Method for preparing Y2Ce2O7 transition layer thin film for superconduction coatings

A superconducting coating, y2ce2o7 technology, applied in the field of high-temperature superconducting thin film buffer layer preparation, can solve the problems of loose thin film, rough surface, poor texture, etc., and achieve the effect of increasing the proportion, reducing the probability of occurrence and reducing the performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

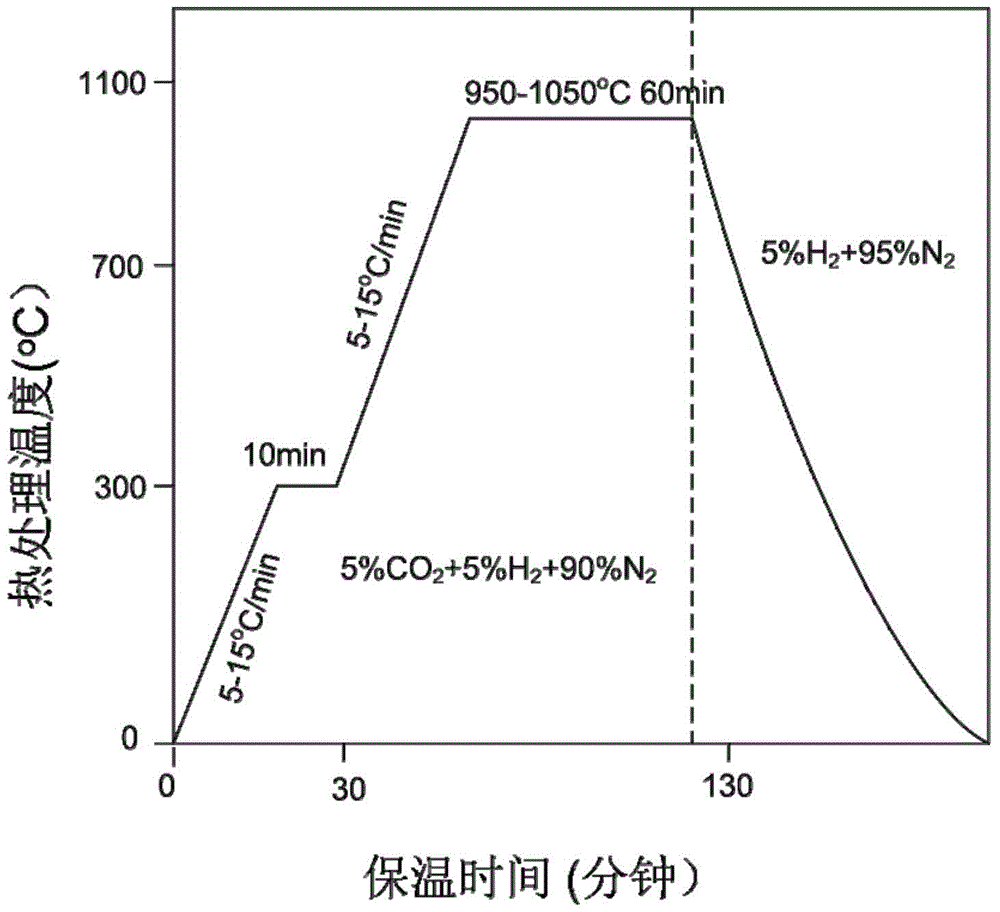

[0032] Embodiment 1: Y for a kind of superconducting coating 2 Ce 2 o 7 The preparation method of transition layer thin film, comprises the following steps:

[0033] Step 1. After mixing yttrium acetate, the first organic additive, and methanol, stir at 35° C. for 2 hours to obtain a clear yttrium-containing solution. The molar ratio of the yttrium acetate to the first organic additive is 1:2;

[0034] Step 2: adding cerium nitrate, acetylacetone, and propionic acid into methanol solvent in a molar ratio of 1:3.5:5, and stirring at 35°C for 2 hours to obtain a clear cerium-containing solution;

[0035] Step 3, mixing the yttrium-containing solution obtained in step 1 with the cerium-containing solution obtained in step 2 to obtain a first mixed solution, and then adding methanol as a diluent solvent to the first mixed solution to adjust the concentration of metal ions, so that yttrium, The total metal ion concentration of cerium reaches 0.3mol / l, and it is stirred and clari...

Embodiment 2

[0042] Embodiment 2: a kind of Y for superconducting coating 2 Ce 2 o 7 The preparation method of transition layer thin film is characterized in that: comprises the following steps:

[0043] Step 1. After mixing yttrium acetate, the first organic additive, and methanol, stir at 45° C. for 1.5 hours to obtain a clear yttrium-containing solution. The molar ratio of the yttrium acetate to the first organic additive is 1:2.5;

[0044] Step 2: adding cerium nitrate, acetylacetone, and propionic acid into methanol solvent in a molar ratio of 1:3:7, and stirring at 35°C for 2.5 hours to obtain a clear cerium-containing solution;

[0045] Step 3, mixing the yttrium-containing solution obtained in step 1 with the cerium-containing solution obtained in step 2 to obtain a first mixed solution, and then adding methanol as a diluent solvent to the first mixed solution to adjust the concentration of metal ions, so that yttrium, The total metal ion concentration of cerium reaches 0.25mol / ...

Embodiment 3

[0052] Embodiment 3: a kind of Y for superconducting coating 2 Ce 2 o 7 The preparation method of transition layer thin film, comprises the following steps:

[0053] Step 1. After mixing yttrium acetate, the first organic additive, and methanol, stirring at 38°C for 3 hours to obtain a clear yttrium-containing solution, the molar ratio of the yttrium acetate to the first organic additive is 1:2.8;

[0054] Step 2: adding cerium nitrate, acetylacetone, and propionic acid into methanol solvent in a molar ratio of 1:4:5, and stirring at 40° C. for 1 hour to obtain a clear cerium-containing solution;

[0055] Step 3, mixing the yttrium-containing solution obtained in step 1 with the cerium-containing solution obtained in step 2 to obtain a first mixed solution, and then adding methanol as a diluent solvent to the first mixed solution to adjust the concentration of metal ions, so that yttrium, The total metal ion concentration of cerium reaches 0.28mol / l, stirring and clarifying a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com