Patents

Literature

67 results about "Acetone oxime" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

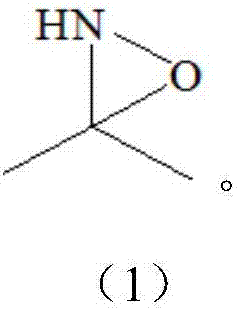

Acetone oxime (acetoxime) is the organic compound with the formula (CH₃)₂CNOH. It is the simplest example of a ketoxime. It is a white crystalline solid that is soluble in water, ethanol, ether, chloroform, and ligroin. It is used as a reagent in organic synthesis.

Smoke desulphurization agent and smoke desulphurization method

ActiveCN101721884AHigh desulfurization rateReduce absorptionDispersed particle separationAbsorption capacityDesorption

The invention provides a smoke desulphurization agent. The desulphurization agent is aqueous solution containing a main absorption component, an activating agent, an anti-oxidation component and acid, wherein the main absorption component is one or more of alkyl piperazine, hydroxyalkyl piperazine and hydroxyalkyl piperazine ketone; the activating agent comprises piperazine and diazabicyclo; and the anti-oxidation component is at least one of 4-tert-butyl catechol, 2,6-di-tert-butyl-p-phenylcresol, acetone oxime and N,N-bi (2-ethoxy) glycine. The smoke desulphurization agent provided by the invention can remove and reclaim sulfur dioxide in the smoke, and has higher desulphurization rate; moreover, even if the smoke desulphurization agent is strongly oxidized and then is recycled, the absorption capacity for the sulfur dioxide is still stable; and in addition, the rich liquor formed by desulphurization after adopting the desulphurization agent has better desorption performance such as high desorption rate.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +2

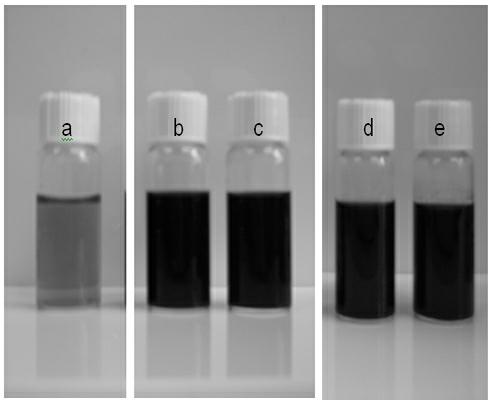

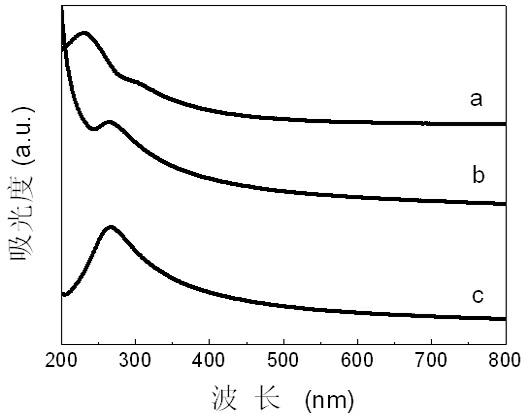

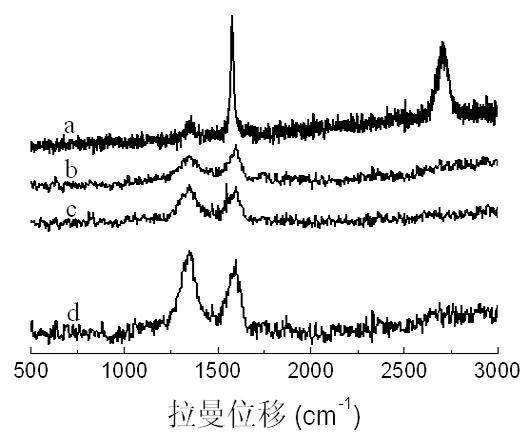

Reduction method for graphene oxide

The invention discloses a reduction method for graphene oxide. The method comprises the following steps: using acetone oxime, acetaldoxime or methyl ethyl ketoxime as a reducing agent, and then preparing the graphene by reducing the graphene oxide in a graphene oxide aqueous solution the pH value of which is 6-10, wherein the reaction temperature is 80-100 DEG C and the mass ratio of graphene oxide to the reducing agent acetone oxime, acetaldoxime or methyl ethyl ketoxime is 1: (0.2-5). The method is characterized in that the oximido having lower toxicity is used as the reducing agent and thegraphene is acquired by reducing the graphene oxide by using a chemical reduction method. The preparation method is simply and easily performed, the reaction process is easily controlled, no special requirement for equipment exists, the cost is low, the pollution is free, and the method is easily popularized and used.

Owner:NORTHWEST UNIV(CN)

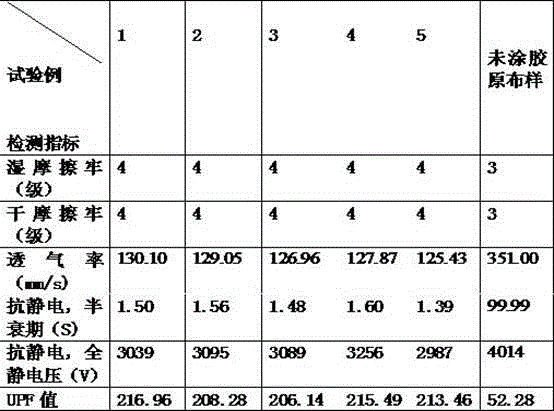

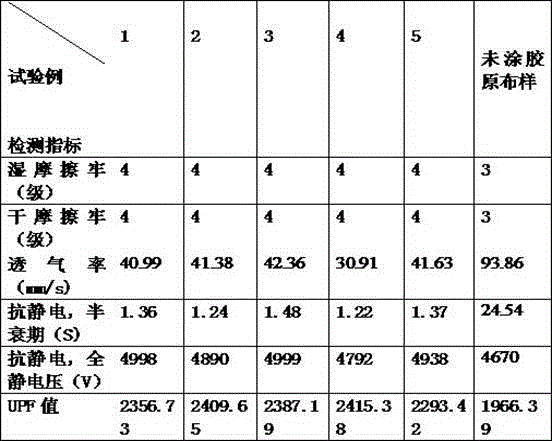

Breathable ultraviolet-resistant anti-static polyurethane resin coating adhesive and preparation method thereof

The invention is a breathable ultraviolet-resistant anti-static polyurethane resin coating adhesive and a preparation method thereof. The breathable ultraviolet-resistant anti-static polyurethane resin coating adhesive is prepared by compounding water-based breathable anti-static polyurethane resin, a blocked polyurethane crosslinking agent, nano zinc oxide and a thickening agent, wherein the water-based breathable anti-static polyurethane resin is prepared from components A, the blocked polyurethane crosslinking agent is prepared from components B, the components A comprise 50-200 parts of polyoxyethylene ether glycol, 50-200 parts of polyoxypropylene ether glycol, 1-5 parts of trimethylolpropane, 40-200 parts of polyisocyanate, 3-10 parts of a chain extender, 0.02-0.06 part of a catalyst, 30-60 parts of a solvent, 3-10 parts of sodium hydrogen carbonate, 3-10 parts of sodium hydrogen sulfite and 500-1,500 parts of deionized water, and the components B comprise 100-200 parts of 1.6-hexylidene diisocyanate trimer, 42-92 parts of acetone oxime or methyl ethyl methyl ethyl ketoxime, 0.02-0.06 part of a catalyst, 400-900 parts of a solvent and 30-80 parts of an ultraviolet-resistant additive. The breathable ultraviolet-resistant anti-static polyurethane resin coating adhesive has excellent air permeability, ultraviolet resistance and static resistance and has good dry and wet rubbing fastness.

Owner:LIAONING FIXED STAR FINE CHEM

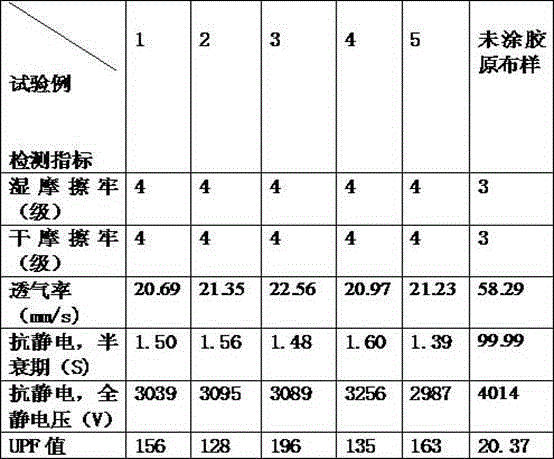

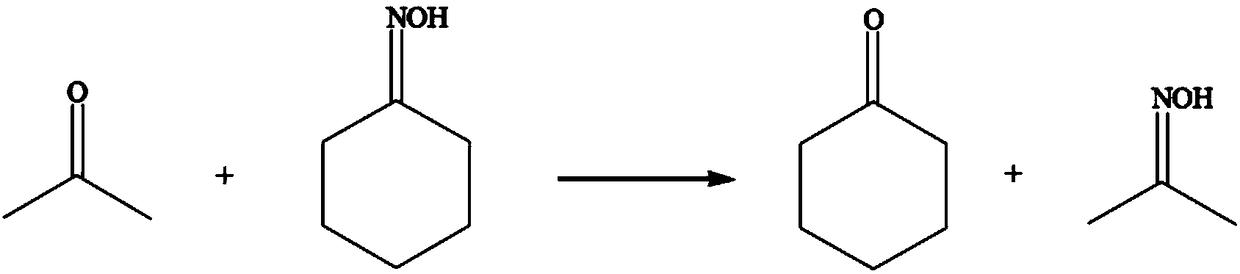

Preparation method of cyclohexanone oxime

The invention provides a new preparation method of cyclohexanone oxime, and the preparation method comprises performing a hydrolysis reaction of 4 or less than 4 carbon atom containing oxime such as acetaldoxime, acetone oxime or butanone oxime and the like which is produced by an ammoxidation method and phosphoric acid added in a phosphate buffer solution to obtain an inorganic liquid containing hydroxylamine phosphate, then performing an oximation reaction of the inorganic liquid and cyclohexanone to obtain the high purity cyclohexanone oxime. According to the preparation method, due to the direct oximation reaction of the hydroxylamine phosphate and the cyclohexanone, the shortcoming that the cyclohexanone oxime prepared by the direct ammoxidation method is high in impurity content and is difficult to separate, and thus affecting the quality of caprolactam prepared from the cyclohexanone oxime can be overcomed; at the same time, the advantages of a plurality of processes for industrial production of the cyclohexanone oxime are combined, the inorganic liquid cycle can be realized, the high purity cyclohexanone oxime is prepared, the process cycle is realized, and the preparation method is conducive to energy saving and consumption reduction, and the realization of safe, environmentally friendly, low-cost and high-quality production.

Owner:刘建青

Organic silicon sealing adhesive with toughness

InactiveCN107760257ANon-macromolecular adhesive additivesMacromolecular adhesive additivesPolyethylene terephthalate glycolAdhesive

The invention relates to organic silicon sealing adhesive with toughness, which belongs to the technical field of organic silicon sealing adhesive. The organic silicon sealing adhesive is prepared from dihydroxy polydimethylsiloxane, dimethicone, dimethyl dibutanoneoximido silane, methyltris(dimethylketoxime) silane, polyethylene glycol, fused white carbon black, nanoscale calcium carbonate, methyltriacetoxysilane, Di-t-butoxydiacetoxysilane, bis(lauroyloxy)dioctyltin and polyethylene terephthalate. After the organic silicon sealing adhesive is cured, the product has certain shape stability and deformation-resisting toughness.

Owner:高成龙

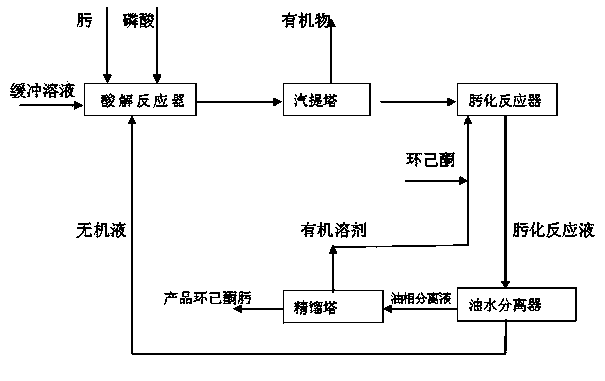

High-temperature O2/CO2 corrosion inhibitor for coiled tubing and preparation method of agent B of high-temperature O2/CO2 corrosion inhibitor

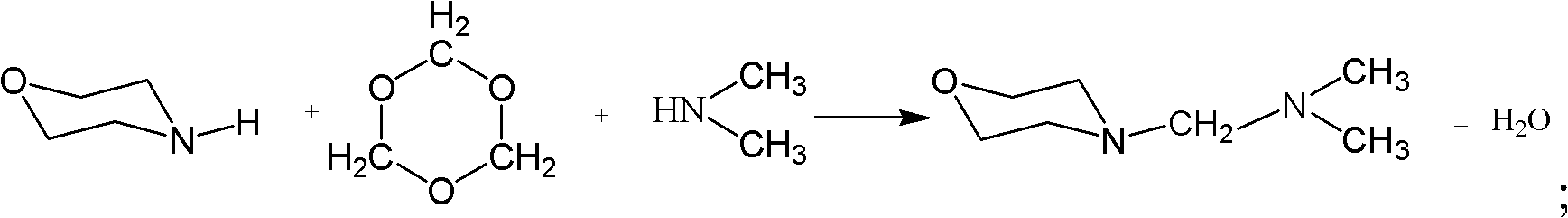

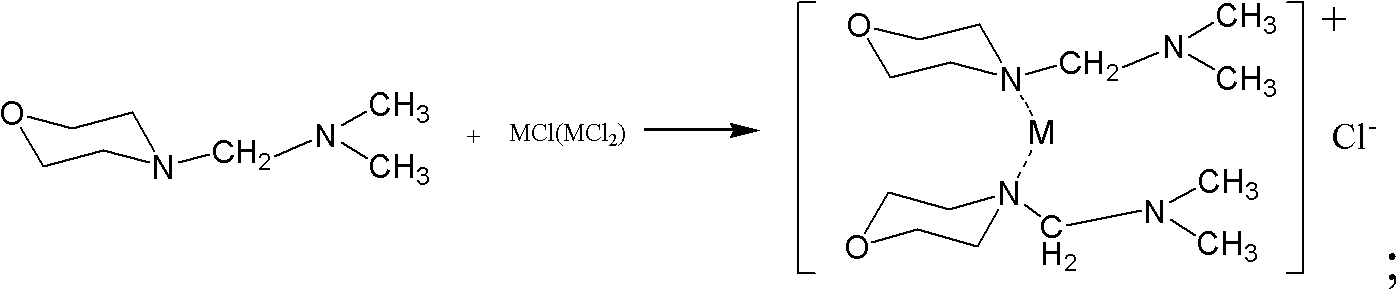

ActiveCN102627955AEnsure safe operationAvoid corrosionBorehole/well accessoriesSulfite saltMannich reaction

The invention discloses a high-temperature O2 / CO2 corrosion inhibitor for coiled tubing. The high-temperature O2 / CO2 corrosion inhibitor for the coiled tubing is used by matching an agent A mainly used for deoxidizing and an agent B mainly used for resisting corrosion of carbon dioxide, wherein the agent A is acetone oxime, D-ascorbic acid, sodium sulfite or ferrous sulphate; and the agent B is formed by mixing the components in percentage by weight: 20-30 percent of quaternary pyridine salt, 10-15 percent of mannich base chelate, 3-7 percent of surfactant and 48-67 percent of solvent. The quaternary pyridine salt is obtained by reacting pyridine with benzyl chloride; and the mannich base chelate is obtained by aldehyde ketone amine condensate generated by morpholine, trioxymethylene and dimethylamine through a mannich reaction with metal chloride. The corrosion inhibitor provided by the invention has use temperature up to 170DEG C, is suitable for a water-corrosive medium in which oxygen and carbon dioxde coexist and can be used for effectively inhibiting the corrosion of media such as the oxygen and the carbon dioxide and ensuring safe operation of the coiled tubing in the production process.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Octadecylamine corrosion inhibition formula for furnace shutdown protection of thermal power plant

The invention discloses an octadecylamine corrosion inhibition formula for furnace shutdown protection of a thermal power plant. The formula mainly comprises octadecane amine, acetone oxime and ascorbic acid; the concentration ranges thereof are respectively controlled to be 20-250mu g / L, 60-150mu g / L and 15-100mu g / L; and the glacial acetic acid is taken as cosolvent of octadecylamine and the ammonia is taken as the pH value regulator. The preparation method of the formula comprises the following steps of: firstly adding the octadecane amine; diluting with the ionized water; adding the acetone oxime and the ascorbic acid; completely dissolving the corrosion inhibitor by means of heating, stirring and adding the glacial acetic acid; adding corrosion inhibitor solution into water vapour systems when the furnace is shutdown and lifted down in a sliding way, so that the solution is evenly distributed and fully filled into all the water vapour systems of the furnace; and generating an octadecylamine protection film with a monomolecular layer through the afterheat of the furnace before a heat furnace of the furnace discharges water, wherein the generated protection film can play a part in good protection at the water side of the heating surface of the furnace for 5 months. The method not only is suitable for a high-parameter DC furnace, but also is suitable for a high-parameter steam pocket furnace, can effectively protect the shutdown furnace, can be convenient for workers to overhaul the furnace, solves the disadvantage that the conventional method is short in protection time and is not suitable for overhaul, and can not pollute the furnace after being turned on again. The invention has obvious economic benefit, environmental benefit and social benefit, can not generate harmful substance, and has no secondary pollution.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

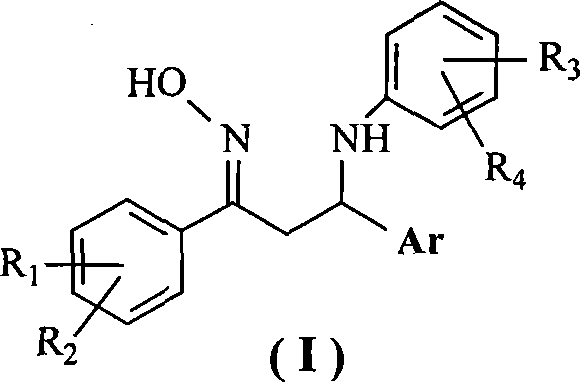

1,3-diaryl-3-aryl amidine-1-acetoxime compounds, preparation method and use thereof

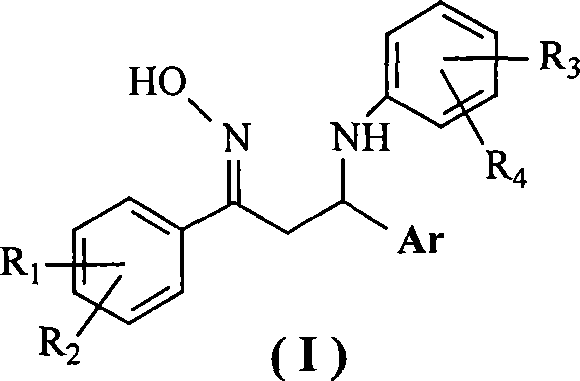

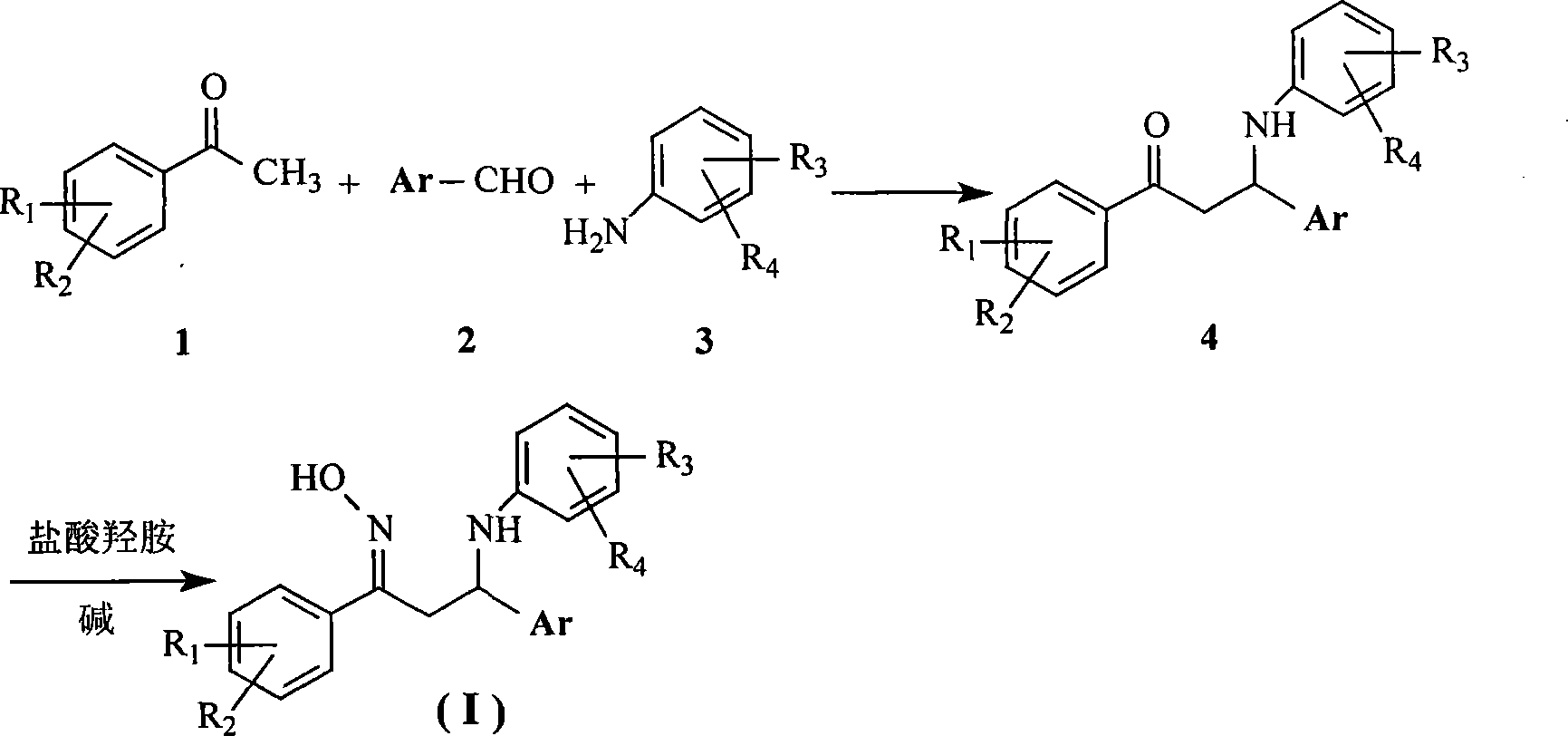

InactiveCN101250136AAR antagonistic activityOrganic chemistryUrinary disorderDiseaseHormone Receptor Modulators

The invention relates to a non-steroidal androgen receptor modulator compound containing 1, 3-diaryl-3-aromatic amine-1-acetoxime compound (I), or relative medical acceptable salt and a relative preparation method. The invention also relates to a drug compound of 1, 3-diaryl-3-aromatic amine-1-acetoxime compound (I) and relative medical acceptable salt. The1, 3-diaryl-3-aromatic amine-1-acetoxime compound (I) or relative medical acceptable salt has androgen receptor antagonistic activity, therefore, the compound can be used to prepare the non-steroidal drug for preventing or / treating prostatic hyperplasia, prostate cancer, hirsutism, serious androgen dependence alopecia and acne or the like.

Owner:SICHUAN UNIV

Preparation method of O-3-chloro-2-propenylhydroxylamine

InactiveCN109438280AReduce the chance of collisionLittle pollutionOximes preparationWater bathsHydroxylamine

The invention belongs to the technical field of organic synthesis, and in particular relates to a preparation method of O-3-chloro-2-propenylhydroxylamine. The preparation method of the O-3-chloro-2-propenylhydroxylamine comprises the following steps: uniformly stirring hydroxylamine salt, water and acetone, adding a sodium hydroxide solution, reacting at room temperature for 1 to 2 hours, then adding 1,3-dichloropropene and a phase transfer catalyst, heating in water bath, controlling the temperature at 60 to 90 DEG C, reacting for 5 to 10 hours, standing still for stratification, separatingand collecting an oil phase, extracting the oil phase 2 to 3 times with an extractant, drying extract liquid with anhydrous sodium sulfate, and removing a solvent under reduced pressure to obtain theO-3-chloro-2-propenylhydroxylamine. According to the preparation method of the O-3-chloro-2-propenylhydroxylamine provided by the invention, acetone oxime is firstly prepared by taking the hydroxylamine salt and acetone as raw materials, and then 1,3-dichloropropene and the phase transfer catalyst are added for a reaction to prepare the O-3-chloro-2-propenylhydroxylamine; the O-3-chloro-2-propenylhydroxylamine prepared with the preparation method has the purity of 99% or more than 99% and the yield of 88% or more than 88%, and the method is suitable for industrial production.

Owner:江苏艾科维科技股份有限公司

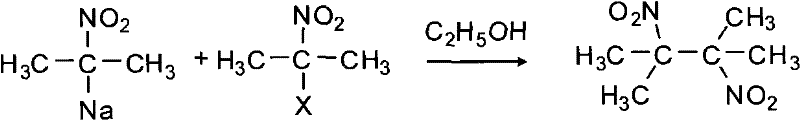

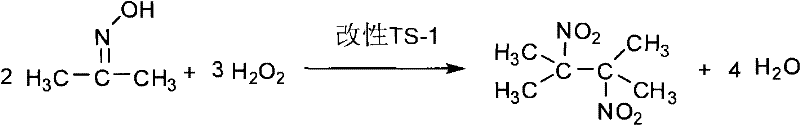

The synthetic method of 2,3-dimethyl-2,3 dinitrobutane

InactiveCN102267913AMild reaction conditionsImprove operational safetyNitro compound preparationFiltrationDistillation

The invention discloses a synthetic method of 2,3-dimethyl-2,3-dinitrobutane. The synthetic method comprises the following steps that 1, acetoxime, water, and catalyst modified titanium silicalite (TS)-1 are added into a reaction container at room temperature; 2, aqueous alkali and hydrogen peroxide are added dropwisely into the reaction system obtained by the previous step at a temperature of 60to 90 DEG C with stirring; the pH of the reaction system is kept in a range of 8 to 10; and a mol ratio of hydrogen peroxide and acetoxime is in a range of 1 to (3: 1); 3, after dropwiseaddition, themixture obtained from the step 2 undergoes a reaction at a temperature of 60 to 90 DEG C for 0 to 2 hours; 4, reaction products obtained from the step 3 is cooled to room temperature and then is subjected to a filtration or a centrifugation process thus modified TS-1 is separated from the cooled reaction product and mother liquor is obtained; the modified TS-1 is washed by acetone; washing liquidis collected; and the collected washing liquid is added into the mother liquor; and 5, the mother liquor containing the collected washing liquid is subjected to a distillation process at a temperature less than or equal to 80 DEG C so that acetone in the reaction system is removed; the mother liquor treated by the distillation process is cooled and filtrated; and filter residues are washed by water to form 2,3-dimethyl-2,3-dinitrobutane products. Raw materials adopted by the synthetic method have the advantages of good safety and low cost. 2,3-dimethyl-2,3-dinitrobutane synthesized by the synthetic method has the advantages of less impurities and high product quality.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

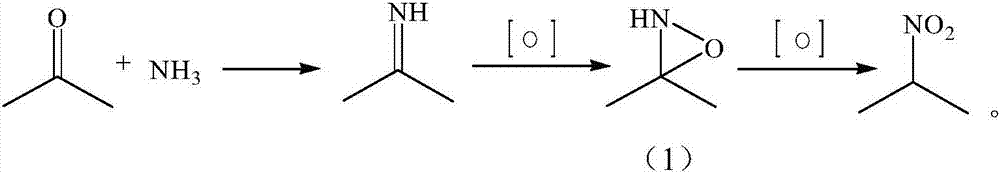

Synthesizing method of 2-nitropropane

ActiveCN106986772AMild reaction conditionsSimple processOrganic compound preparationImino compound preparationMass ratioCatalytic oxidation

The invention discloses preparation of substituted saturated hydrocarbon and particularly relates to a synthesizing method of 2-nitropropane. The 2-nitropropane is prepared by oxidizing isohydrazone. The synthesizing method includes the steps of S1, condensing acetone, water and ammonia in the presence of a catalyst to generate ketimine, wherein the mass ratio of the acetone to the water is 1:(1-5), and the use amount of the catalyst is 5-11% of the use amount of the acetone; S2, oxidizing the ketimine obtained in the step S1 to form the isohydrazone, wherein reaction system temperature is 30-60 DEG C and heat-preservation reaction time is 0.5-3 hours; S3, oxidizing the isohydrazone obtained in the step S2 to form the 2-nitropropane, wherein reaction system temperature is 50-80 DEG C and heat-preservation reaction time is 0.5-3 hours; rectifying obtained primary reaction liquid to obtain qualified 2-nitropropane products. The synthesizing method has the advantages that the acetone, the ammonia and the water are used as the initial raw materials, and the method is mild in catalytic oxidizing reaction condition, simple in process, convenient to operate, suitable for large-batch 2-nitropropane production, simple in post-processing and high in product purity and does not coproduce acetone oxime or acetone azine.

Owner:宁波四明化工有限公司

Modified zeolite functional material for fixing benzene degrading bacteria and preparation method thereof

InactiveCN106701733AHigh mechanical strengthEnhanced mass transferWater contaminantsOn/in inorganic carrierNitroureaPyran

The invention discloses a modified zeolite functional material for fixing benzene degrading bacteria. Zeolite is modified by a mixed solution prepared from ammonium dihydrogen phosphate, tetrahydro-4H-pyran-4-one, 5-bromothiophen-2-formaldehyde, 2,5-dichloro-3-bromopyridine, tetrabromothiophene and 2-acetylene thiophene to obtain a substance B; the substance B is modified by a mixed solution prepared from 3-chloropyridazine, acetaldehyde phenylhydrazone, acetone oxime, guanidine nitrate and indole-6-carboxaldehyde to obtain a substance C; the substance C is modified by a mixed solution prepared from 3-formylthiophene, di-tert-amylbenzoquinone and 4-amino-3-hydroxy-1-naphthalene sulfonic acid to obtain a substance D; and the substance D is modified by a mixed solution prepared from propyl sulfate, 2-aminoanthraquinone and nitrourea to obtain a substance, namely the modified zeolite functional material for fixing the benzene degrading bacteria.

Owner:光合强化(北京)生物科技有限公司

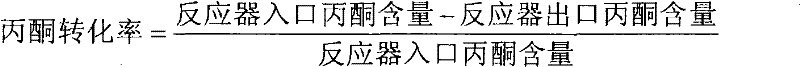

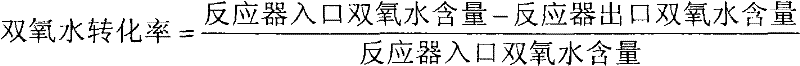

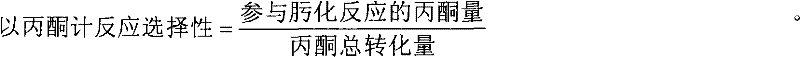

Preparation method of ketoxime

The invention provides a preparation method of ketoxime, which is characterized by comprising contact of ketone and oximation agent under oximation reaction conditions with solvents, oxidizing agents, surfactants and catalysts. The preparation method of the acetone oxime has the advantages that the reaction operation is simple, the process time is short and continuous production can be achieved. For example, by adopting the method, the acetone conversion rate, the hydrogen peroxide conversion rate and the acetone oxime selectivity can reach above 98 percent within 40 minutes. For comparison in Example 1, the acetone conversion rate, the hydrogen peroxide conversion rate and the acetone oxime selectivity can only reach about 96 percent within 600 minutes under the same condition except for surfactants. Therefore, the production efficiency can be greatly increased when the method is adopted.

Owner:LINZIZHENGHUA ACCESSORY INGREDIENT ZIBO

Sterilizing algicide for circulating cooling water and preparation method of sterilizing algicide

InactiveCN103444760AImprove the bactericidal effectLong duration of actionBiocideDisinfectantsEngineeringDiethyl ether

The invention relates to a sterilizing algicide for circulating cooling water and a preparation method of the sterilizing algicide. The sterilizing algicide comprises the following components in parts by mass: 10-19 parts of chlorophenasic acid, 10-19 parts of parachlorophenol, 3-10 parts of dodecyl dimethyl benzyl ammonium chloride, 0.5-3 parts of dithiocyano-methane, 8-15 parts of sodium dodecyl benzene sulfonate, 1-5 parts of acetone oxime, 2-5 parts of methyl alcohol, 1-3 parts of diethyl ether, 4-8 parts of sodium hydroxide, and 19-37 parts of water. The sterilizing algicide has good sterilizing and algae removal effects, and has a long pesticide effect, the sterilizing rate reaches over 98%, and the pesticide effect time is more than 25 hours.

Owner:SUZHOU KANGHUA PURIFYING SYST ENG

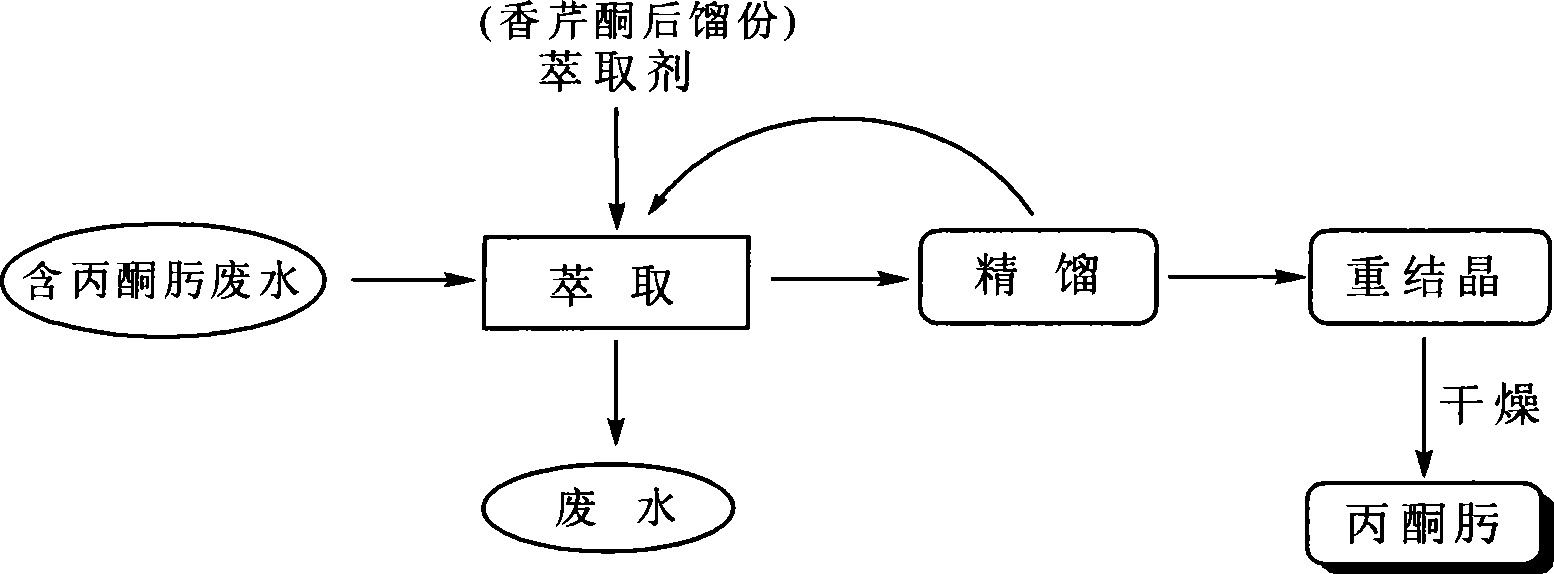

Method for using carvone production wastewater for recycling acetone oxime

ActiveCN101475510AImprove extraction abilityTo achieve the purpose of governanceOximes preparationRoom temperatureWastewater

The invention discloses a method for reclaiming acetone oxime from carvone production wastewater. The method comprises the following steps: firstly, reclaiming of an extractant, namely collecting 120-150 DEG C / 2mmHg after-cut under the condition of rectification during carvone production as the extractant, wherein the mass content of the carvone is less than 0.5 percent; secondly, extraction of the wastewater, namely mixing the wastewater containing the acetone oxime and the extractant according to the weight ratio of 3.4-3.8:1, raising the temperature to be between 40 and 50 DEG C, stirring for 30 to 45 minutes, cooling the mixture to the room temperature, performing standing and delamination, re-extracting a water phase until reaching the standards, introducing the water phase into a wastewater purification treatment system, and reclaiming the acetone oxime from an organic phase, wherein the mass content of the acetone oxime in the water phase is less than 1.5 percent; thirdly, rectification, namely performing vacuum rectification on the organic phase, and collecting 80-85 DEG C / 300mmHg acetone oxime cut fractions; and fourthly, recrystallization, namely dissolving the acetone oxime cut fractions into water according to the mass ratio of 1.5:1, reducing the temperature to be between 3 and 5 DEG C for crystallization and centrifugal separation, recycling a mother liquor, drying solid under vacuum and obtaining the acetone oxime. The method has simple technique, is convenient to operate and easy in industrial implementation, and changes the prior mode of no products after environment-friendly investment, and has high economic efficiency and social efficiency.

Owner:HUAIAN WAN BANG SPICE IND CO LTD

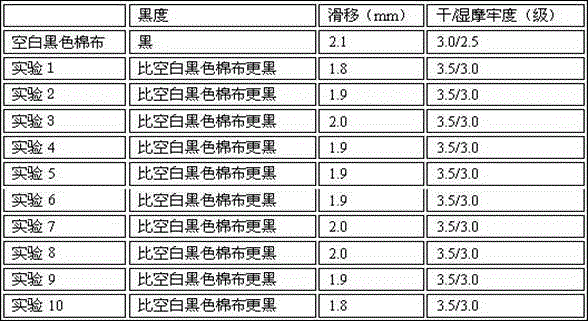

Dyeing fabric deepening finishing agent and preparation method

The invention discloses a dyeing fabric deepening finishing agent and a preparation method. The dyeing fabric deepening finishing agent is prepared in a mixed and matched manner from water-based close polyurethane resin and water-based acrylic resin, wherein the water-based close polyurethane resin is prepared by polypropylene oxide triol, N-methyl diethanol amine, hexamethylene diisocyanate, acetone, acetoxime, dimethyl sulfate, glacial acetic acid, sodium hydrogen sulfite, deionized water and dibutyltin dilaurate, and the water-based acrylic resin is prepared by methyl acrylate, acrylonitrile, dimethylaminoethyl methacrylate, trifluoroethyl methacrylate, hydroxyethyl acrylate, methacryloyloxyethyl trimethyl ammonium chloride, azobis isobutylamidine hydrochloride and deionized water. The dyeing fabric deepening finishing agent is resistant in cracking and slipping and good in fixation effect.

Owner:LIAONING FIXED STAR FINE CHEM

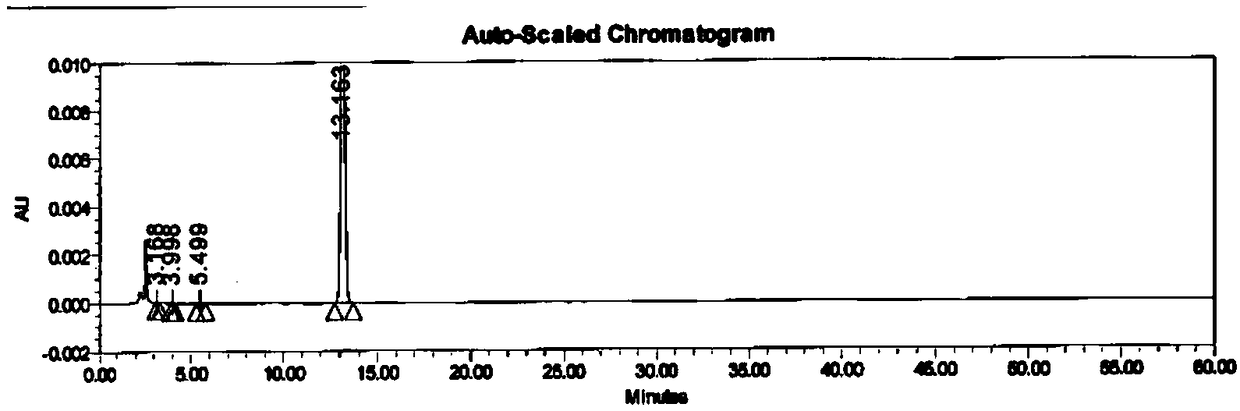

Purification method of acetone oxime

InactiveCN106478450AReduce decompositionReduce decomposition rateOximes preparationPurification methodsEthyl acetate

The invention discloses a purification method of acetone oxime, and relates to the technical field of organic compound purification. The method comprises the steps that acetone, ammonia gas or ammonia water, hydrogen peroxide, a solvent and a catalyst make contact with one another, and an acetone ammoximation reaction is conducted to obtain an acetone oxime reaction solution, wherein the solvent is a mixture of water and an organic solvent; for the purification process, the acetone oxime reaction solution is filtered at first, a filtrate is subjected to rectification to remove the organic solvent, tower kettle water and oxime mixed liquid is extracted with an extraction agent to obtain extraction liquid, the extraction liquid is subjected to rectification, the extraction agent is rectified out, and then pure acetone oxime is rectified out, wherein the extraction agent is ethyl acetate or dichloromethane or trichloromethane or methylbenzene. The method has the advantages of being capable of obtaining the extraction agent easily, high in extraction rate, capable of separating the extraction agent easily, simple in process, low in energy consumption, mild in separation condition, high in product purity and the like.

Owner:定州旭阳科技有限公司

Smoke desulphurization agent and smoke desulphurization method

ActiveCN101721884BHigh desulfurization rateReduce absorptionDispersed particle separationDesorptionKetone

The invention provides a smoke desulphurization agent. The desulphurization agent is aqueous solution containing a main absorption component, an activating agent, an anti-oxidation component and acid, wherein the main absorption component is one or more of alkyl piperazine, hydroxyalkyl piperazine and hydroxyalkyl piperazine ketone; the activating agent comprises piperazine and diazabicyclo; and the anti-oxidation component is at least one of 4-tert-butyl catechol, 2,6-di-tert-butyl-p-phenylcresol, acetone oxime and N,N-bi (2-ethoxy) glycine. The smoke desulphurization agent provided by the invention can remove and reclaim sulfur dioxide in the smoke, and has higher desulphurization rate; moreover, even if the smoke desulphurization agent is strongly oxidized and then is recycled, the absorption capacity for the sulfur dioxide is still stable; and in addition, the rich liquor formed by desulphurization after adopting the desulphurization agent has better desorption performance such ashigh desorption rate.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +2

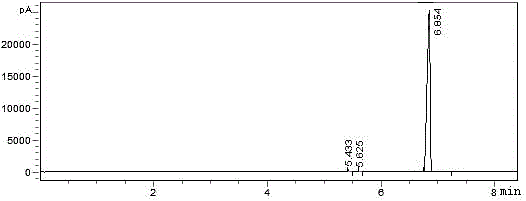

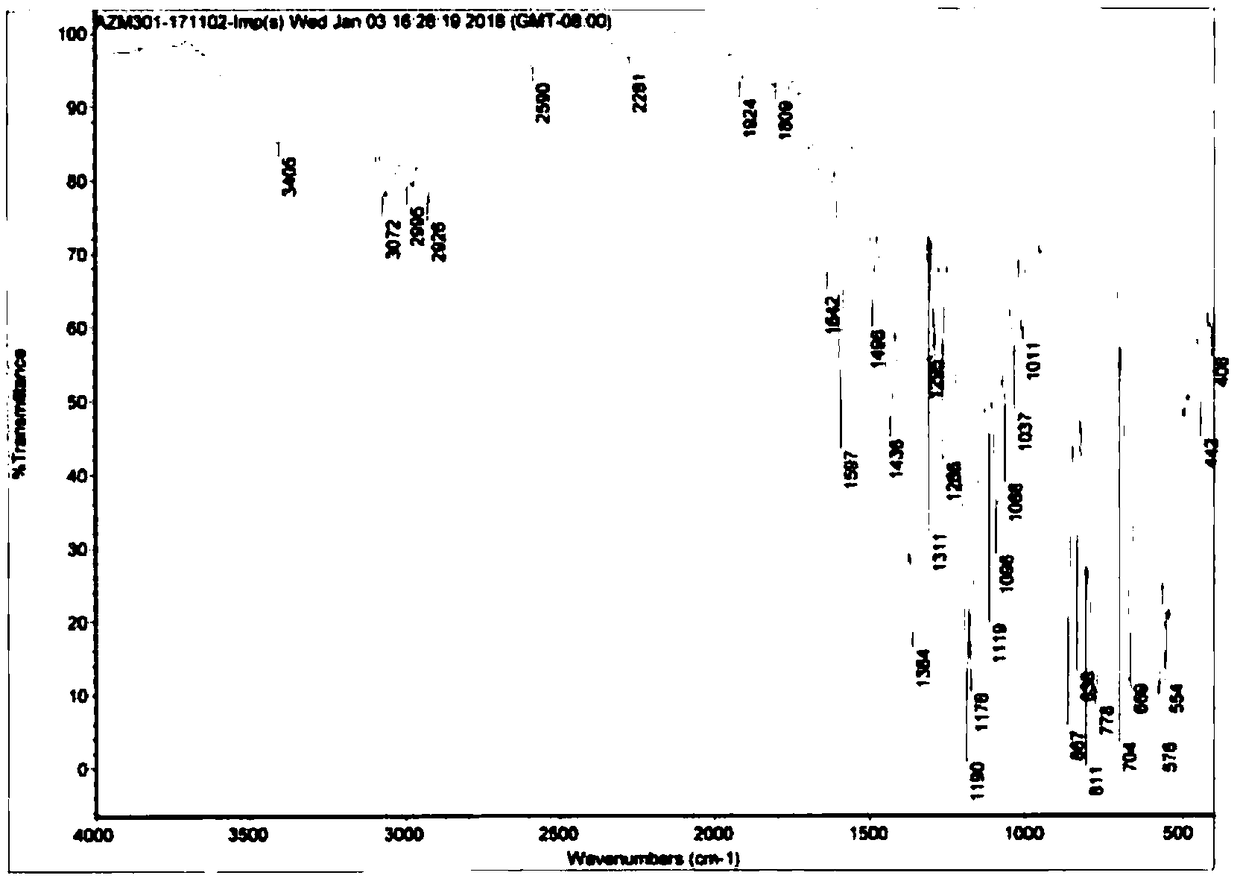

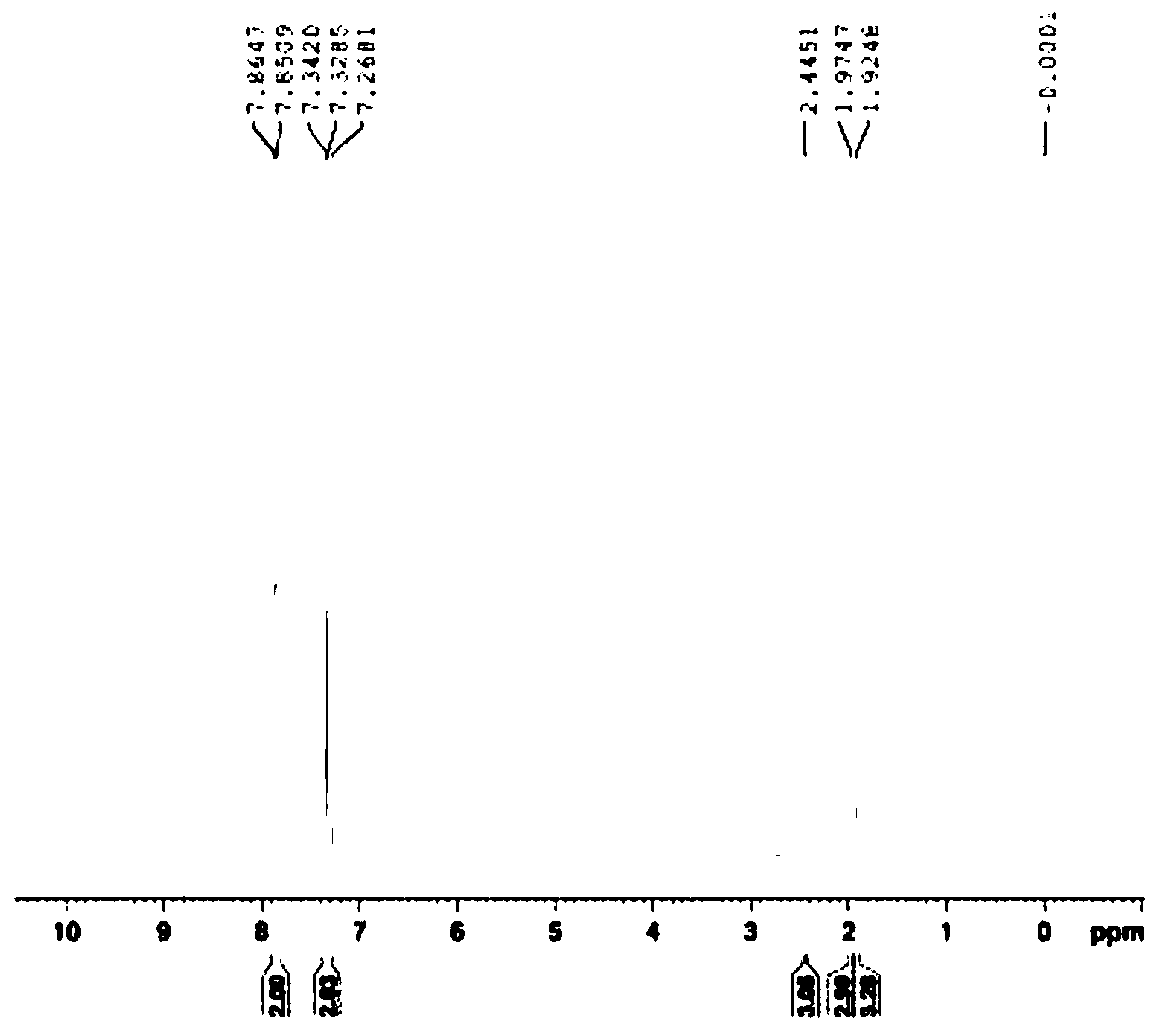

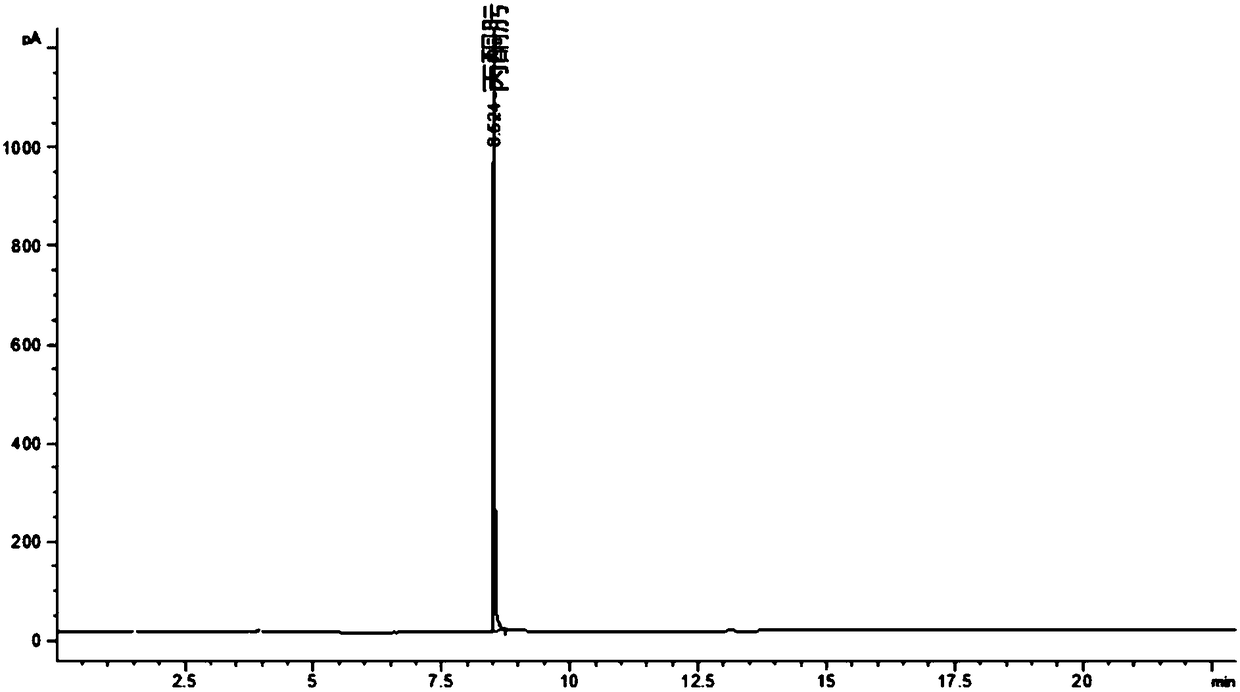

Synthetic method of azithromycin genotoxic impurities

ActiveCN109134331AGood qualityEasy to quantitative controlOrganic chemistryHydroxylamineHydroxylamine Hydrochloride

The invention belongs to the field of chemical technology, and in particular relates to a synthetic method of azithromycin genotoxic impurities, wherein the impurity is acetone oxime-O-p-methyl sulfonic acid ester. The preparation method comprises the following main steps: firstly, preparing a compound with acetone and hydroxylamine through oximation, then conducting esterification reaction with the compound and p-toluenesulfonyl chloride, and finally refining the substance to obtain the acetone oxime-methyl sulfonic acid ester impurities with purity of higher than 99.5%. The high purity synthetic acetone oxime-methyl sulfonic acid ester serves as the impurity standard for azithromycin finished products testing, facilitates the enhancement of positioning and qualitative identification of the genotoxic impurities in the testing of the azithromycin finished products, and improves the quality control of the azithromycin crude drugs.

Owner:HEC PHARM

Preparation method for acetoxime

Owner:BEIJING RISUN TECH CO LTD

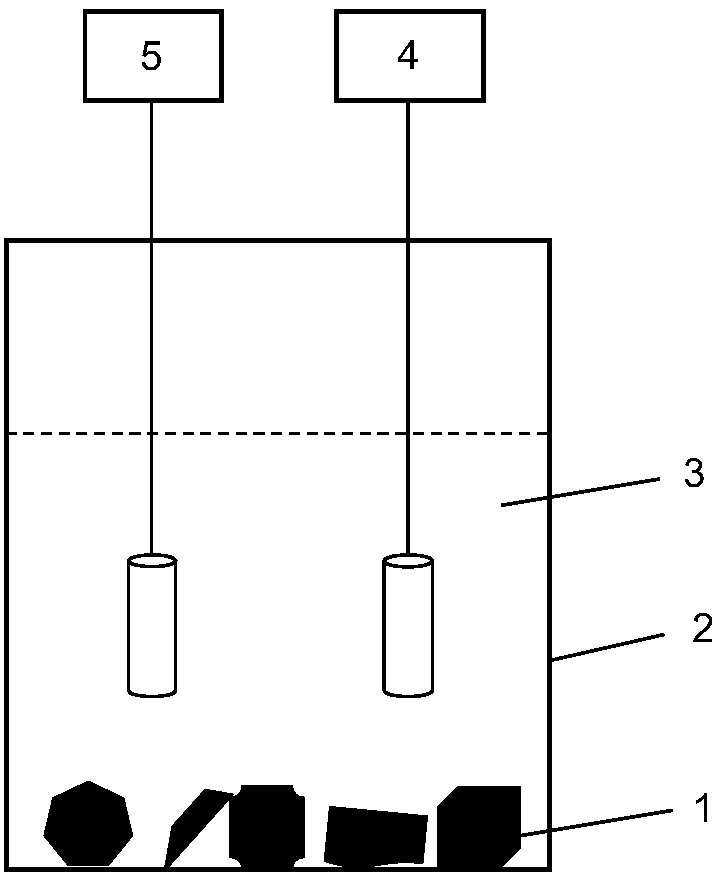

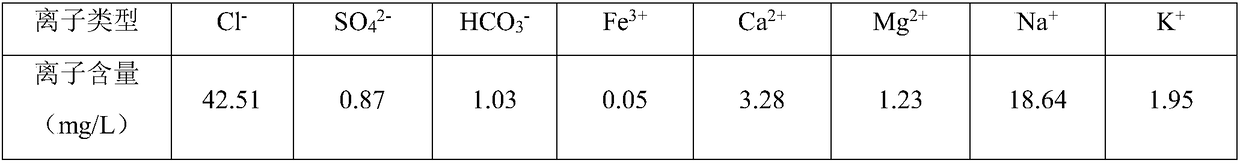

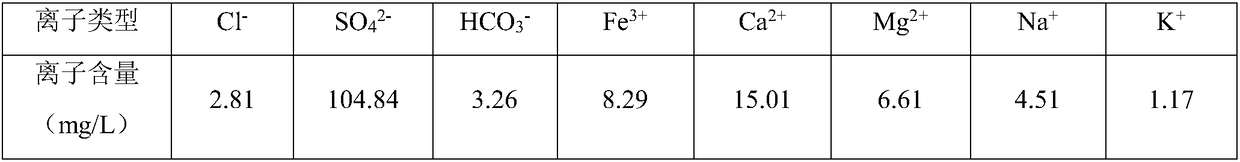

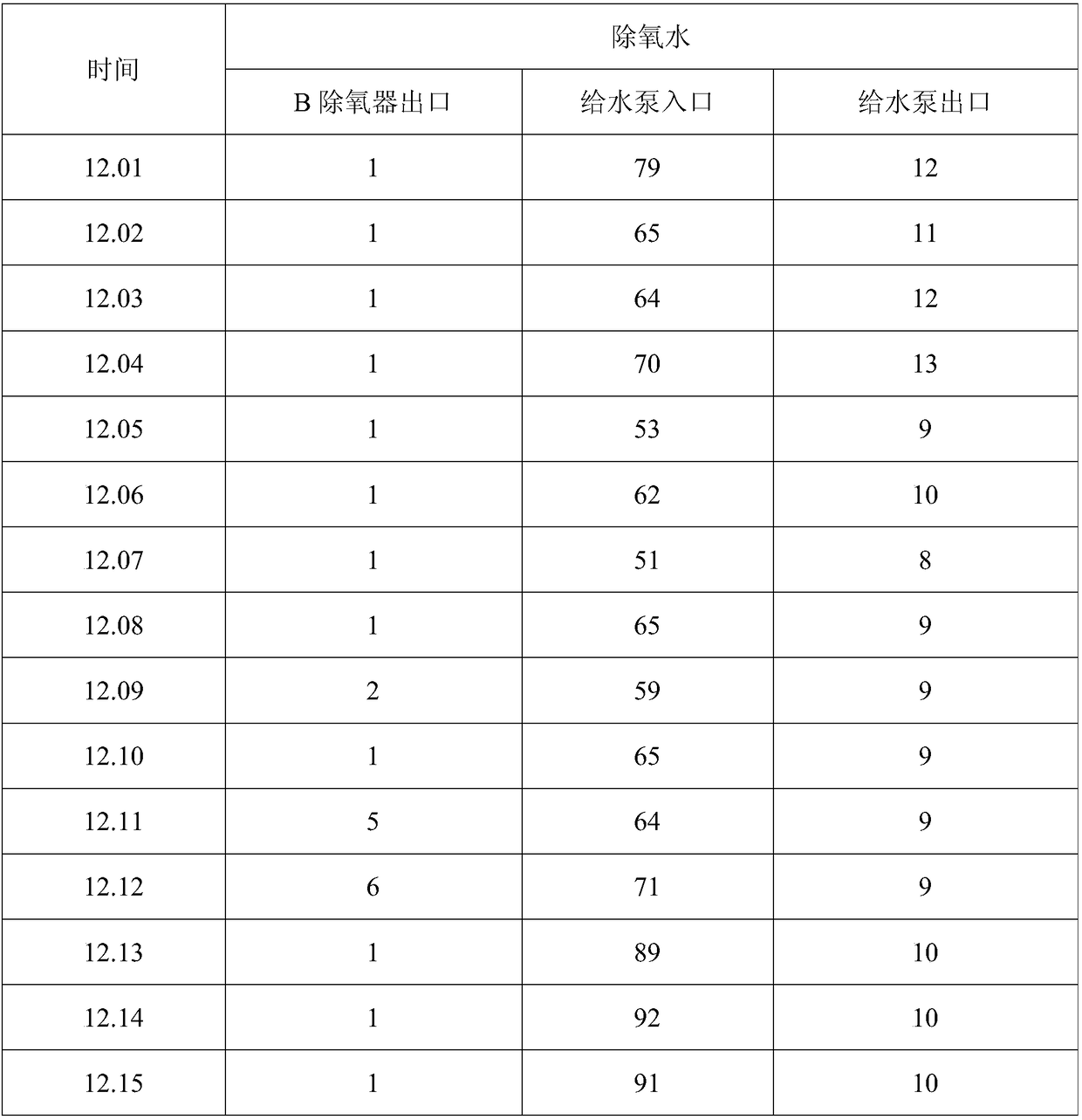

Black shale soluble salt extracting method

The invention discloses a black shale soluble salt extracting method which comprises the following steps: (1) preparing black shale into a centimeter-level block sample in any shape; (2) utilizing a vacuum drying box to dry the sample and weighing; (3) adding distilled water and an organic reducing agent acetone oxime into a container to make a water solution be in strong reducing environment (anEh value is lower than -200mV); (4) completely immersing the shale block sample into the water solution in the step (3) and utilizing an oxidizing and reducing potentiometer and a conductivity meter to respectively monitor the Eh value and conductivity of the water solution in real time; (5) controlling the adding amount of the acetone oxime in an extracting experiment process to make the water solution keep the strong reducing environment (the Eh value is smaller than -200mV); (6) obtaining an extracting solution containing the black shale soluble salt when a conductivity value of the water solution does not increase any more. By means of the black shale soluble salt extracting method disclosed by the invention, mineral oxidization and dissolution in a soluble salt extracting process areeffectively avoided, and the soluble salt is prevented from being lost in a sample preparing process; thus, accurate black shale soluble salt ion composition data can be obtained.

Owner:SOUTHWEST PETROLEUM UNIV

Boiler deoxidizer and application thereof

PendingCN108529709AReduce dosageImprove oxygen removal efficiencyWater treatment parameter controlLiquid degasificationCarbazideButanone

The invention discloses a boiler deoxidizer and application thereof. The boiler deoxidizer comprises acetone oxime, carbazide, diacetylmonoxime and deionized water and respectively comprises the following raw materials in percentage by mass: 8-15% of acetone oxime, 10-25% of carbazide, 15-25% of diacetylmonoxime and the balance of deionized water. The boiler deoxidizer disclosed by the invention is capable of rapidly reacting with dissolved oxygen in water, has the characteristics of being small in usage amount, high in deoxidizing efficiency, non-toxic, free in environmental pollution and thelike, does not influence salt content in boiler water after decomposition, is an optimum medicine for shutdown protection and passivating treatment of a subcritical boiler, and is also an ideal product for replacing the traditional chemical deoxidizer in medium and high-pressure boiler water supply. The boiler deoxidizer disclosed by the invention can be applied to boiler water supply deoxidizingin refinery enterprises.

Owner:廊坊明泉化工建材有限公司

Preservative for marine pipe pigging pressure testing and sealing and production method thereof

InactiveCN110144591AAvoid corrosion damagePrevent scalingSeawater treatmentSpecific water treatment objectivesSulfite saltPhosphate

The invention discloses a preservative for marine pipe pigging pressure testing and sealing and a production method thereof. The preservative comprises 8-35 weight parts of polyhydric alcohol phosphate ester, 25-75 weight parts of clear water, 5-25 weight parts of inorganic compounds, 1-12 weight parts of polymers, 0.5-10 weight parts of sterilization components and 2-10 weight parts of deoxidation components, which are fully stirred and dissolved in a synthesis kettle under normal temperature and are uniformly dissolved for split charging to form a finished product. Inorganic compounds are one or mixtures of more than two of zinc gluconate, sodium gluconate, sodium tripolyphosphate and sodium hexametaphosphate; the polymers are one or mixtures of more than two of polyaspartic acid, polyepoxysuccinic acid, hydrolytic polymaleic anhydride, polyacrylic acid and copolymers; the sterilization components are one or mixtures of more than two of dodecyl dimethyl benzyl ammonium chloride, dodecyl dimethyl benzyl ammonium bromide, tetradecyl benzyl dimethyl ammonium chloride and glutaraldehyde; and the deoxidation components are one or mixtures of more than two of methyl ethyl ketoxime, acetone oxime and sodium sulfite.

Owner:ZHONGKE CORROSION CONTROL ENG TECH CENT SHENYANG

Preparation method of acetone oxime

InactiveCN109593046AImprove conversion rateHigh extraction rateOximes preparationSolubilityMolecular sieve

The invention relates to the technical field of acetone oxime production processes, in particular to a preparation method of acetone oxime. The preparation method of acetone oxime comprises the following steps: 1) dissolving acetone in an organic solvent to prepare an acetone solution and then adding a TS-1 molecular sieve catalyst and ammonia water into the acetone solution to be mixed to obtaina prereaction liquid; and 2) heating the prereaction liquid to 40-80 DEG C, and adding a hydrogen peroxide solution to react for 3-10 hours under the condition that the temperature is 40-80 DEG C andthe pressure is 0-1.0MPa, then carrying out filtration and rectification, extracting the solution with an extraction agent to obtain an extraction solution, and rectifying the extraction solution to obtain acetone oxime. The preparation method is simple in production process. Acetone is dissolved by isopropanol or cyclohexane, so that the solubility is good and the conversion ratio of acetone is improved. Isopropanol or cyclohexane is easily separated from a mixture of acetone oxime separately in the later period. The extraction agent is used for acetone oxime, so that the extraction rate is high, and in the whole process course, environmental pollution caused by a conventional process is avoided.

Owner:江苏艾科维科技有限公司

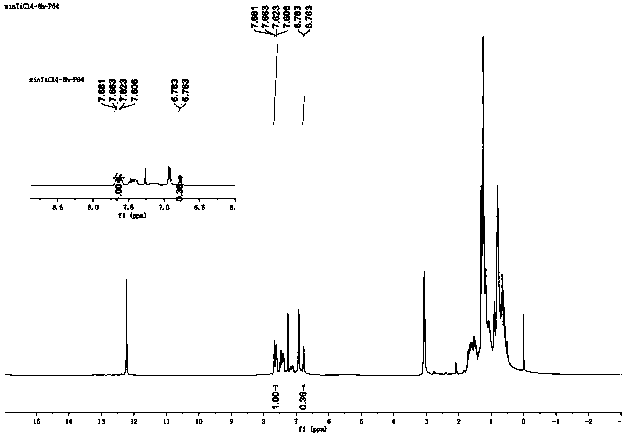

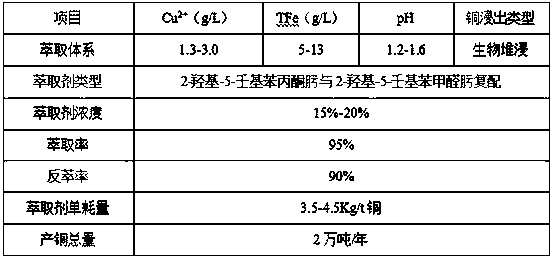

Synthesis method of 2-hydroxy-5-nonylpropiophenone and application of 2-hydroxy-5-nonylpropiophenone in copper extraction agent

InactiveCN111484399ALess side effectsImprove conversion ratePreparation from carboxylic acid halidesOrganic compound preparationPtru catalystLewis acid catalysis

The invention provides a synthesis method of 2-hydroxy-5-nonylpropiophenone and an application of the 2-hydroxy-5-nonylpropiophenone in a copper extraction agent. The synthesis method of the 2-hydroxy-5-nonylpropiophenone comprises the following steps: esterification reaction, rearrangement reaction, hydrolysis reaction and distillation purification. The method has the beneficial effects that thebrand-new synthetic route of the 2-hydroxy-5-nonylpropiophenone has the advantages that TiCl4 is adopted as a Lewis acid catalyst to carry out the rearrangement reaction of 4-nonylphenol ester, side reactions are fewer, and higher conversion rate and product purity can be obtained; according to the application of the 2-hydroxy-5-nonylpropiophenone oxime in the efficient copper extraction agent, the efficient copper extraction agent can be obtained after the 2-hydroxy-5-nonylpropiophenone oxime and the 2-hydroxy-5-nonylbenzaldoxime are compounded according to the ratio of 1:1, the product performance exceeds that of a Lix984N product, and the use stability and the unit consumption are lower.

Owner:福建紫金选矿药剂有限公司

Anti-corrosion corrosion inhibitor for heat supply network and preparation method and application method of anti-corrosion corrosion inhibitor

The invention discloses an anti-corrosion corrosion inhibitor for a heat supply network and a preparation method and application method of the anti-corrosion corrosion inhibitor. The anti-corrosion corrosion inhibitor is characterized by comprising, by weight, 15-25 parts of sodium sulfite or carbohydrazide or dimethyl ketoxime or acetone oxime, 4-12 parts of trisodium phosphate or sodium tripolyphosphate in phosphate, 8-15 parts of ammonium hydroxide or monoethanolamine or sodium hydroxide or potassium hydroxide as a pH conditioning agent, 15-25 parts of 1H-benzotriazole or mercaptobenzothiazole or dicyclohexylaminenitrite as a passivator and 33-48 parts of cyclohexylamine carbonate or hexamethylenetetramine or tetrahydroglyoxaline as a corrosion inhibitor body. The application method of the anti-corrosion corrosion inhibitor comprises the step that anti-corrosion corrosion inhibitor powder is directly added into water of the heat supply network, wherein the using amount is 80-120 mg / L. By means of the corrosion inhibitor, stainless steel pitting corrosion and galvanic corrosion occurring in the heat supply network can be effectively prevented; effective protection is formed between a gaseous phase space and a liquid phase space at the same time; and environmental friendliness is achieved.

Owner:沈阳防锈包装材料有限责任公司

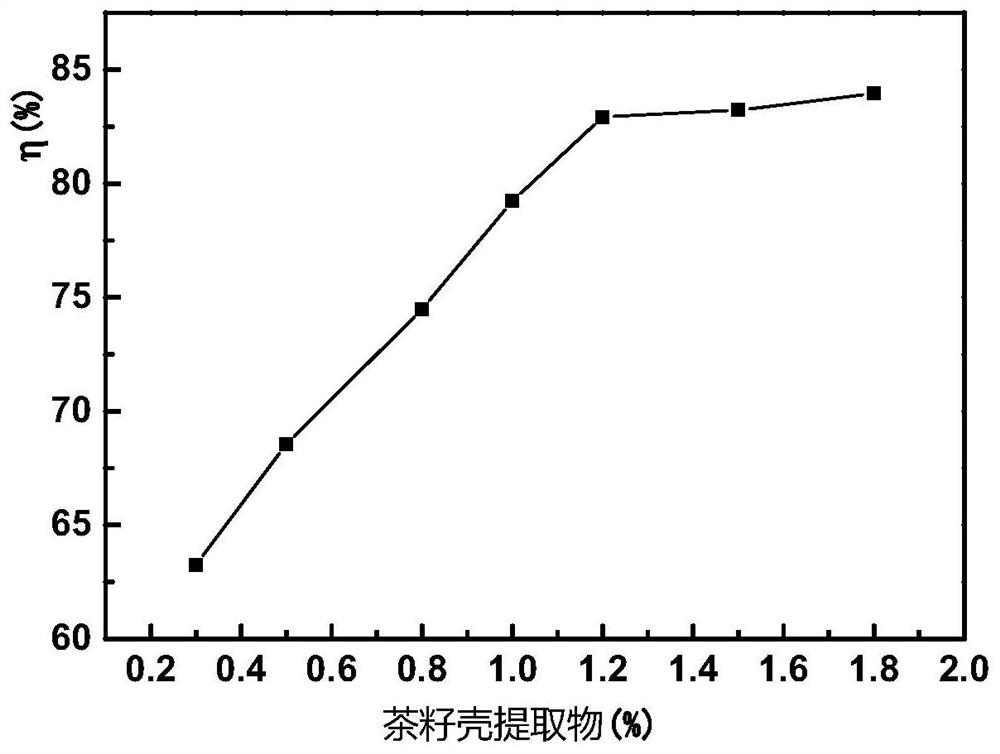

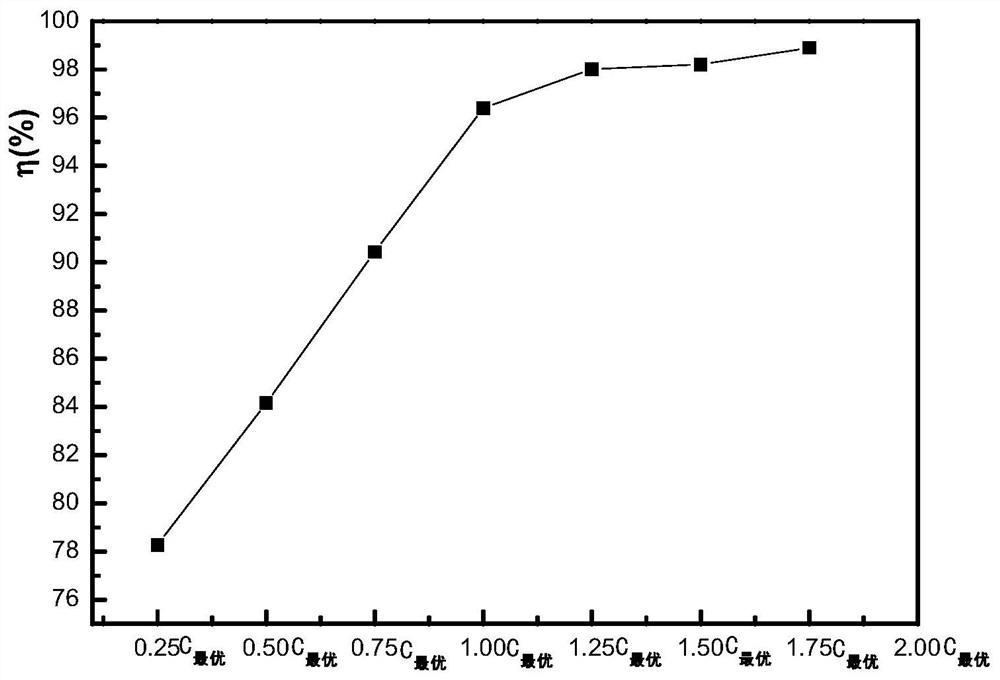

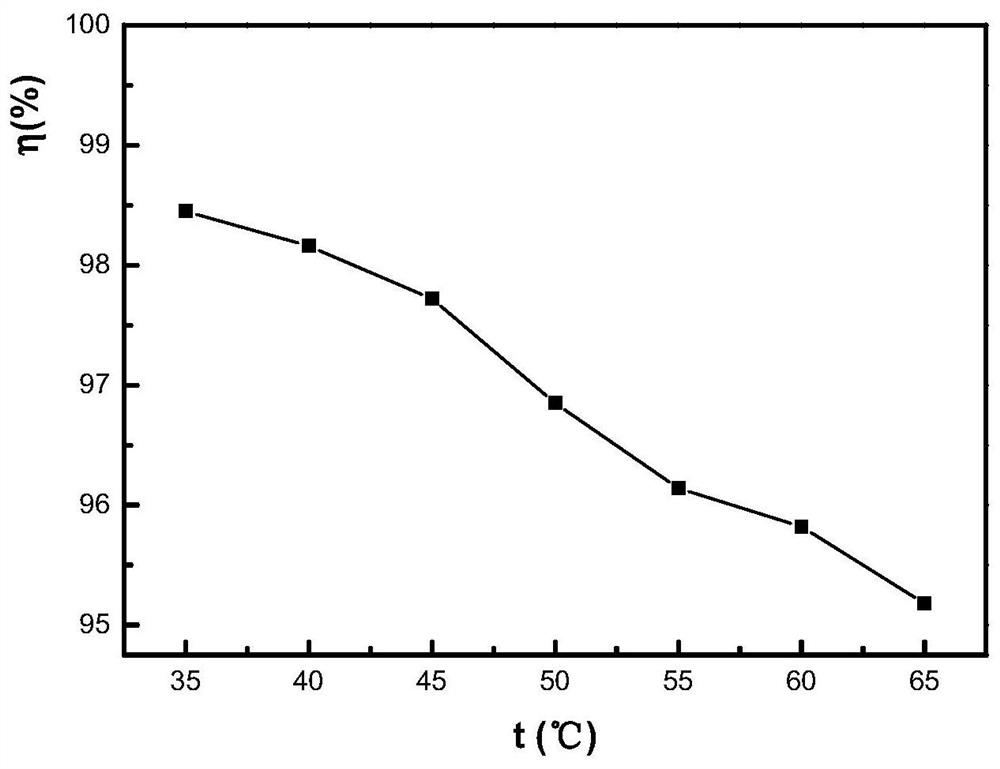

Pickling compound corrosion inhibitor for thermal equipment and preparation method thereof

ActiveCN111663143AGood corrosion inhibition effectImprove efficiencyChemical industryPhysical chemistrySodium salt

The invention discloses a pickling compound corrosion inhibitor for thermal equipment and a preparation method thereof. The compound corrosion inhibitor is prepared from a tea seed shell ethanol extract, quaternary ammonium bis-imidazoline, acetone oxime, sodium alkyl benzene sulfonate, and an EDTA disodium salt. The compound corrosion inhibitor has a good corrosion inhibition effect in the temperature range of a hydrochloric acid pickling technology for the thermal equipment, and the corrosion inhibition rate can reach 96%.

Owner:CHONGQING ELECTRIC POWER COLLEGE

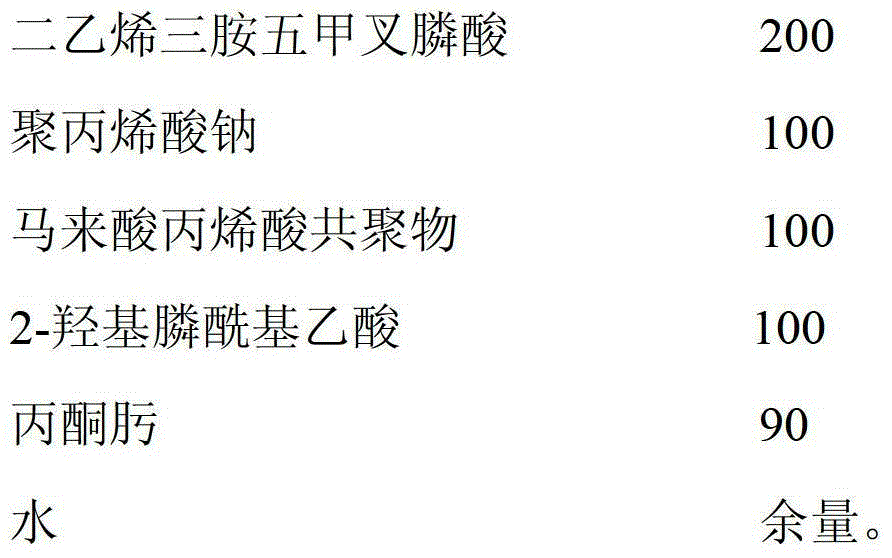

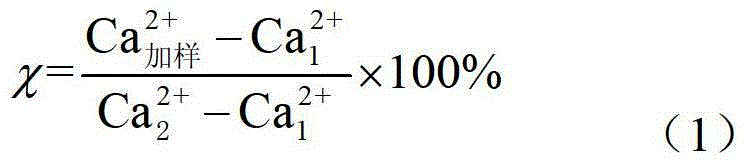

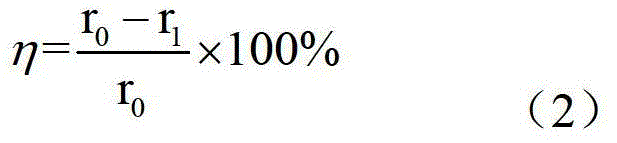

Composite water treatment agent for thickened oil thermal recovery boiler and preparation method thereof

InactiveCN103332794ASolve corrosiveAvoid badScale removal and water softeningAcetic acidComponents of crude oil

The invention relates to a composite water treatment agent for a thickened oil thermal recovery boiler and a preparation method thereof. The composite water treatment agent for the thickened oil thermal recovery boiler comprises the following components according to weight percentage: 10%-25% of DTPMP (diethylene triamine penta methylene phosphonic acid), 10%-15% of sodium polyacrylate, 10%-12% of maleic acid acrylic copolymer, 5%-10% of 2-hydroxyphosphonoacetic acid, 5%-10% of acetone oxime, and the balance of water. The preparation method of the composite water treatment agent for the thickened oil thermal recovery boiler comprises the following steps of adding water into a reaction kettle, then stirring and simultaneously adding the DTPMP, the sodium polyacrylate, the maleic acid acrylic copolymer, the 2-hydroxyphosphonoacetic acid and the acetone oxime, then reacting for 30-40 minutes, and obtaining the composite water treatment agent for the thickened oil thermal recovery boiler. According to the composite water treatment agent for the thickened oil thermal recovery boiler, problems of corrosion and scaling of a steam drive thermal recovery are solved, and the requirement on production on site is met.

Owner:PETROCHINA CO LTD

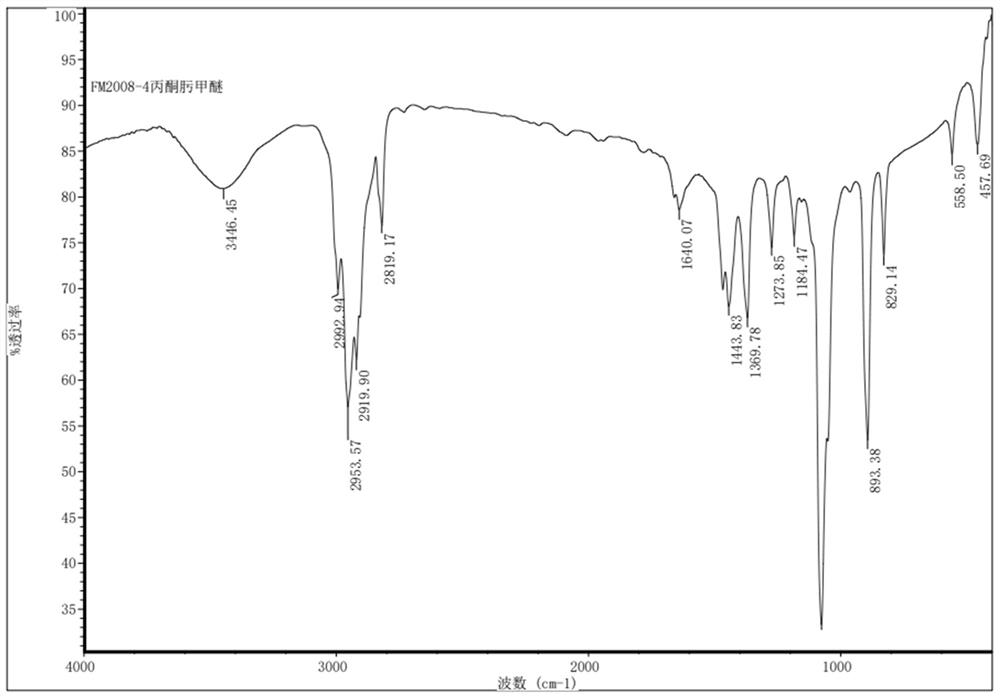

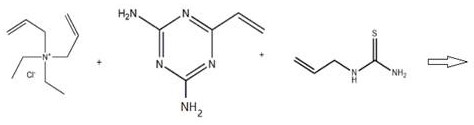

Preparation method of acetoxime methyl ether

ActiveCN113429313AHigh yieldHas etherification catalytic effectOrganic-compounds/hydrides/coordination-complexes catalystsOximes preparationPtru catalystHeteropoly acid

The invention relates to the field of chemical engineering, in particular to a preparation method of acetoxime methyl ether, which comprises the following steps: performing etherification reaction on acetoxime, methane chloride and sodium hydroxide under the action of a phase transfer catalyst to generate acetoxime methyl ether, and rectifying to obtain the finished product of acetoxime methyl ether. The reaction conditions are mild, the operation is simple, the synthesis is easy, the byproduct acetone can be recycled, and the cost and the energy consumption can be reduced; under the action of the heteropolyacid salt phase transfer catalyst, the etherification reaction can solve the problem of compatibility during the organic-inorganic two-phase reaction and improve the reaction efficiency and yield, and meanwhile, the catalyst also has an etherification catalysis effect and is beneficial to forward movement of the reaction and increase of the yield of the product; compared with the prior art, the reaction yield is higher, the material utilization rate is large, and the preparation method of the acetoxime methyl ether has an industrial prospect.

Owner:ZHEJIANG JINHUA NEW MATERIALS

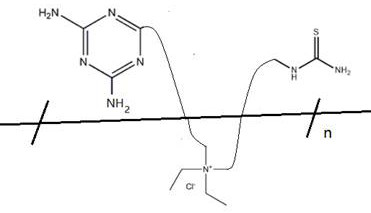

Organic synthesis intermediate acetone oxime synthesis method

InactiveCN108203397AReduce intermediate linksShort reaction timeOximes preparationHydroxylamineOrganic synthesis

The invention relates to an organic synthesis intermediate acetone oxime synthesis method, which mainly comprises: dissolving 0.5 mol hydroxylamine phosphate in 20 L of a potassium chloride solution,slowly adding 0.6-0.8 mol of an acetone solution, controlling the solution temperature at 35-39 DEG C, standing for 90-110 min after the adding, reducing the solution temperature to 31-34 DEG C, adding 0.9 mol of a potassium bicarbonate solution, adjusting the pH value of the solution to 8.5-9, controlling the solution temperature at 41-45 DEG C, layering after cooling, extracting the obtained oillayer, carrying out pressure reducing distillation, collecting the distillate at a temperature of 90-95 DEG C, washing with a cyclohexane solution, washing with an isopropanol solution, dehydrating with a dehydrating agent, and carrying out cooling crystallization to obtain the finished product acetone oxime.

Owner:CHENGDU KA DI FU TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com