Rapidly-dried water-dispersible isocyanate curing agent composition and preparation method thereof

An isocyanate and fast-drying technology, which is applied in the field of isocyanate curing agent, can solve the problems of short usable time and achieve the effect of long usable time, simple preparation method and extremely fast drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

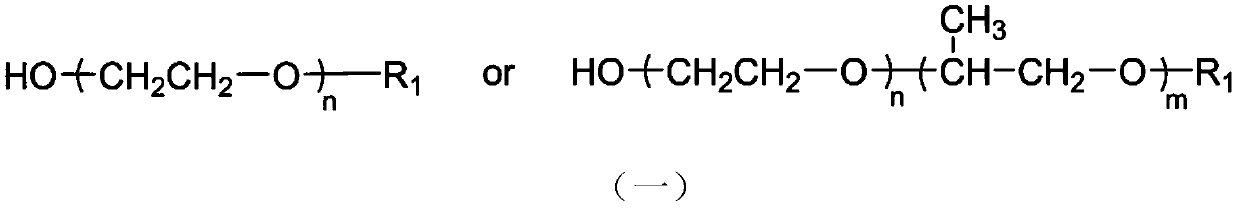

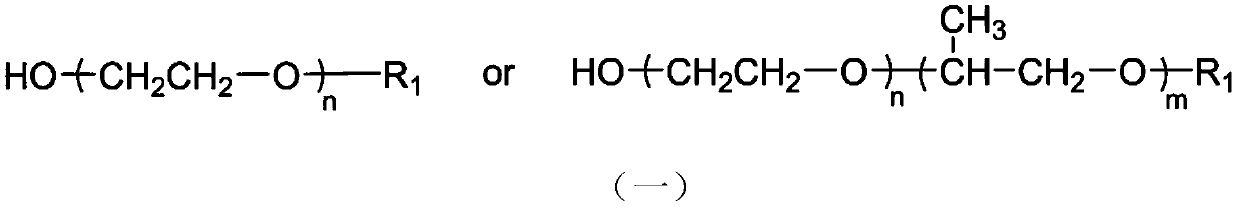

Method used

Image

Examples

Embodiment 1

[0035] Heat 10.54 parts by mass of polyethylene glycol monomethyl ether (500 molecular weight, Haian Petrochemical, Jiangsu Province) to 100-110°C for 2 hours, then cool down to 60°C, add Desmodur N 3300 (a solvent-free HDI trimer from Covestro, NCO content is 21.8±0.3%) 49.18 parts by mass and propylene glycol methyl ether acetate 29.74 parts by mass. After the addition, the temperature is raised to 100° C., and the reaction is continued at this temperature for 4 hours. Cool to room temperature, add 10.54 parts by mass of Desmodur IL BA (Covestro TDI trimer, 51% solid content, NCO content is 8.0%), and stir evenly to obtain a 65% solid isocyanate curing agent composition that is pale yellow It is a transparent liquid with a measured NCO value of 10.7% and a viscosity (25° C.) of 300 cps.

Embodiment 2

[0037] Heat 12.43 parts by mass of polyethylene glycol polypropylene glycol monobutyl ether (2250 molecular weight, Covestro trade name LB 25, polyethylene glycol / polypropylene glycol segment ratio: 75:25) to 100-110°C for 2 hours, Cool down to 60°C, add 54.94 parts by mass of DesmodurN 3300 (Covestro solvent-free HDI trimer, NCO content: 21.8±0.3%), and 27.40 parts by mass of propylene glycol methyl ether acetate, and raise the temperature to 100°C after adding , and continued to react at this temperature for 4h. Cool to room temperature, add 5.23 parts by mass of Desmodur IL BA (Covestro TDI trimer, 51% solid content, NCO content is 8.0%), and stir evenly to obtain a 70% solid isocyanate curing agent composition that is light yellow It is a transparent liquid with a measured NCO value of 12.2% and a viscosity (25° C.) of 350 cps.

Embodiment 3

[0039]Heat 10.78 parts by mass of polyethylene glycol polypropylene glycol monobutyl ether (2250 molecular weight, Covestro trade name LB 25, polyethylene glycol / polypropylene glycol segment ratio: 75:25) to 100-110 ° C for 2 hours, Cool down to 60°C, add 47.67 parts by mass of DesmodurN 3300 (Covestro solvent-free HDI trimer, NCO content: 21.8±0.3%), and 18.84 parts by mass of propylene glycol methyl ether acetate, and raise the temperature to 100°C after adding , and continued to react at this temperature for 4h. Cool to room temperature, add Desmodur IL BA (Covestro TDI trimer, 51% solid content, NCO content is 8.0%) 22.70 parts by mass, and stir evenly to obtain a 70% solid isocyanate curing agent composition that is light yellow It is a transparent liquid with a measured NCO value of 12.0% and a viscosity (25° C.) of 400 cps.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com