Preparation method of material of negative electrode of lithium ion battery

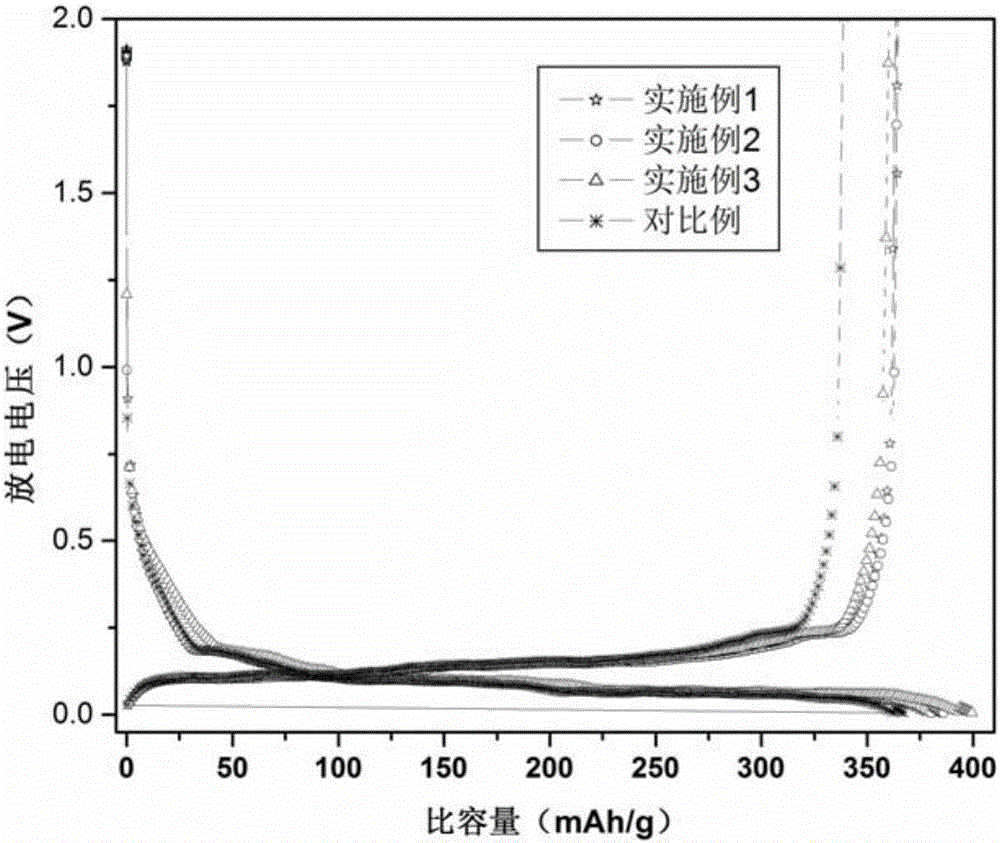

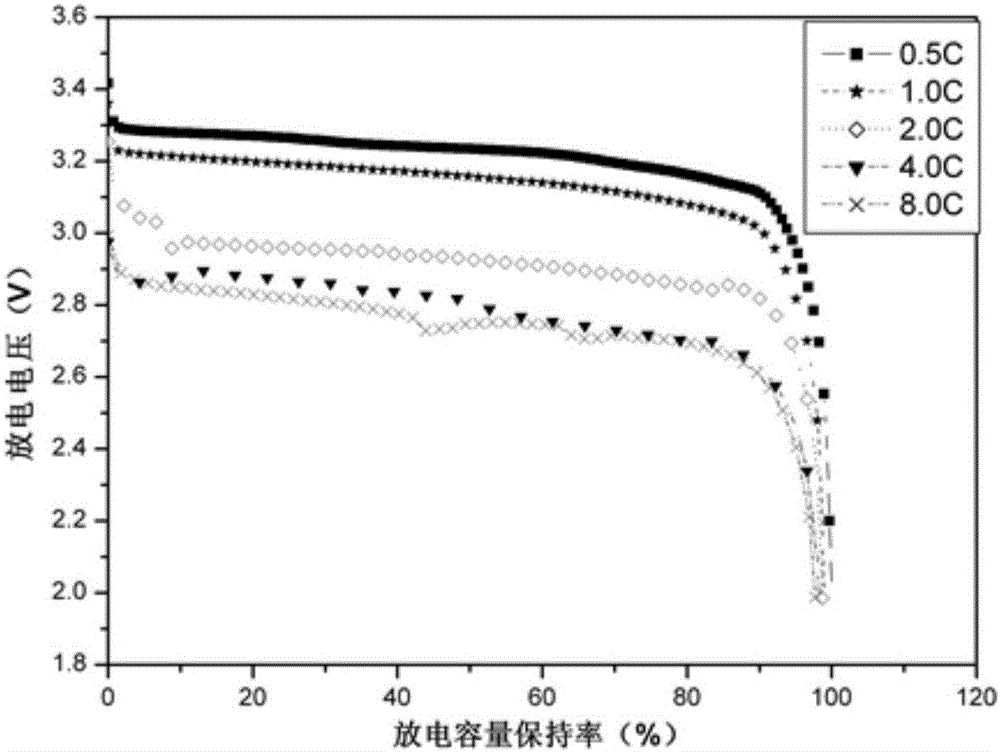

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of lower initial charge and discharge, low initial charge and discharge efficiency of graphite materials, side reactions, etc., and achieve weakening of P-type doping , Improve the first charge and discharge efficiency, reduce the concentration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation method of the lithium-ion battery negative electrode material of the present embodiment comprises the following steps:

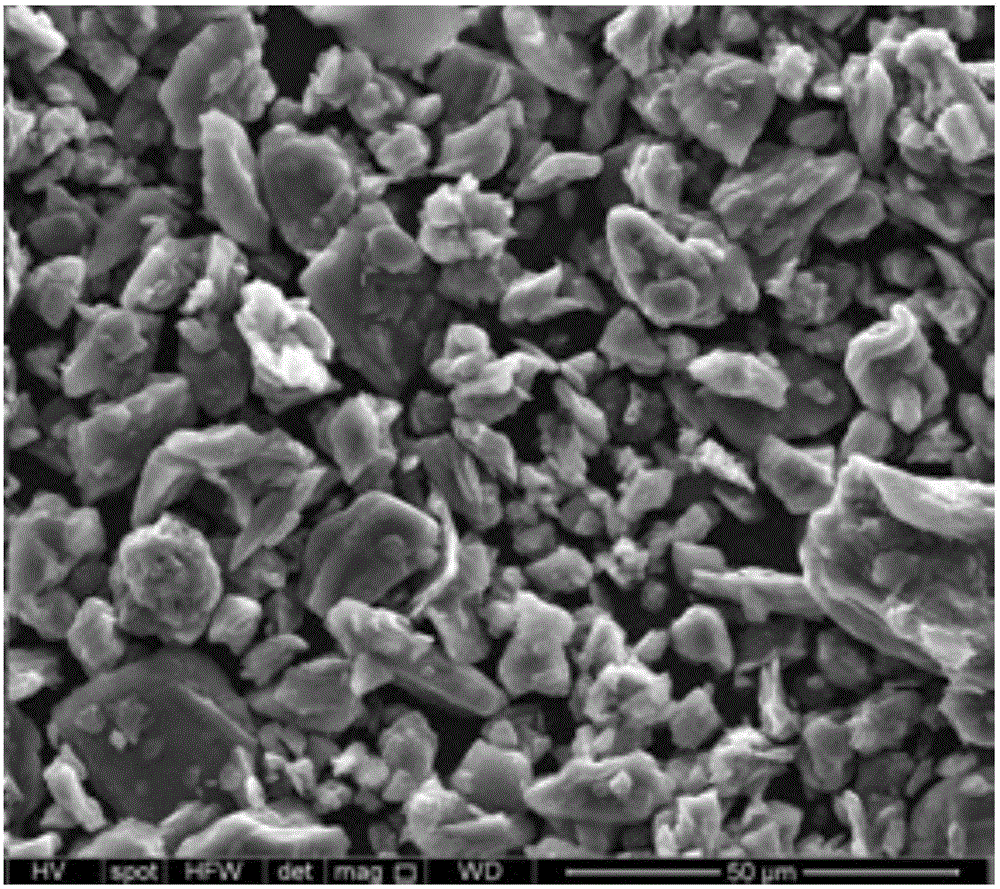

[0035] 1) 10 g of spheroidized flake graphite, 40 g of oxidant hydrogen peroxide, and 20 g of organic acid oxalic acid are mixed, and the particle diameter of the spheroidized flake graphite is D 50 =30 μm, carbon content is 99.96wt%, stirred at 40°C, reacted for 2 hours, washed the obtained mixture with water to pH=6, dried at 80°C to obtain powder A;

[0036] 2) Send powder A into a muffle furnace, raise the temperature to 800°C at a heating rate of 2°C / min, keep it warm for 2 hours, and cool down to room temperature with the furnace to obtain intercalated graphite.

[0037] 3) The intercalation graphite that 5g makes is added in the NaOH solution that concentration is 0.75g / L, and NaOH solution is formulated by NaOH1g, twice distilled water 1330g, and the mass ratio of NaOH and intercalation graphite in NaOH solution is: m NaOH :m ...

Embodiment 2

[0039] The preparation method of the lithium-ion battery negative electrode material of the present embodiment comprises the following steps:

[0040] 1) spheroidized spherical graphite 10g, oxidizing agent hydrogen peroxide 30g, organic acid succinic acid 10g mix, the particle diameter D of this spheroidized spherical graphite 50 = 40 μm, with a carbon content of 99.96 wt%, stirred at 20°C, reacted for 4 hours, washed the obtained mixture with water until pH = 7, and dried at 60°C to obtain powder A;

[0041] 2) Send powder A into a muffle furnace, raise the temperature to 600°C at a heating rate of 1°C / min, keep it warm for 4 hours, and cool down to room temperature with the furnace to obtain intercalated graphite.

[0042] 3) 10g of prepared intercalated graphite is added into the NaOH solution with a concentration of 0.5g / L. The NaOH solution is prepared from NaOH1g and twice distilled water 2000g. The mass ratio of NaOH in the NaOH solution to the intercalated graphite is...

Embodiment 3

[0044] The preparation method of the lithium-ion battery negative electrode material of the present embodiment comprises the following steps:

[0045] 1) 10 g of spheroidized flake graphite, 50 g of oxidant hydrogen peroxide, and 30 g of organic acid adipic acid are mixed, and the particle diameter of the spheroidized flake graphite is D 50 = 50 μm, with a carbon content of 99.96 wt%, stirred at 60°C, reacted for 0.5h, washed the obtained mixture with water to pH = 6, and dried at 100°C to obtain powder A;

[0046] 2) Send powder A into a muffle furnace, raise the temperature to 900°C at a heating rate of 3°C / min, keep it warm for 1h, and cool down to room temperature with the furnace to obtain intercalated graphite.

[0047] 3) 1.0g of prepared intercalated graphite is added into the NaOH solution with a concentration of 1.0g / L. The NaOH solution is prepared from NaOH1g and twice-distilled water 1000g. The mass ratio of NaOH in the NaOH solution to the intercalated graphite i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com