Carbon raw material for carbon composite refractory material and preparation method thereof

A refractory and carbon composite technology is applied in the field of carbon raw materials and preparation of carbon composite refractories, which can solve the problems of limiting the application of graphene, easy to agglomerate, uniform dispersion, etc., and achieve excellent physical and chemical properties and retain carbon content. , good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

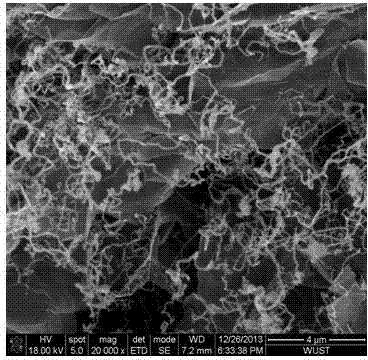

Image

Examples

preparation example Construction

[0022] The preparation method of the expanded graphite is as follows: firstly, the graphite oxide with a particle size greater than 0.038 mm and less than 0.2 mm is kept at 800 to 1250 ° C for 5 to 70 seconds to obtain prefabricated expanded graphite, and then the prefabricated expanded graphite is placed in urea or urea. In the boric acid aqueous solution, stir evenly, and filter to obtain the surface-modified expanded graphite; finally, the surface-modified expanded graphite is dried in an argon atmosphere at 400-1100° C. for 24 hours to obtain the expanded graphite.

[0023]The preparation method of the described graphene is: first place commercially available graphene in an aqueous solution of urea or boric acid, stir evenly, filter to obtain surface-modified graphene; then place the surface-modified graphene in an argon atmosphere Graphene was prepared by drying at 400~1100°C for 24 hours.

Embodiment 1

[0025] A carbon raw material for carbon composite refractories and a preparation method thereof. First, the elemental silicon powder is evenly filled at the bottom of the graphite crucible, and then the expanded graphite is evenly covered on the elemental silicon powder, and then kept in an argon atmosphere at 1000-1100 ℃ for 1-1.5 hours, and the silicon powder covered on the elemental silicon powder is taken out. material to obtain carbon raw materials for carbon composite refractories.

[0026] The material ratio of the expanded graphite and the elemental silicon powder in this embodiment is (0.01~0.2):1.

Embodiment 2

[0028] A carbon raw material for carbon composite refractories and a preparation method thereof. First, the elemental silicon powder is evenly filled at the bottom of the graphite crucible, and then the expanded graphite is evenly covered on the elemental silicon powder, and then kept at 1100~1200℃ for 1.5~2 hours in a nitrogen atmosphere, and the substance covered on the elemental silicon powder is taken out. , to obtain carbon raw materials for carbon composite refractories.

[0029] The material ratio of the expanded graphite and the elemental silicon powder in this embodiment is (0.2~0.4):1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com