Single-component water-based outdoor top-coat varnish

A clear topcoat, single-component technology, applied in the direction of coating, etc., can solve the problems of paint film damage, loss of protection and beautification, etc., to achieve the effect of prolonging the service life, excellent protection, decoration and beautification, and improving the use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

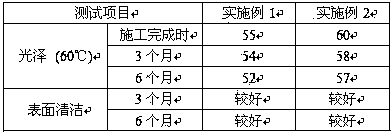

Examples

Embodiment 1

[0029] Raw material weight percentage

[0030] Water-based acrylic resin 77%

[0031] Wetting agent 0.3%

[0032] Defoamer 0.4%

[0033] Co-solvent 6%

[0034] Thickener 0.6%

[0035] Preservatives 0.3%

[0036] Antifungal agent 0.4%

[0037] Water 15%.

[0038] The preparation steps of the present invention are as follows:

[0039] Add 77 kg of water-based acrylic resin in turn to a clean container that meets the requirements, start stirring, and disperse at a low speed at a speed of 400-600 r / min. Min high-speed dispersion for 10~15 min, pre-mix 6 kg of co-solvent and 13 kg of water to form a uniformly dispersed mixed solution, then add it to the system, disperse for 5 min, add 0.6 kg of thickener and 2 kg of water to adjust the viscosity to 65- 70KU / 25 o C, stir at high speed for 5 minutes; finally add 0.3 kg of preservative and 0.4 kg of antifungal agent, and disperse evenly for 5 minutes.

[0040] How to use: When using, dilute with water to the required viscosi...

Embodiment 2

[0042] raw material weight

[0043] Water-based acrylic resin 85 kg

[0044] Wetting agent 0.4 kg

[0045] Defoamer 0.3 kg

[0046] Co-solvent 7 kg

[0047] Thickener 0.6 kg

[0048] Preservative 0.3 kg

[0049] Antifungal agent 0.4 kg

[0050] 6 kg of water.

[0051] The preparation steps of the present invention are as follows:

[0052] Add 85 kg of water-based acrylic resin in turn to a clean container that meets the requirements, start stirring, and disperse at a low speed at a speed of 400-600 r / min. Min high-speed dispersion for 10~15 min, pre-mix 7 kg of co-solvent and 5 kg of water to form a uniformly dispersed mixed solution, then add it to the system, disperse for 5 min, add 0.6 kg of thickener and 1 kg of water to adjust the viscosity to 65 -70KU / 25 o C, stir at high speed for 5 minutes; finally add 0.3 kg of preservative and 0.4 kg of antifungal agent, and disperse evenly for 5 minutes.

[0053] How to use: When using, dilute with water to the required vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com