Method for extracting gold from material liquid with high gold content

A gold content and material liquid technology, applied in the field of gold extraction, can solve the problems of short production cycle, difficult to guarantee direct yield, high gold impurity content and other problems of chemical method, and achieve the advantages of small floor area, strong raw material adaptability and low material cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

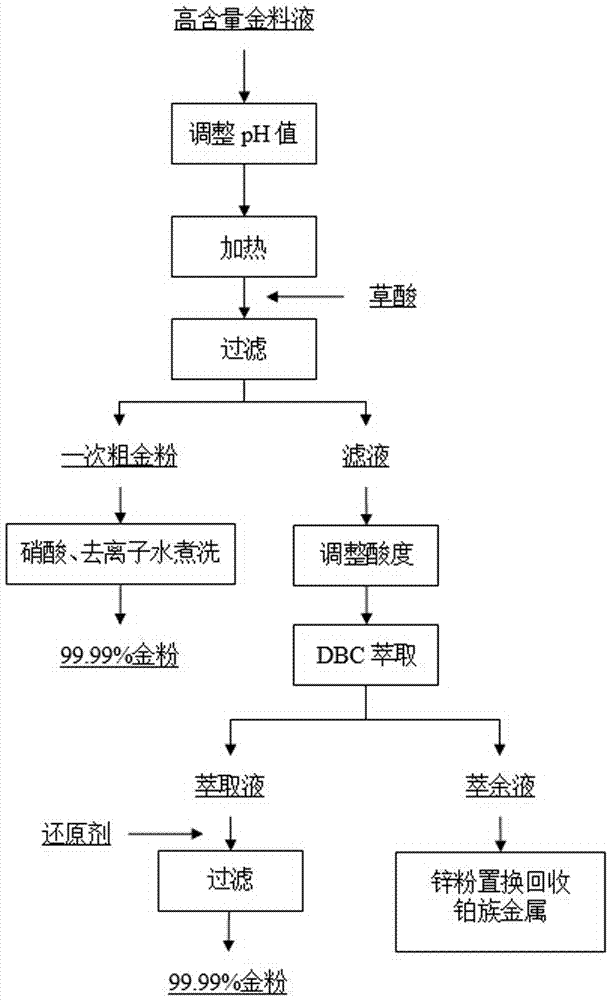

Image

Examples

Embodiment 1

[0019] The first step is to adjust the pH value of the solution: select 1L of gold electrolyte as a raw material, add 620g of 40% sodium hydroxide solution to it, and adjust the pH to 1.5.

[0020] The second step is to moderately heat the solution: raise the temperature of the solution to 70°C.

[0021] The third step is to add acid to filter and separate: add 115 g of oxalic acid to the heated solution, and filter after reacting for 1 hour to obtain a precipitate as a primary coarse gold powder and a gold-containing solution.

[0022] The 4th step, primary coarse gold powder purification: the gained coarse gold powder obtains 263.6g of 99.99% gold powder after boiling and washing with 20% nitric acid for 24 hours.

[0023] The fifth step, the acidity adjustment and extraction of the remaining solution: use hydrochloric acid to adjust the acidity of the remaining solution in the third step to 1mol / L, and then use dibutyl carbitol (DBC) to extract the gold element.

[0024] T...

Embodiment 2

[0028] The first step is to adjust the pH value of the solution: select 100L Jinwang water solution as a raw material, add 65.7L of 40% sodium hydroxide solution to it, and adjust the pH to 1.5.

[0029] The second step is to moderately heat the solution: raise the temperature of the solution to 80°C.

[0030] The third step, add acid and filter and separate: add 12.1 kg of oxalic acid to the heated solution, react for 2 hours and then filter.

[0031] The 4th step, primary coarse gold powder purification: the obtained coarse gold powder was boiled and washed with 30% nitric acid for 48 hours to obtain 26397g of 99.99% gold powder.

[0032] The fifth step, the acidity adjustment and extraction of the remaining solution: use hydrochloric acid to adjust the acidity of the remaining solution in the third step to 3mol / L, and then use dibutyl carbitol (DBC) to extract the gold element.

[0033] The sixth step, back extraction and solid-liquid separation: add the reducing agent sod...

Embodiment 3

[0037] The first step is to adjust the pH value of the solution: select 10L of Jinwang water solution as a raw material, add 6.3L of 40% sodium hydroxide solution to it, and adjust the pH to 1.5.

[0038] The second step is to moderately heat the solution: raise the temperature of the solution to 80°C.

[0039] The third step, add acid and filter and separate: add 1.32 kg of oxalic acid to the heated solution, react for 2 hours and then filter.

[0040] The 4th step, primary coarse gold powder purification: the obtained coarse gold powder was boiled and washed with 30% nitric acid for 48 hours to obtain 1567.6g of 99.99% gold powder.

[0041] The fifth step, the acidity adjustment and extraction of the remaining solution: use hydrochloric acid to adjust the acidity of the remaining solution in the third step to 1mol / L, and then use dibutyl carbitol (DBC) to extract the gold element.

[0042] The sixth step, back extraction and solid-liquid separation: add the reducing agent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com