Coating method of lithium ion battery cathode material

A technology for lithium-ion batteries and cathode materials, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of uneven coating layer, difficult coating, and uncontrollable size of coating material, and achieve uniform particle size distribution. , Improve the coating efficiency, the effect of significant industrialization significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

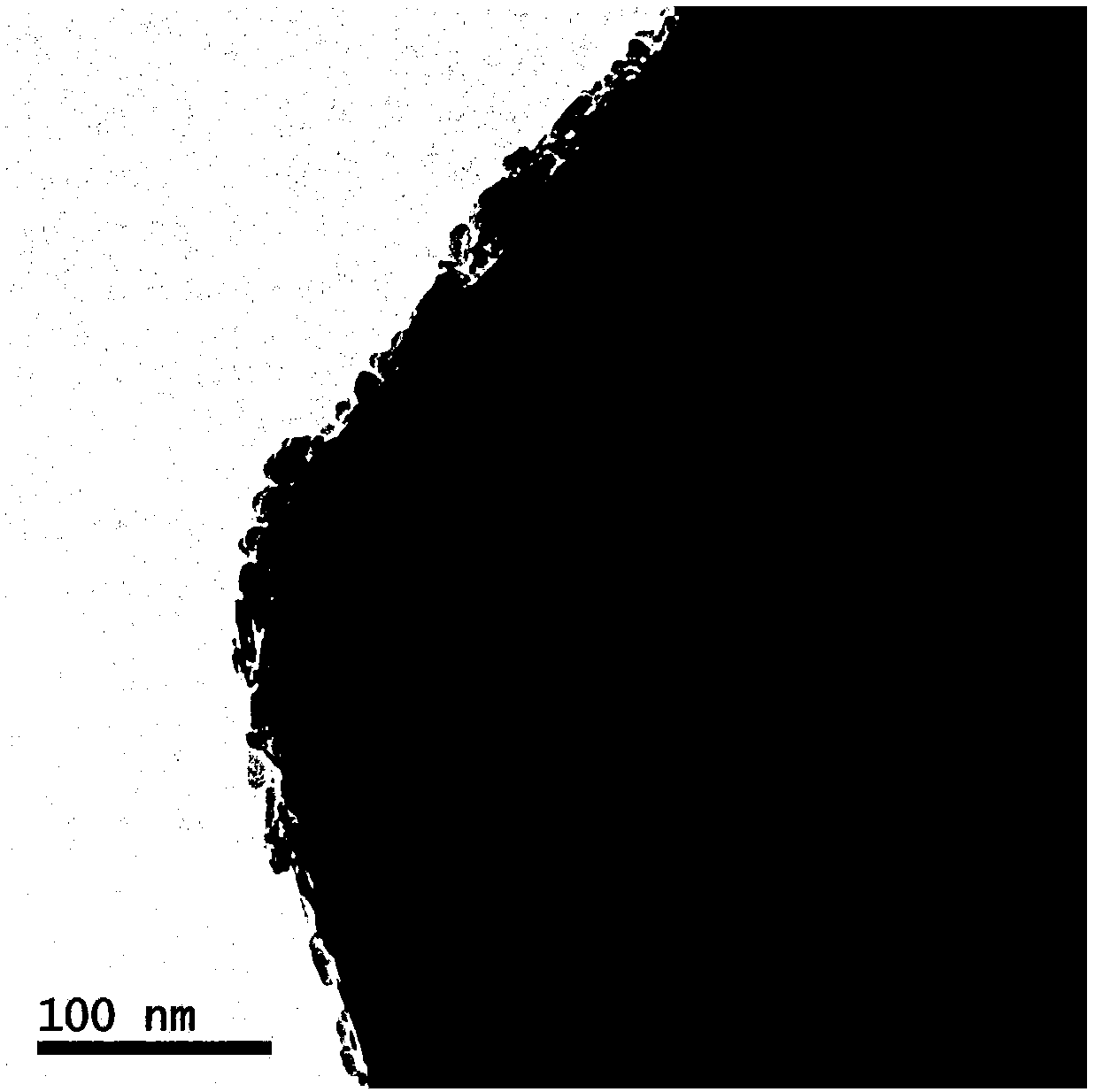

[0057] Preparation of LiNi 0.6 co 0.2 mn 0.2 o 2 (NCM622) coated with 0.2wt% Al 2 o 3 sample. Dissolve 10% aluminum sol in deionized water to prepare a concentration of 2wt% Al 2 o 3 aluminum sol coating solution. Turn on the disc nest mill to preheat, so that the inlet temperature is 200°C, the outlet temperature is 100°C, the host speed is 2000 rpm, and the air flow rate is 4000 cubic meters / hour; then press LiNi 0.6 co 0.2 mn 0.2 o 2 The solid powder feed rate is 400 kg / hour, the liquid feed rate is 80 kg / hour, and the solid and liquid raw materials are input into the disc nest mill for reaction simultaneously; the reaction obtains a lithium-ion battery cathode material with a coating layer. The lithium-ion battery positive electrode material of the obtained coating layer is continuously transported to the collector under the action of fan suction, and finally the coated product is collected by the collector. The wind speed of the fan is 20 m / s.

[0058] from ...

Embodiment 2

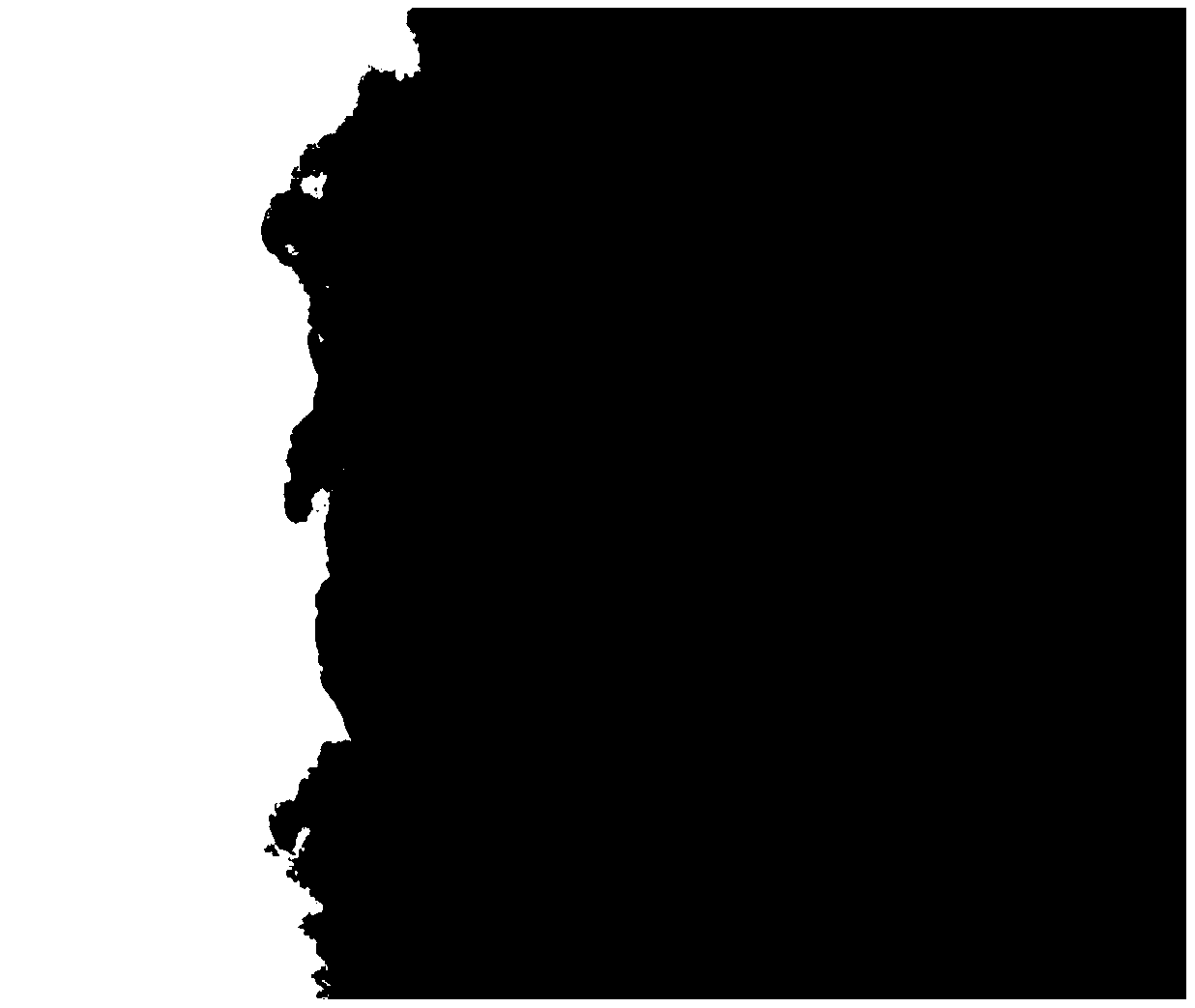

[0060] Preparation of LiMn 2 o 4 Sample coated with 0.3% MgO. Magnesium acetate is dissolved in ethanol to prepare a magnesium acetate coating solution with a concentration of 5 wt%. Turn on the disc nest mill to preheat, so that the inlet temperature is 250°C, the outlet temperature is 80°C, the host speed is 1500 rpm, and the air flow rate is 3000 cubic meters / hour; then press LiMn 2 o 4 The solid powder feed rate is 200 kg / hour, the liquid feed rate is 20 kg / hour, and the solid and liquid raw materials are input into the disc nest mill for reaction simultaneously; the reaction obtains a lithium-ion battery cathode material with a coating layer. The lithium-ion battery positive electrode material of the obtained coating layer is continuously transported to the collector under the action of fan suction, and finally the coated product is collected by the collector. The wind speed of the fan is 10 m / s.

[0061] figure 2 LiMn coated with MgO 2 o 4 Transmission electron ...

Embodiment 3

[0063] Preparation of LiCoO 2 Coated with 0.8% TiO 2 sample. Using titanium sol as the coating source, add deionized water to dilute to form a titanium oxide coating solution with a concentration of 5%. Turn on the disc nest mill to preheat, so that the inlet temperature is 300°C, the outlet temperature is 120°C, the host speed is 2400 rpm, and the air flow rate is 4000 cubic meters / hour; then press LiCoO 2 The solid powder feed rate is 500 kg / hour, the liquid feed rate is 80 kg / hour, and the solid and liquid raw materials are input into the disc nest mill for reaction simultaneously; the lithium-ion battery cathode material with a coating layer is obtained. The lithium-ion battery positive electrode material of the obtained coating layer is continuously transported to the collector under the action of fan suction, and finally the coated product is collected by the collector. The wind speed of the fan is 10 m / s.

[0064] image 3 For coated TiO 2 LiCoO 2 The transmissio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com