Preparation method of durable and stable titanium silicalite molecular sieve catalyst for producing 2-nitropropane

A technology of titanium-silicon molecular sieve and nitropropane, applied in molecular sieve catalysts, catalyst activation/preparation, molecular sieve compounds, etc., can solve the problems of poor durability and service life, high deactivation rate, etc., to improve diffusion problems and increase efficiency , Optimizing the effect of pressure and temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

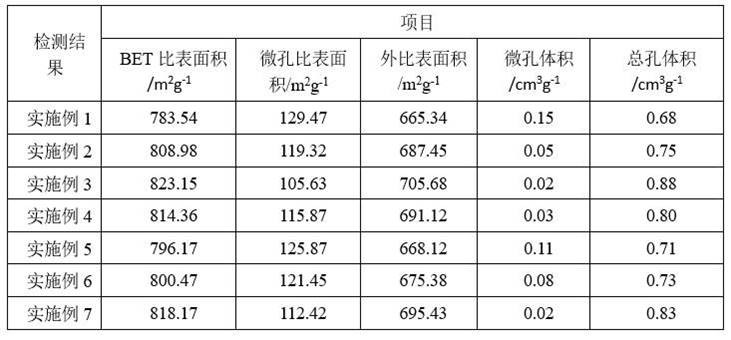

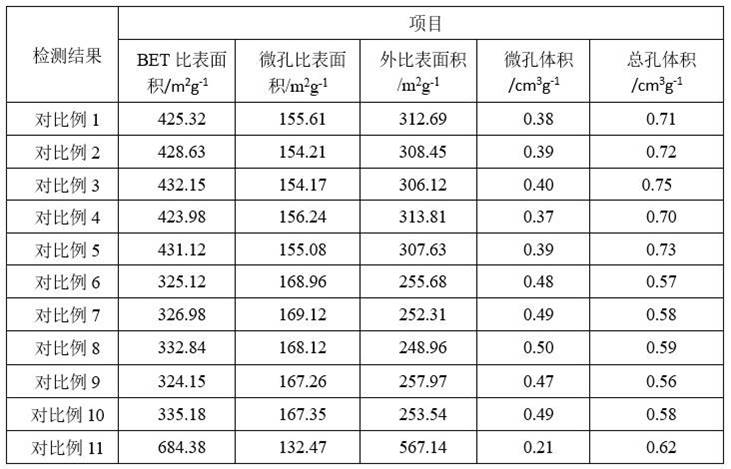

Examples

Embodiment 1

[0033] S1. Take the wood pulp and place it in the acid hydrolysis solution, heat and stir it at 70°C for 3 hours, collect the reaction solution and filter to obtain the filter cake, wash it with deionized water until the washing solution is neutral, then collect the acid hydrolysis solution Modified material, described acidolysis liquid is the hydrochloric acid ethanol solution mixed by mass ratio 1:20, and described hydrochloric acid concentration is 0.5mol / L, and described ethanol is the ethanol solution of mass concentration 75%; In parts by weight, Weigh 45 parts of deionized water, 1 part of 0.8 mol / L sodium hydroxide solution, 3 parts of urea and 15 parts of acid hydrolyzed modified materials and place them in a Erlenmeyer flask, stir to mix and collect the cellulose solution.

[0034] S2. According to the mass ratio of 1:50:100, the cellulose solution, 1-allyl-3-methylimidazolium chloride salt and absolute ethanol were stirred and mixed and added dropwise to the regenera...

Embodiment 2

[0039] S1. Take the wood pulp pulp and place it in the acid hydrolysis solution, heat and stir it at 75°C for 4 hours, collect the reaction solution and filter to obtain the filter cake, wash it with deionized water until the washing solution is neutral, then collect the acid hydrolysis solution Modified material, described acidolysis liquid is the hydrochloric acid ethanol solution mixed by mass ratio 1:20, and described hydrochloric acid concentration is 0.7mol / L, and described ethanol is the ethanol solution of mass concentration 77%; In parts by weight, Weigh 47 parts of deionized water, 1 part of 0.8 mol / L sodium hydroxide solution, 4 parts of urea and 17 parts of acid hydrolyzed modified materials and put them into Erlenmeyer flask, stir and mix and collect the cellulose solution.

[0040] S2. According to the mass ratio of 1:50:100, the cellulose solution, 1-allyl-3-methylimidazolium chloride salt and absolute ethanol were stirred and mixed and added dropwise to the rege...

Embodiment 3

[0045] S1. Take the wood pulp pulp and place it in the acid hydrolysis solution, heat and stir it at 80°C for 5 hours, collect the reaction solution and filter to obtain the filter cake, wash it with deionized water until the washing solution is neutral, then collect the acid hydrolysis solution Modified material, described acidolysis liquid is the hydrochloric acid ethanol solution mixed by mass ratio 1:20, and described hydrochloric acid concentration is 0.8mol / L, and described ethanol is the ethanol solution of mass concentration 80%; By weight parts, Weigh 50 parts of deionized water, 2 parts of 0.8 mol / L sodium hydroxide solution, 5 parts of urea and 15 parts of acid-hydrolyzed modified materials and place them in a Erlenmeyer flask, stir and mix and collect the cellulose solution.

[0046] S2. According to the mass ratio of 1:50:100, the cellulose solution, 1-allyl-3-methylimidazolium chloride salt and absolute ethanol were stirred and mixed and added dropwise to the rege...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com