Cavity lining of plasma etching equipment

An etching equipment and plasma technology, applied in the field of chamber lining, can solve the problems of chamber pollution, damage, poor uniformity, etc., and achieve the effects of large area, improved uniformity, and maintenance of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

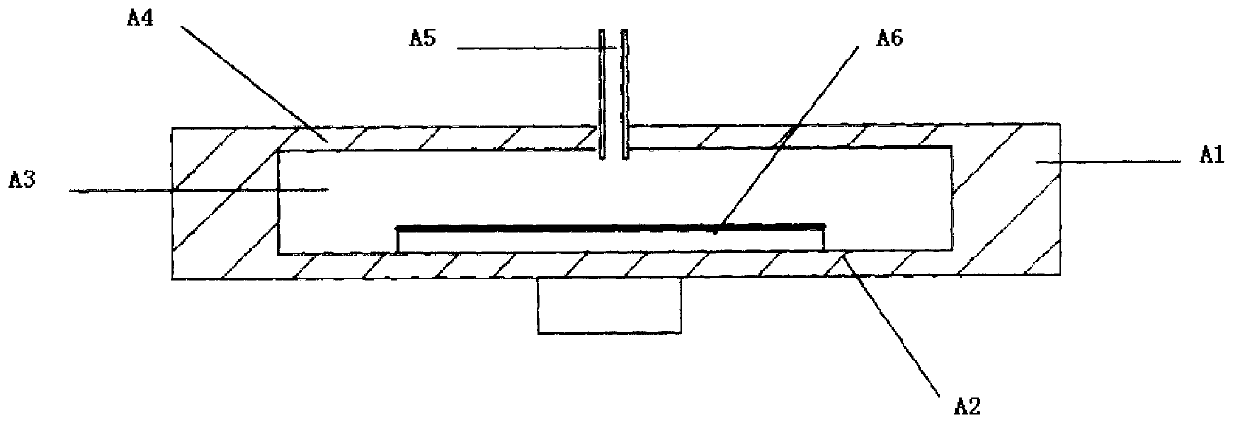

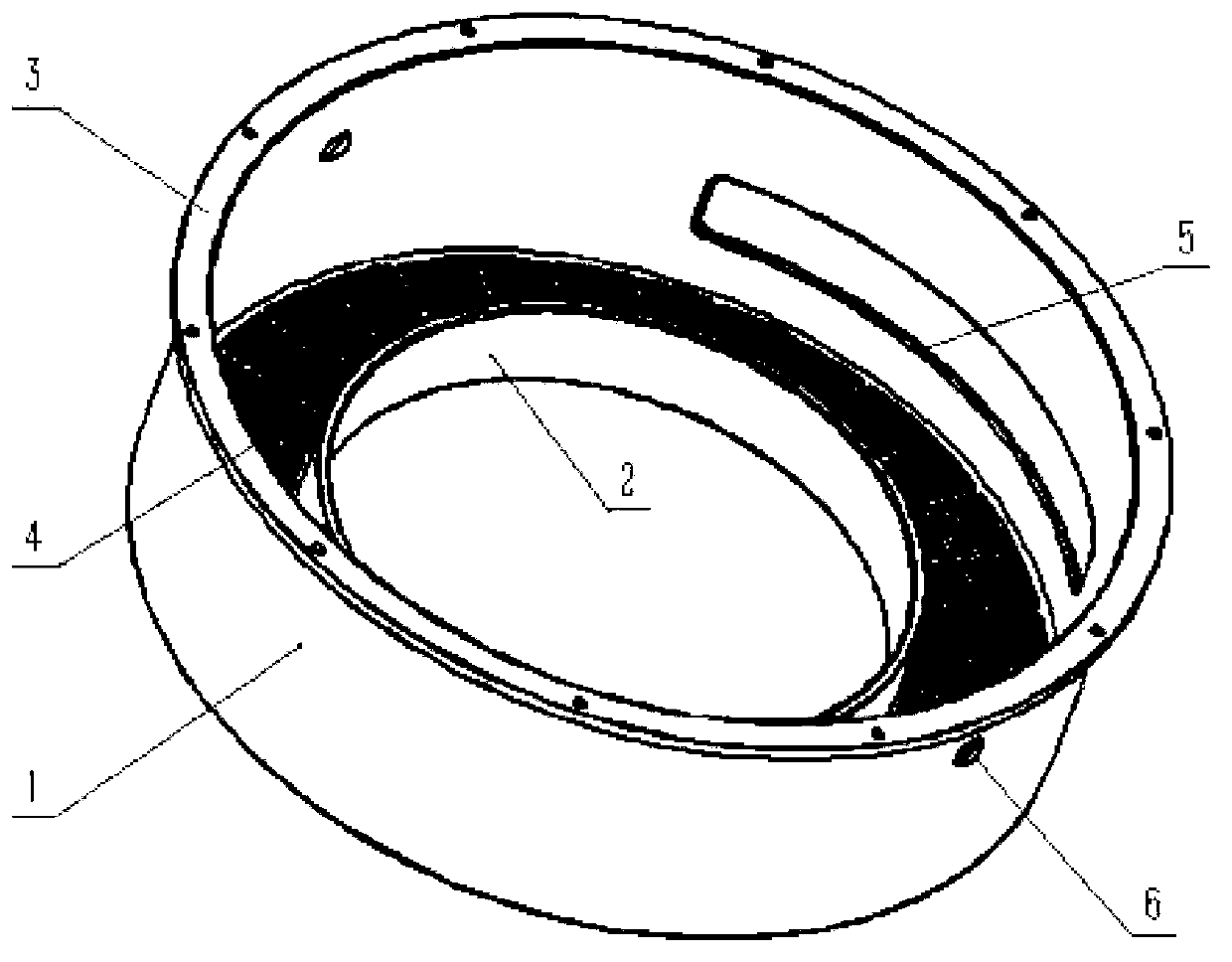

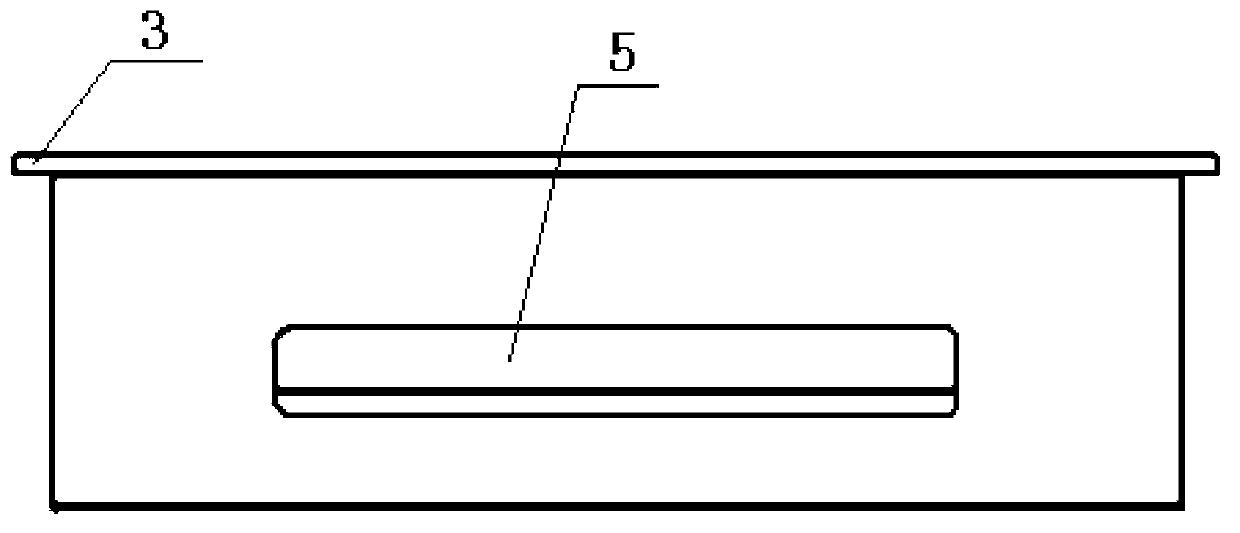

[0020] like Figure 2-5 As shown, the chamber lining of the plasma etching equipment includes a cylindrical body 1, which is provided with a conveying sheet opening 5 for picking up and sending wafers to be etched, and the outer wall of the body 1 and the reaction chamber of the plasma etching equipment The chamber 7 is adapted, and the bottom of the body 1 is provided with a ring-shaped bottom plate 2 extending inward. The ring-shaped bottom plate 2 matches the position of the wafer 9 to be etched. There is a fixed flange 3 connected to the reaction chamber 7 . The position matching of the annular bottom plate 2 and the wafer 9 to be etched refers to that the top surface of the annular bottom plate 2 is flush with the wafer 9 to be etched.

[0021] One side of the reaction chamber 7 is provided with a vacuum chamber 8, the inner substrate separates the reaction chamber 7 and the vacuum chamber 8, and the vacuum chamber 8 is connected with a vacuum pump.

[0022] The even fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com