert gas circulation gas stripping

ActiveCN104190105ALow heating temperatureReduced chance of reactionOrganic compound preparationCarboxylic acid esters preparationSteam condensationProcess engineering

The invention discloses equipment and method for removing light components through inert gas circulation gas stripping and relates to equipment and method which utilize gas stripping and steam condensation. The invention aims to provide equipment and method for removing light components through inert gas circulation gas stripping with the advantages of low cost and applicability to heat-sensitive materials. The equipment disclosed by the invention comprises a gas stripping tower, a light component collection tank, a heavy component collection tank, a demister, a first heater, a second heater, a first cooling device, a second cooling device, an ultralow temperature condenser, a circulating fan and a vacuum pump. The method disclosed by the invention comprises the following steps: heating inert gases; heating materials; carrying out gas stripping; cooling and collecting the light components and heavy components and recycling the inert gases. According to the equipment and method disclosed by the invention, local heating of the materials can be reduced, coking is avoided, and the reaction among the heat-sensitive materials is avoided; and moreover, the equipment can operate continuously and is suitable for large-scale industrial production. The equipment and method disclosed by the invention are applied to the separation field of organic matter monomers and intermediates, fine chemical engineering products, medicines, spices and the like.

Owner:TIANJIN AOZHAN XINGDA TECH

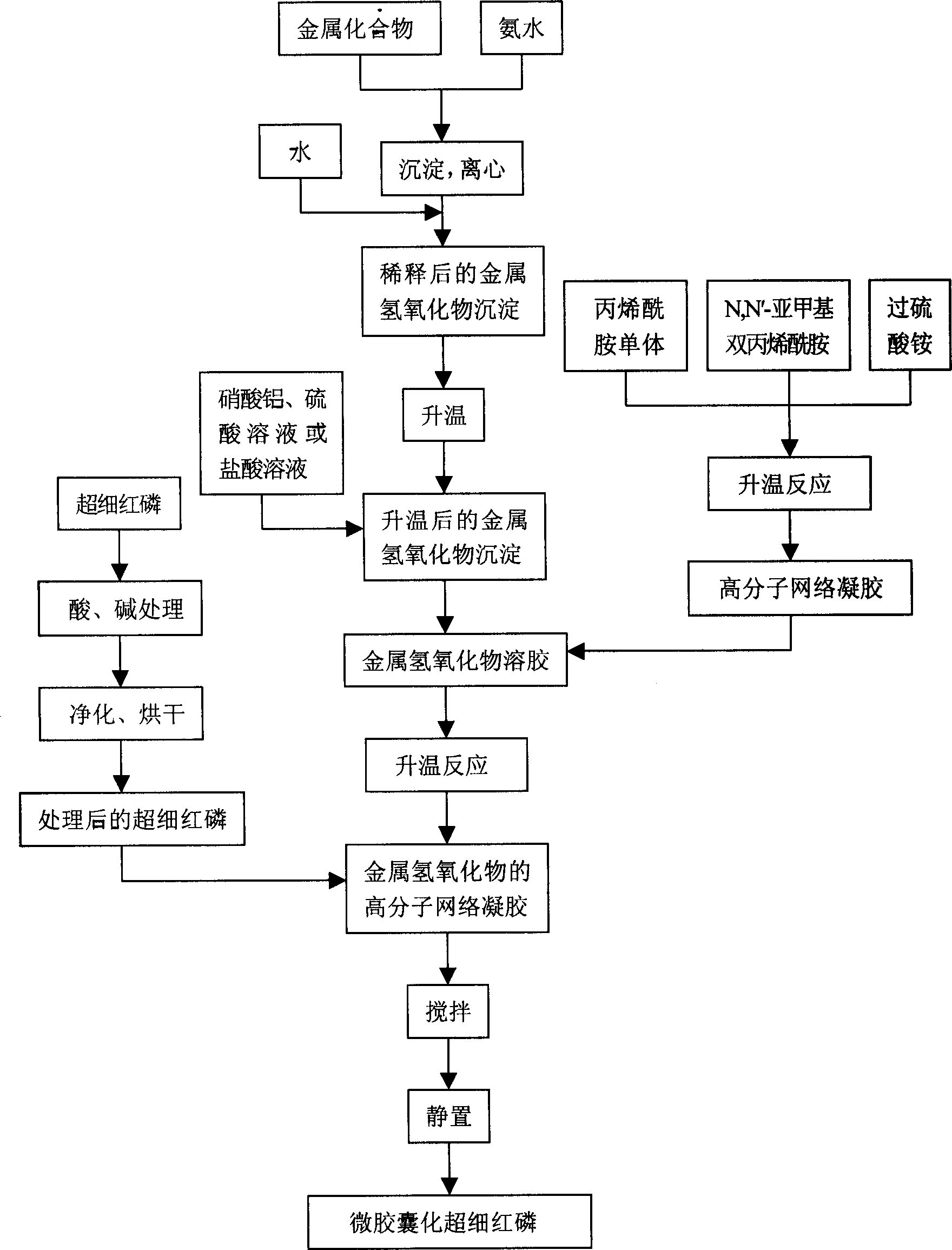

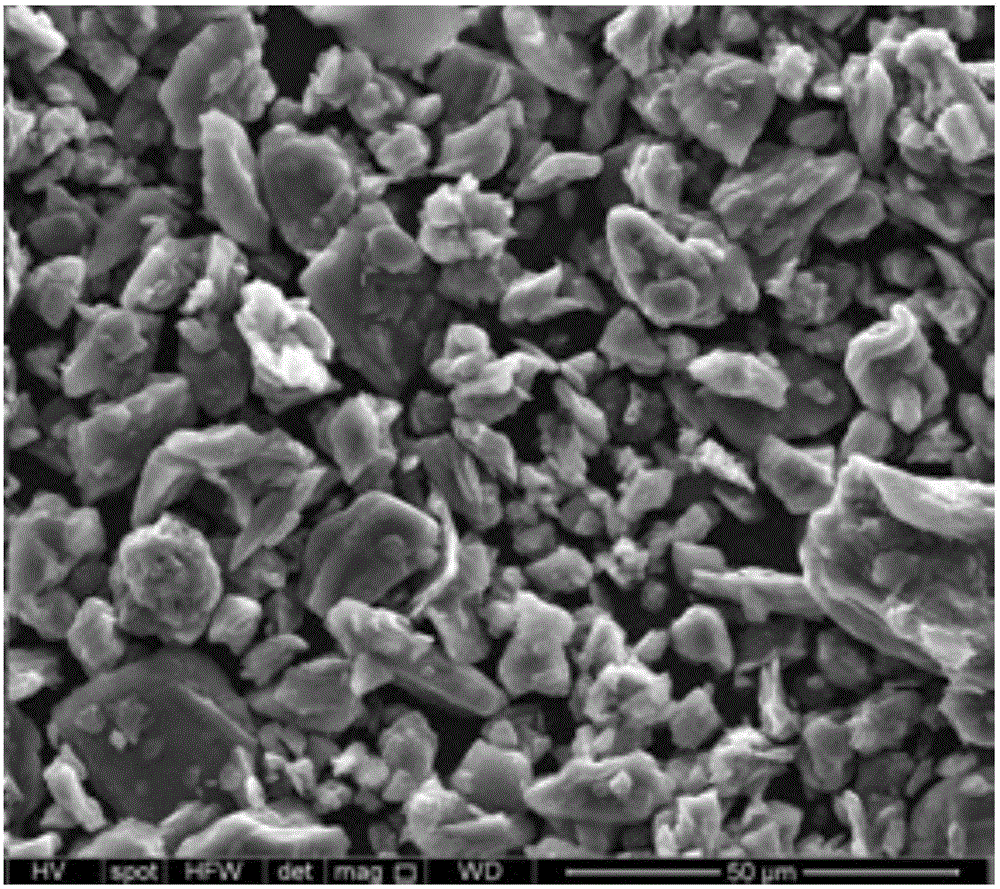

Method for preparing microcapsulated superfine red phosphorus

InactiveCN1775664ASlow water absorptionReduce productionPhosphorus compoundsMolecular networkSodium cyanide

The invention discloses a method for preparing micro-capsulized superfine red phosphorus, boiling the superfine red phosphorus with vitriol, sodium cyanide solution and sodium hydroxide solution, separately, filtering, eliminating impurities, and drying, and storing by sealing; blending and dissolve metal compound, depositing with ammonia, centrifuging and adding water to dilute, raising temperature, dropping in aluminum nitrate, vitriol or HCl and making metal hydroxide sol; mixing propylene acylamide monomers and N, Ní»-methylene dipropylene acylamide with ammonium persulphate, raising temperature and reacting to form high molecular network gel; adding the high molecular network gel into the metal hydroxide sol, raising the temperature and reacting to form high molecular network gel of metal hydroxide, mixing the high molecular network gel of metal hydroxide with the processed superfine red phosphorus, blending and placing still so that the sol takes the red phosphorus as the center to make surface absorption to form gel and coating a layer of colloid membrane on the red phosphorus surface, so as to obtain the micro-capsulized superfine red phosphorus. The advantages of the invention: it improves the stability, invariability and surface activity of the red phosphorus, improving processing property.

Owner:NANJING UNIV OF SCI & TECH

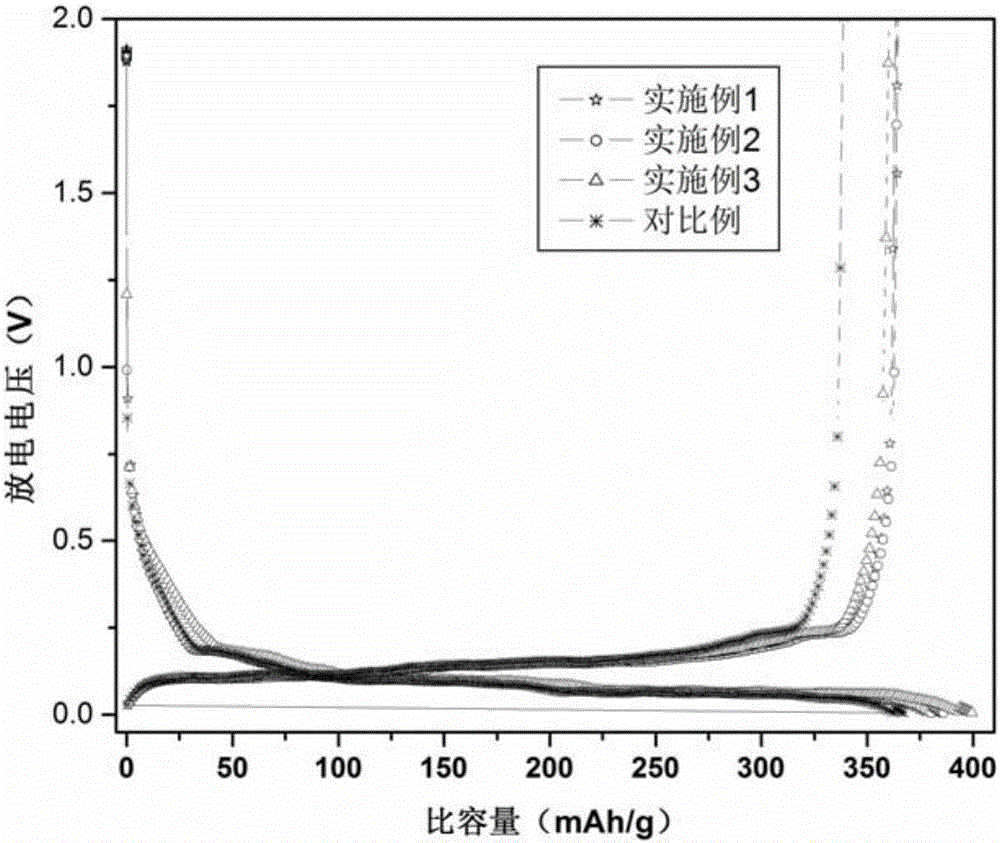

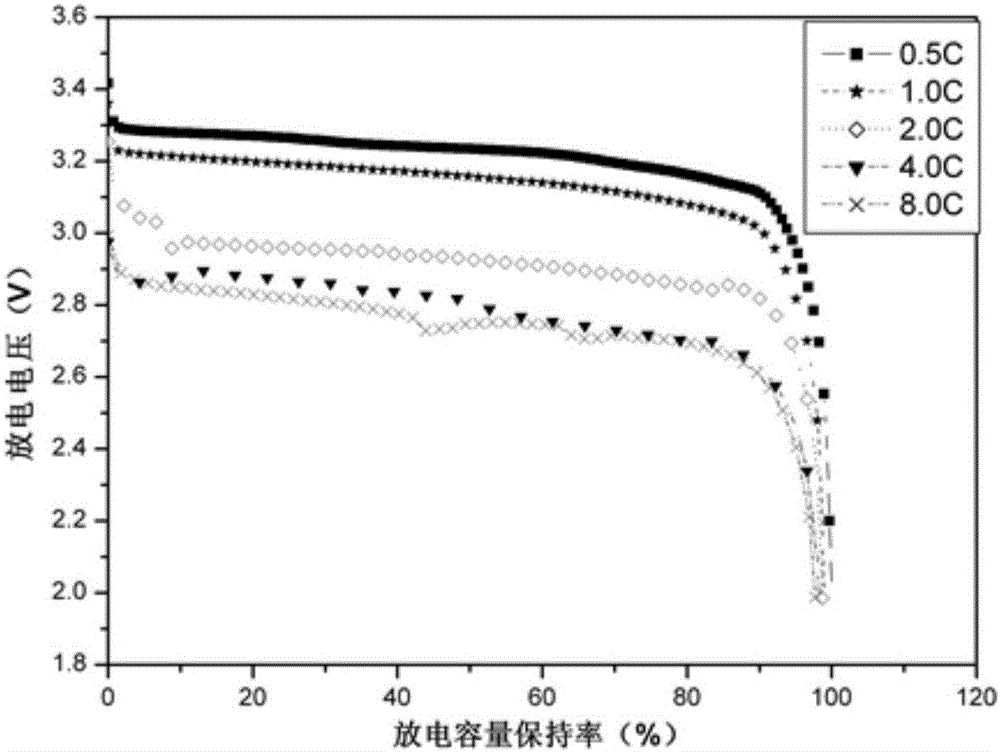

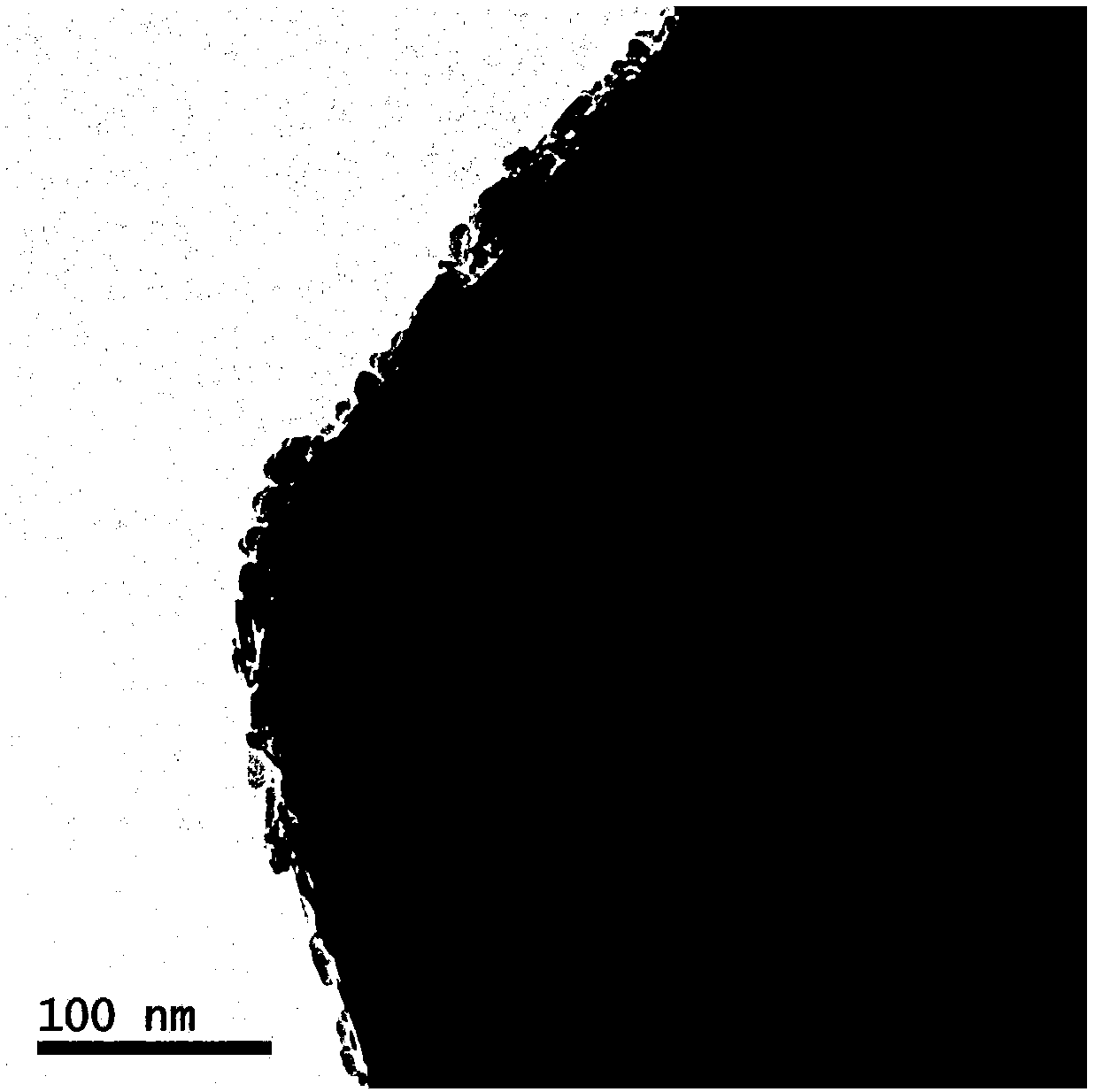

Preparation method of material of negative electrode of lithium ion battery

ActiveCN104993174AImprove mobilityImprove the first charge and discharge efficiencyCell electrodesSecondary cellsDischarge efficiencyOrganic acid

The invention relates to a preparation method of a material of a negative electrode of a lithium ion battery, and belongs to the technical field of lithium ion batteries. The method includes the following steps of making graphite, oxidizing agent and organic acid react to obtain intercalated graphite, adding the intercalated graphite to a NaOH solution, and conducting soaking, washing, smashing and spheroidizing to obtain the material. According to the material of the negative electrode of the lithium ion battery, the intercalated graphite is processed through a soaking method, non-graphitic carbon and surface impurities on surfaces of the graphite are reduced, lithium ions consumed by irreversible carbon are reduced, and then the primary charging and discharging efficiency of the graphite is improved.

Owner:HENAN ZHONGLIAN GAOKE NEW ENERGY

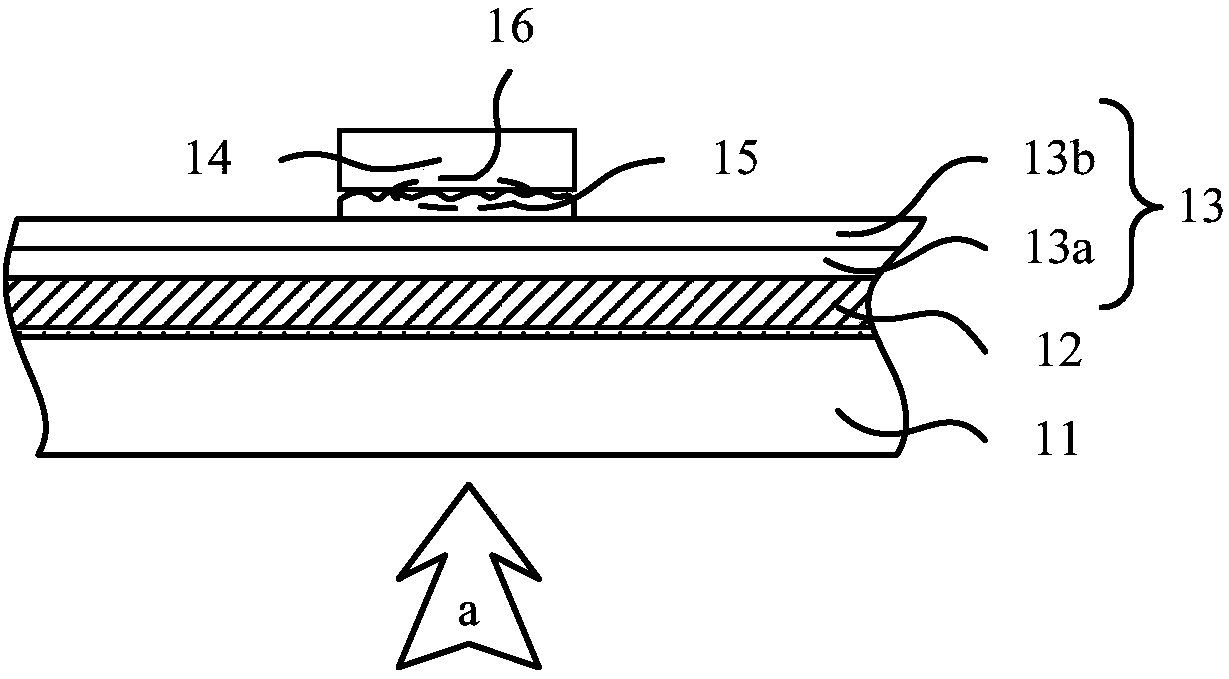

Photoelectric detector

ActiveCN108172634AAvoid damageStrong forceMaterial nanotechnologySemiconductor/solid-state device detailsHeterojunctionPhotovoltaic detectors

The invention provides a photoelectric detector. The photoelectric detector comprises a photoelectric detection layer and a first electrode layer, wherein the first electrode layer is arranged on a surface of one side of a photoelectric layer to obtain a photoelectric detection structure, and the photoelectric detection layer is formed by fabrication of a two-dimensional material or a two-dimensional material heterojunction structure. Since the two-dimensional material or the two-dimensional material heterojunction structure is sensitive to light and is simultaneously thin (the thickness is smaller than 1 nanometer), the probability of reaction with radiation particles is extremely small, and the false triggering probability is extremely small; and moreover, an acting force among atoms ina two-dimensional material plane is relatively high, the photoelectric detector is stable in structure, and the damage generated by the radiation particle is relatively small.

Owner:GUIZHOU MINZU UNIV

Rapidly-dried water-dispersible isocyanate curing agent composition and preparation method thereof

The invention belongs to the technical field of isocyanate curing agents, and discloses a rapidly-dried water-dispersible isocyanate curing agent composition and a preparation method thereof. The rapidly-dried water-dispersible isocyanate curing agent composition disclosed by the invention comprises the following two parts: 50-95 parts by mass of a hydrophilically modified aliphatic polyisocyanatepart and 5-50 parts by mass of a non-hydrophilically modified aromatic polyisocyanate part. After emulsification in a water system, the non-hydrophilically modified aromatic polyisocyanate is partially wrapped by the hydrophilically modified aliphatic polyisocyanate, so that long usable time can be kept in a water phase. After water of coating construction is volatilized, the drying speed is greatly improved, and a long usable time is achieved while rapid drying is realized. The problem that an application is limited due to the fact that hydrophilically modified aliphatic polyisocyanate is fast in drying speed but very short in usable time and hydrophilically modified aliphatic polyisocyanate is slow in curing speed is solved.

Owner:GUANGZHOU GUANZHI NEW MATERIAL TECH

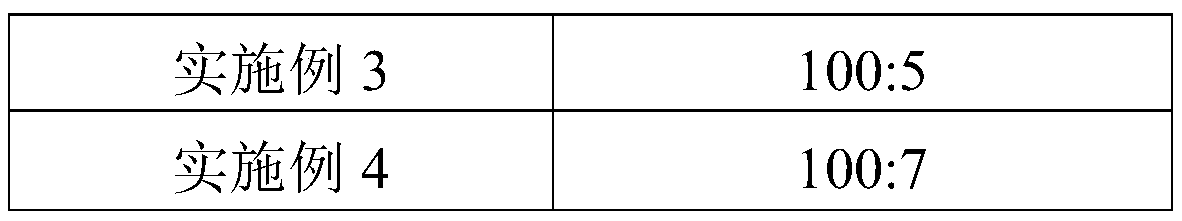

Material for manufacturing modified phenolic fireproofing insulation board

The invention relates to the technical field of building materials, in particular to a material for manufacturing a modified phenolic fireproofing insulation board and a preparation method thereof. The material for manufacturing the modified phenolic fireproofing insulation board comprises the following components in part by weight: 100 parts of modified phenolic resin, 2 to 4 parts of surfactant, 5 to 7 parts of foaming agent and 8 to 10 parts of curing agent. Due to the adoption of the technical scheme, the free phenol of the material is 0.09 percent, the free formaldehyde is less than 0.1 percent, the release amount of the formaldehyde is reduced obviously, and the physical and chemical properties of the material have no obvious difference compared with those of phenolic foam prepared under the normal condition, so the material can be applied to interior wall construction (interior wall heat-insulating systems) of buildings.

Owner:上海雅达特种涂料有限公司 +1

Making method of fiber softening type areca seeds with prolonged quality guarantee period

ActiveCN110432426AImprove JuiceReduce the chance of exposureClimate change adaptationFood coatingGas explosionAreca

The invention discloses a making method of fiber softening type areca seeds with prolonged quality guarantee period. The making method comprises the following steps of sorting raw materials, and performing cleaning; performing soaking treatment; performing corruption gas explosion treatment so that fibers are softened; performing vacuum seed germinating so as to improve the juice feeling when people chew areca seeds; roasting the seeds: performing vacuum drying; performing glue applying, and performing glue covering; performing seed cutting, and removing kernels; performing solidification withbrine, and performing airing; and performing packing and performing sterilization, so as to obtain the fiber softening type areca seeds with prolonged quality guarantee period. The invention aims toprovide the making method of the fiber softening type areca seeds with prolonged quality guarantee period. According to the making method, through steam explosion, on one hand, cellulose in the arecaseeds can be softened, the condition of enabling the areca seeds to be tasteful through fermentation liquid is facilitated, and on the other hand, the juice chewing feeling of the areca seeds can be improved in a focused manner; and besides, through vacuum seed germinating and seed roasting, the contact probability of the areca seeds and bacteria can be greatly reduced, and the quality guarantee period of products can be greatly prolonged to half a year or above.

Owner:湖南胖哥鑫鸿实业有限公司

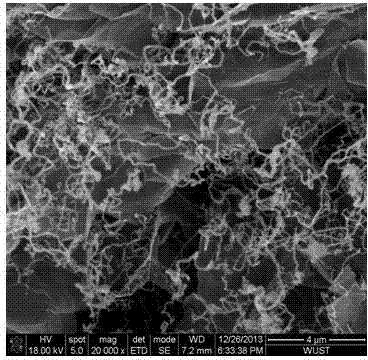

Method for preparing copper-tungsten alloy doped graphene

InactiveCN108893637ASolve the uneven distribution of two phasesAddresses the presence of large copper enrichment zonesTransportation and packagingMetal-working apparatusCopper platingDoped graphene

The invention discloses a method for preparing copper-tungsten alloy doped graphene. The method comprises the following steps: uniformly and quantitatively depositing a layer of copper on the surfaceof tungsten powder, and modifying the surface state of copper-plated tungsten powder and graphene respectively with PVA and PVP; sufficiently stirring in a liquid medium to sufficiently mix the copper-plated tungsten powder and graphene, and performing cold-press molding and hog-press sintering to obtain the graphene doped copper-tungsten alloy. The method can be used for improving the wetting performance of the sintering process, and the chemical, electrical, thermal and other performance of the alloy prepared by the method are greatly improved in comparison with those of alloy prepared by atraditional method, the vacuum ablation performance is promoted when the alloy is applied to an electrical contact, the service life of the contact is prolonged, and the ablation can be more uniform.

Owner:XI AN JIAOTONG UNIV

Method for leaching bauxite ore pulp

InactiveCN102009990AReduced chance of reactionReduce scarsAluminium oxides/hydroxidesTitaniumMaceral

The invention relates to a method for leaching bauxite ore pulp, in particular to a method for leaching bauxite ore pulp during aluminium oxide production by a Bayer process. The method is characterized in that (1) the bauxite ore pulp is subject to intensifying pre-desilication; and (2) the ore pulp after intensifying pre-desilication is preheated in a first preheating pipeline, then the ore pulp is introduced into a heat preservation reactor to react and then is pumped into a second preheating pipeline to be heated, and then the ore pulp is introduced into the heat preservation reactor to react and then is introduced into a heating pipeline to be heated to leaching temperature, thus completing the leaching process. In the method provided by the invention, the high temperature intensifying pre-desilication process with longer reaction time is adopted, thus the pre-desilication efficiency of the ore pulp is improved; and meanwhile retention reactors are arranged in the pipeline preheating process of the ore pulp after pre-desilication by sections, so that mineral containing silicon and mineral containing titanium fully react in the retention reactors and the probability of precipitation from follow-up heat exchange surface is reduced, thus slowing down scabbing in the preheating process of the ore pulp.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Carbon raw material for carbon composite refractory material and preparation method thereof

The invention relates to a carbon raw material for a carbon composite refractory material and a preparation method thereof. The technical scheme comprises the following steps: firstly uniformly filling the bottom of a graphite crucible with a monatomic silicon powder, uniformly coating the monatomic silicon powder with graphite, carrying out thermal insulation at 1000-1400 DEG C in the atmosphere of argon or nitrogen for 1-4 hours, and taking out a substance which covers the monatomic silicon powder so as to prepare the carbon raw material for the carbon composite refractory material, wherein graphite is one of expandable graphite and graphene, and mass ratio of graphite to the monatomic silicon powder is (0.01-0.9):1. By adjusting the mass ratio of graphite to the monatomic silicon powder, in-situ preparation of different numbers and sizes of silicon carbide whiskers is realized on the edge of graphite. The prepared carbon raw material for the carbon composite refractory material has excellent resistance to oxidation, good dispersibility and excellent mechanical properties, is used in a carbon composite refractory material, and can be used to raise overall performance of a carbon composite refractory material and especially enhance mechanical properties and oxidation resistance of the carbon composite refractory material.

Owner:WUHAN UNIV OF SCI & TECH

Process for preparing high-hydroxyl-value polyester resin

The invention relates to a preparation method of polyester resin having high hydroxy value. Raw materials of the invention comprise polybasic acid, polyol and diluent; the invention is characterized in that: the esterification polymerization of the polybasic acid and the polyol is completed through the method of multistep feeding so as to obtain the polyester resin with solid content of 70-80 percent in mass, hydroxy value of 3.5-5.5 percent and viscosity of 1500-8000cm<2> / s; the resin yielded is employed as crosslinking agent after being added with HDI biuret and HDI trimer to prepare aviation coatings, which is characterized by high solid content, good wettability to pigments, excellent environmental protection, weatherability, impact resistance and chemical resistance and so on.

Owner:BASF SHANGHAI COATINGS CO LTD

Use method of self-generated gel for water plugging profile control and flooding

ActiveCN109779564AReduce calcium and magnesium ion contentImprove performanceFluid removalDrilling compositionCross-linkEconomic benefits

A use method of self-generated gel for water plugging profile control and displacement comprises the following steps: adding sodium alginate into a dispensing tank with wastewater under stirring to form the self-generated gel; adding a polymer in a water plugging profile control and flooding cross-linking system, and uniformly stirring; adding the rest components in the water plugging profile control and flooding cross-linking system 20-400 minutes before extrusion injection, then performing extrusion injection construction, enabling the self-generated gel and the water plugging profile control and flooding cross-linking system to form a mixed multiphase water plugging agent under stirring, and extruding the mixed multiphase water plugging agent into a well under the action of an injectionpump. Sodium alginate in the self-generated gel reacts with calcium and magnesium ions in wastewater to generate self-generated gel particles with very stable performance; therefore, the content of calcium and magnesium ions in the wastewater can be greatly reduced due to the generation of the self-generated gel particles, the concentration of the calcium and magnesium ions is greatly reduced dueto the generation of the self-generated gel particles, and the dissolving speed and viscosity of the polymer in a profile control and flooding system are improved. The investment cost of wastewater treatment can be greatly reduced, the yield increase range is increased, and economic benefits are obviously increased.

Owner:PETROCHINA CO LTD

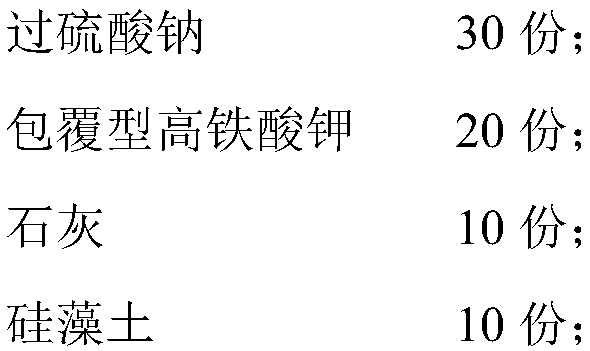

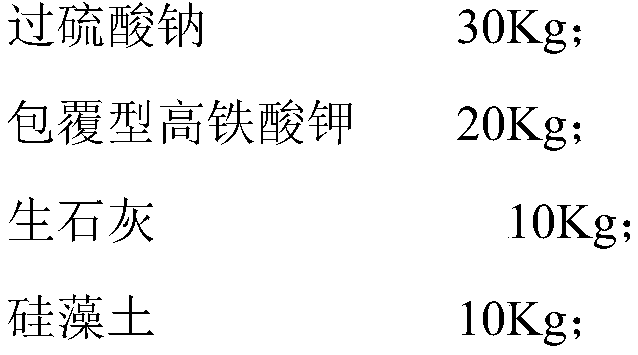

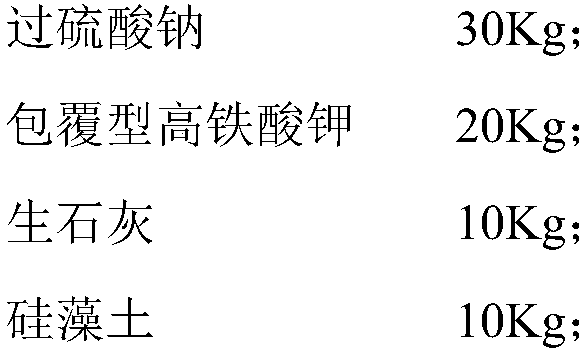

Wastewater treatment agent as well as preparation method and use method thereof

ActiveCN108190976AEasy to handlePromote flocculation and sedimentationWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionCompound aPotassium

The invention relates to a wastewater treatment agent as well as a preparation method and a use method thereof. The wastewater treatment agent comprises a compound A and a compound B; the compound A comprises the following components in part by weight: 20 parts of iron carbon sphere particles and 10 parts of citric acid; the compound B comprises the following components in part by weight: 30 partsof sodium persulfate, 20 parts of encapsulation-type potassium ferrate, 10 parts of lime and 10 parts of diatomite; and the mass ratio of the compound A to the compound B is 1:(2-6). In addition, theinvention further provides the preparation method and the use method of the wastewater treatment agent. According to the wastewater treatment agent prepared by the preparation method provided by theinvention and a method for wastewater treatment by the wastewater treatment agent, the treatment time of wastewater can be effectively shortened, and the degradation rates of various substances in thewastewater are improved.

Owner:SHIJIAZHUANG YUANSHENGYUAN ENVIRONMENTAL

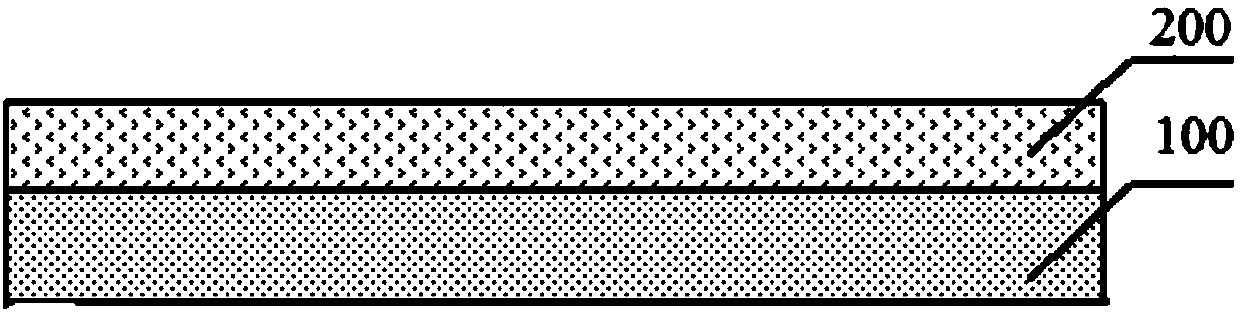

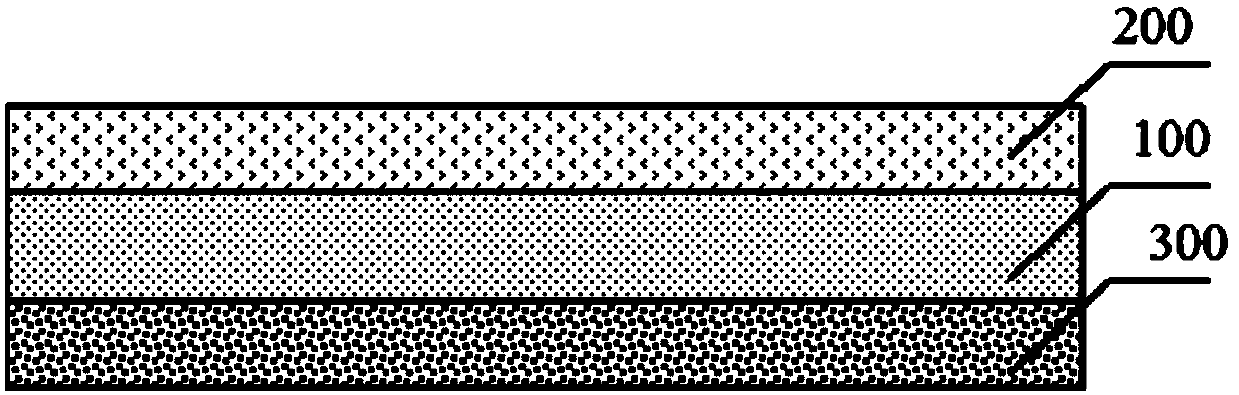

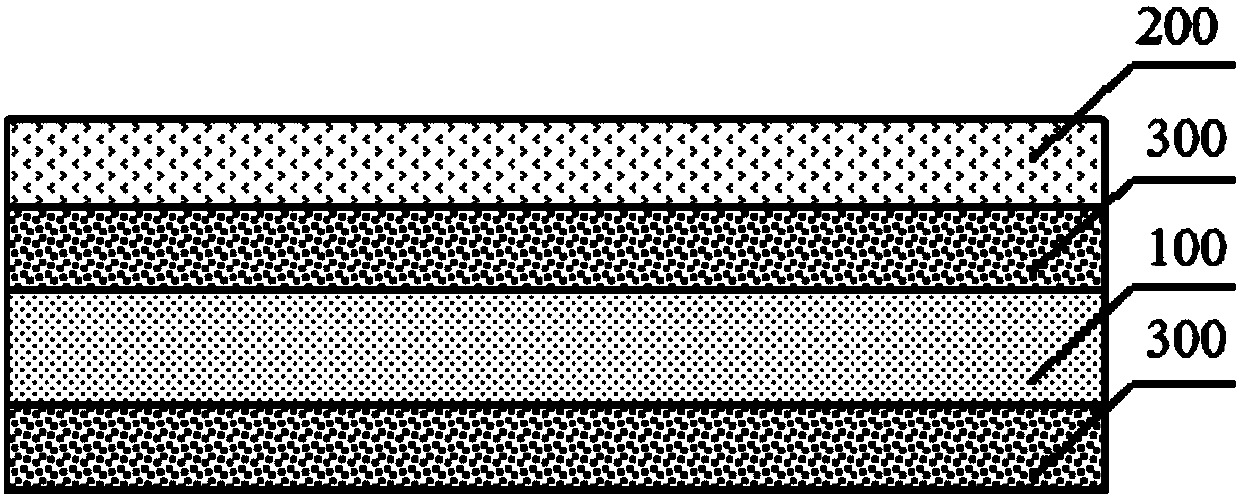

Lithium ion battery diaphragm and lithium ion battery equipped with same

PendingCN109585749AReduce contentReduced chance of reactionSecondary cellsCell component detailsLithium-ion batteryBattery cell

The invention relates to a lithium ion battery diaphragm. The lithium ion battery diaphragm comprises a porous base material layer and an oxygen absorption layer which are arranged in a stacked mode,wherein the oxygen absorption layer comprises an oxygen absorbing material. The invention further relates to a lithium ion battery which comprises a positive electrode, a negative electrode, the lithium ion battery diaphragm arranged between the positive electrode and the negative electrode, and an electrolyte, wherein the lithium ion battery diaphragm comprises the abovementioned lithium ion battery diaphragm; and the oxygen absorption layer is close to the positive electrode.

Owner:TSINGHUA UNIV

Cleaning method of anode net of ionic membrane electrolysis bath

InactiveCN106555205AImprove solubilityEffective dissolutionElectrolysis componentsElectrolysisCleaning methods

The invention discloses a cleaning method of an anode net of an ionic membrane electrolysis bath. Through the method, a compound scale layer on the surface of the anode net can be effectively removed, a surface coating of the anode net can be prevented from being damaged, and a voltage of the electrolysis bath can be lowered. The method includes the steps of carrying out pre-cleaning and leakage testing on a cleaning bath through pure water and placing the electrolysis bath into the cleaning bath after a cathode and an anode of the electrolysis bath are pressed by plastic membranes at an interval; preparing a primary cleaning agent through the pure water, heating the primary cleaning agent to 55-85 DEG C, then cleaning the anode net of the electrolysis bath for 1-4 hours, draining the primary cleaning agent and adding the pure water for flushing, wherein the primary cleaning agent is composed of 2-6% of hydrochloric acid and 0.2-0.3% of lan-826 corrosion inhibitors in concentration percentage; and preparing a secondary cleaning agent through the pure water, heating the secondary cleaning agent to 55-85 DEG C, then cleaning the anode net of the electrolysis bath for 4-6 hours, draining the secondary cleaning agent and adding the pure water for flushing, wherein the secondary cleaning agent is composed of 3-8% of citric acid, 0.2-0.35% of lan-826 corrosion inhibitors and 3-6% of sulfamic acid in concentration percentage.

Owner:PANZHIHUA STEEL ENTERPRISES XINYU CHEM

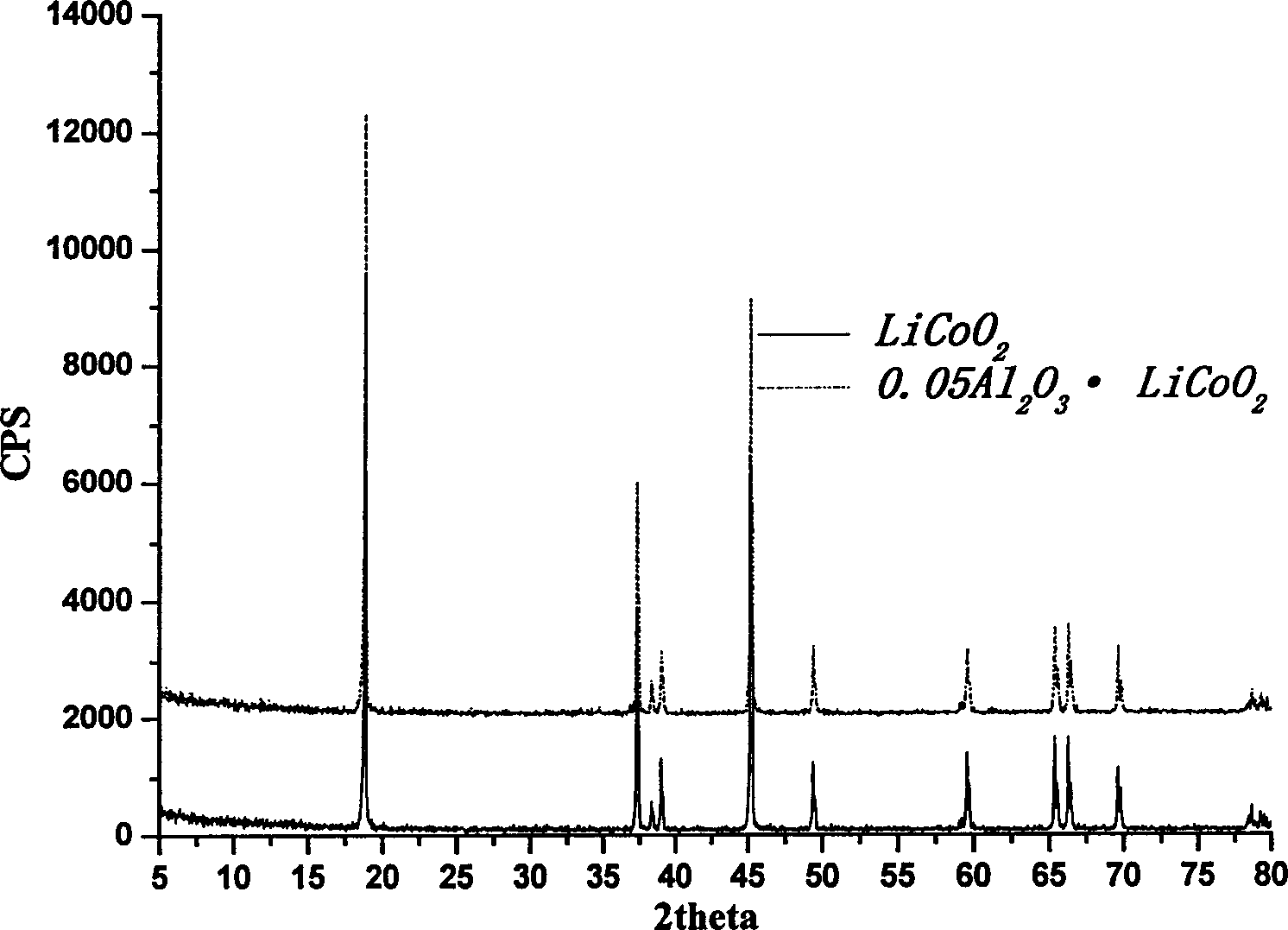

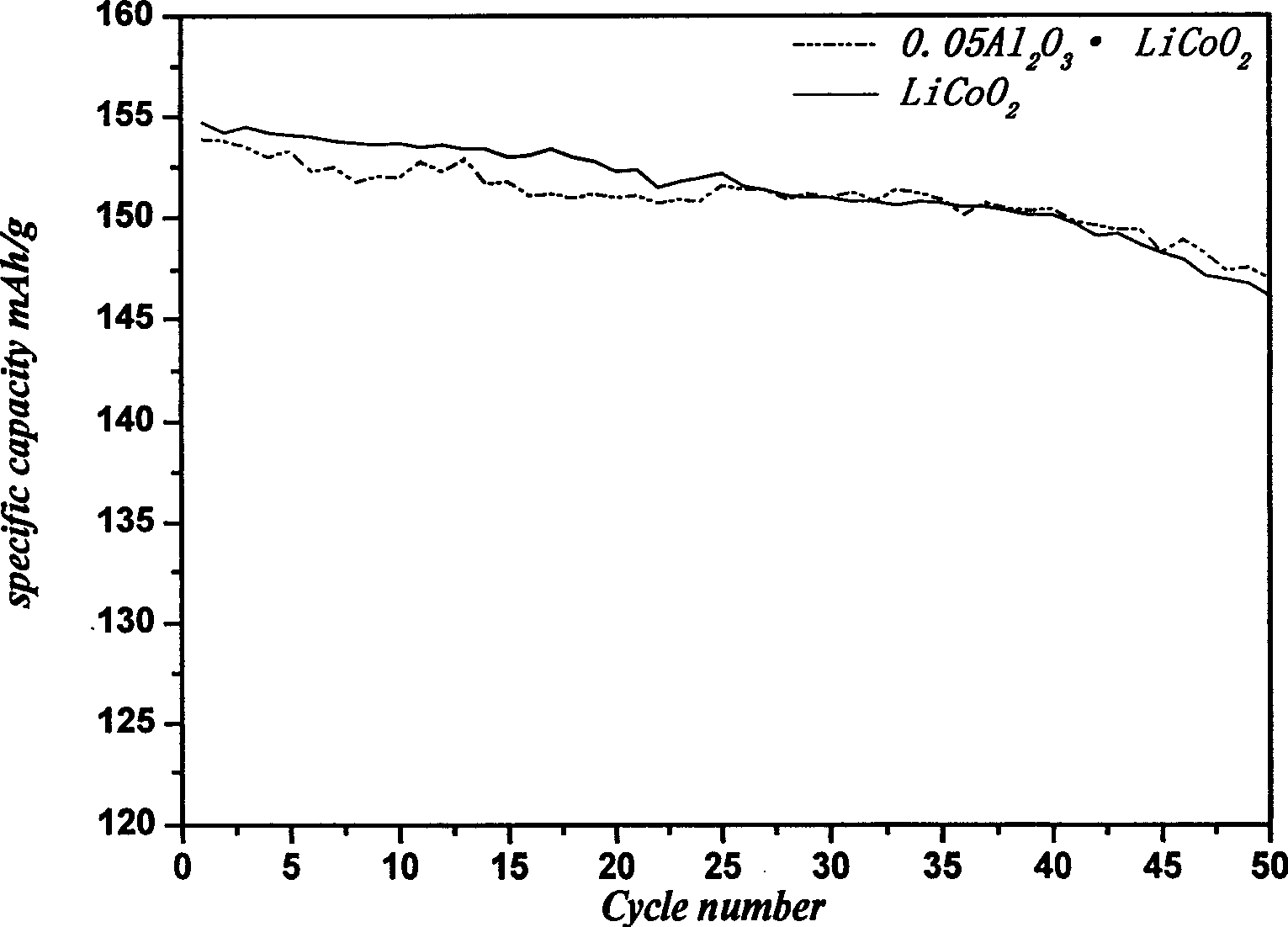

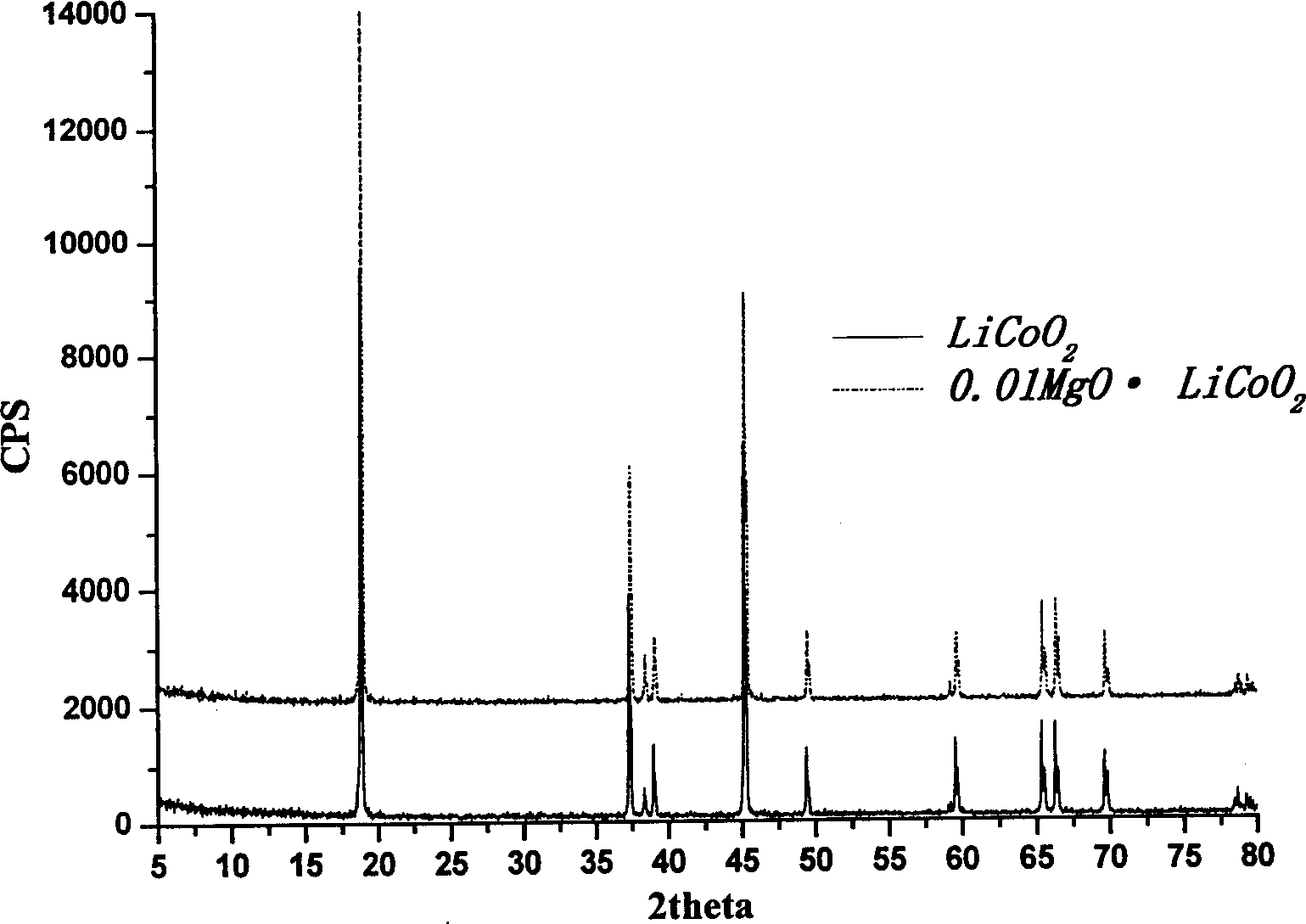

Method for preparing modified anode material of lithium ion battery

InactiveCN1803635AHigh reversible capacityImprove cycle performanceCell electrodesLithium compoundsMuffle furnaceChemistry

The preparation method for modified anode material in lithium ion cell comprises: (1) dispersing the metal salt or metal hydroxides into organic solvent, stirring at 80-90Deg, and adding LiCoO2 (LiNi(1-x)CoxO2, x=0.2 / 0.3) to form gel; (2) grinding the gel in tank for 4-8h; wherein, adding acetone, alcohol or mixed liquid by mass ratio as 10:1~20:1, and the mole measurement ratio of MyOz / LiCoO2(LiNi(1-x)CoxO2, x=0.2 / 0.3) as 0.01-0.05; (3) drying the grinded gel for 1-3h at 80-100Deg, and removing the organic solvent; (4) constant-temperature calcining the gel in muffle furnace for 6-12h at 400-600Deg, cooling naturally and obtaining the MyOzíñLiCoO2 (MyOzíñLiNixCo(1-x)O2, x=0.2 / 0.3). This invention improves the product cycle performance.

Owner:TIANJIN LISHEN BATTERY

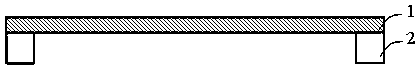

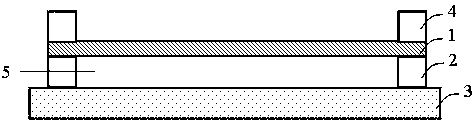

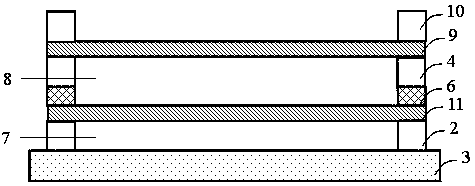

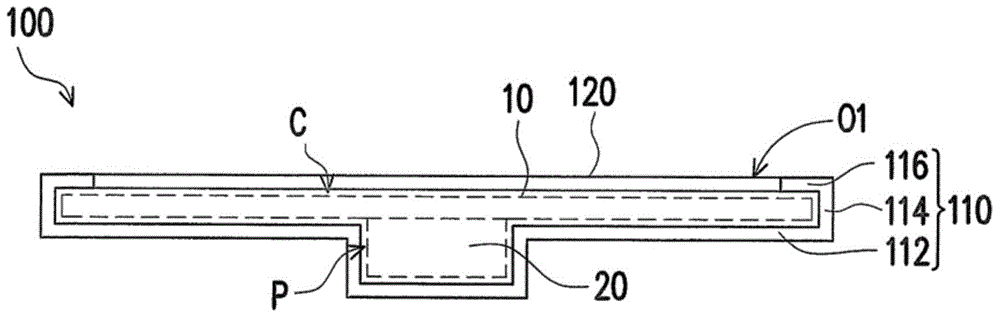

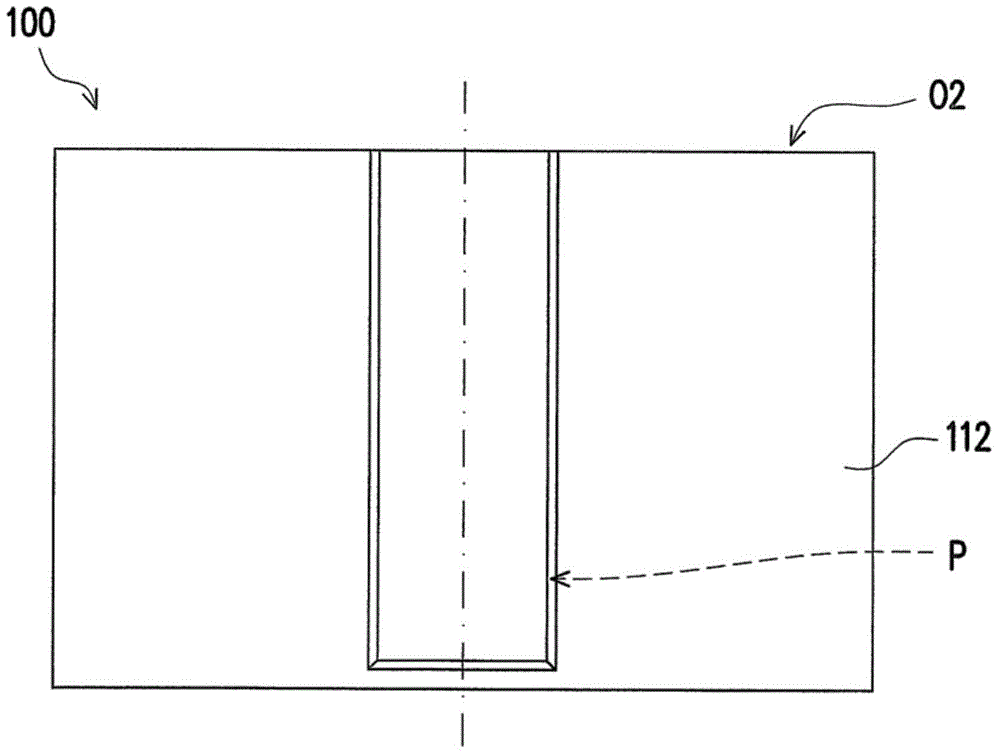

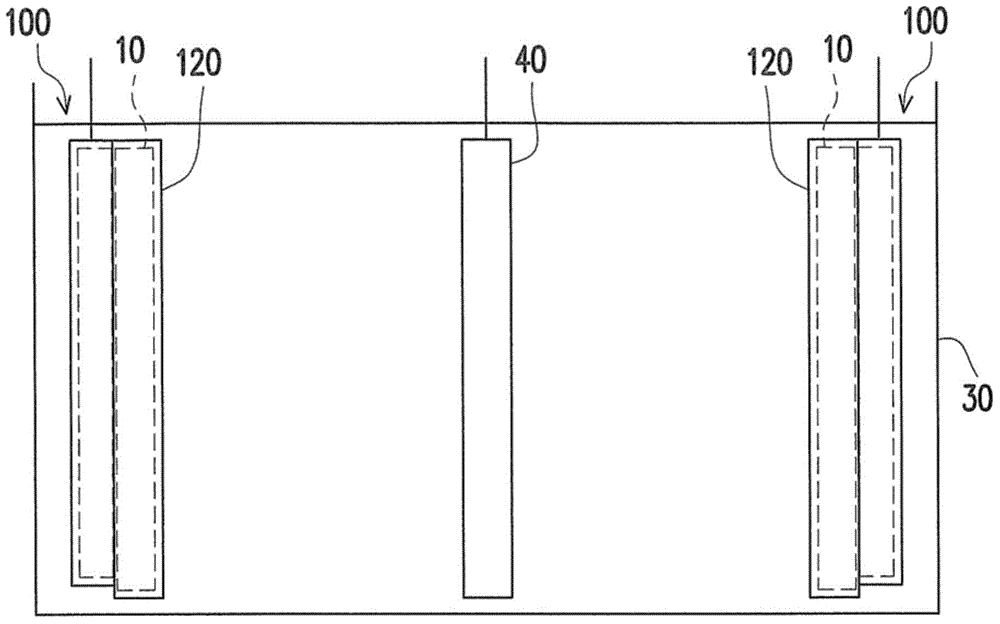

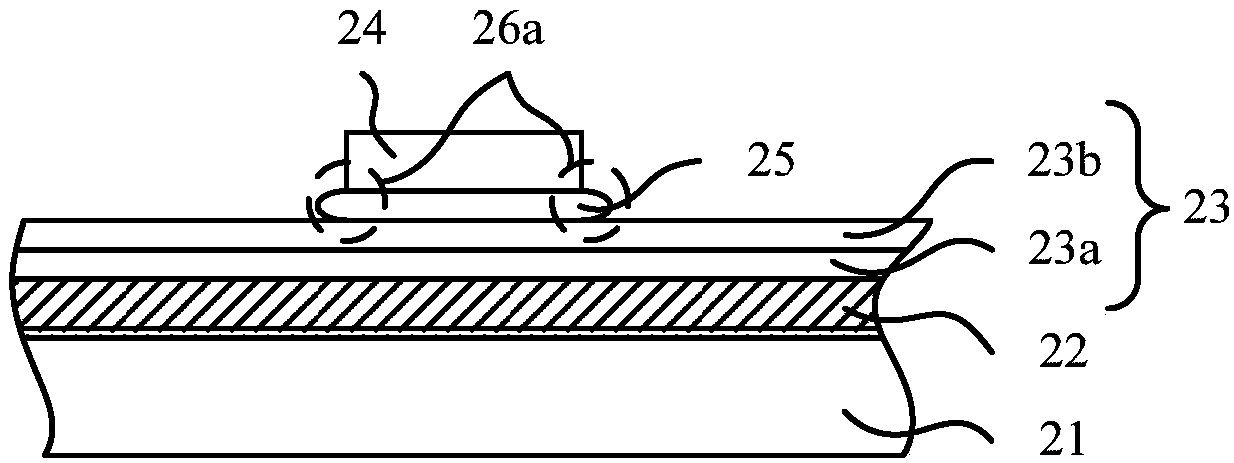

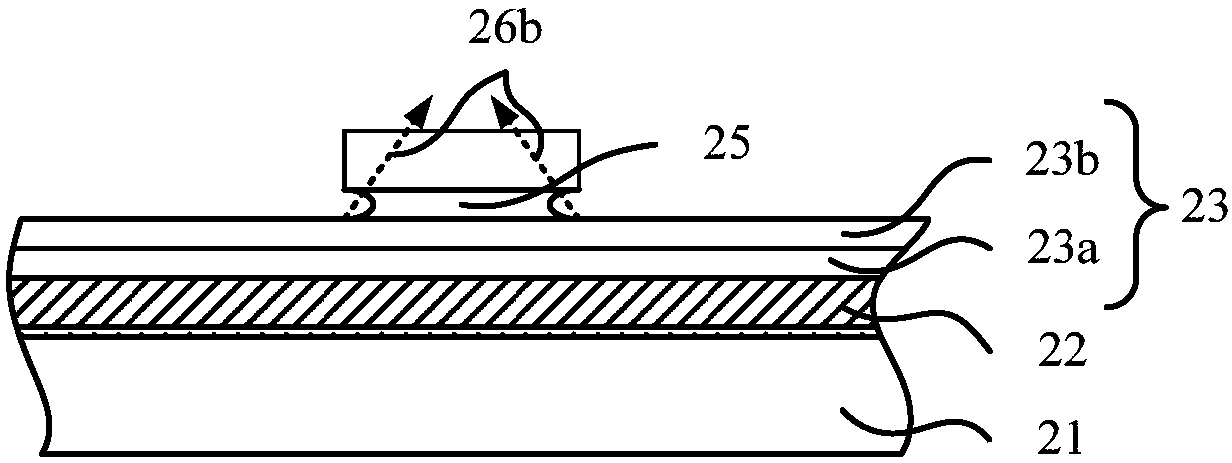

Diaphragm device

The invention discloses a diaphragm device which is suitable for an infusible electroplating anode. The diaphragm device comprises a shell and a diaphragm, wherein the shell is provided with a cavity and a first opening communicated with the cavity, the cavity is suitable for accommodating the infusible electroplating anode, and the depth of the cavity is close to the thickness of the infusible electroplating anode. The diaphragm is connected with the first opening. In addition, the invention provides another diaphragm device, wherein the diaphragm device comprises a diaphragm bag body and a back plate. The back plate is configured in the diaphragm bag body, wherein the infusible electroplating anode is suitable for being placed in the diaphragm bag body and is in contact with the back plate.

Owner:UNIMICRON TECH CORP

Electronic device

PendingCN109753856AReduce deformationKeep the effectCharacter and pattern recognitionFingerprintElastic modulus

An electronic device comprises: a fingerprint identification module; a protective cover plate comprising a protective layer and a protective layer, a decorative layer positioned on at least one surface of the protective layer; a first bonding layer located between the protective cover plate and the fingerprint identification module, so that the fingerprint identification module is attached to theprotective cover plate. The protective cover plate further comprises a second bonding layer, the second bonding layer is located between the decorative layer and the protective layer so as to achieveattachment of the decorative layer and the protective layer, and the elastic modulus of the second bonding layer is larger than that of the first bonding layer. And the connection strength between thedecorative layer and the second bonding layer is relatively high, so that the texture effect of the decorative layer can be kept, and the user experience is improved.

Owner:SHANGHAI OXI TECH

Preparation method of slate alkali reactivity restraining addition agent

The invention discloses a preparation method and a material using standards of a slate alkali reactivity restraining addition agent (FLSR-I). The addition agent is composed of mixing materials, ganister sands, nanometer SiO2, triethanolamine, a high-efficient plasticizing agent and an air entraining agent, the preparation method comprises accurately weighting dosage of the mixing materials, the ganister sands, the nanometer SiO2, the triethanolamine, the high-efficient plasticizing agent and the air entraining agent in proportion during preparation; sufficiently blending the mixing materials,the ganister sands, the nanometer SiO2, the high-efficient plasticizing agent and the air entraining agent, and manufacturing end products of the restraining addition agent by blending with the triethanolamine; and mixing in preparation of alkali reactive aggregate concrete in carious grades in proportion. The preparation method can effectively restrain reaction of slate alkali aggregate with expansion ratio between 0.2% to 0.5% and is obvious in restraining effect, simple and convenient in using method and free of needs of special construction control, thereby being capable of greatly lowering engineering using materials and transportation cost, and expanding material selecting range of the engineering using materials simultaneously.

Owner:CHINA RAILWAY NO 5 ENG GRP

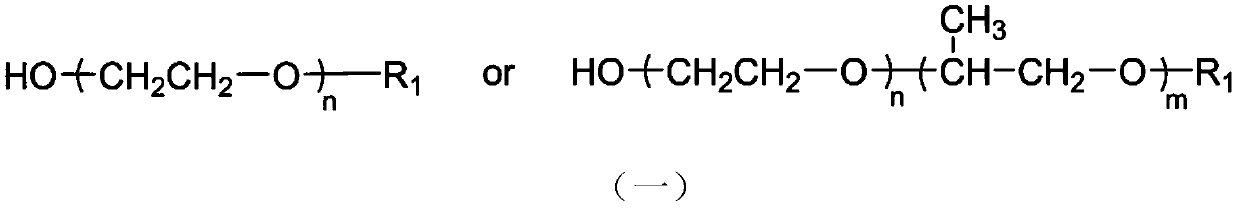

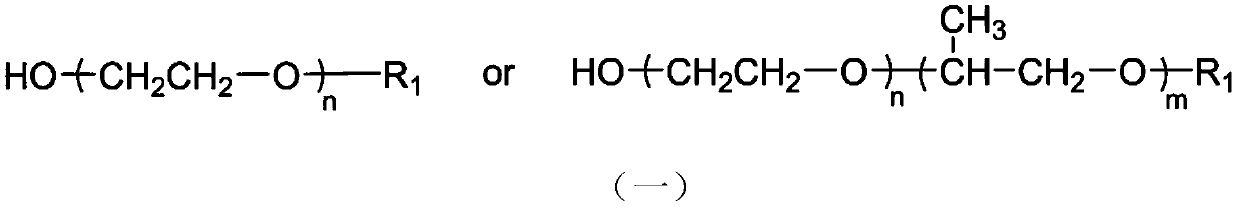

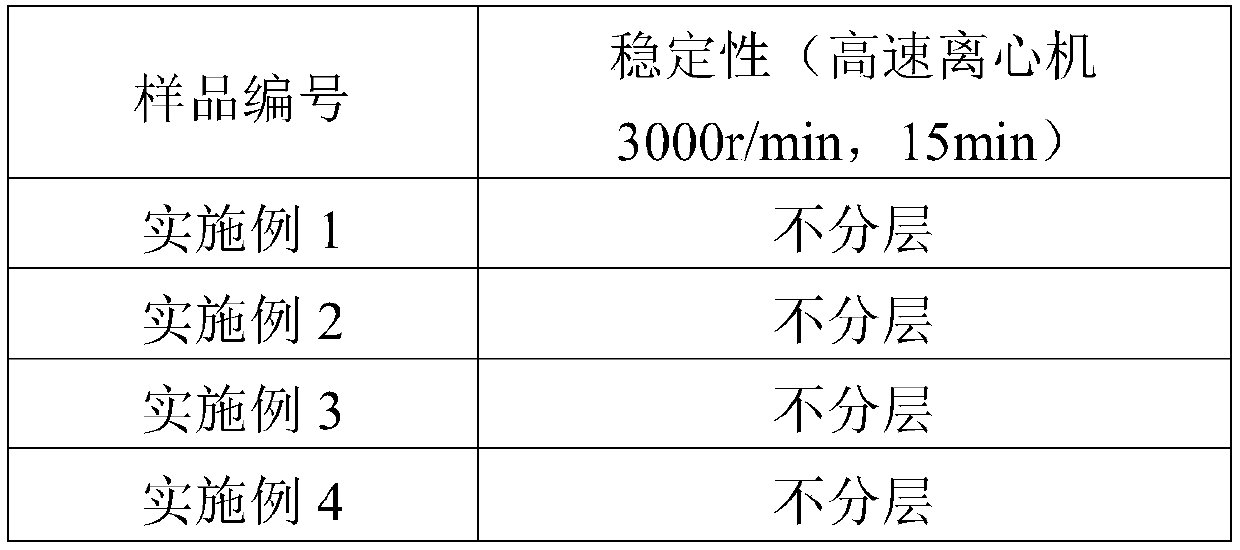

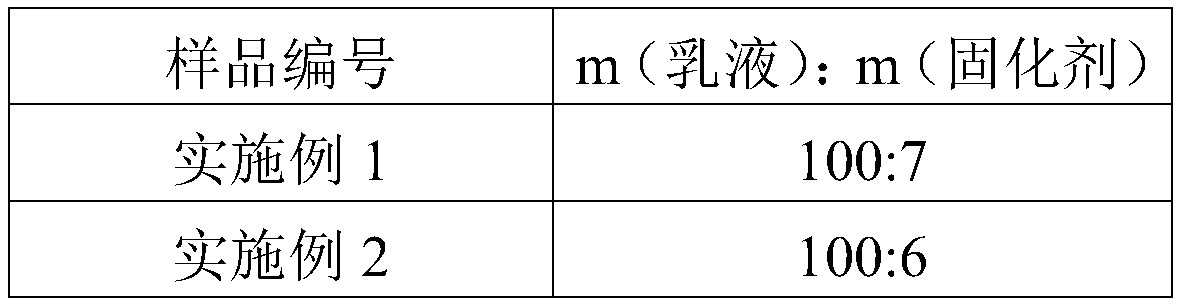

Reactive emulsifier, water-borne epoxy resin emulsion, preparation and application

InactiveCN111171309ACorrosiveReduced corrosion resistanceAnti-corrosive paintsEpoxynovolac adhesivesPolymer sciencePolyethylene glycol

The invention belongs to the technical field of waterborne epoxy resin, and particularly relates to a reactive emulsifier, waterborne epoxy resin emulsion, preparation and application. Phenolic aldehyde amine generated by condensation reaction of cardanol, paraformaldehyde and micromolecular polyamine reacts with polyethylene glycol diglycidyl ether to obtain the reaction type emulsifier being ofan "amine-polyoxyethylene ether-amine" structure, which is terminated by the aldehyde group of the cardanol and has hydrophilic middle chain sections; then mixing the reactive emulsifier with water toform a nano-scale emulsion, and mixing the nano-scale emulsion with epoxy resin at a high speed to obtain the water-borne epoxy resin emulsion. The method is simple in technological process, safe tooperate, mild in reaction and low in production cost. The preparation method is simple and the prepared reactive emulsifier is good in emulsifying effect, so that the water-borne epoxy resin emulsionwith good stability is obtained under the condition that few hydrophilic components are introduced. The water-borne epoxy resin emulsion has excellent mechanical property, adhesion property, water resistance and corrosion resistance when used as a water-borne coating.

Owner:GUANGZHOU CHEM GROUTING CO LTD CAS

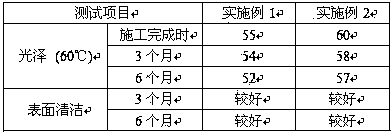

Single-component water-based outdoor top-coat varnish

ActiveCN103627280AReduced chance of reactionImprove chemical resistanceCoatingsSolventDefoaming Agents

The invention relates to a single-component water-based outdoor top-coat varnish. The single-component water-based outdoor top-coat varnish substantially consists of ingredients in percentage by weight: 75%-85% of water-based acrylic resin, 0.2%-0.4% of wetting agent, 0.3%-0.5% of defoaming agent, 6%-8% of cosolvent, 0.4%-0.6% of thickener, 0.1%-0.3% of preservative, 0.2%-0.4% of mould inhibitor, and 6%-15% of water. A layer of compact reticular thin film structure is formed on the surface in the film forming process by adopting water-based acrylic resin of self-crosslinked nanoscale polymer, the single-component water-based outdoor top-coat varnish has excellent hydrophobic performance, the contamination resistance and gloss retention of the product in outdoor use can be promoted, and the coating effect of the product in outdoor coating, protection and decoration materials can be improved.

Owner:GUANGDONG BADESE CHEM

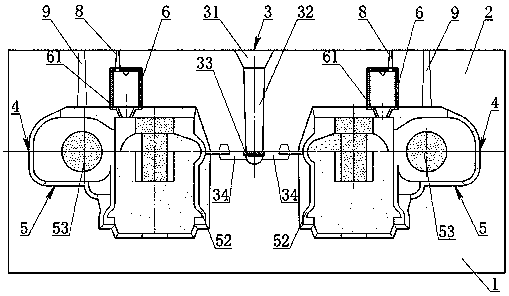

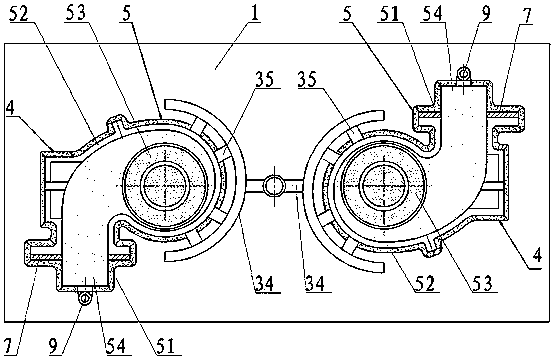

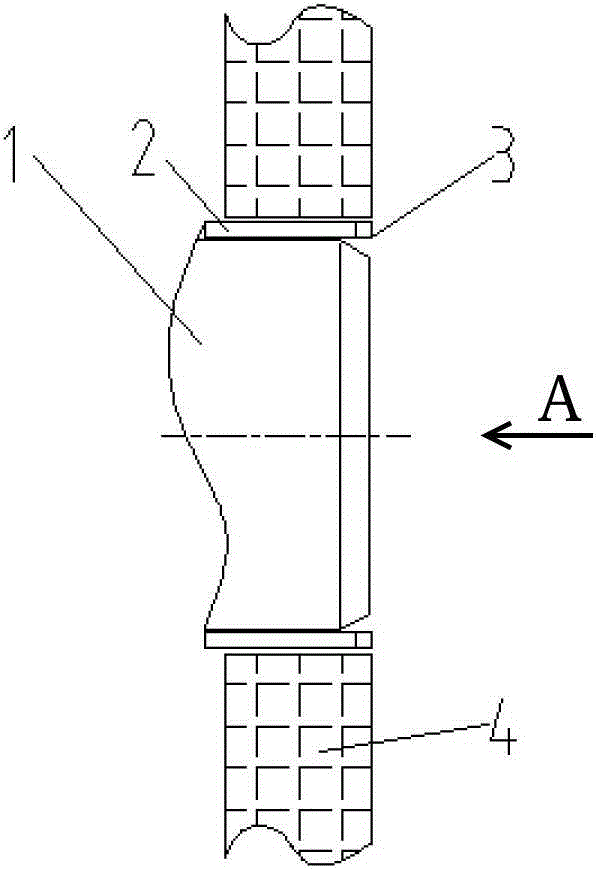

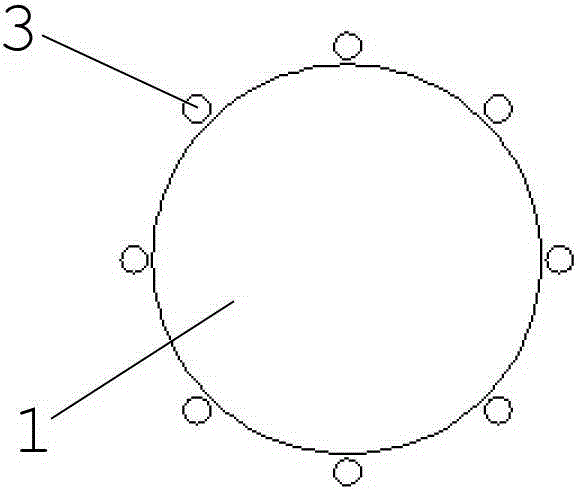

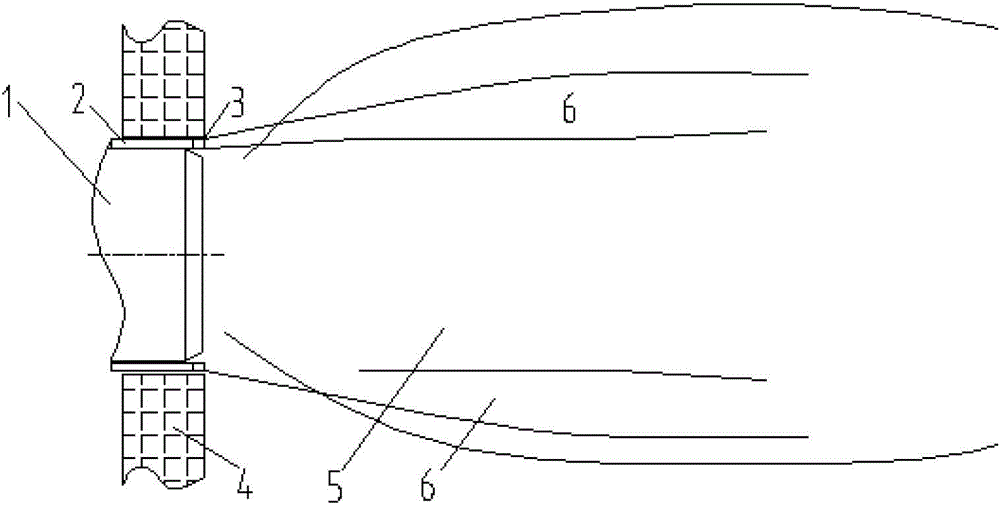

Ceramic riser neck and sand mould structure capable of reducing defects of high-nickle nodular iron reaction layer

PendingCN108145077AFlow charge stableEasy dischargeFoundry mouldsFoundry coresReaction layerMaterials science

The invention discloses a ceramic riser neck and sand mould structure capable of reducing defects of a high-nickle nodular iron reaction layer. The ceramic riser neck and sand mould structure comprises a wet mould lower sand mould, a wet mould upper sand mould, a casting mould cavity formed in the interface of the wet mould lower sand mould and the wet mould upper sand mould and a cladding assembly arranged in the casting mould cavity and further comprises a casting assembly, wherein one end of the casting assembly is positioned at the interface of the wet mould lower sand mould and the wet mould upper sand mould and communicates with the casting mould cavity and a cladding mould cavity; the other end of the casting assembly stretches out of the wet mould upper sand mould; and the claddingassembly comprises a cladding shell mould, a cladding sand core and a heat insulating riser. According to the ceramic riser neck and sand mould structure, on the one hand, during pouring, wet mould sand moulds, a precoated sand cladding shell mould, a cladding sand core and a heat insulating riser sleeve react with iron liquid to generate plenty of turbulent flow oxidized gas, and the turbulent flow oxidized gas can be conveniently discharged out of a second exhausting rod to reduce the reaction probability of gas and Mg in the iron liquid; and on the other hand, a ceramic riser neck is arranged at the bottom of the heat insulating riser to prevent influence of the turbulent flow oxidized gas to nodularization of casting at the riser neck, so that generation of defects of the casting reaction layer at the high-nickle nodular iron riser neck is effectively reduced.

Owner:溧阳市联华机械制造有限公司

Vapor mixing device reducing NOx emission

InactiveCN105222150AReduce oxygen concentrationReduce emission concentrationNon-combustible gases/liquids supplyCombustion chamberCombustor

The invention provides a vapor mixing device reducing NOx emission, aims at achieving the technical purpose of mixing atomized vapor with flames and reducing NOx emission of industrial fuel oil and fuel gas combustors and belongs to the technical field of emission reduction of the industrial fuel oil and fuel gas combustors. The vapor mixing device reducing NOx emission is characterized in that a plurality of spray guns are evenly arranged on the periphery of the outer side of a throat opening of a combustor; the spray guns and the axis of the throat opening of the combustor are arranged in the same direction in parallel; the ends, facing a hearth combustion chamber, of the spraying guns are provided with spray gun heads; and the tail ends of the spray guns are communicated with a high-pressure water / vapor pipeline. When the tail ends of the spray guns are connected with high-pressure water, the corresponding spray gun heads are mechanical atomization heads. When vapor exists in the pipeline, axial spraying through holes are formed in the middles of the corresponding spray gun heads. The mixing device is simple in structure, a combustor body does not need to be modified, running is stable, and the effect is obvious. As shown by a plurality of field test results, when gas is combusted, the NOx emission concentration can be reduced by 25%, and when oil is combusted, the NOx emission concentration can be reduced by 10-30%.

Owner:SHANGHAI WISEBOND TECH

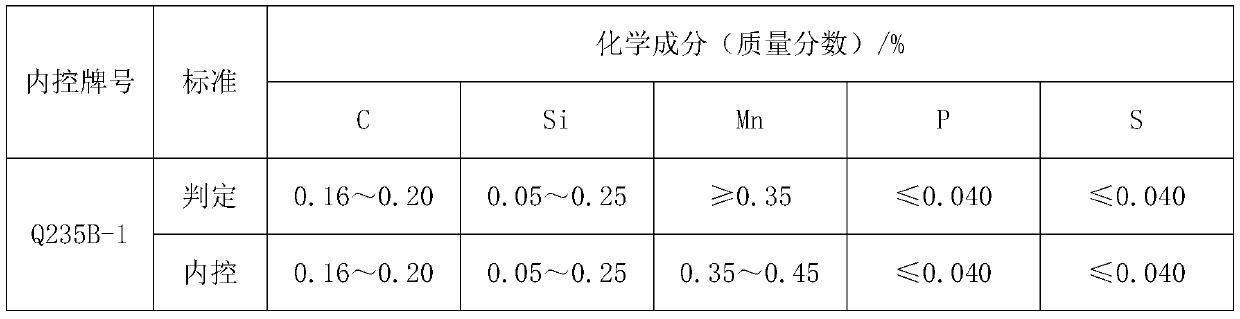

Control method of boron content in refining process of acid slag produced in silicon killed steel production

The invention discloses a control method of boron content in the refining process of acid slag produced in silicon killed steel production. The control method includes the steps of firstly, molten steel is subjected bessemerizing and tapping, silicon iron and ferromanganese are added in the tapping process to perform deoxidization alloying, low-nitrogen carbon powder is added according to tappingcarbon content, a final slag modifier is added, and a tapping end point adopts slag-stopping tapping; secondly, after LF furnace slag temperature rise, 0.17-0.35kg of silicon iron is added into each ton of steel to perform slag top deoxidization; 2-4kg of lime is added into each ton of steel to produce high-alkalinity reducing slag, FeO and MnO in the slag is not more than 2.0%, and the alkalinityof the slag is not smaller than 2; thirdly, alloy is regulated according the components of refined molten steel, quartz sand is added to regulate the alkalinity to be not larger than 1.2, soft blow is performed for 15-20 minutes after slugging, and ferroboron is added to perform alloying; fourthly, argon stirring is performed for at least 5 minutes after the ferroboron is added, and delivering the molten steel out of a station. The control method has the advantages that boron alloying is performed in the refining late stage when O and N are stable, boron content fluctuation in the steel is controlled within 6ppm, boron yield is increased by 15%, and ferroboron adding quantity is reduced by 30%.

Owner:武汉钢铁有限公司

Coating method of lithium ion battery cathode material

ActiveCN108767232AUniform particle size distributionShort covering timeCell electrodesSecondary cellsImpellerAirflow

The invention discloses a coating method of a lithium ion battery cathode material. According to the method, disk-nest grinding equipment is utilized to continuously input a lithium ion battery cathode material to be covered into a disk-nest grinder in a form of solid powder, solid powder is dispersed by an impeller and a disk which rotate at a high speed in a cavity of the disk-nest grinder, multiple nest type rotational flows are formed between the disk and a special lining plate, and air flow impact force between the disk and the special lining plate can fully disperse the solid powder; meanwhile, the rotation speed can be controlled to make a powder material keep morphology or be smashed; furthermore, a coating material can enter the disk-nest grinder in a form of solution or slurry ina mist spray mode and can evenly contact certain-temperature solid powder particles to be covered to finish coating. By means of the lithium ion battery cathode material coating method, a traditionalcoating technology for an existing lithium ion battery cathode material is greatly simplified, productivity is remarkably improved, a product coating effect is greatly improved, and cost is obviouslyreduced.

Owner:CENT SOUTH UNIV

Method for increasing CO content of converter gas

InactiveCN111575431AReduce CO oxidationIncrease CO contentManufacturing convertersSteelmakingFlue gas

The invention relates to a method for increasing the CO content of converter gas, and belongs to the technical field of ferrous metallurgy steelmaking. The method comprises the following steps of 1) adding a batch of FeO-containing cold charge while blowing the converter; 2) blowing the converter for 1.5-2.0 minutes, and adding raw dolomite accounting for 1 / 3 of the total amount of the lime; 3) after the raw dolomite is added, reducing the lance position and the oxygen supply flow; 4) adding a FeO-containing cold material 3 minutes before blowing and 2 minutes before stopping oxygen supply; 5)reducing the lance position and the oxygen supply flow 1.5-2 minutes before smelting to stop oxygen supply, and 6) finishing the coal gas recovery time from 2 minutes before smelting to 0.5 minute before stopping oxygen supply. The method can prolong the coal gas recovery time, improve the CO content and the coal gas calorific value in the flue gas, and reduce the energy consumption of the steelmaking process.

Owner:SHANDONG IRON & STEEL CO LTD

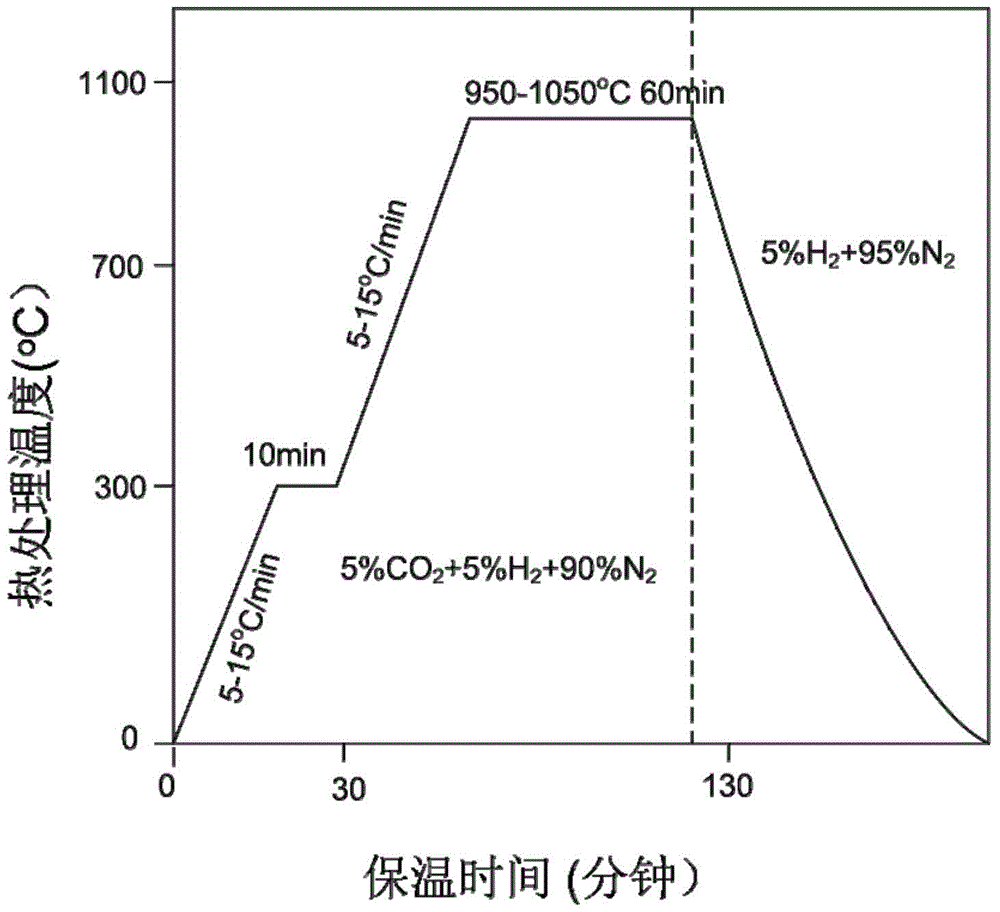

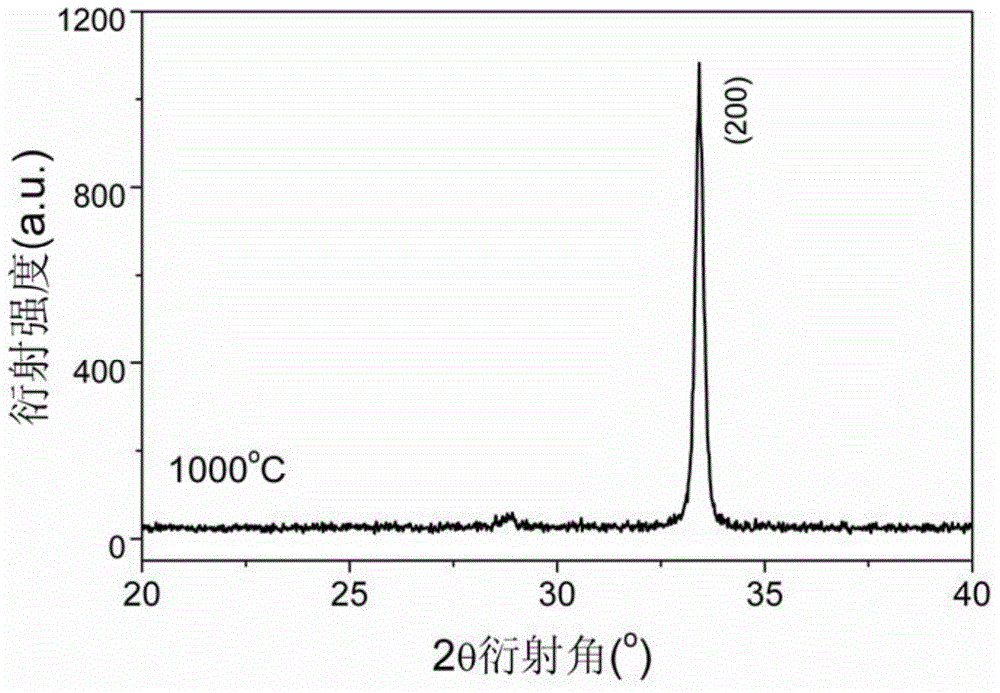

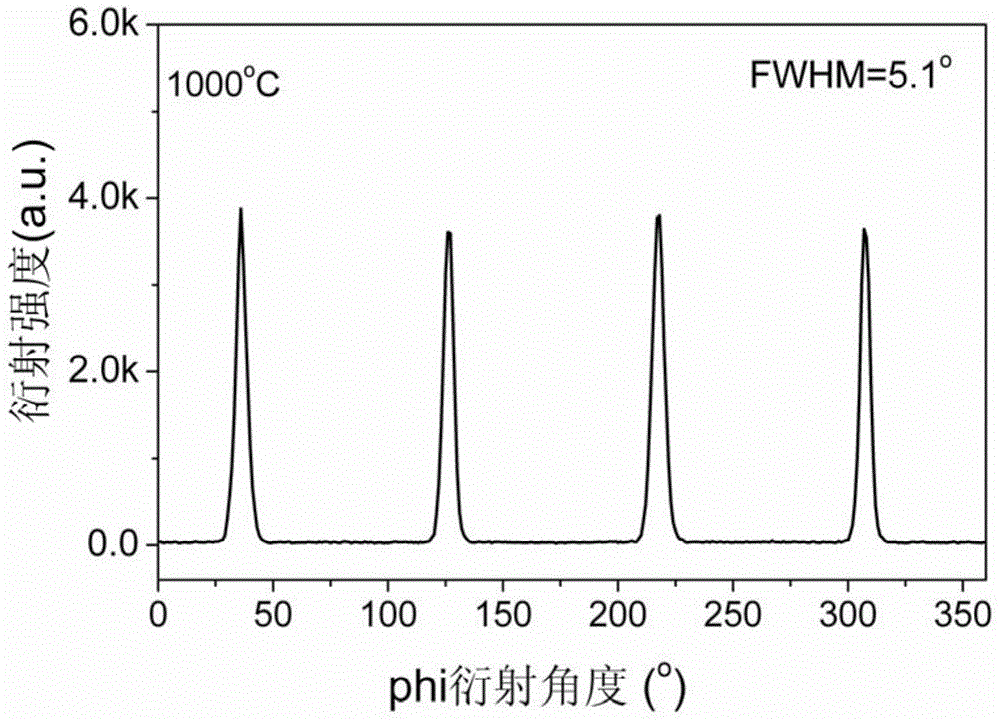

Method for preparing Y2Ce2O7 transition layer thin film for superconduction coatings

ActiveCN104538113AIncreasing the thicknessIncrease concentrationSuperconductors/hyperconductorsSuperconductor devicesPropanoic acidElectrical conductor

The invention discloses a method for preparing Y2Ce2O7 transition layer thin film for superconduction coatings. The method includes the following steps: acetic acid yttrium, a first organic addition agent and methyl alcohol are mixed and blended to obtain a clear yttrium-contained solution; cerous nitrate, acetylacetone and propionic acid are mixed to obtain a clear cerium-contained solution; the obtained yttrium-contained solution and the obtained cerium-contained solution are mixed to obtain a first mixed solution, and methyl alcohol is added into the first mixed solution to obtain a precursor solution of the Y2Ce2O7 transition layer thin film; the Y2Ce2O7 transition layer thin film is coated on flexible nickel-tungsten alloy base bands through the adoption of the precursor solution of the Y2Ce2O7 transition layer thin film; after drying is conducted and 180 nm-250 nm ultraviolet irradiation is carried out, heat treatment is carried out in a first protective atmosphere, cooling is carried out in a second protective atmosphere, and the Y2Ce2O7 transition layer thin film is obtained from corresponding base sheets or the corresponding base bands. The method overcomes the defects that existing transition layer thin film is easy to crack, the surface is rough, and the texture degree is poor; YBCO superconduction thin film prepared on the basis of the transition layer is free of impurity phases, the good c-axis texture is achieved, and the application requirement of high temperature superconductor coating conductors is met.

Owner:JIANGSU HENGTONG PHOTOELECTRIC

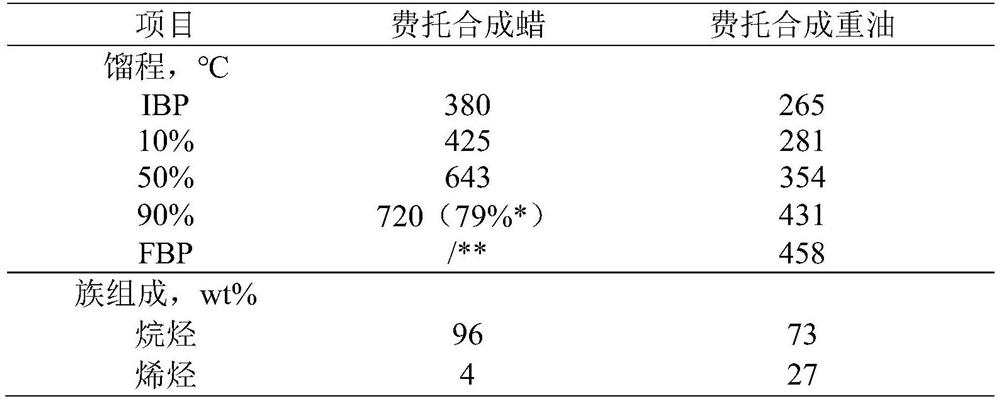

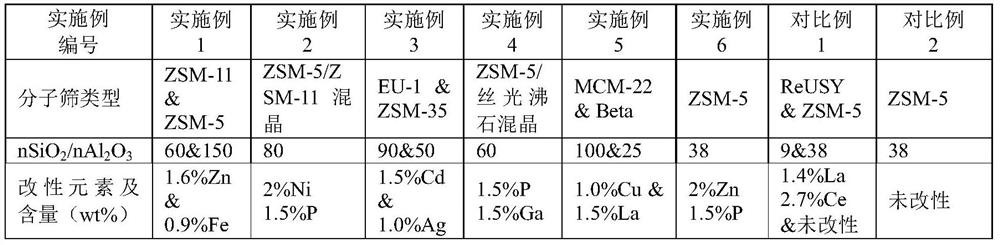

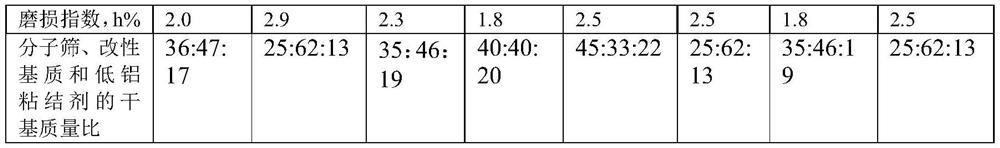

Catalyst for producing high-octane-number component gasoline as well as preparation method and application thereof

ActiveCN112371167AHigh aromatic contentGuaranteed activityCatalytic crackingMolecular sieve catalystsMolecular sievePtru catalyst

The invention relates to a catalyst for producing high-octane-number component gasoline from Fischer-Tropsch synthesis heavy hydrocarbon. The catalyst comprises a modified ten-membered ring pore molecular sieve, a modified matrix and a low-aluminum binder in a dry basis mass ratio of (10-70): (80-5): (10-25), wherein the modified matrix is modified clay, and the aluminum content of the low-aluminum binder is 0-35 wt% based on the dry basis of the aluminum / binder. Moreover, the invention also relates to a method for preparing the catalyst and application of the catalyst in a method for producing high-octane-value component gasoline by taking Fischer-Tropsch synthesis heavy hydrocarbon as a raw material. When the catalyst provided by the invention is applied to catalytic cracking reaction ofFischer-Tropsch synthesis of heavy hydrocarbons, the gasoline yield is reasonable, the aromatic hydrocarbon content of gasoline is higher, and the octane value is higher. The performance of the catalyst is obviously superior to that of typical traditional heavy oil catalytic cracking reaction catalysts.

Owner:SYNFUELS CHINA INNER MONGOLIA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com