Method for using carvone production wastewater for recycling acetone oxime

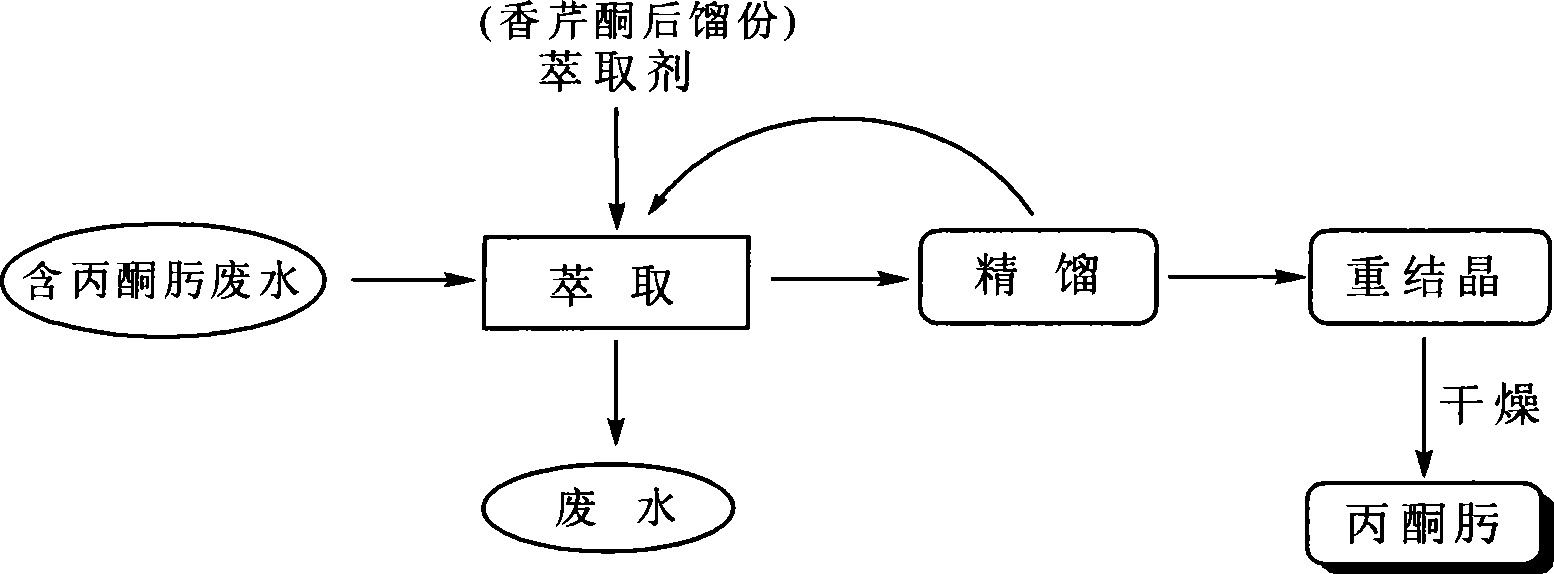

A technology for producing waste water and acetone oxime, which is applied in oxime preparation, organic chemistry, etc., can solve the problems of difficult biochemical degradation, acetone oxime energy consumption, large equipment investment, complex components, etc., and achieve the effect of strong extraction capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Put 165 grams of 120-150°C / 2mmHg back fraction during rectification in the production process of carvone and 600 grams of waste water with a mass concentration of 19.5% acetone oxime into a 1000ml three-necked flask, heat up to 45°C, stir for 37min, and cool to room temperature. Transfer to a 1000ml separating funnel, let it stand for stratification, determine that the water phase contains 1.3% acetone oxime, and transfer it to the sewage station for treatment; the organic phase is rectified under reduced pressure, collect 105 grams of fractions at 80-85°C / 300mmHg, and analyze the acetone oxime by chromatography The content is 99.2%; 105 grams of acetone oxime fractions are dissolved in 70 grams of water, and a large amount of crystals are precipitated when the temperature is slowly lowered to 5°C. The crystallization solution is centrifuged, the mother liquor is recycled, and the solids are vacuum-dried to obtain 100 grams of acetone oxime product, which is analyzed by G...

Embodiment 2

[0019] Put 160 grams of 120-150°C / 2mmHg rear fraction during rectification in the production process of carvone and 550 grams of waste water with a mass concentration of 18.3% acetone oxime into a 1000ml three-necked flask, heat up to 50°C, stir for 45min, and cool to room temperature. Transfer to a 1000ml separatory funnel, let it stand for stratification, determine that the water phase contains 1.1% acetone oxime, and transfer it to the sewage station for treatment; the organic phase is rectified under reduced pressure, collect 90 grams of fractions at 80-85°C / 300mmHg, and analyze the acetone oxime by chromatography The content is 99.3%; 90 grams of acetone oxime fractions are dissolved in 60 grams of water, and the temperature is slowly cooled to 4° C. A large amount of crystals are precipitated. The crystallization solution is centrifuged, the mother liquor is recycled, and the solids are vacuum-dried to obtain 86 grams of acetone oxime product, which is analyzed by GC The ...

Embodiment 3

[0021] Put 175 grams of 120-150°C / 2mmHg back fraction and 655 grams of waste water with a mass concentration of 17.5% acetone oxime into a 1000ml three-neck flask during the rectification in the production process of carvone, heat up to 40°C, stir for 30min, and cool to room temperature. Transfer to a 1000ml separatory funnel, let it stand for stratification, determine that the water phase contains 1.0% acetone oxime, and transfer it to the sewage station for treatment; the organic phase is rectified under reduced pressure, collect 100 grams of 80-85°C / 300mmHg fraction, and analyze the acetone oxime by chromatography The content is 99.1%; 100 g of acetone oxime fraction is dissolved in 65 g of water, and the temperature is slowly cooled to 3° C., a large amount of crystals are precipitated. The crystallization liquid is centrifuged, the mother liquor is recycled, and the solid is vacuum-dried to obtain 94 g of acetone oxime product, which is analyzed by GC The content is 99.7%....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com