Catalyst for producing high-octane-number component gasoline as well as preparation method and application thereof

A technology with high octane number and catalyst, applied in the direction of catalyst activation/preparation, molecular sieve catalyst, chemical instruments and methods, etc., can solve the problem of unsatisfactory gasoline aromatics content and octane number in gasoline yield, and achieve the protection of modifying elements , The preparation process is simple, and the effect of slowing down the release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

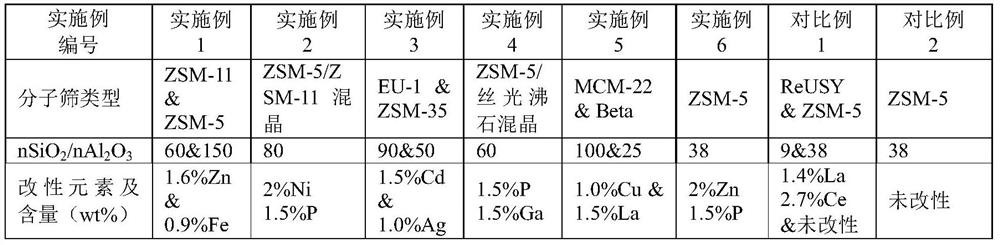

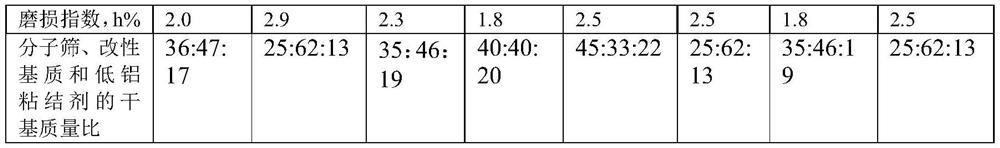

Embodiment 1

[0123] Preparation of phosphoraluminum glue binder: 4108g pseudoboehmite and 10969g deionized water were stirred and beaten for 15min, then slowly added 8483g phosphoric acid (85wt%) at a rate of about 40g / min, and the temperature of the control system was below 75°C. Then add 3440g hydrochloric acid (33wt%), continue to stir for 30min to obtain translucent phosphorus-aluminum glue as a low-aluminum binder, measured pH=2.2, viscosity (25°C) is 65mPa·s, calculated as aluminum / bonding agent total dry The aluminum content on a basis was 18.3 wt%.

[0124] Catalyst preparation: Mix 2579g zinc-modified ZSM-11 molecular sieve (modified by impregnation method), 737g iron-modified ZSM-5 molecular sieve (modified by impregnation method) and 4800g deionized water at 50°C, then add 315g Urea was stirred and beaten for 90 minutes to obtain a modified molecular sieve slurry; 4433g kaolin was mixed with 6510g deionized water at 50°C, and then 668g phosphoric acid (concentration 85wt%) was a...

Embodiment 2

[0127] Mix 2303g of nickel phosphorus modified ZSM-5 / ZSM-11 mixed crystal molecular sieve (modified by impregnation method) and 4800g of deionized water at 60°C, then add 131g of n-butylamine and stir for 30 minutes to obtain a modified molecular sieve slurry; 5522g of perlite and 6940g of deionized water were mixed at 60°C, then 1318g of ammonium dihydrogen phosphate particles were added and stirred for 120min to obtain a modified matrix slurry; The base aluminum content is 0.3wt% (impurity aluminium)) is added in above-mentioned modified substrate slurry, stirs 30min, adds modified molecular sieve slurry, stirs 30min, obtains catalyst slurry, the solid content of gained catalyst slurry is 32wt%. The above-mentioned catalyst slurry was emulsified and homogenized, and the viscosity (25°C) was measured to be 6220mPa·s, spray-dried into microspheres, and the formed microspheres were calcined at 600°C for 1 hour to obtain the finished microspherical catalyst, which was designated ...

Embodiment 3

[0130] Mix 829g cadmium modified EU-1 molecular sieve (modified by ion exchange method), 2395g silver modified ZSM-35 molecular sieve (modified by ion exchange method) and 4800g deionized water at 50°C, then add 184g hexadiene Amine was stirred and beaten for 40 minutes to obtain a modified molecular sieve slurry; 4338g of montmorillonite and 6164g of deionized water were mixed at 80°C, and then 748g of diammonium hydrogen phosphate particles were added and stirred for 90 minutes to obtain a modified matrix slurry; 2333g of Example 1 Prepared phosphoraluminum glue binder and 3208g acidic silica sol binder (the aluminum content is 7.9wt% according to the total dry basis of aluminum / bonding agent) join in the above-mentioned modified matrix slurry successively, stir 30min, The modified molecular sieve slurry was added and stirred for 30 minutes to obtain a catalyst slurry with a solid content of 38 wt%. The viscosity (25°C) of the catalyst slurry was measured to be 5300mPa·s aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com