Lithium ion battery and lithium ion battery electrolyte for ultralow temperature discharge

A lithium-ion battery and electrolyte technology, which is applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problem of not fully disclosing the components and ratio of lithium-ion batteries, hindering the better development of lithium-ion batteries, and reducing the cost of lithium-ion batteries. Use surface and other issues to achieve the effect of facilitating rapid migration, improving low-temperature discharge performance, and ensuring low-temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

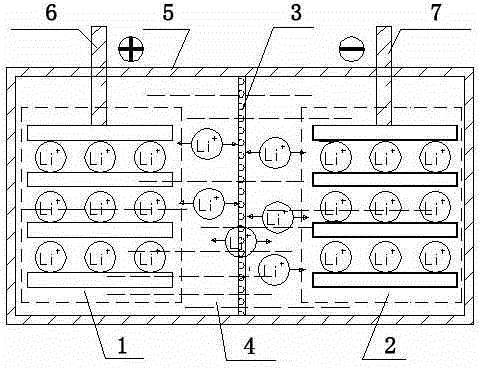

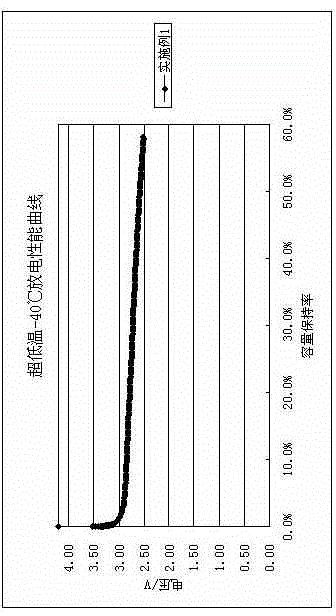

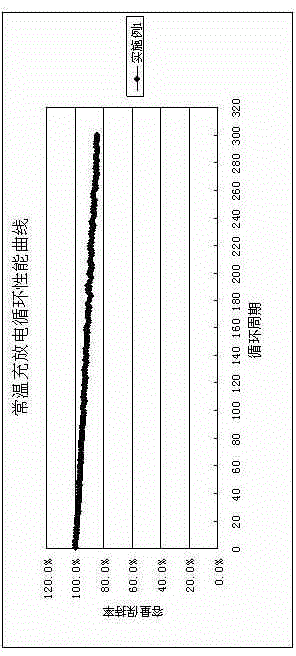

[0037] The positive electrode active material lithium cobalt oxide (LiCoO 2 ), the binder polyvinylidene fluoride (PVDF) and the conductive carbon are combined, and these compounds are respectively dispersed in N-methyl-2-pyrrolidone as a solvent at a weight ratio of 92:3:5 to form a positive electrode active material The above slurry was coated on a 16 μm thick aluminum foil, dried and rolled to form a positive electrode. The negative electrode active material made of artificial graphite is suspended and dispersed in carboxymethyl cellulose aqueous solution, and styrene-butadiene rubber (SBR) is added as a binder to form a negative electrode active material slurry. The material was coated on a 12 μm thick copper foil, dried and rolled to form the negative electrode. The positive and negative electrodes are wound or laminated together with a polyethylene separator with a thickness of 25 μm to form a battery core, and then the resulting battery core is placed in a metal contai...

Embodiment 2

[0040] Example 1 was repeated except that 2 wt% triethoxyboron as an anion chelating agent and 8 wt% nitroethane as a low melting point additive were added to the mixture of quaternary solvent and lithium hexafluorophosphate.

Embodiment 3

[0042] Example 1 was repeated except that 1 wt% triethoxyboron as an anion chelating agent and 9 wt% nitroethane as a low melting point additive were added to the mixture of quaternary solvent and lithium hexafluorophosphate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com