Black shale soluble salt extracting method

A black shale and salt-dissolving technology, applied in the direction of material resistance, can solve the problems of unscientific, easy oxidation and corrosion of minerals, easy loss of soluble salt, leaching time setting, etc., to achieve slow water absorption rate and avoid contamination by foreign substances , the effect of long leaching time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

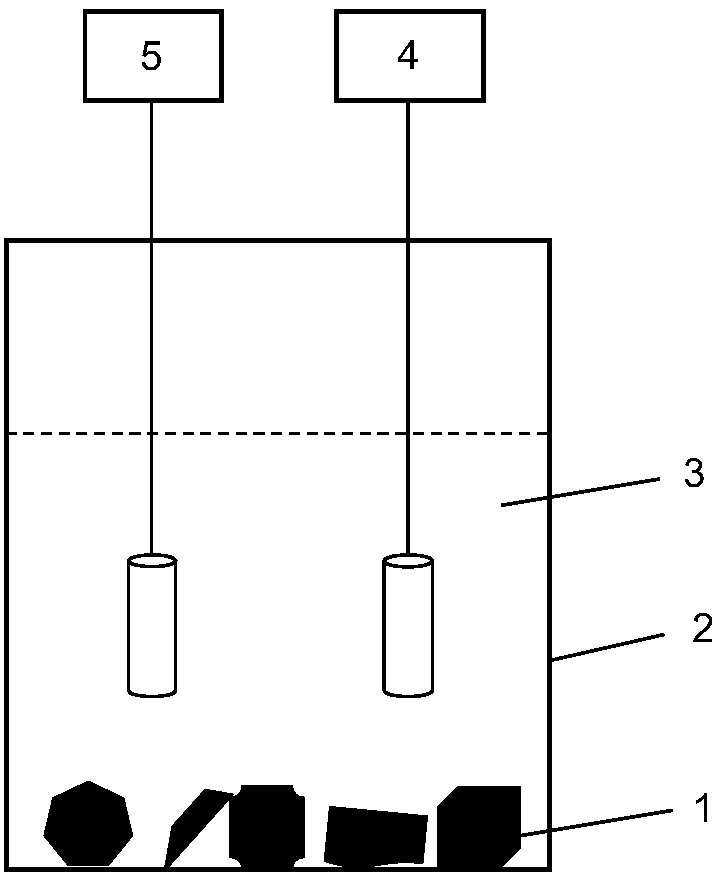

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0028] A method for leaching black shale soluble salts, comprising the following steps in sequence:

[0029] (1) Select black shale from the XX shale gas well in the Sichuan Basin, and quickly prepare centimeter-scale massive shale samples of any shape in a dry air environment1;

[0030] (2) Put the massive shale sample 1 into a vacuum drying oven, dry the sample at a temperature of 60°C, and weigh the sample mass (40.05g) after drying;

[0031] (3) Add a known volume of distilled water 3 (400mL) into the container 2, insert the redox potentiometer 4 to monitor the redox potential (Eh) of the water body, and continuously add the organic reducing agent acetone oxime until the Eh value of the aqueous solution is lower than -200mV ;

[0032] (4) Submerge the weighed massive shale sample 1 in the aqueous solution 3, insert the redox potentiometer 4, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com