Patents

Literature

45 results about "Nitropropane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nitropropane may refer to: 1-Nitropropane 2-Nitropropane

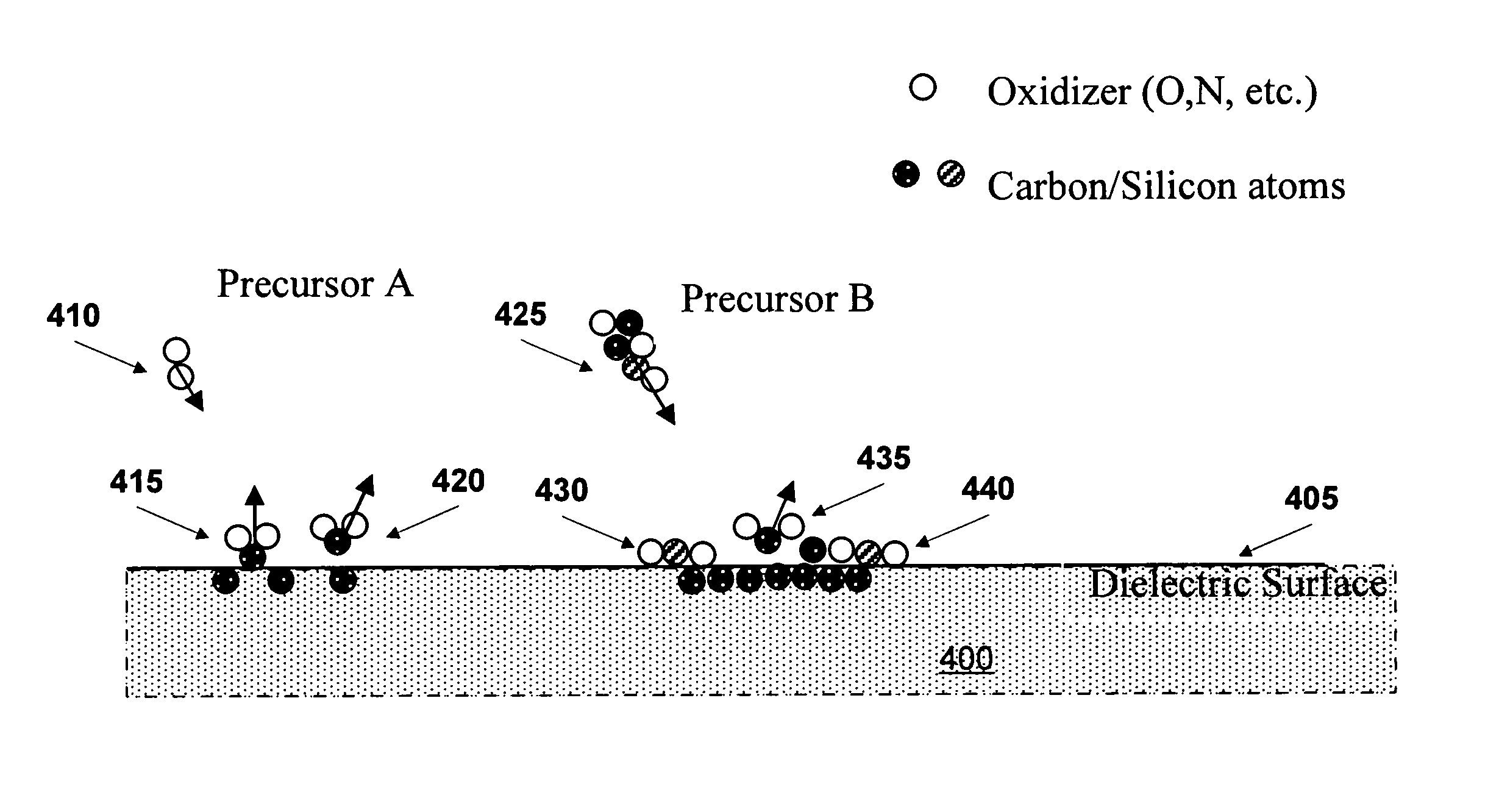

FIB milling of copper over organic dielectrics

ActiveUS7060196B2Electric discharge tubesDecorative surface effectsCharged particle beamNitropropane

Apparatus and processes are disclosed for milling copper adjacent to organic low-k dielectric on a substrate by directing a charged-particle beam at a portion of the copper and exposing the copper to a precursor sufficient to enhance removal of the copper relative to removal of the dielectric, wherein the precursor contains an oxidizing agent, has a high sticking coefficient and a long residence time on the copper, contains atoms of at least one of carbon and silicon in amount sufficient to stop oxidation of the dielectric, and contains no atoms of chlorine, bromine or iodine. In one embodiment, the precursor comprises at least one of the group consisting of NitroEthanol, NitroEthane, NitroPropane, NitroMethane, compounds based on silazane such as HexaMethylCycloTriSilazane, and compounds based on siloxane such as Octa-Methyl-Cyclo-Tetra-Siloxane. Products of the processes are also disclosed.

Owner:DCG SYST

Process for the manufacture of nitropropanes

ActiveUS20110028731A1Increase conversionsHigh yieldAmino compound purification/separationOrganic compound preparationNitrationPropane

Provided is a process for the formation of 2-nitropropane and / or 2,2-dinitropropane by the nitration of propane with dilute nitric acid.

Owner:ANGUS CHEM CO

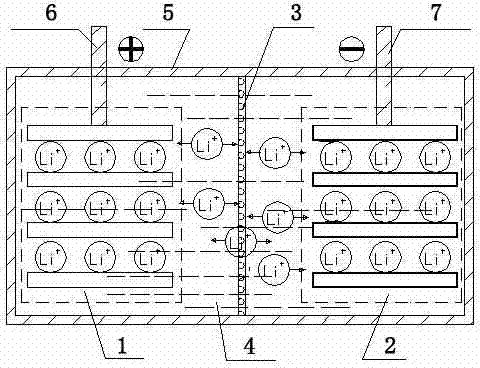

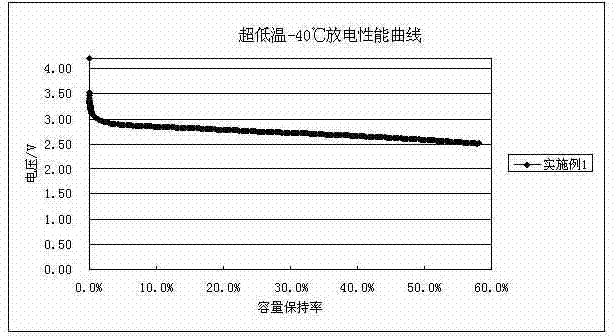

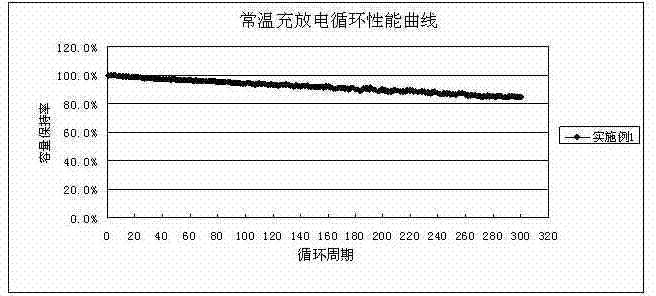

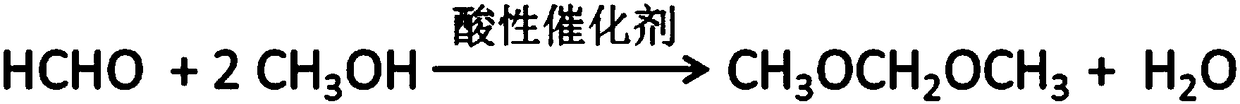

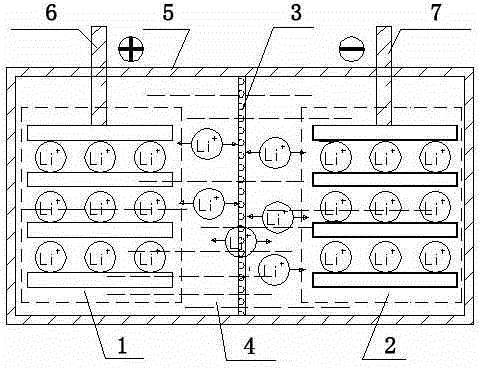

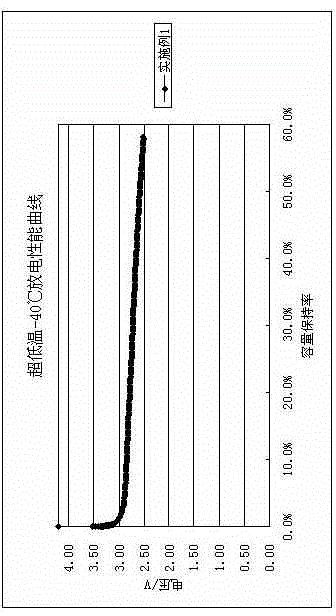

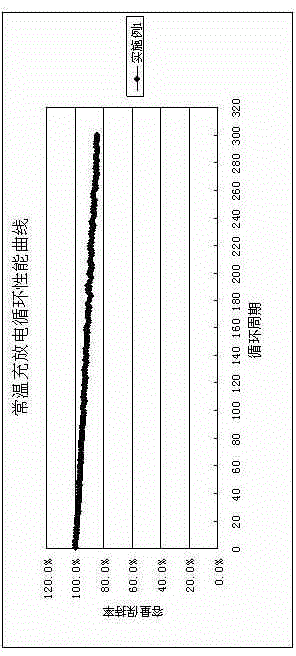

Lithium ion battery and lithium ion battery electrolyte for ultralow temperature discharge

ActiveCN102231442AWork lessImprove discharge performanceSecondary cellsElectrolytic agentMethyl carbonate

The invention relates to a lithium ion battery and a lithium ion battery electrolyte for ultralow temperature discharge. a lithium ion battery with the advantages of ultralow temperature discharge, stable performances and good cycle performance is not available at present. The invention is characterized in that the lithium ion battery electrolyte comprises lithium hexafluorophosphate, triethoxyboron, a low-melting-point additive and a quaternary solvent, wherein nitroethane and / or nitropropane is selected as the low-melting-point additive; the quaternary solvent consists of ethylene carbonate, DMC (dimethyl carbonate), ethyl methyl carbonate and dimethoxyethane; and the dimethoxyethane accounts for 0.8-10% of the total weight of the quaternary solvent. In the lithium ion battery electrolyte, the concentration of lithium hexafluorophosphate is 0.8-1.3mol / L, the mass percent of triethoxyboron is 0.2-8wt%, the mass percent of low-melting-point additive is 2-20wt% and the mass percent of quaternary solvent is 70-90wt%. The lithium ion battery is reasonable in structure design, can realize the ultralow temperature discharge, and has stable performances and good cycle performance.

Owner:HANGZHOU SKYRICH POWER CO LTD

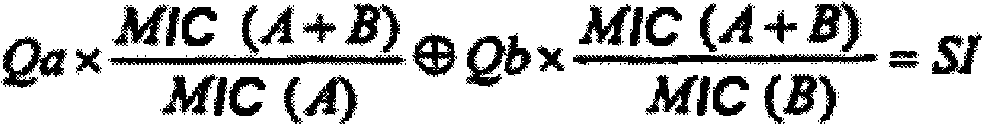

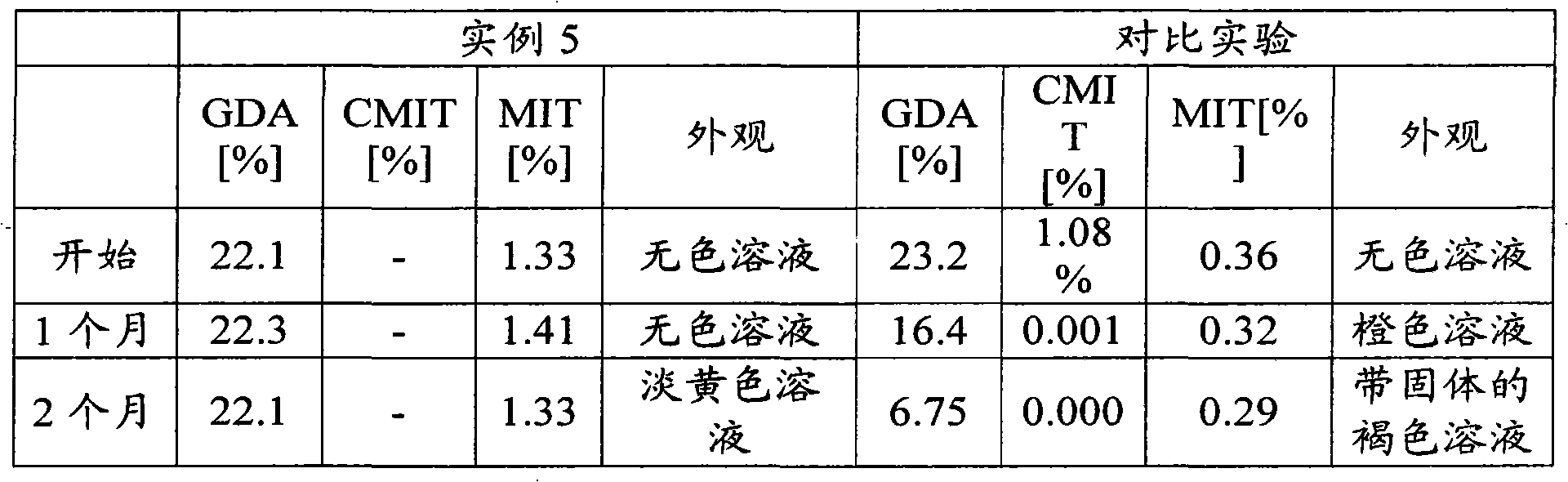

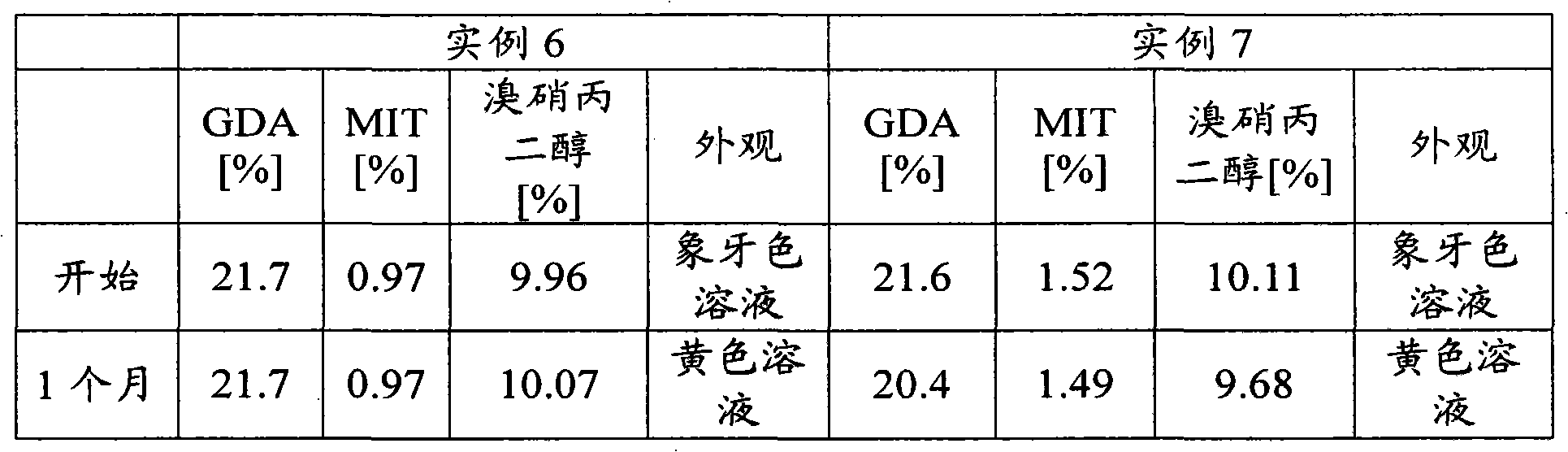

Stable, synergistic mixtures

The present invention relates to storage-stable, synergistically acting combinations comprising glutaraldehyde (GDA) and 2-methyl-2H-isothiazol-3-one (methylisothiazolinone, MIT) and, where appropriate, 2-bromo-2-nitropropane-1,3-diol (bronopol) and / or other active substances for protecting industrial materials.

Owner:LANXESS DEUTDCHLAND GMBH

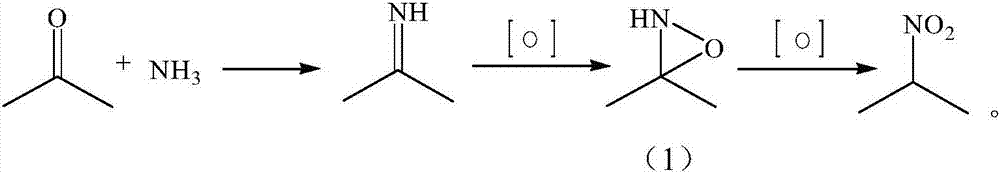

Synthesizing method of 2-nitropropane

ActiveCN106986772AMild reaction conditionsSimple processOrganic compound preparationImino compound preparationMass ratioCatalytic oxidation

The invention discloses preparation of substituted saturated hydrocarbon and particularly relates to a synthesizing method of 2-nitropropane. The 2-nitropropane is prepared by oxidizing isohydrazone. The synthesizing method includes the steps of S1, condensing acetone, water and ammonia in the presence of a catalyst to generate ketimine, wherein the mass ratio of the acetone to the water is 1:(1-5), and the use amount of the catalyst is 5-11% of the use amount of the acetone; S2, oxidizing the ketimine obtained in the step S1 to form the isohydrazone, wherein reaction system temperature is 30-60 DEG C and heat-preservation reaction time is 0.5-3 hours; S3, oxidizing the isohydrazone obtained in the step S2 to form the 2-nitropropane, wherein reaction system temperature is 50-80 DEG C and heat-preservation reaction time is 0.5-3 hours; rectifying obtained primary reaction liquid to obtain qualified 2-nitropropane products. The synthesizing method has the advantages that the acetone, the ammonia and the water are used as the initial raw materials, and the method is mild in catalytic oxidizing reaction condition, simple in process, convenient to operate, suitable for large-batch 2-nitropropane production, simple in post-processing and high in product purity and does not coproduce acetone oxime or acetone azine.

Owner:宁波四明化工有限公司

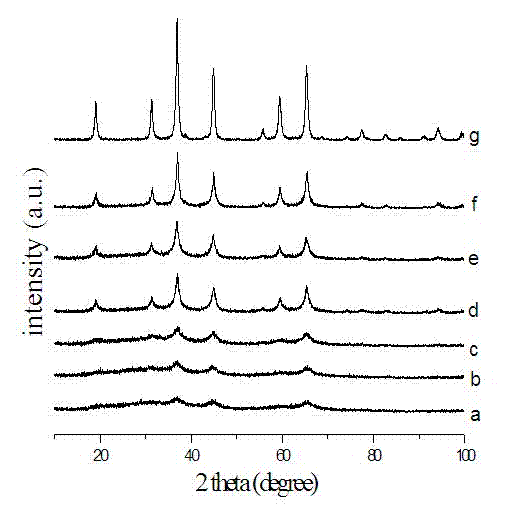

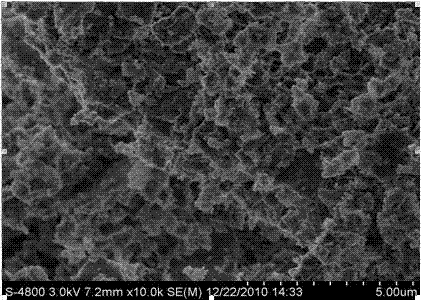

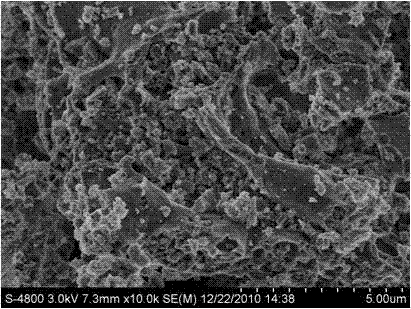

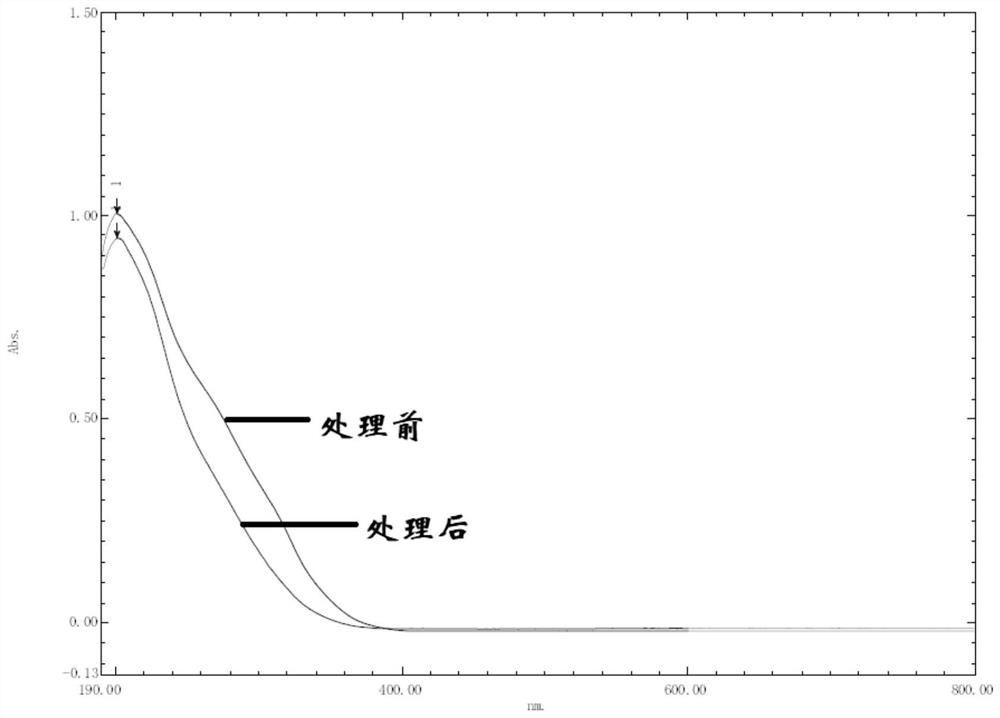

Visible light photocatalyst containing amorphous MgAl2O4 and preparation method thereof

InactiveCN102198395ALow costRapid responseWater/sewage treatment by irradiationCatalyst activation/preparationMethyl carbamatePtru catalyst

The invention discloses a visible light photocatalyst containing amorphous MgAl2O4 and a preparation method thereof. The visible light photocatalyst containing amorphous MgAl2O4 comprises 15 to 98 wt% of crystal MgAl2O4 and 2 to 85 wt% of amorphous MgAl2O4. The preparation method comprises the following steps: 1, treating urea as a fuel A and selecting one of glycine, methyl carbamate, 1-nitropropane, DL-alanine, L-alanine and beta-alanine as a fuel B; mixing magnesium nitrate, aluminium nitrate, the fuel A and the fuel B according to a molar ratio of 1:2:(1 to 8):(1 to 15), and fusing to a liquid through heating on an electric furnace; 2, forming a solid through carrying out complete combustion on the liquid by continuing heating; and 3, cooling the solid formed in step 2 to room temperature and grinding. So the visible light photocatalyst containing amorphous MgAl2O4 is obtained. The preparation method has the advantages of simple operation, short time and low cost, and is suitable for industrial large-scale production.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Plant enzyme cleaning bubble liquid preparation

InactiveCN108498447ARefreshing skinEasy to cleanCosmetic preparationsToilet preparationsBetaineCocoyl glutamate

The invention discloses a plant enzyme cleaning bubble liquid preparation which is prepared from the following components in parts by weight: 20-60 parts of glycerin, 10-40 parts of disodium cocoyl glutamate, 20-60 parts of coco fatty acid diethanol amide propyl betaine, 10-20 parts of coco fatty acid diethanol amide DEA, 5-20 parts of flos lonicerae extract, 5-20 parts of fructus cnidii extract,5-20 parts of radix sophorae flavescentis extract, 5-20 parts of herba portulacae extract, 5-20 parts of oat extract, 3-10 parts of lipase, 10-20 parts of bromelain, 5-15 parts of bacillus fermentation product, 5-15 parts of citric acid, 0.5-5 parts of 2-bromo-2-nitropropane-1,3-diol, 0.5-5 parts of methylisothiazolinone, 1-5 parts of rose essence and 300-600 parts of water. The invention also discloses a preparation method and application of the liquid preparation. The plant enzyme cleaning bubble liquid preparation has remarkable beverage removing and wrinkle reducing effects.

Owner:广州保妈优健康产业有限公司

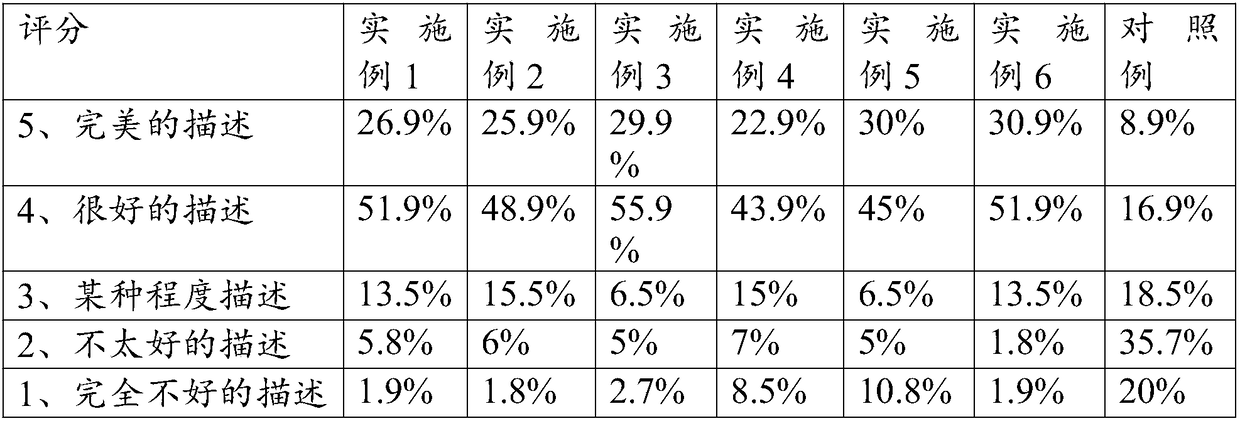

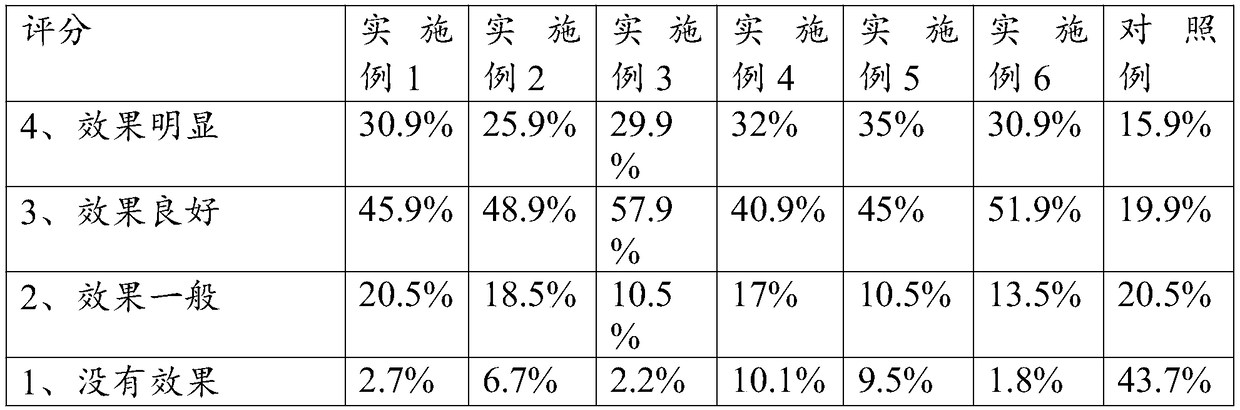

Anti-freckle cream and preparation method thereof

ActiveCN103566300ALow costSignificant effectAnthropod material medical ingredientsDermatological disorderVitamin CGLYCYRRHIZA EXTRACT

The invention discloses an anti-freckle cream prepared from the following raw materials: isohexadecane, olive fruit oil, stearyl alcohol, polydimethylsiloxane, glycerin stearate, cetearyl alcohol polyether-6, cetearyl alcohol polyether-25, propyl hydroxybenzoate, butanediol, 2-bromo-2-nitropropane-1, 3-diol, imidazolidinyl urea, deionized water, functional components of traditional Chinese medicines and vitamin C, wherein the functional components of traditional Chinese medicines include the following constituents: silkworm larva, olibanum, savia miltiorrhiza, panax pseudoginseng, liquorice, cortex fraxini, turmeric and sambucus williamsii hance. The functional components of the traditional Chinese medicines in the anti-freckle cream are screened by adopting the syndrome differentiation theory of the traditional Chinese medicine and combining many-year clinical experience according to a freckle forming principle. The anti-freckle cream disclosed by the invention is low in cost, remarkable in curative effect and capable of achieving the aims of regulating qi and blood, dredging channels, activating blood and dissolving stasis as well as nourishing qi and blood, so that freckles are fundamentally treated.

Owner:TIANJIN JIASHITANG SCI & TECH

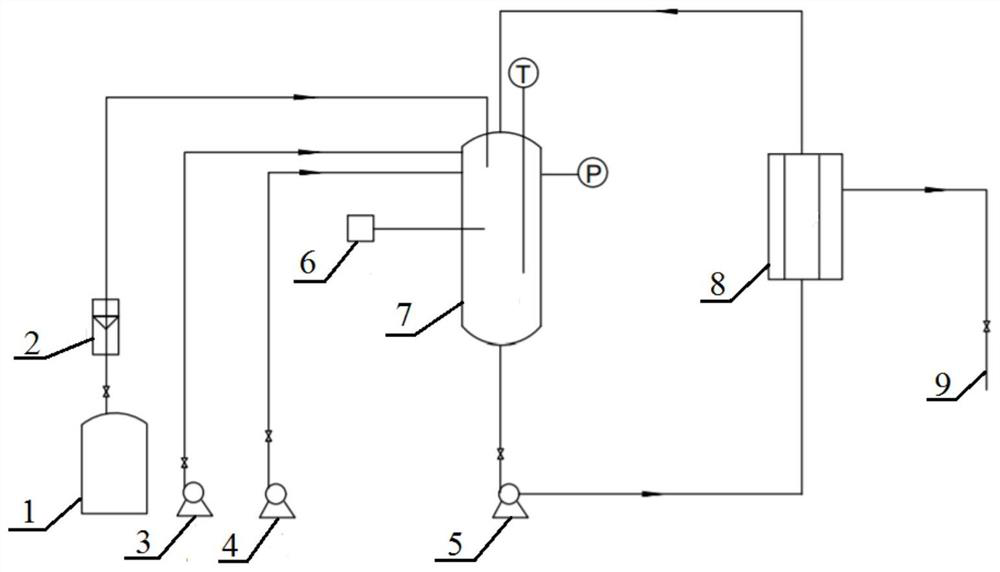

Safe method for preparing nitropropane by vapor-phase nitration

InactiveCN102079710AProcess Safety ContinuityReduce power consumptionNitro compound preparationGas phaseNitration

The invention relates to a safe method for preparing nitropropane by vapor-phase nitration, which comprises the following steps: carrying out reaction in a single-channel reactor, wherein after the reaction material propane enters a preheating pipe via a flowmeter and is mixed with pumped nitric acid in a mixing pipe, the mixed materials are sent into a reaction pipe, and the mol ratio of the propane to the nitric acid is controlled at (1-8):1; the mixed materials are subjected to nitration reaction by mass transfer and heat transfer in the reaction pipe, and the products enter a separator; and the reaction products stand in the separator until the reaction products stratify, the organic phase is separated from the water phase, and the organic phase is washed and dried to obtain the product. By using the invention, the propane and the nitric acid can be directly synthesized into various nitroparaffins under the condition of no catalyst, and the process is safe and continuous. The masstransfer and heat transfer are completed in the single channel without additional heat dissipation, thereby reducing the power consumption. The invention has the advantage of simple structure and is easy to operate. The conversion rate of the propane is higher than 20%, and the selectivity of the nitropropane is higher than 80%.

Owner:中国科学院嘉兴绿色化学工程中心 +2

Additive formulation and method of using same

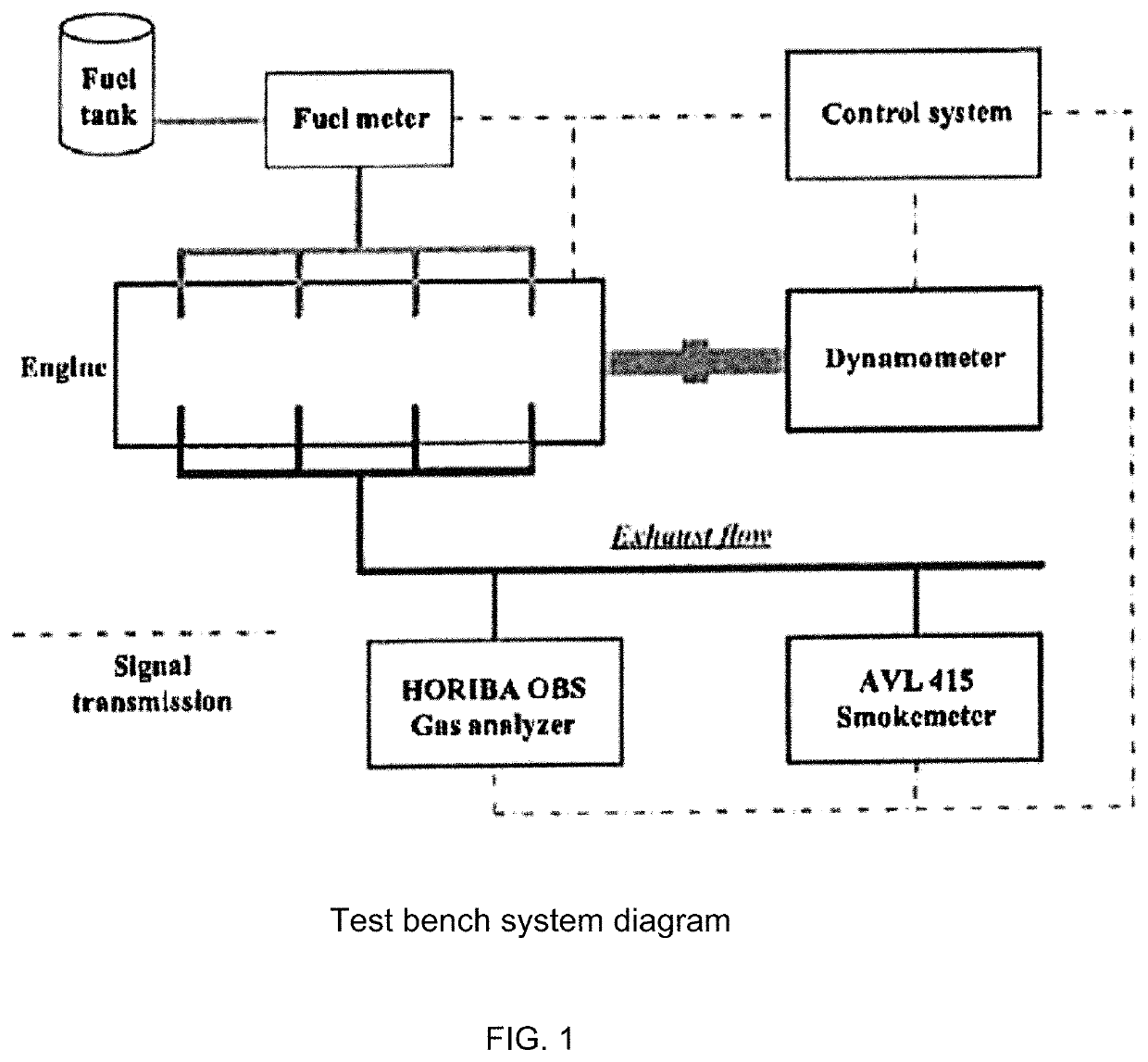

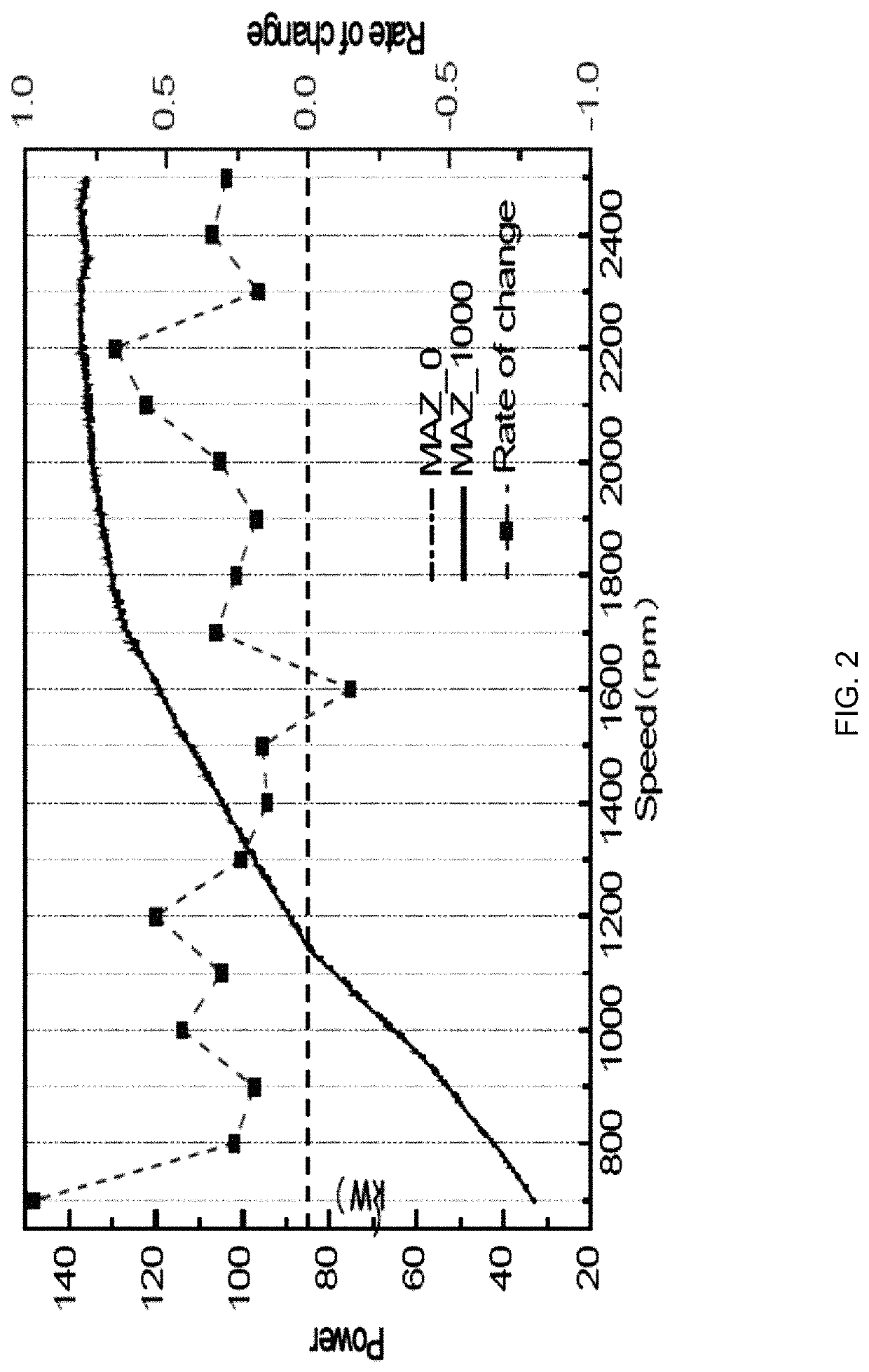

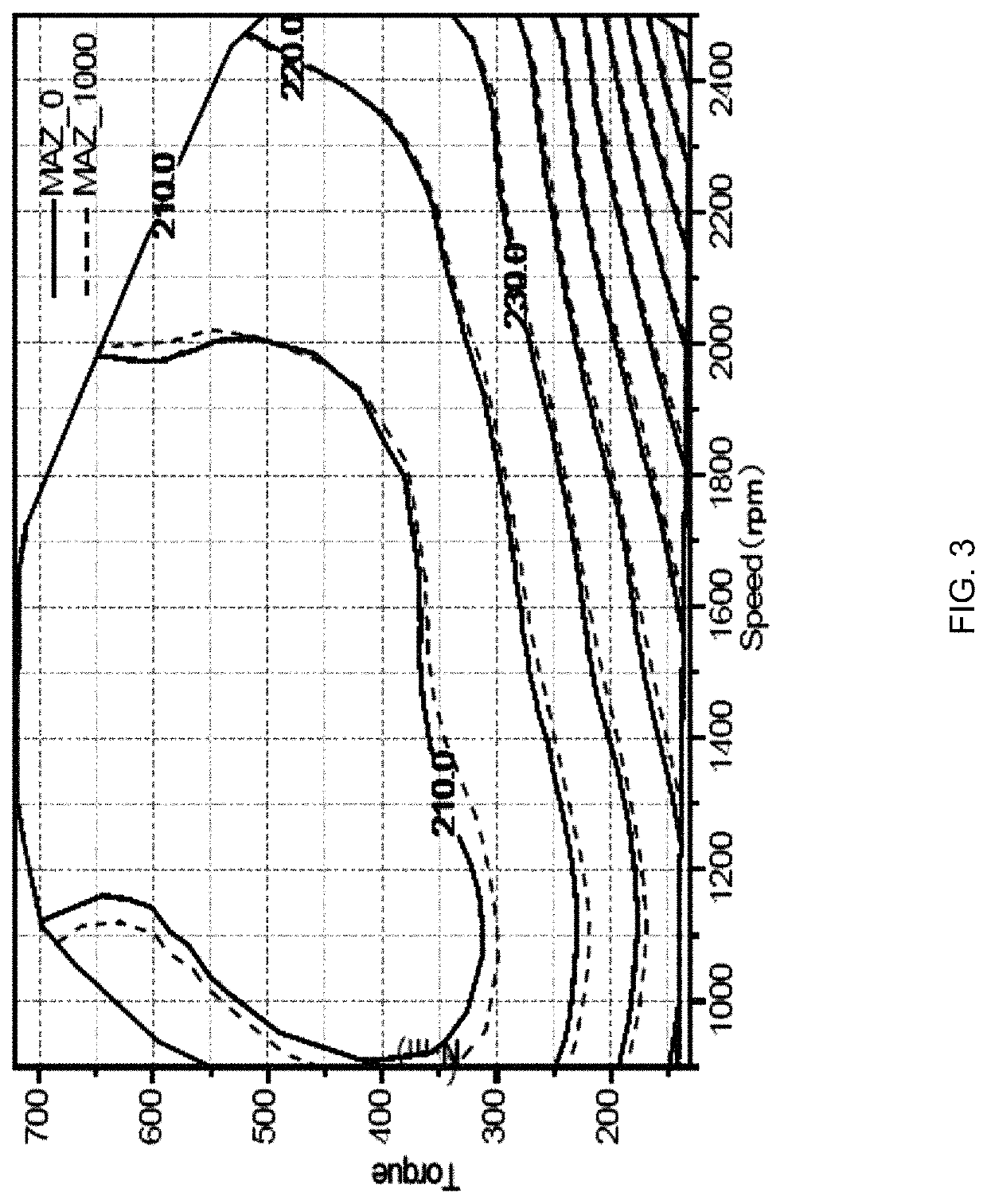

ActiveUS10752854B1Improve performanceEmission reductionLiquid carbonaceous fuelsFuel additivesAlkaneNitroalkane

A fuel additive formulation, method of use, and method of producing the fuel additive formulation are described. The fuel additive of the present disclosure comprises a mixture of nitroparaffins comprising nitropropane and nitromethane, a lubricant, and an aromatic hydrocarbon. The fuel additive formulation is substantially free of nitroethane. The combustion in an internal combustion engine of a fuel containing the additive results in reduced emissions relative to the combustion of a fuel not containing the additive.

Owner:MAZOIL TECH LTD

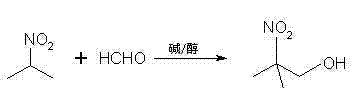

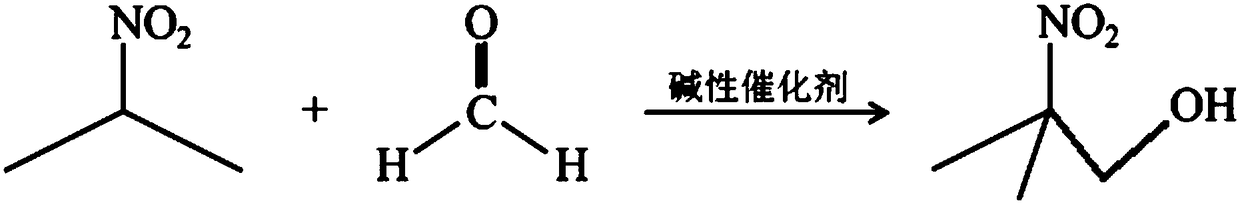

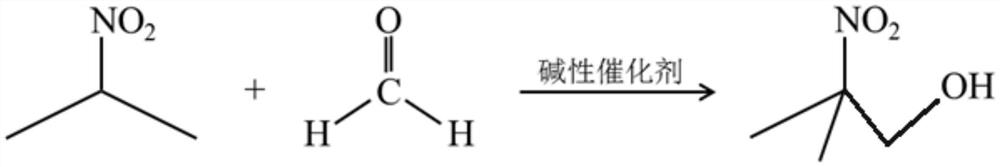

Method for preparing 2-nitro-2-methyl-1-propanol

ActiveCN104262160AReduce consumptionFacilitate continuous productionOrganic chemistryOrganic compound preparationPropanolAlcohol

The invention relates to a method for preparing 2-nitro-2-methyl-1-propanol. The method comprises the following steps: (1) dissolving an alkali in an alcohol solvent to obtain a solution and dissolving paraformaldehyde in the solution to obtain a dissolving solution, wherein the mass ratio of alcohol to alkali to paraformaldehyde is equal to 1: (0.005-0.05): (0.2-2); (2) adding the dissolving solution into 2-nitropropane for reacting, after the reaction is completed, neutralizing with an acid and then filtering to obtain a filtrate, wherein the molar ratio of 2-nitropropane to paraformaldehyde in the step (1) is equal to 1: (0.5-2); and (3) distilling the filtrate under reduced pressure to obtain 2-nitro-2-methyl-1-propanol crystals. The method is simple in process and is easily operated, and the yield of the product is high. Since alcohol is used as a solvent, the energy consumption during the concentration is reduced and the industrial continuous production is easily achieved.

Owner:NANJING BAOCHUN CHEMICAL INDUSTRY CO LTD

PU matte color repairing golden oil and preparation process thereof

The invention discloses PU matte color repairing golden oil and a preparation process thereof. The process comprises the following steps: feeding styrene modified alkyd resin and cyclohexanone into a dispersion cylinder, switching on a stirring device switch, regulating the rotating speed to be 1,000 revolutions per minute, and continuously performing stirring for 5 to 8 minutes; feeding matting powder, increasing the stirring rotating speed to be 1,500 revolutions per minute, and continuously performing stirring for 15 minutes; feeding nitrocotton, nitropropane and absolute ethyl alcohol, lowering the stirring rotating speed to be 1,000 revolutions per minute, and continuously performing stirring for 8 to 10 minutes; feeding polyamide wax, a leveling agent, an antifoaming agent and butyl acrylate, lowering the rotating speed to be 800 revolutions per minute, and continuously performing stirring for 5 minutes; discharging the product after dispersion is determined to be completed. According to the PU matte color repairing golden oil and the preparation process thereof, the performance such as leveling performance, cracking resistance and floating resistance is improved to a certain extent compared with that of a similar product; moreover, the PU matte color repairing golden oil is more environment-friendly, and has higher stability.

Owner:YINGDE YAJIA PAINT

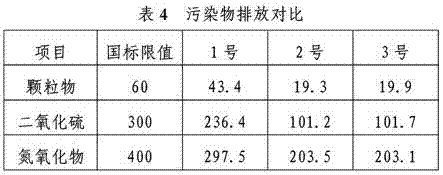

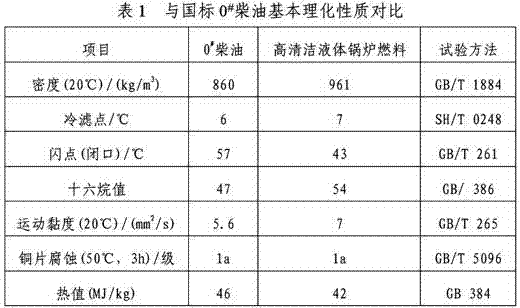

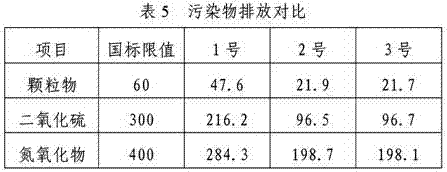

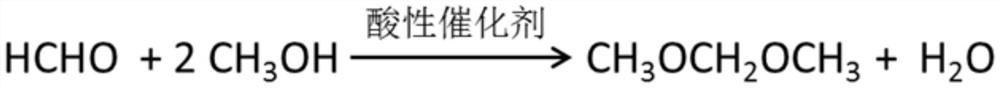

High-cleanness liquid boiler fuel

InactiveCN106947549AEmission reductionHigh calorific valueLiquid carbonaceous fuelsEthylene glycol monophenyl etherAlkylphenol

The invention relates to high-cleanness liquid boiler fuel. The fuel is prepared by blending following raw materials by volume: 60-80% of polymethoxymethylal, 13-29.5% of heavy naphtha, 5-10% of fatty acid methyl ester and 0.5-2% of an additive. The additive includes, by mass, 10-20% of alkylphenol barium, 10-20% of 2,6-bis(1,1-dimethylethyl)-4-methylphenol, 50-75% of nitropropane, 2.5-5% of ethylene glycol monophenyl ether, 1.25-2.5% of trimethyl borate and 1.25-2.5% of N,N'-bis(salicylidene)-1,2-propanediamine. The calorific value of the fuel is substantially equivalent to the calorific value of Chinese national standard 0# diesel oil, consumption amounts of the fuel and the diesel oil are at the same level, but SO2 in combustion emission of the fuel is reduced by about 60% than that of the diesel oil, NOx in combustion emission of the fuel is reduced by 30% or above than that of the diesel oil, and particles in combustion emission of the fuel are reduced by about 50% or above than those of diesel oil, and therefore cleanness of the fuel is significantly improved.

Owner:TAIYUAN NORMAL UNIV

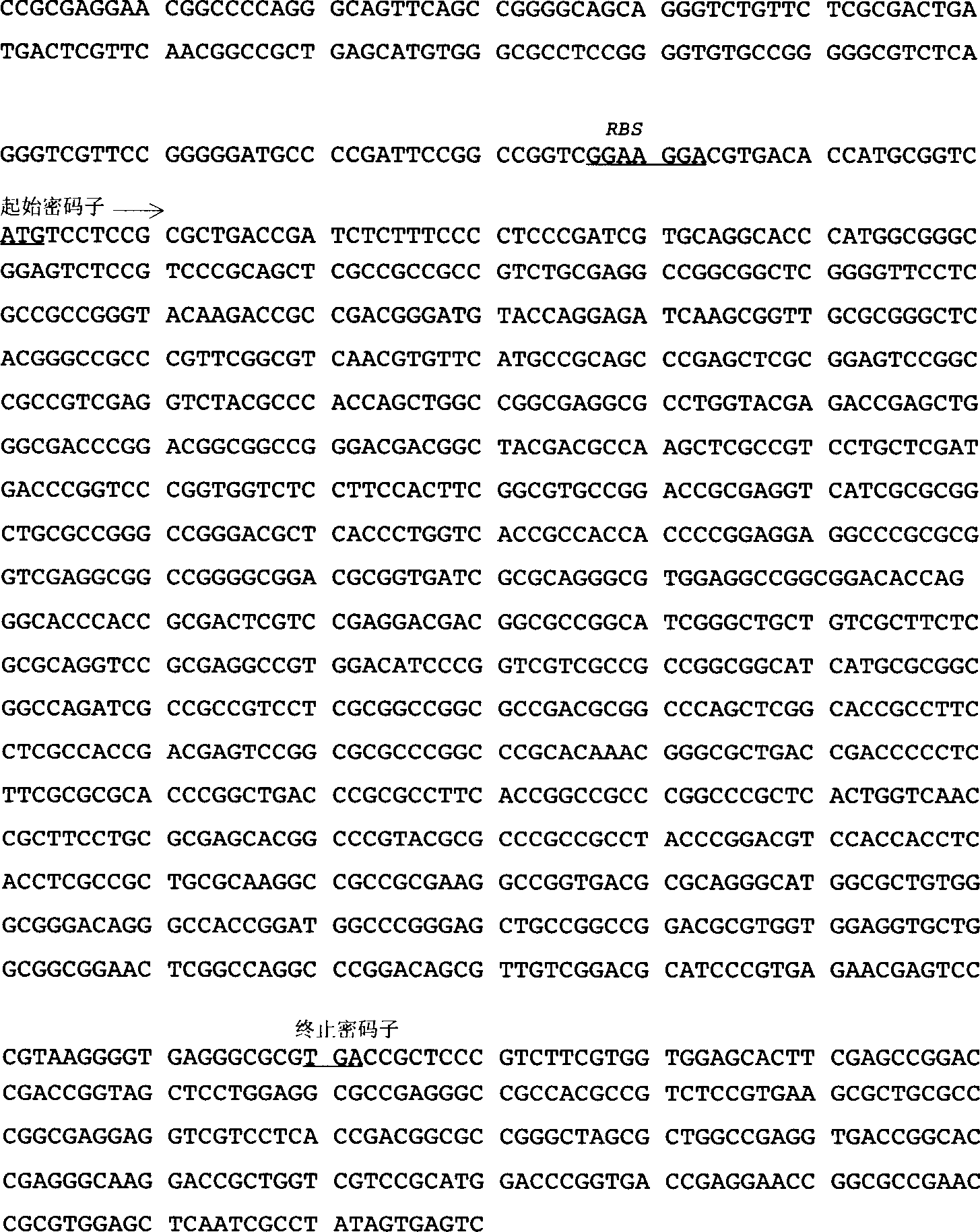

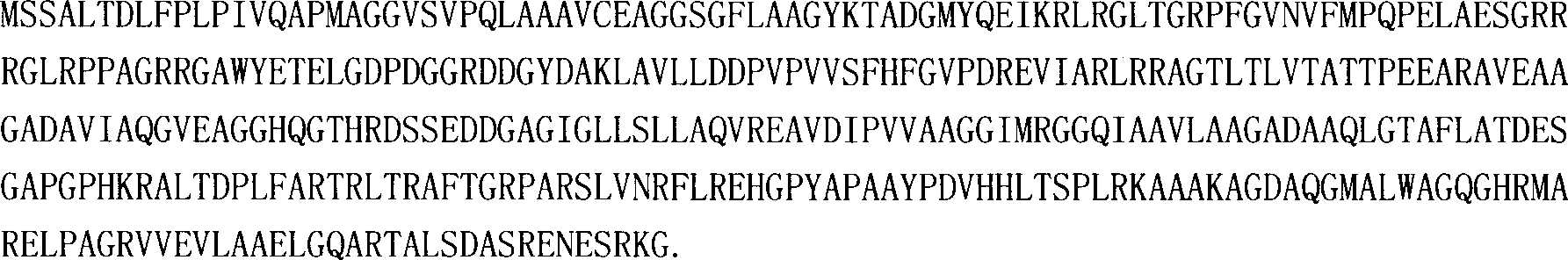

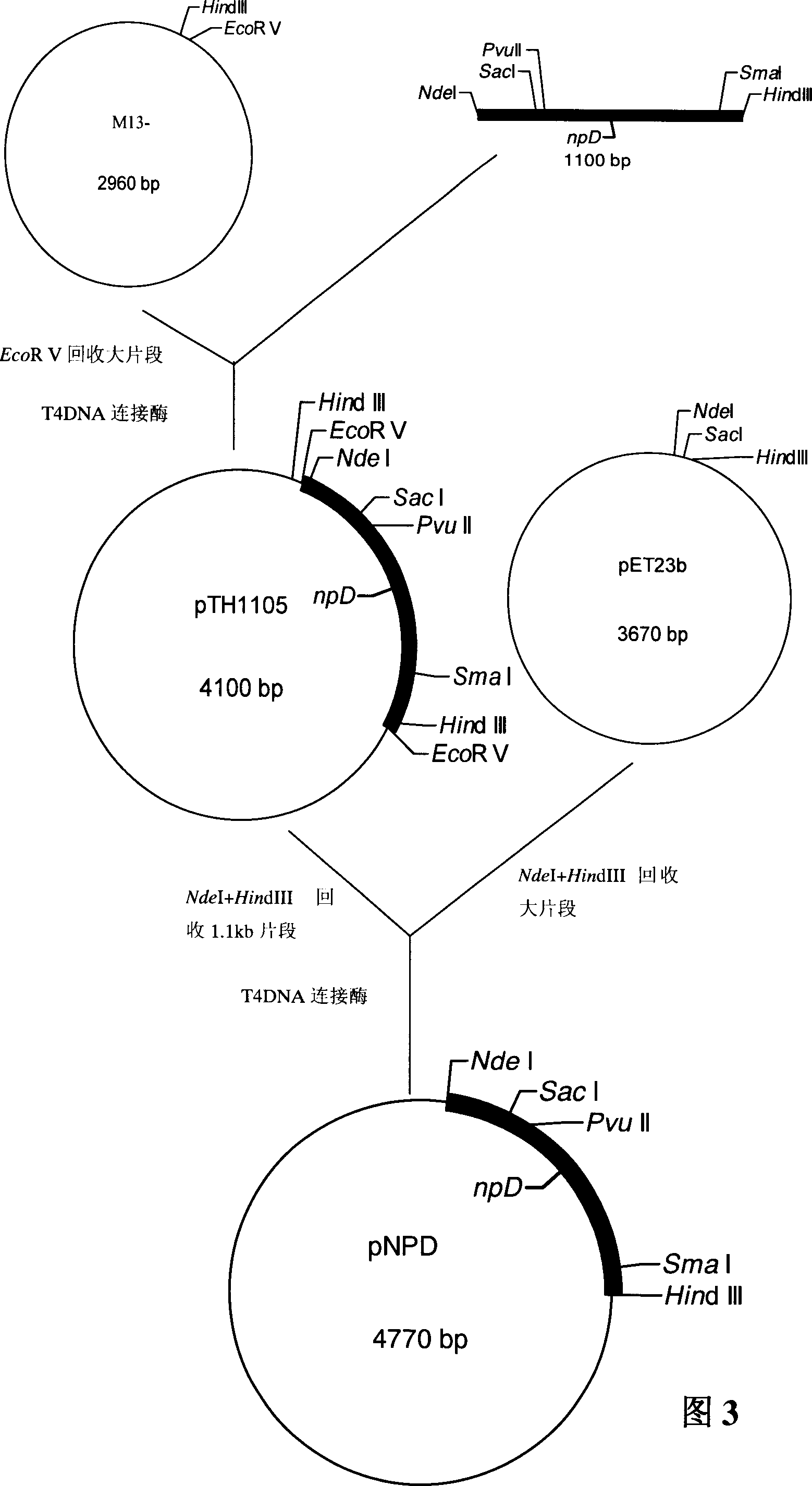

Streptomycete 2-nitropropane dioxyenase gene and its application

The present invention relates to the application of environmental microbe. Especially, by means of molecular technology, one new gene is cloned from Streptomyces ansochromogenes 7100 and the gene encodes one kind of 2-streptomycete dioxyenase. The encoded product has great value in biologically degrading industrial pollutant nitroalkane and in improving environment.

Owner:INST OF MICROBIOLOGY - CHINESE ACAD OF SCI

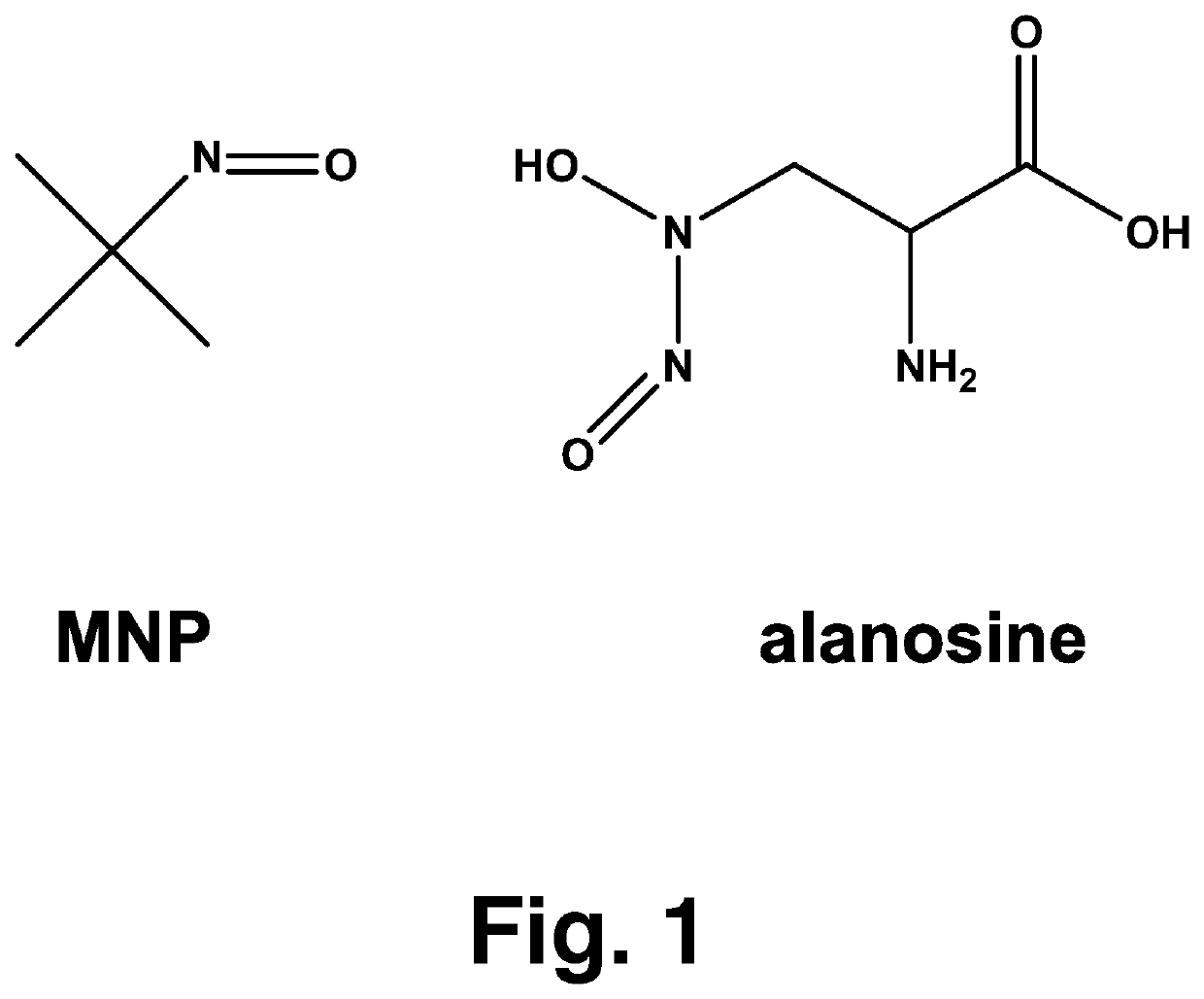

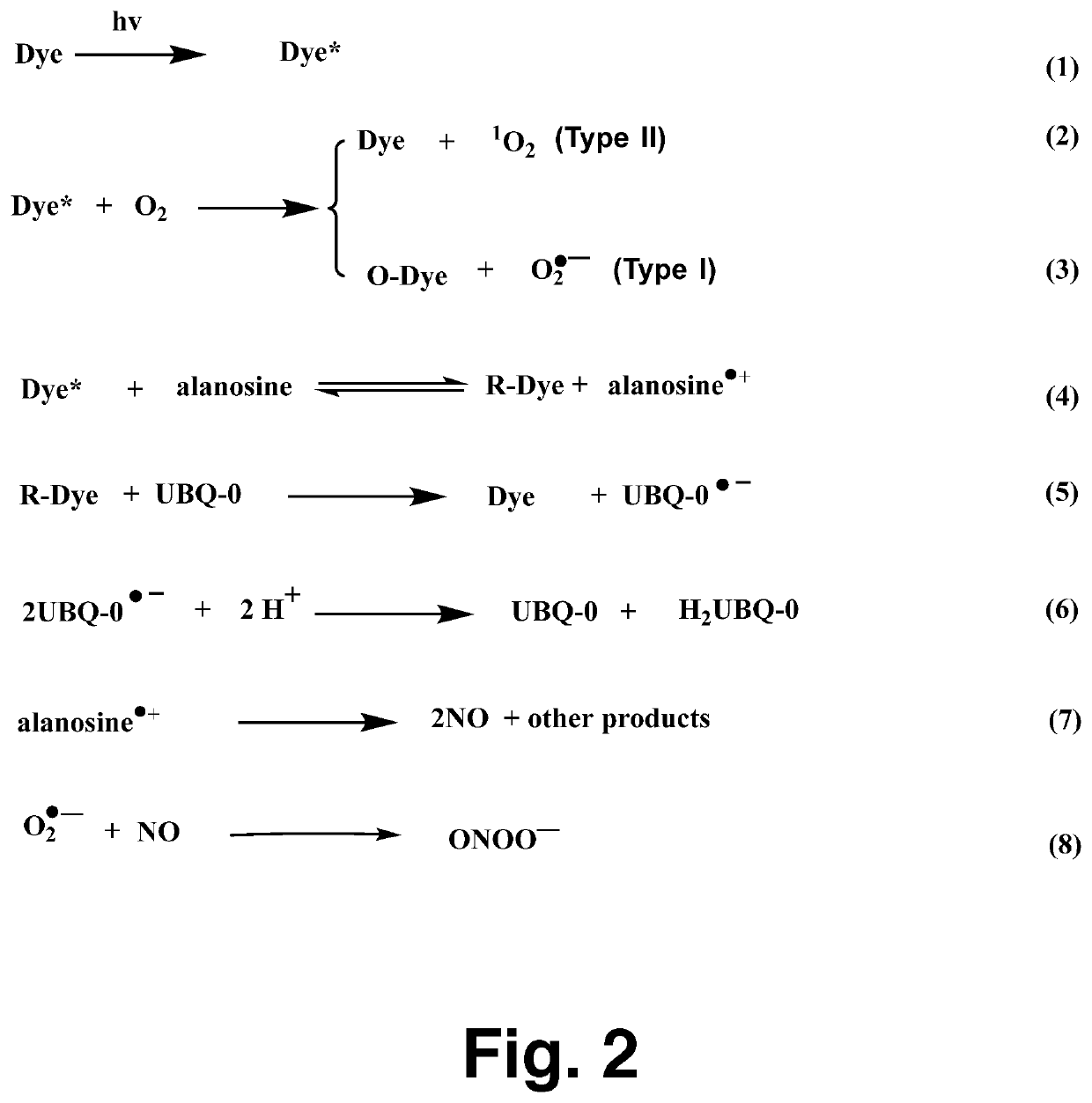

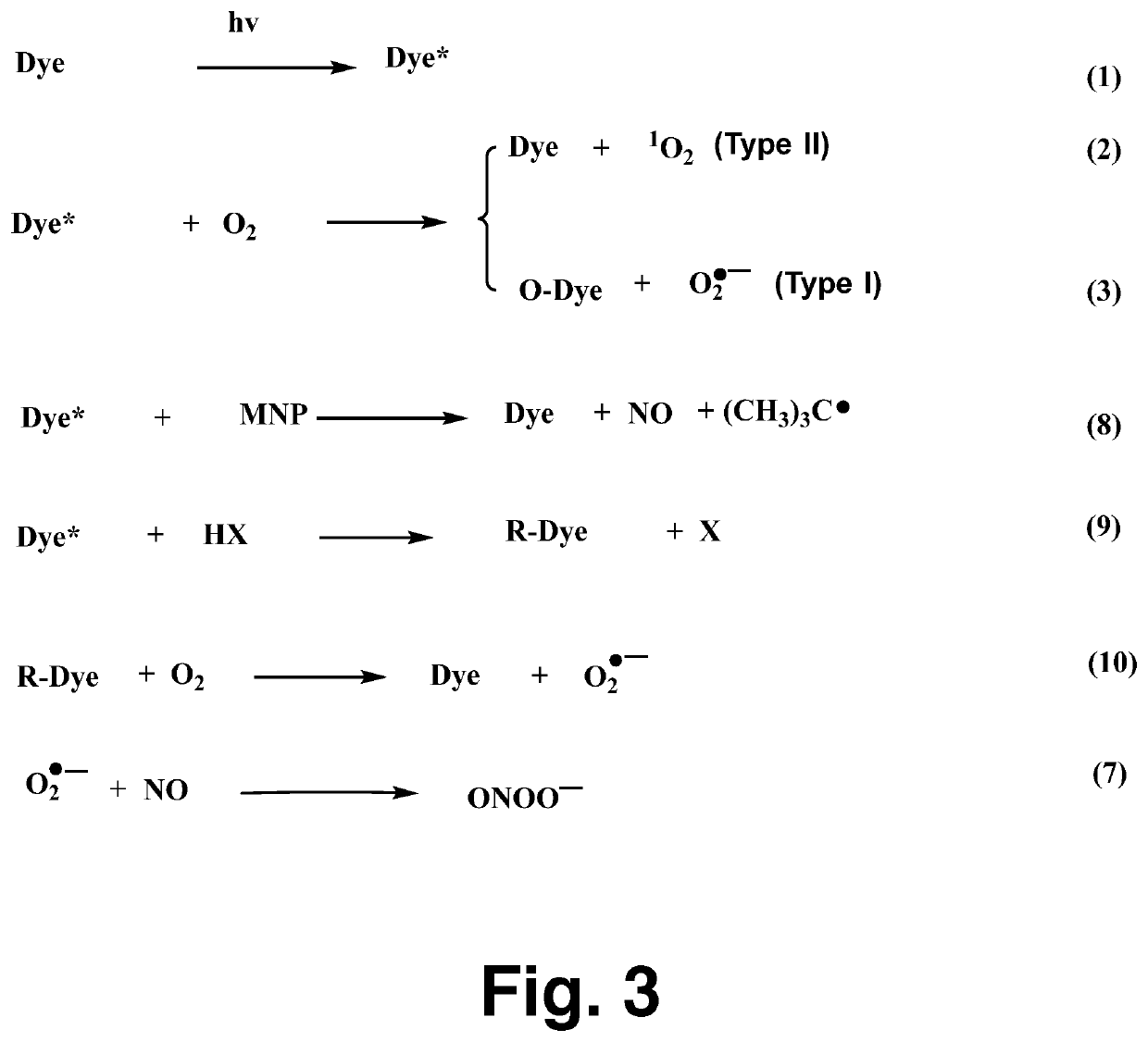

Photosensitized release of nitric oxide

The invention proposes the photosensitized generation of nitric oxide (NO) from alanosine (3-(hydroxynitrosoamino)-D,L-alanine) by aluminum phthalocyanine tetrasulfonate (AlPcS4). While NO is obtained in nitrogen-saturated solutions, the invention proposes that both NO and peroxynitrite are produced in air-saturated solutions. Enhancement of NO production occurs in the presence of ubiquinone-0. The invention evidence that NO is produced by the photosensitized oxidation of alanosine. Both NO and peroxynitrite are detected during photoirradiation of AlPcS4 in the presence of 2-methyl-2-nitrosopropane (MNP) and hypoxanthine, but not in the absence of hypoxanthine, in air-saturated solutions, where HX is acting as sacrificial electron donor, thus promoting superoxide formation.

Owner:UNIVERSITY OF PUERTO RICO

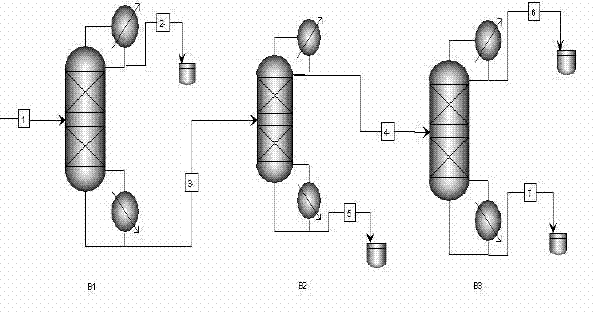

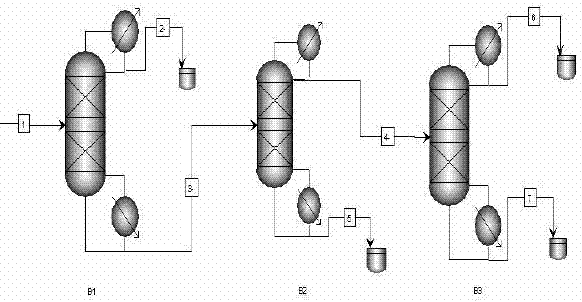

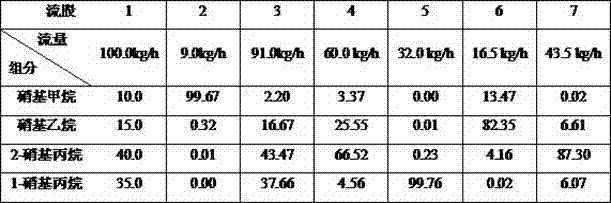

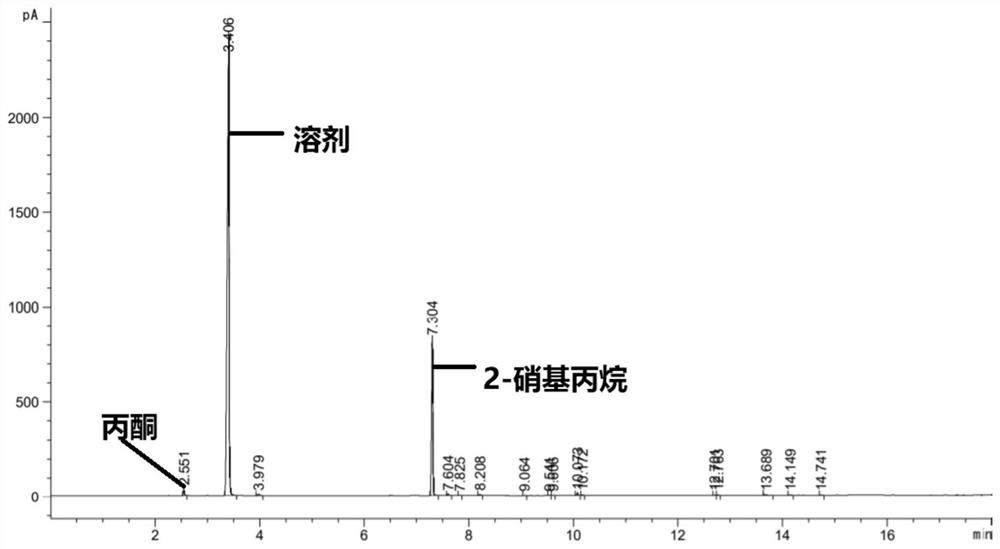

Method for orderly rectifying and separating nitromethane-nitroethane-nitropropane by continuous three towers

InactiveCN102229535AIncrease contentHigh yieldOrganic chemistryOrganic compound preparationTowerDistillation method

The invention relates to a method for orderly rectifying and separating nitromethane-nitroethane-nitropropane by continuous three towers, the raw material (an mixed solution of nitromethane, nitroethane,2-nitropropane and 1-nitropropane) is separated through a first continuous rectifying tower at first(B1), the content of the separated nitromethane on the top of the tower can reach over 99.5%, a distillate from the bottom is separated through the second continuous rectifying tower (B2), the content of the separated 1-nitropropane at the bottom of the tower can reach over 99.5%, the once through yields are respectively reach to 89.7% and 91.2%; a distillate from top of a second continuous rectifying tower (B2) is entered into a third continuous rectifying tower (B3) for separating nitroethane and 2-nitropropane, the content of nitroethane can reach above 82.0%, the content of 2-nitropropane can reach above 87.0%. Compared with the multi-times distillation method in the prior art, the separated product content and yield rate of the method provided in the invention are higher than that of the multi-times distillation method.

Owner:NANJING NORMAL UNIVERSITY

Preparation method of impregnation liquid for refreshing wet tissue

The invention discloses a preparation method of an impregnation liquid for refreshing wet tissue. The refreshing wet tissue is obtained by: proportionally mixing ethyl alcohol, menthol, menthyl lactate, PEG-40 castor oil, polyaminopropyl biguanide, lauryl pyridinium chloride, 2-bromo-2-nitropropane-1,3-diol and caffeine to obtain the impregnation liquid of wet tissue and padding tissue nonwoven with the impregnation liquid. Compared with traditional wet tissues, the wet tissue produced using the impregnation liquid of the invention has health functions of refreshing and skin moisturizing, can be used daily to provide fatigue relief and meets the requirements of modern high-quality market.

Owner:黄桂洪

Preparation method of 2-nitro-2-methyl-1-propanol crystal

ActiveCN108976128AReduce typesLow costOrganic chemistryOrganic compound preparation1-PropanolMethyl group

The invention provides a preparation method of a 2-nitro-2-methyl-1-propanol crystal. According to the method, 2-nitro-2-methyl-1-propanol is prepared through a reaction between 2-nitropropane and paraformaldehyde, the residual formaldehyde is removed with an acidic solid catalyst, and the product is subjected to secondary purification with cyclohexane so as to obtain the 2-nitro-2-methyl-1-propanol crystal, wherein the purity is up to 99.8-99.99%, and the residual formaldehyde is 5-200 ppm; and the conversion rate of the reaction based on 2-nitropropane can be 98-99.7%, and the final yield after the secondary purification is 90-97%.

Owner:BEIJING RISUN TECH CO LTD

A kind of preparation method of 2-nitro-2-methyl-1-propanol crystal

ActiveCN108976128BReduce typesLow costOrganic chemistryOrganic compound preparationPropanolPtru catalyst

The invention provides a preparation method of a 2-nitro-2-methyl-1-propanol crystal. According to the method, 2-nitro-2-methyl-1-propanol is prepared through a reaction between 2-nitropropane and paraformaldehyde, the residual formaldehyde is removed with an acidic solid catalyst, and the product is subjected to secondary purification with cyclohexane so as to obtain the 2-nitro-2-methyl-1-propanol crystal, wherein the purity is up to 99.8-99.99%, and the residual formaldehyde is 5-200 ppm; and the conversion rate of the reaction based on 2-nitropropane can be 98-99.7%, and the final yield after the secondary purification is 90-97%.

Owner:BEIJING RISUN TECH CO LTD

Lithium ion battery and lithium ion battery electrolyte for ultralow temperature discharge

ActiveCN102231442BWork lessImprove discharge performanceSecondary cellsElectrolytic agentMethyl carbonate

The invention relates to a lithium ion battery and a lithium ion battery electrolyte for ultralow temperature discharge. a lithium ion battery with the advantages of ultralow temperature discharge, stable performances and good cycle performance is not available at present. The invention is characterized in that the lithium ion battery electrolyte comprises lithium hexafluorophosphate, triethoxyboron, a low-melting-point additive and a quaternary solvent, wherein nitroethane and / or nitropropane is selected as the low-melting-point additive; the quaternary solvent consists of ethylene carbonate, DMC (dimethyl carbonate), ethyl methyl carbonate and dimethoxyethane; and the dimethoxyethane accounts for 0.8-10% of the total weight of the quaternary solvent. In the lithium ion battery electrolyte, the concentration of lithium hexafluorophosphate is 0.8-1.3mol / L, the mass percent of triethoxyboron is 0.2-8wt%, the mass percent of low-melting-point additive is 2-20wt% and the mass percent of quaternary solvent is 70-90wt%. The lithium ion battery is reasonable in structure design, can realize the ultralow temperature discharge, and has stable performances and good cycle performance.

Owner:HANGZHOU SKYRICH POWER CO LTD

Preparation method of pore-tendering astringent water

PendingCN112315876ALong-lasting skin rejuvenationReduce aging speedCosmetic preparationsToilet preparationsTrichosanthes kirilowiiHydroxamic acid

The invention discloses a preparation method of pore-tendering and astringent water. The preparation method comprises the following steps of taking 90-110 parts of water, 1-10 parts of butanediol, 0.1-2 part of carbomer, 0.1-2 part of aminomethyl propanol, 0.1-1 part of a trichosanthes kirilowii maxim extract, 0.1-1 part of a cherokee rose fruit extract, 0.1-1 part of a pomelo fruit extract, 0.1-1part of a persimmon fruit extract, 1-5 parts of butanediol, 0.1-1 part of a hamamelis virginiana extract, 0.1-1 part of sodium hyaluronate, 0.1-1 part of ginkgo leaf extract, 0.1-1 part of moso bamboo leaf extract, 0.1-1 part of capryloyl hydroxamic acid, 0.1-1 part of 2-bromine 2-nitropropane-1,3-diol and 0.1-1 part of butanediol to prepare the astringent water. The fructus trichosanthis extract, the black cherry fruit extract, the pomelo fruit extract and the persimmon fruit extract are added into the astringent water, so that the astringent water has a lasting skin tendering effect duringuse, anthocyanin and procyanidine which are high in oxygen free radical absorption capacity and oxidation resistance are contained in the additive, so that the skin aging speed is reduced, and the skin of people can be continuously beautified.

Owner:广州市古得化妆品有限公司

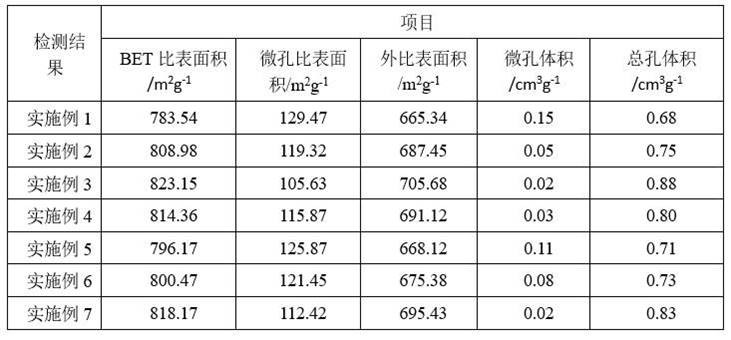

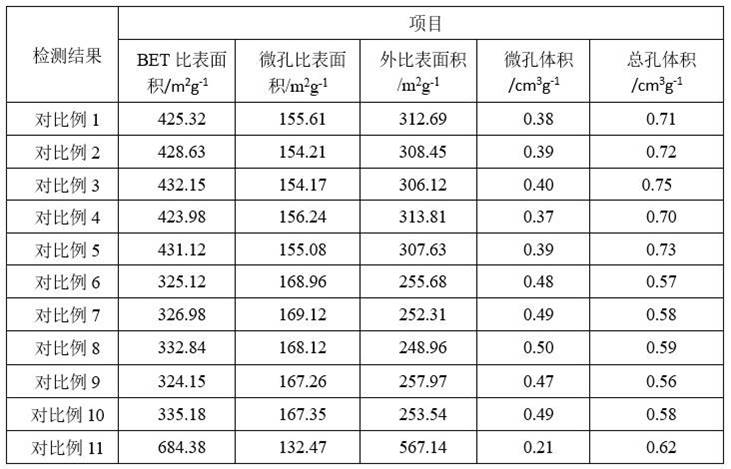

Preparation method of durable and stable titanium silicalite molecular sieve catalyst for producing 2-nitropropane

ActiveCN112624138AFacilitated DiffusionReduce inactivationMolecular sieve catalystsCatalyst activation/preparationCelluloseMolecular sieve

The invention relates to the field of chemical materials, and particularly discloses a preparation method of a durable and stable titanium silicalite molecular sieve catalyst for producing 2-nitropropane. The durable and stable titanium silicalite molecular sieve catalyst is prepared by the following steps: S1, taking wood pulp as a raw material, carrying out acidolysis modification and dissolving treatment to prepare a cellulose solution; S2, dropwise adding the cellulose solution serving as a main raw material into regenerated liquid to prepare a cellulose microsphere template; S3, calcining the cellulose solution to obtain a matrix carbon aerogel template; S4, preparing a catalyst material by using the cellulose microsphere template and the matrix carbon aerogel template; and S5, respectively removing the cellulose microsphere template and the matrix carbon aerogel template to prepare the durable and stable titanium silicalite molecular sieve catalyst for producing 2-nitropropane. According to the durable and stable titanium silicalite molecular sieve catalyst, the catalyst deactivation phenomenon caused by pore channel blockage is improved, the service life of the catalyst is prolonged, and the durability of a catalyst material is improved.

Owner:宁波四明化工有限公司

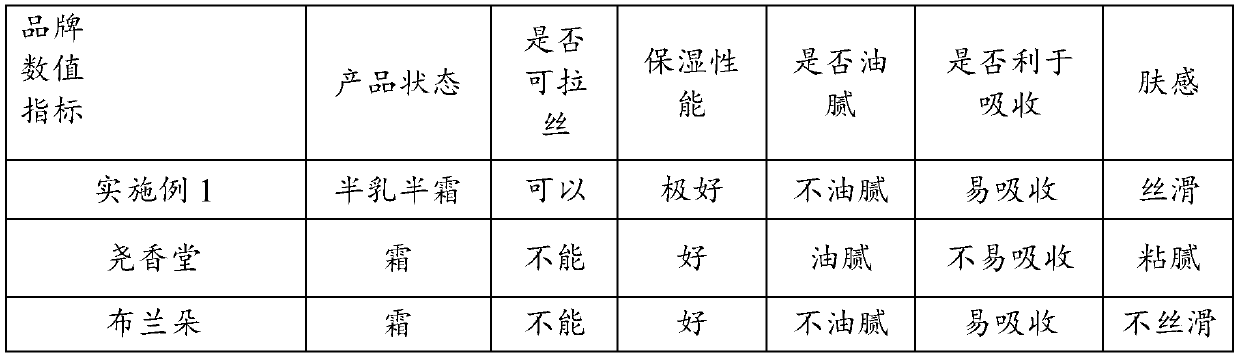

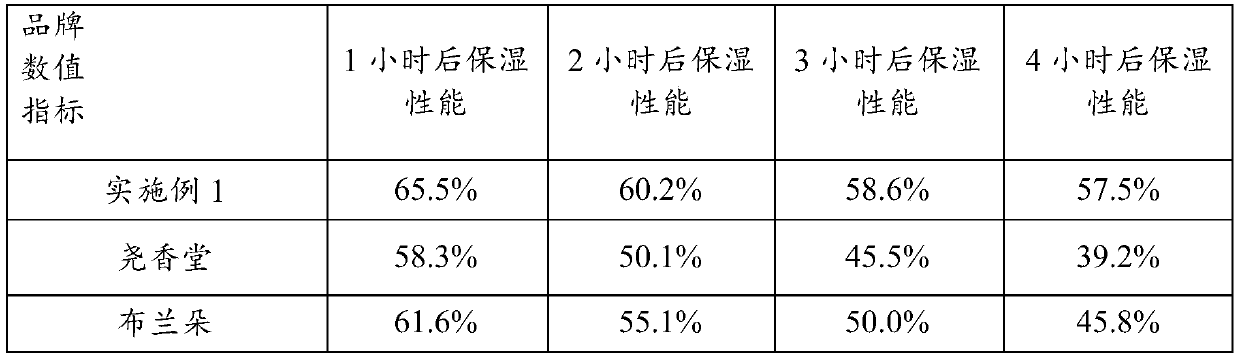

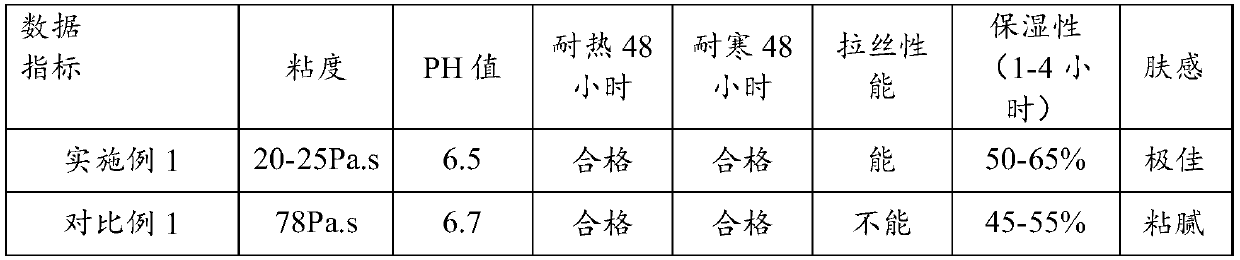

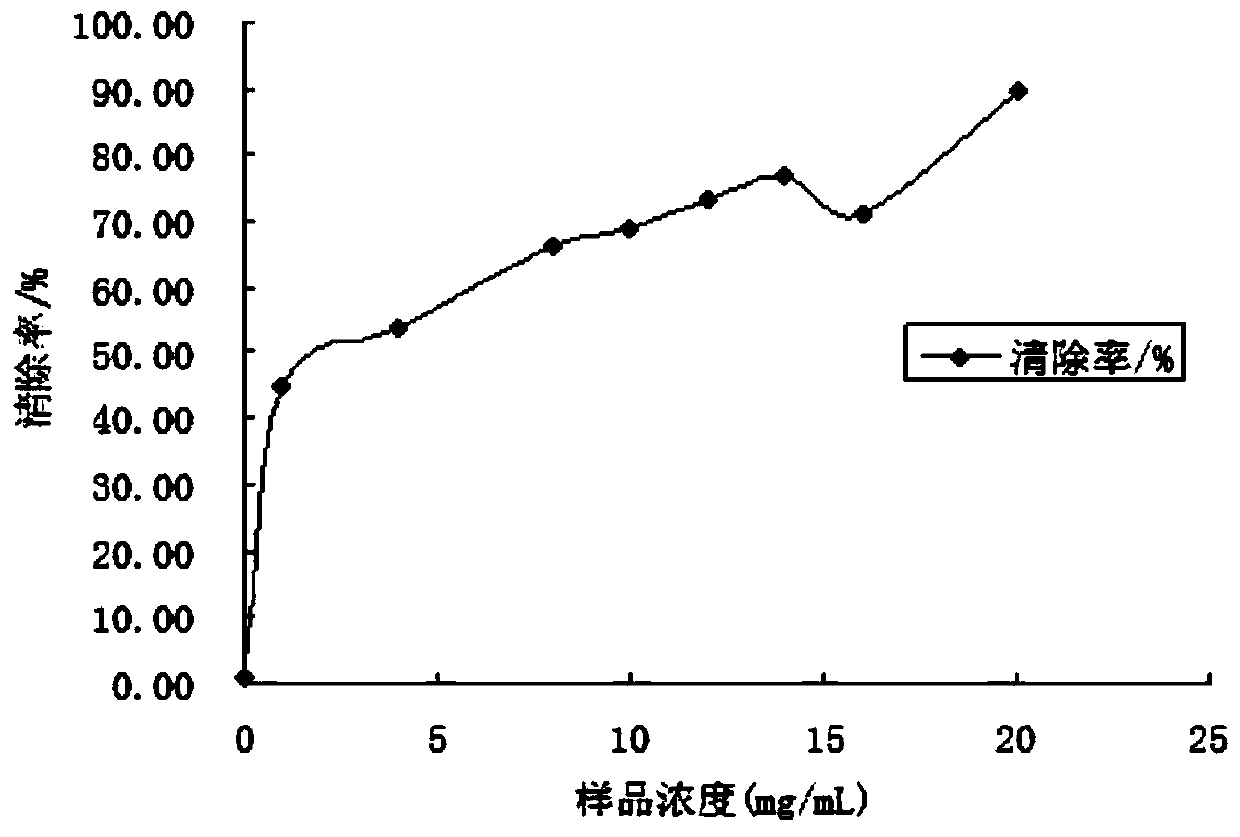

Coconut oil cream containing coconut oil and preparation method of coconut oil cream

InactiveCN110917072APrevent agingIncrease elasticityCosmetic preparationsToilet preparationsHydroxamic acidGlycerol

The invention relates to the technical field of cosmetics, in particular to a coconut oil cream containing coconut oil and a preparation method of the coconut oil cream. The coconut cream consists ofglycerin, coconut oil, isononyl isononanoate, trehalose, hydroxyethyl acrylate / sodium acryloyldimethyl taurate copolymer, cetearyl alcohol, polydimethylsiloxane, polydimethylsiloxane alcohol, sodium acrylate / sodium acryloyldimethyl taurate copolymer, isohexadecane, polysorbate-80, carbomer, triethanolamine, alpha-arbutin, allantoin, sodium hyaluronate, sodium polyacrylate, capryloyl hydroxamic acid, propylene glycol, 2-bromo-2-nitropropane-1,3-diol, essence and water. According to the preparation method, the coconut oil is compounded with high-molecular water-soluble polymers, so that the prepared product has good drawing performance, and can be beaten to form a rain mist shape; has good moisturizing effect; is non-greasy and silky; is easy to absorb; has an emollient effect on the skin, and can prevent skin aging and increase skin elasticity.

Owner:HAINAN OPEARL BIOLOGICAL ENG

A green plum extremely moisturizing facial mask and preparation method thereof

ActiveCN107213083BGood moisturizing effectMaintain humidityCosmetic preparationsToilet preparationsGlycerolButanediol

The invention discloses a green plum extreme-moistening moisturizing facial mask and a making method thereof. The green plum extreme-moistening moisturizing facial mask consists of the following components: a green plum active extract, propylene glycol, butanediol, glycerinum, rosa damascena flower water, aloe vera leaf juice, hydrolyzed jojoba esters, phenoxyethanol, methylparaben and 2-bromine-2-nitropropane-1,3-diol mixed liquid, allantoin, chondrus crispus powder, an acrylic acid (ester) type / C10-30 alkanol acrylic ester cross-linking polymer, triethanolamine, EDTA (Ethylene Diamine Tetraacetic Acid) disodium, PEG-40 hydrogenated castor oil, essential oil and water. The green plum extreme-moistening moisturizing facial mask disclosed by the invention is capable of effectively and safely improving skin activity, promoting skin metabolism, promoting new skin cell generation and reducing melanin, and has remarkable effects on facial skin whitening, inflammation elimination, moisturizing and the like.

Owner:ZHANGPU CAILUHUA COSMETICS

Nail care cream for tumor patients

ActiveCN106902348BAlleviate pigmentation problemsPrevent discolorationAntibacterial agentsHydroxy compound active ingredientsTissue repairGlycerol

Owner:JIANGSU SOLOMON BROTHER MEDICAL TECH CO LTD

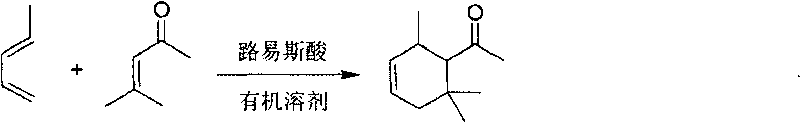

Method for preparing 1-(2,6,6-trimethylcyclohex 3-alkenyl) ethyl ketone

InactiveCN101225032BLow toxicityHigh yieldOrganic compound preparationCarbonyl compound preparationSolubilityKetone

The invention discloses a preparation method of organic compounds, in particular to 1- (2,6,6- trimethyl cyclohexyl - 3- alkenyl) ethyl ketone, which adopts 4- methyl amyl- 3- alkene - 2- alkone and 1,3- piperylenes as the raw material, with the anhydrous aluminum trichloride as the catalyst, and purifying and preparing through Diels-Alder reaction in the nitryl alkane solvent; wherein, the nitrylalkane solvent is one or several combination solvents among the nitroethane, 1- nitropropanes, and 2- nitropropanes, with a mass ratio of 3 to 5 times of 4- methyl amyl- 3- alkene -2- alkone. The preparation method of organic compounds has the advantages of using nitryl alkane as solvent, distinct enhancement of product efficiency, small solvent toxicity, good solubility, high recycling percentage, easy separation and purification of products, pure product fragrance, and other characteristics.

Owner:格林生物科技股份有限公司

Nonmetal gasoline antiknock agent and preparation method thereof

PendingCN112760143AImprove antiknock performanceFast oxidationLiquid carbonaceous fuelsFuel additivesPetroleum naphthaEthyl group

The invention provides a nonmetal gasoline antiknock agent and a preparation method thereof. The nonmetal gasoline antiknock agent comprises the following raw materials in parts by weight: 30-80 parts of N-methyl formamide, 2-8 parts of methyl tertiary butyl ether, 2-15 parts of 1-nitropropane, 5-20 parts of glycerol tripalmitate, 3-18 parts of nonyl phenol polyoxyethylene ether and 2-8 parts of a cosolvent. The cosolvent is methyl ethyl ketone, 2-naphthyl amine and 1,5-dimethyl hexyl amine. According to the nonmetal gasoline antiknock agent disclosed by the invention, the raw materials are scientifically compounded, have better compatibility and synergistically play a role, so that the purpose of improving the antiknock property of gasoline is achieved, sufficient combustion of gasoline is promoted, combustion carbon deposit in a cylinder is effectively eliminated, the combustion efficiency of gasoline is improved, and the requirements of refinery enterprises for blending international gasoline by using naphtha are met; and objective economic benefits can be created for enterprises.

Owner:YANGPU AOLI PETROCHEM

Safe method for preparing nitropropane by vapor-phase nitration

InactiveCN102079710BProcess Safety ContinuityReduce power consumptionNitro compound preparationGas phaseNitration

The invention relates to a safe method for preparing nitropropane by vapor-phase nitration, which comprises the following steps: carrying out reaction in a single-channel reactor, wherein after the reaction material propane enters a preheating pipe via a flowmeter and is mixed with pumped nitric acid in a mixing pipe, the mixed materials are sent into a reaction pipe, and the mol ratio of the propane to the nitric acid is controlled at (1-8):1; the mixed materials are subjected to nitration reaction by mass transfer and heat transfer in the reaction pipe, and the products enter a separator; and the reaction products stand in the separator until the reaction products stratify, the organic phase is separated from the water phase, and the organic phase is washed and dried to obtain the product. By using the invention, the propane and the nitric acid can be directly synthesized into various nitroparaffins under the condition of no catalyst, and the process is safe and continuous. The masstransfer and heat transfer are completed in the single channel without additional heat dissipation, thereby reducing the power consumption. The invention has the advantage of simple structure and is easy to operate. The conversion rate of the propane is higher than 20%, and the selectivity of the nitropropane is higher than 80%.

Owner:中国科学院嘉兴绿色化学工程中心 +2

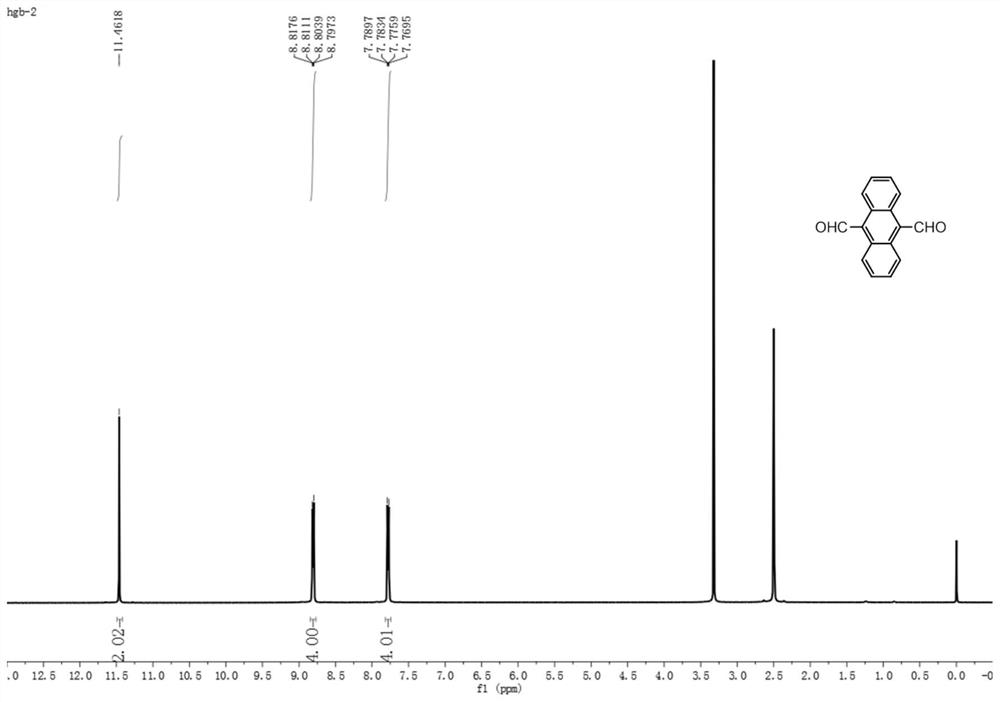

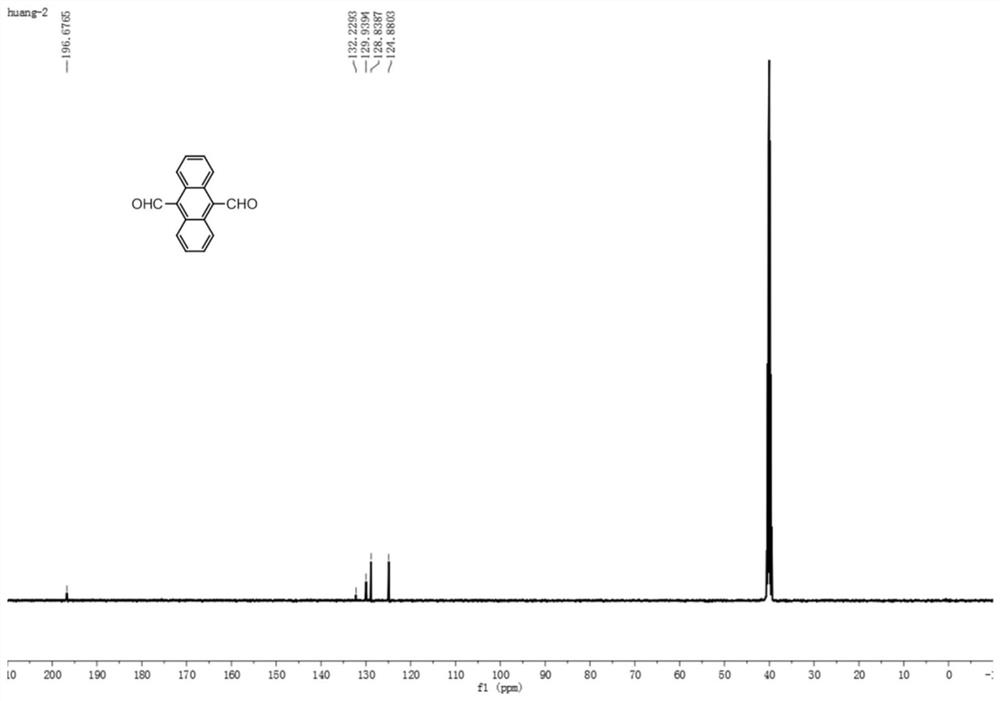

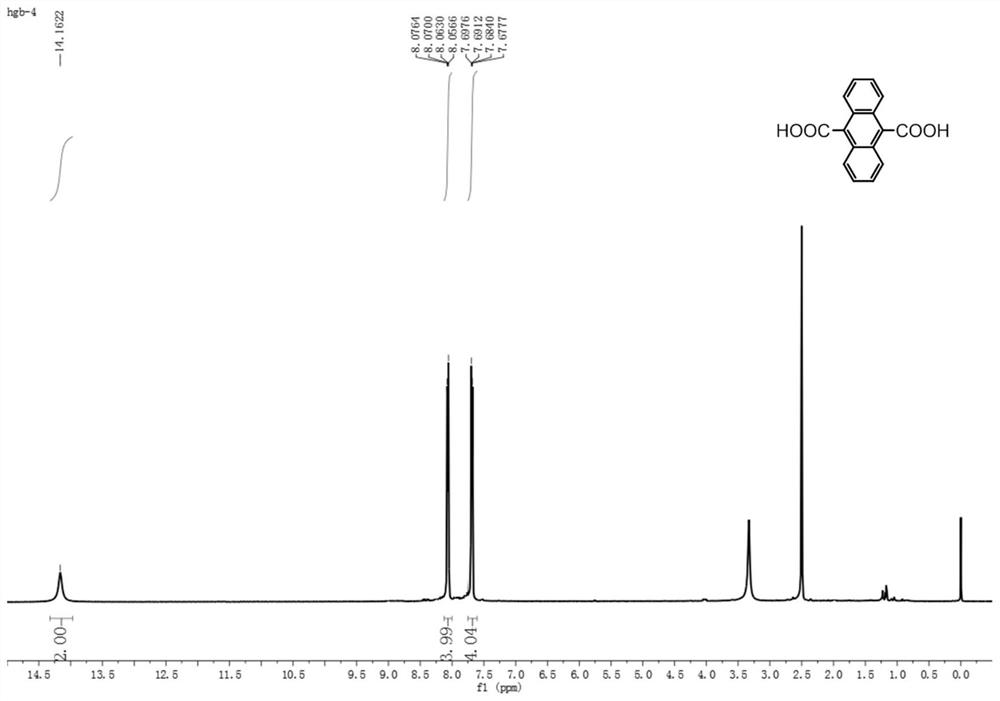

Synthesis method of 9,10-anthracenedicarboxylic acid

PendingCN113387793AThe synthesis method is simpleReaction conditions are easy to controlOrganic compound preparationCarbonyl compound preparation by hydrolysisChromatographic separationEthylic acid

The invention relates to an anthracene compound, and in particular, relates to a synthesis method of 9,10-anthracenedicarboxylic acid, wherein the synthesis method comprises the steps: dissolving anthracene in a hydrogen bromide solution and an acetic acid solution, then adding trioxymethylene and N,N,N-trimethyl-1-tetradecyl ammonium bromide, and reacting under the protection of N2 to obtain a first intermediate; then dissolving the first intermediate in dimethyl sulfoxide, dropwise adding a mixed solution of a sodium ethoxide solution and 2-nitropropane, filtering, and performing chromatographic separation to obtain a second intermediate; and adding a mixed solvent, sulfamic acid and sodium chlorite into the second intermediate to react, adding an ammonium chloride solution after the reaction is finished, and then extracting, drying and filtering to obtain a 9,10-anthracenedicarboxylic acid solid. The method can accurately position the ninth and tenth positions of anthracene, and has the advantages of strong positioning effect, few reaction byproducts, easy separation of target products, and high yield.

Owner:YULIN NORMAL UNIVERSITY

Method for continuously synthesizing 2-nitropropane by adopting slurry reactor

ActiveCN112321435ANo generationSimple processChemical recyclingNitro compound preparationSlurry reactorPtru catalyst

The invention discloses a method for continuously synthesizing 2-nitropropane by adopting a slurry reactor, and belongs to a fine chemical synthesis method. The method comprises the following steps of: adding a treated TS-1 catalyst into a slurry bed according to a certain ratio, controlling the temperature and pressure at certain values, simultaneously introducing an acetone-methanol mixed solution, hydrogen peroxide and ammonia gas according to a certain ratio to control the pH value of a reaction system to be 6-7, and separating the reaction solution through a membrane tube. The method hasthe advantages of realization of continuous production, simple process, convenience in operation and no generation of byproducts. The acetone conversion rate is greater than or equal to 95.0%, and the2-nitropropane selectivity is greater than or equal to 99.0%. The method is green, environment-friendly, safe, reliable and energy-saving.

Owner:CHINA CATALYST HLDG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com