Total-nutritional formula milk powder and preparation method thereof

A technology of formula milk powder and complete nutrition, applied in dairy products, milk preparations, applications, etc., can solve problems such as low energy intake, less activity of the elderly, and decreased muscle mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

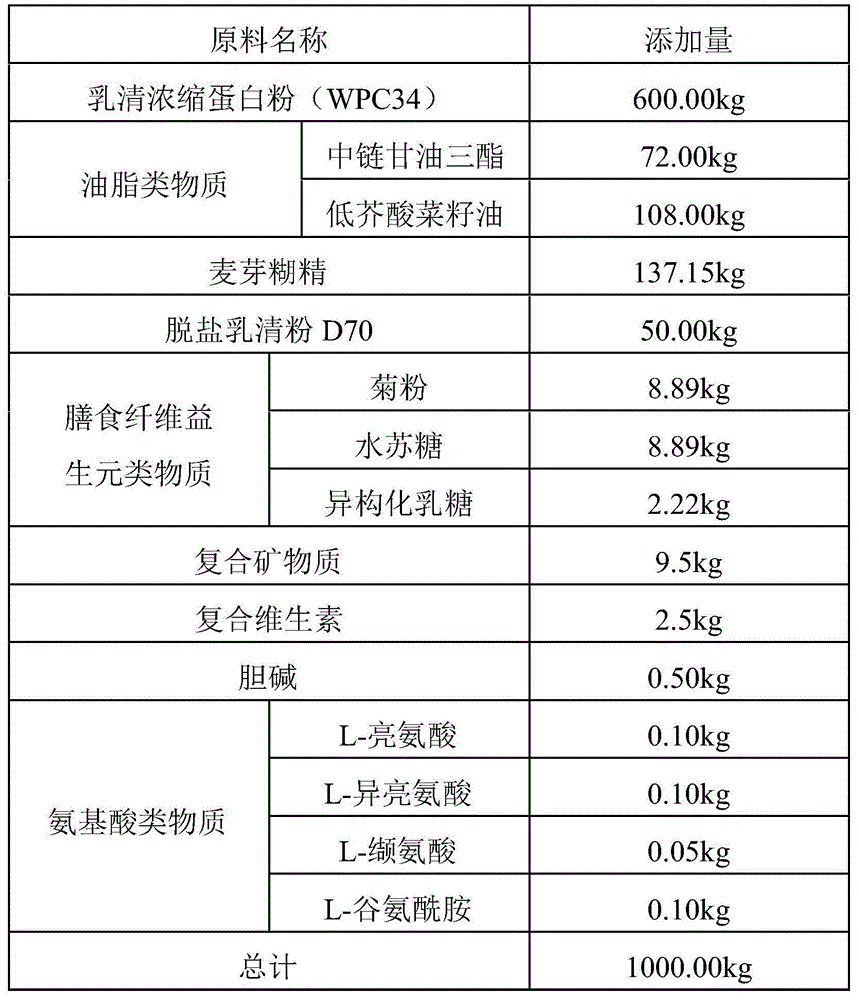

[0070] The raw material formula of table 4 embodiment 1

[0071]

[0072] The specific preparation method is as follows:

[0073] ①Mix the concentrated whey protein powder, desalted whey powder, choline, maltodextrin, dietary fiber prebiotics, amino acids and water at 40°C through a vacuum mixer, and circulate and mix for 10 minutes until the mixture is uniform. Liquid A;

[0074] ②Put the grease in the carburetion room and raise the temperature to 50°C for carburetion treatment for 1.5 hours, then add it to the material liquid A and mix evenly at 40°C; The stage homogenization pressure is 3MPa, the homogenization temperature is 50°C, and the feed liquid B is obtained after homogenization;

[0075] ③ Disperse the compound minerals in deionized water at 20°C to form a mineral solution, the mineral concentration in the mineral solution is 2.0 wt%, to obtain the mineral solution C;

[0076] ④ Add feed liquid C to feed liquid B and mix evenly at 30°C to obtain feed liquid D;...

Embodiment 2

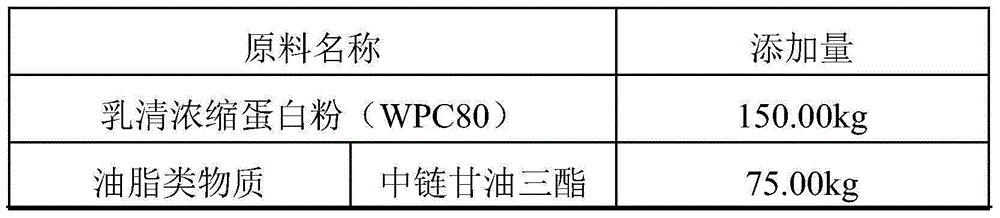

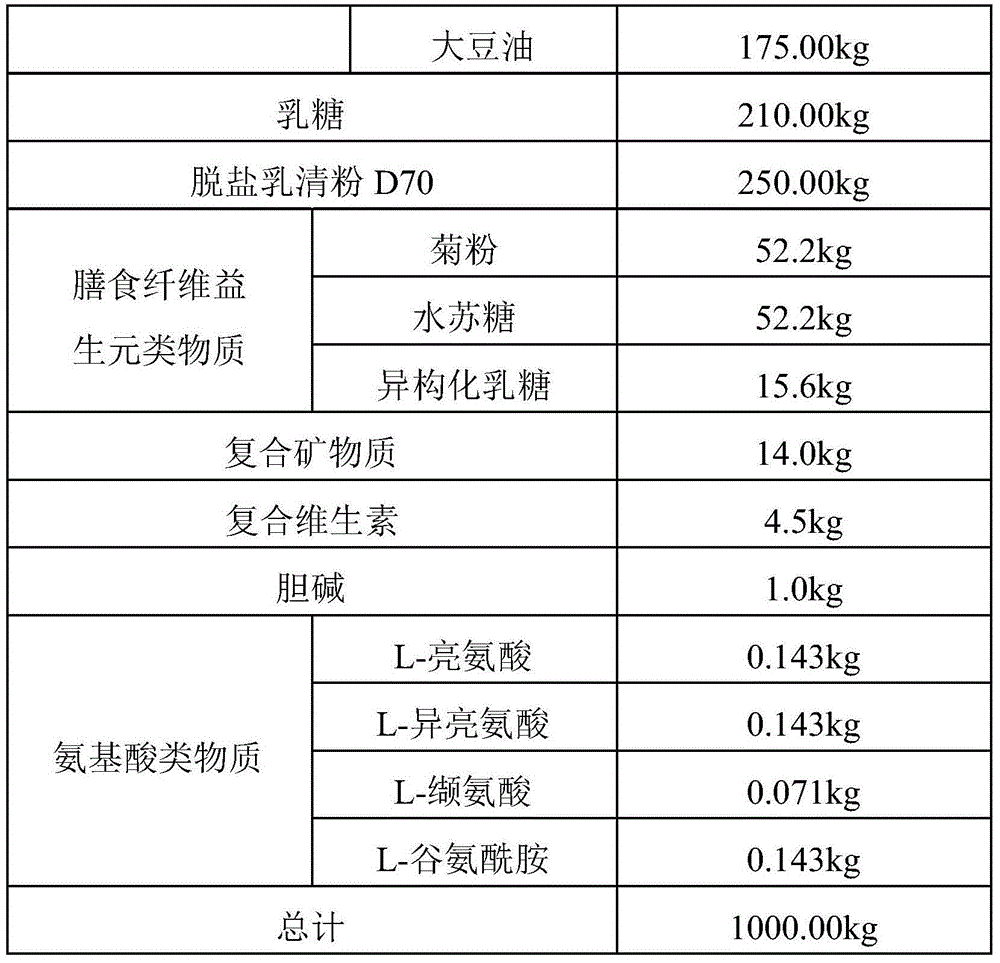

[0085] The raw material formula of table 6 embodiment 2

[0086]

[0087]

[0088] The specific preparation method is as follows:

[0089] ①Mix concentrated whey protein powder, desalted whey powder, choline, lactose, dietary fiber prebiotics, amino acids and water at 45°C through a vacuum mixer, and circulate and mix for 15 minutes until uniformly mixed to obtain feed liquid A ;

[0090] ②Put the grease in the carburetion room and raise the temperature to 55°C for carburetion treatment for 2.5 hours, then add it to the material liquid A and mix evenly at 45°C; The homogenization pressure of the stage is 5MPa, the homogenization temperature is 55°C, and the feed liquid B is obtained after homogenization;

[0091] ③ Dispersing the compound minerals in deionized water at 30° C. to form a mineral solution, the mineral concentration in the mineral solution is 5.0 wt%, to obtain the mineral solution material C;

[0092] ④ Add feed liquid C to feed liquid B and mix evenly a...

Embodiment 3

[0101] The raw material formula of table 8 embodiment 3

[0102]

[0103]

[0104] The specific preparation method is as follows:

[0105] ①Mix concentrated whey protein powder, desalted whey powder, choline, dietary fiber prebiotics, amino acids, and water at 43°C through a vacuum mixer, and circulate and mix for 12 minutes until uniformly mixed to obtain feed liquid A;

[0106] ②Put the grease in the carburetion room and raise the temperature to 52°C for carburetion treatment for 2.0 hours, then add it to the material liquid A and mix evenly at 44°C; The homogenization pressure of the stage is 4MPa, the homogenization temperature is 52°C, and the feed liquid B is obtained after homogenization;

[0107] ③ Dispersing the compound minerals in deionized water at 25°C to form a mineral solution, the mineral concentration in the mineral solution is 4.0wt%, to obtain the mineral solution C;

[0108] ④Add feed liquid C to feed liquid B and mix evenly at 35°C to obtain feed l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com