Patents

Literature

62 results about "Petroleum naphtha" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Petroleum naphtha is an intermediate hydrocarbon liquid stream derived from the refining of crude oil with CAS-no 64742-48-9. It is most usually desulfurized and then catalytically reformed, which rearranges or restructures the hydrocarbon molecules in the naphtha as well as breaking some of the molecules into smaller molecules to produce a high-octane component of gasoline (or petrol).

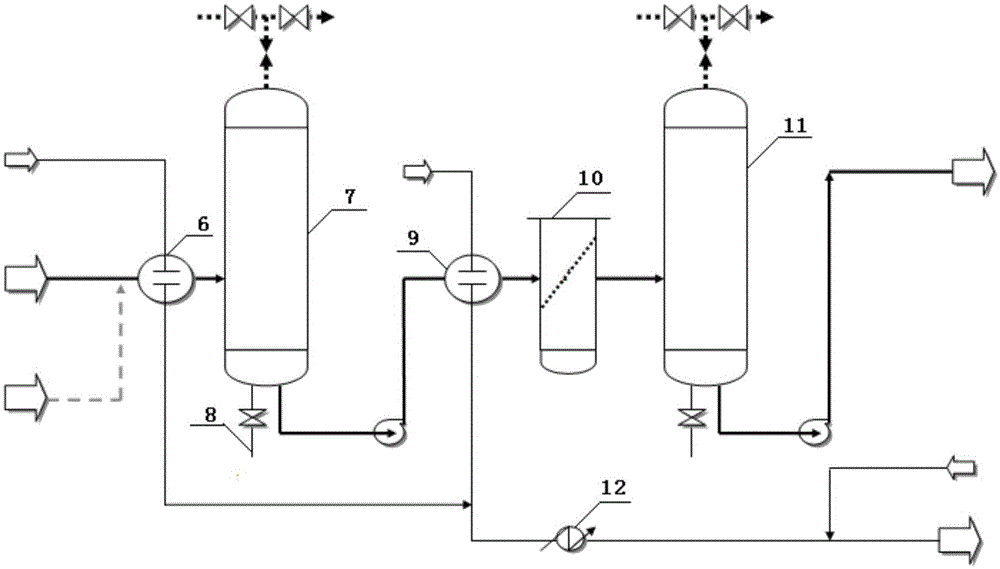

Method for preparing high-quality ethylene raw material with petroleum naphtha hydrogenation

ActiveCN101343557AImprove qualityIncrease productionOrganic chemistryBulk chemical productionVegetable oilPetroleum naphtha

The invention relates to a method for generating the high quality ethylene raw material through naphtha hydrogenation. The method takes naphtha fraction and animal and vegetable oil as the raw material oil, under the condition of hydrofining, the raw material oil and hydrogen are mixed and passed through a hydrofining reaction area, the hydrogen-rich gas recycling utilization can be acquired through separating the hydrofining generated oil, and low Sulfur, low hydrogen and low aromatic naphtha can be acquired through removing hydrogen sulfide of the separated liquid with an air stripping tower. Compared with the prior art, the method has the advantages that the oil is mixed in the naphtha hydrogenation raw material, the quality of the product as the ethylene cracking raw material, in particular to aromatic long chain hydrocarbon nC16 to 18 and propane acquired through the animal and vegetable oil hydrogenation, can be remarkably improved, the cracking furnace ethylene output can be increased and the cracking furnace life can be prolonged through adding the aromatic long chain hydrocarbon nC16 to 18 and propane in the ethylene cracking raw material.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for catalytic pyrolysis

ActiveCN101428233AHigh hydrothermal stabilityIncrease acidityMolecular sieve catalystsBulk chemical productionCatalytic pyrolysisPetroleum naphtha

The invention relates to a catalyst for catalytic cracking and mainly solves the problems of high service temperature and low yield of ethylene-propylene copolymer in the prior catalyst for catalytic cracking in ethylene-propylene copolymer synthesis. In order to solve the problems, the technical scheme is as follows: the catalyst is obtained by loading at least one element of the group IB or the group IIB in the periodic table of elements on a ZSM-5 / mordenite molecular sieve, ZSM-5 / beta-zeolite molecular sieve or ZSM-5 / Y-zeolite molecular sieve. The catalyst is applied to the industrial production of ethylene-propylene copolymer via catalytic cracking of petroleum naphtha.

Owner:CHINA PETROLEUM & CHEM CORP +1

Petroleum hydrocarbon catalytic pyrolysis catalyst and its application

ActiveCN1955255AIncrease throughputHigh airspeedHydrocarbonsNaphtha reformingCatalytic pyrolysisAlkaline earth metal

This invention provides a petroleum hydrocarbon catalytic decomposition accelerant and its application. This accelerant includes following components: (1) lanthanide, its weight amount is 0.1-25%; (2) phosphorus or boron, its weight amount is 0.1-10%; (3) base metal, alkali metal and transition metal, their weight amount is 0.1-15%; (4) The others are ZSM-5,ZRP used as carrier. This accelerant used for production of low carbon alkenes by cracking heavy magnesium alkanes, with space velocity of gas 1-25hr-1, such as naphtha, diesel oil, educed pressure diesel and so on. The yield of ethylene, propylene, butylenes and butadiene will improve by 5%.

Owner:CHINA PETROLEUM & CHEM CORP +1

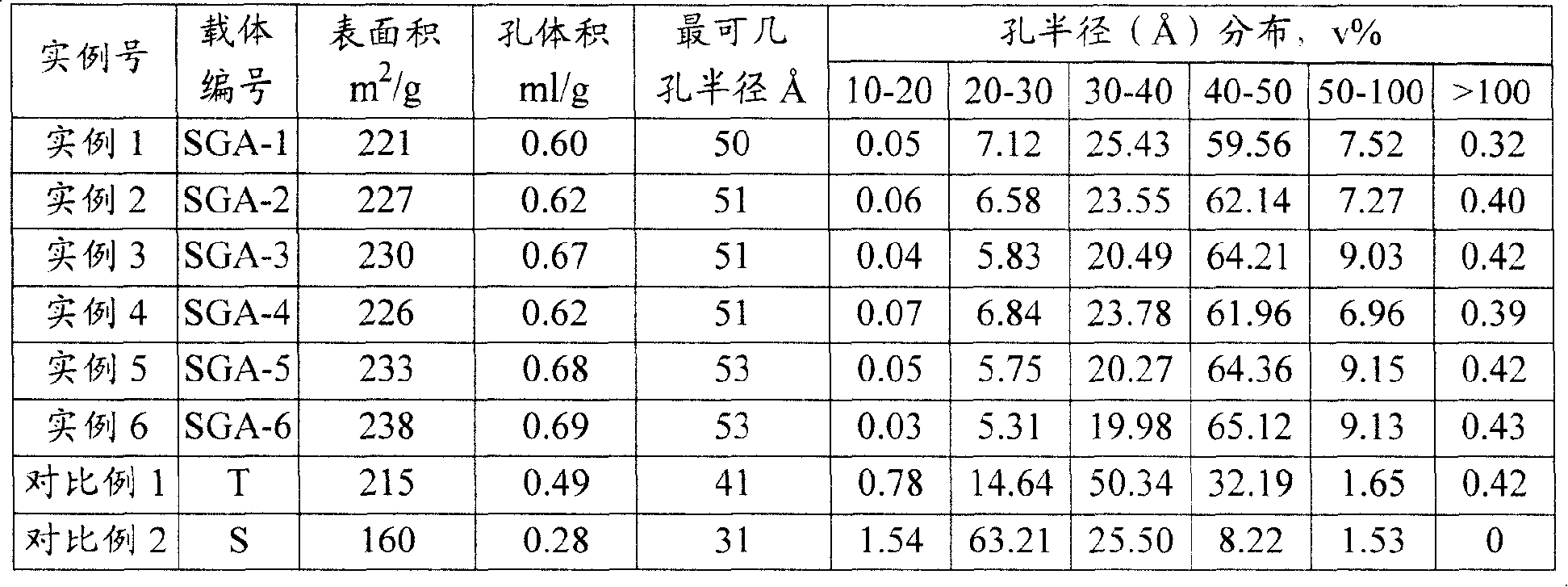

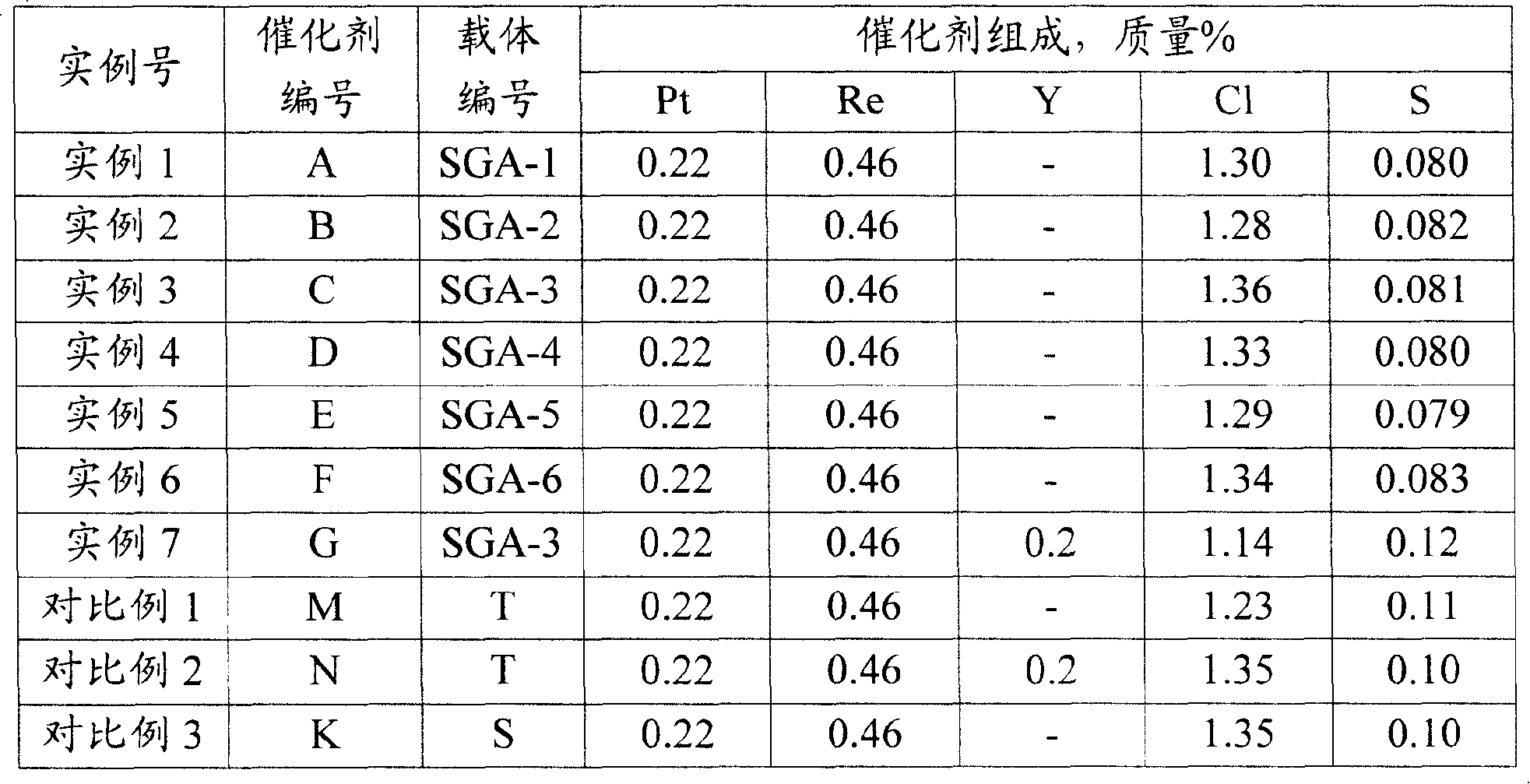

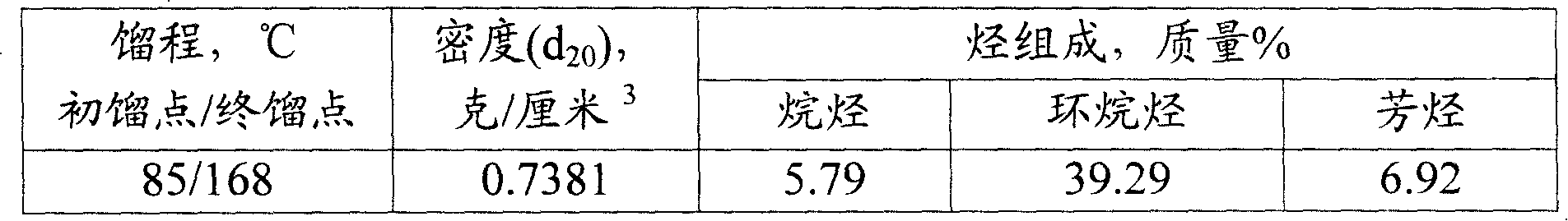

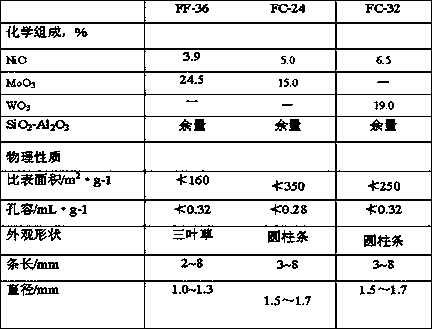

Petroleum naphtha reforming catalyst and preparation method thereof

ActiveCN101190413AImprove liquid yieldHigh selectivityCatalytic naphtha reformingCatalyst activation/preparationPetroleum naphthaHalogen

The invention provides a naphtha reforming activator, comprising an alumina carrier and the following active components corresponding to dry-based alumina content measured by mass of 0.1% to 5.0% of the VIII element, 0.1% to 5.0% of VIIB family metal and 0.1% to 10.0% of halogen. The pore volume of the alumina is from 0.55mL / g to 0.75mL / g and the maximum pore radius is from 48 to 55. The activator is used for naphtha activator reforming and has high catalyzing activity and aromatics yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

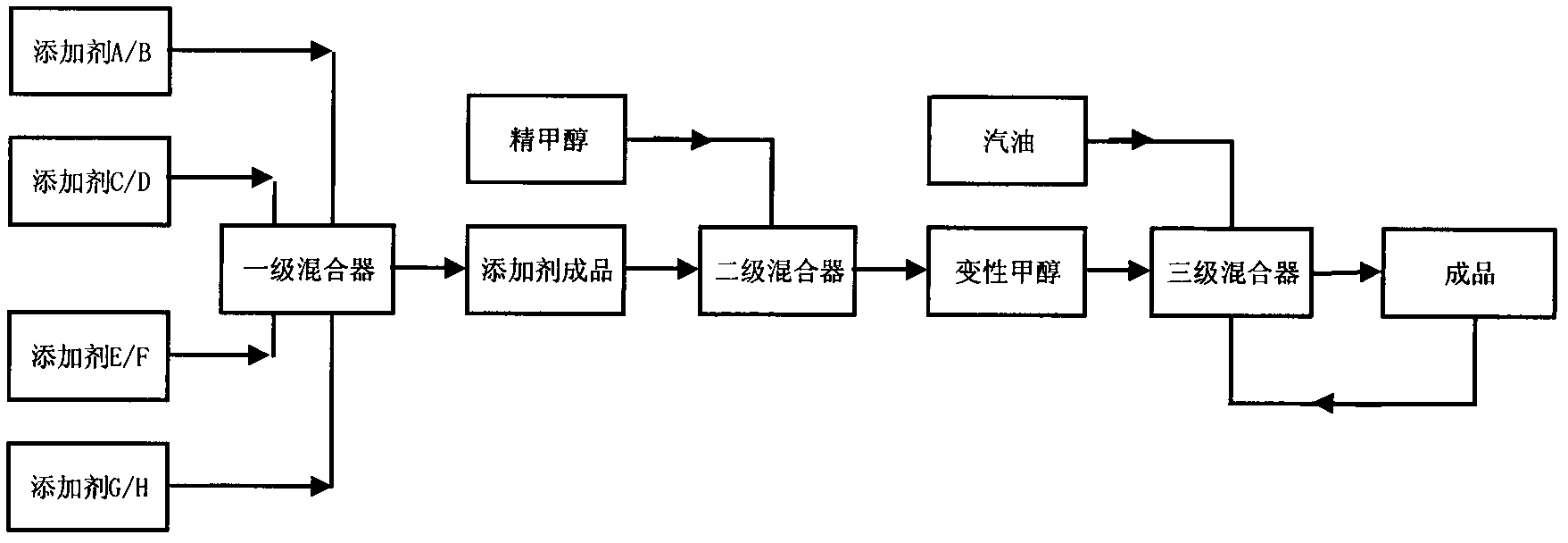

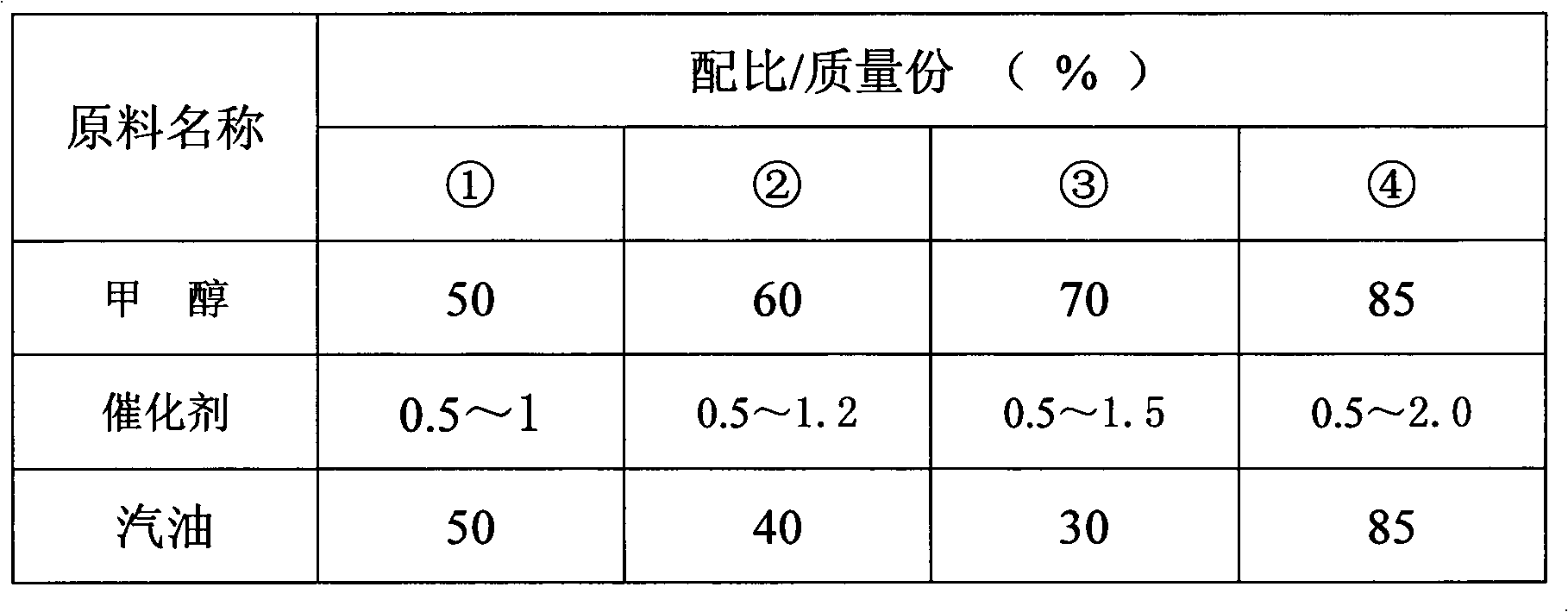

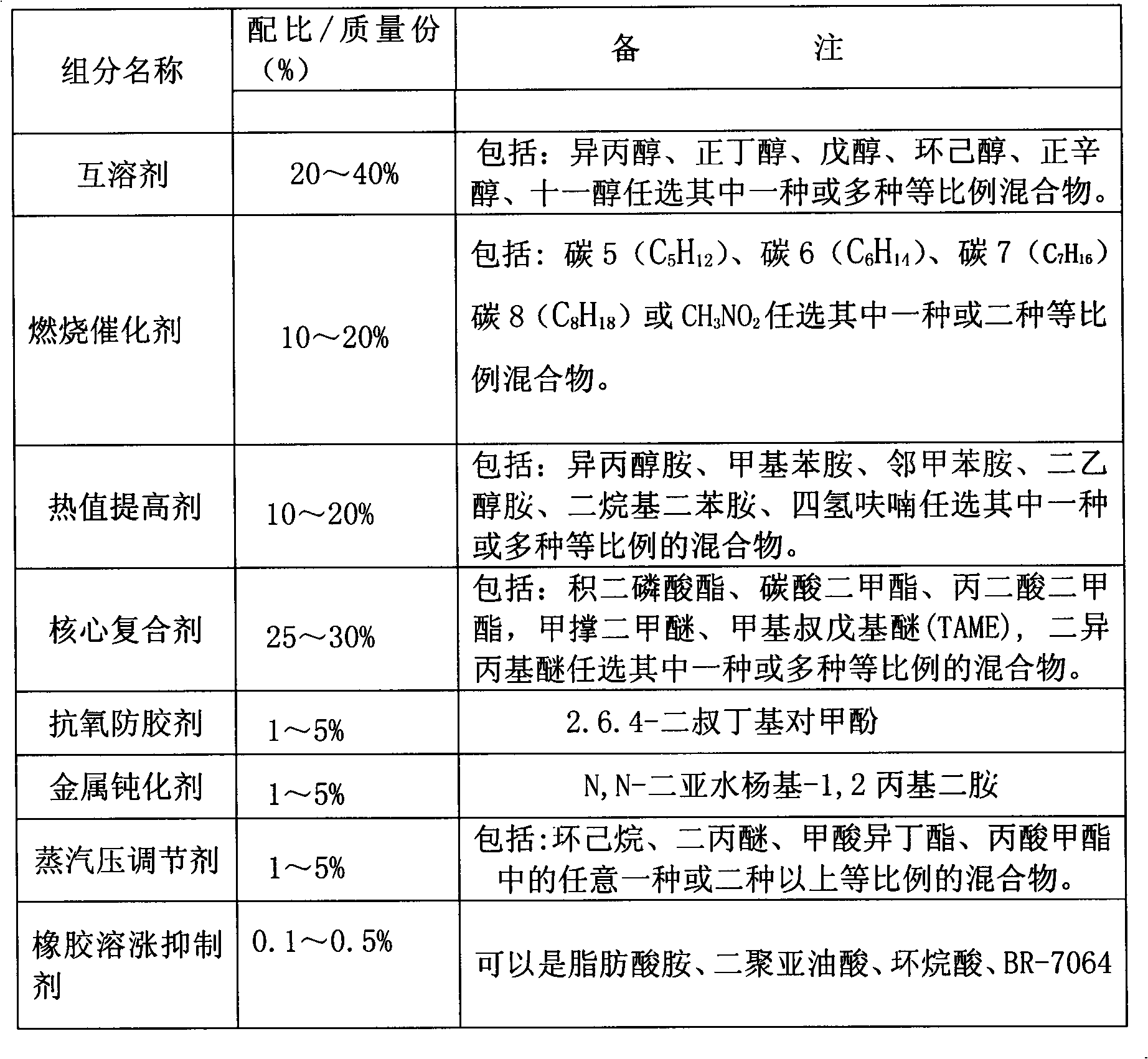

Large-proportion methanol gasoline catalyst and preparation method

InactiveCN103160344AGood miscibilityImprove water resistanceLiquid carbonaceous fuelsFuel additivesAlkaneNaphtha

The invention provides a large-proportion methanol gasoline catalyst and a preparation method thereof. A product mark of the large-proportion methanol gasoline can be expressed by M50 and M85, wherein M represents a first letter of methanol; 50 and 85 respectively represent 50% of methanol and 85% of methanol are added in the gasoline The large-proportion methanol gasoline catalyst is obtained by mixing refined methanol with a purity of 99.9% and national standard gasoline or naphtha and component oil in presence of a special catalyst. A preparation method of the special catalyst is composed of high alcohols (C3-C11), alkanes (C5(C5H12), C6(C6H14), C7(C7H16), C8(C8H18) or CH3NO2), an organic amine, a plurality of esters and auxiliary inhibitors. The large-proportion methanol gasoline produced by the invention passes through a road test longer than 10,000 KM, without changing an engine structure. The large-proportion methanol gasoline is powerful, can be easily started at a low temperature, has no gas block at a high temperature, is not stratified when being contacted with water, can resist rubber swelling, and is low in production cost and flexible in operations. Besides, all project technical indicators are superior to those of national standard gasoline for vehicles. Practice proves that the large-proportion methanol gasoline catalyst has the advantages in a plurality of aspects such as technology, economy, feasibility for large-scale application, and the like, and has obvious competitive advantages as alternative energy.

Owner:杨军

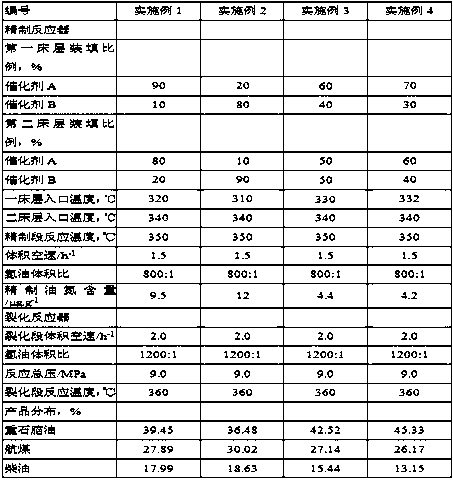

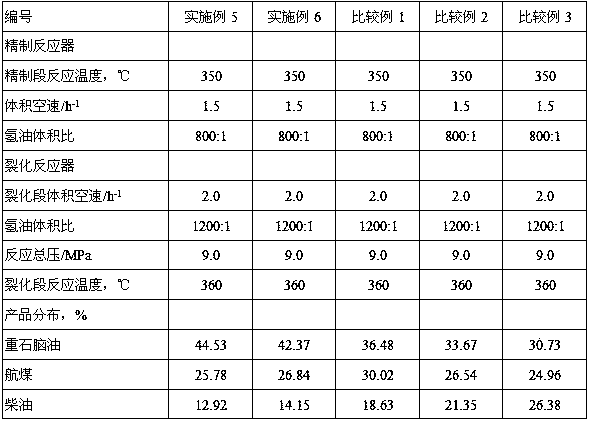

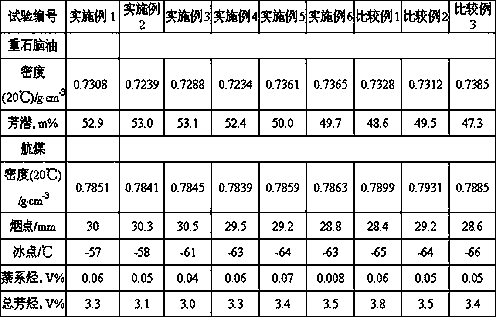

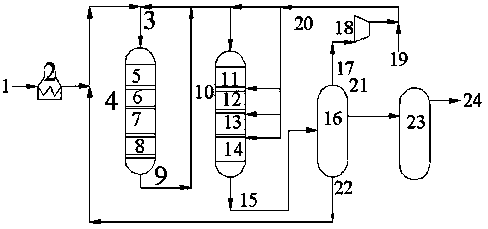

Hydrocracking method of high-yield high-quality chemical raw material

ActiveCN103773452AGood choiceFang QiangaoTreatment with hydrotreatment processesMolecular sievePetroleum naphtha

The invention discloses a hydrocracking method of a high-yield high-quality chemical raw material. According to the hydrocracking method comprises following steps: raw oil and hydrogen are subjected to hydrofinishing and are delivered through a first cracking reaction zone successively, and middle fraction oil is obtained via separation, and is delivered to a second cracking reaction zone for cracking; the first cracking reaction zone comprises two cracking catalysts, an upper zone is filled with a catalyst I, and a lower zone is filled with a catalyst II; the catalyst I comprises 30 to 70% of modified Y molecular sieve; the catalyst II comprises 15 to 50% of modified Y molecular sieve; and the content of the modified Y molecular sieve in the catalyst I is 10 to 30% higher than that in the catalyst II. Acid center of the catalyst I matches hydrogenation center, and the catalyst I possesses excellent heavy naphtha selectivity; and the catalyst II possesses excellent aromatic hydrocarbon transformative capacity, and is capable of transforming aromatic hydrocarbons in heavier components into smaller molecules so as to distribute in heavy petroleum fractions. The two catalysts are combined, so that demands of the high-yield high-quality chemical raw material are satisfied.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking fluid bed catalyst containing molecular sieve

ActiveCN1915516AHigh selectivityCatalytic crackingHydrocarbon by dehydrogenationMolecular sievePetroleum naphtha

A fluidized-bed catalyst containing molecular sieve for preparing ethene or propene from petroleum naphtha is composed of the molecular sieve as carrier and AaBbPcOx as active component. It has low reaction temp and high activity and selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

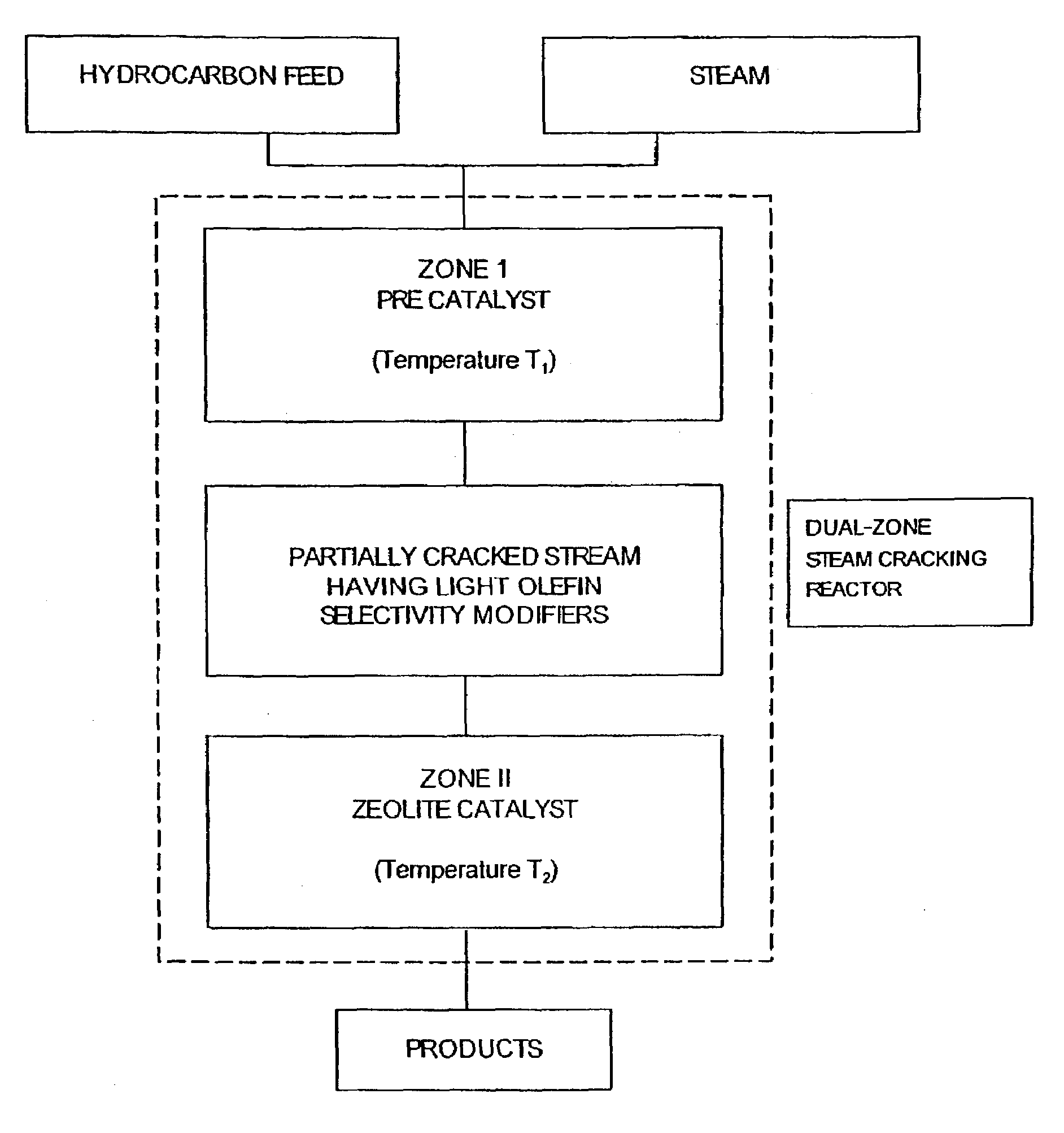

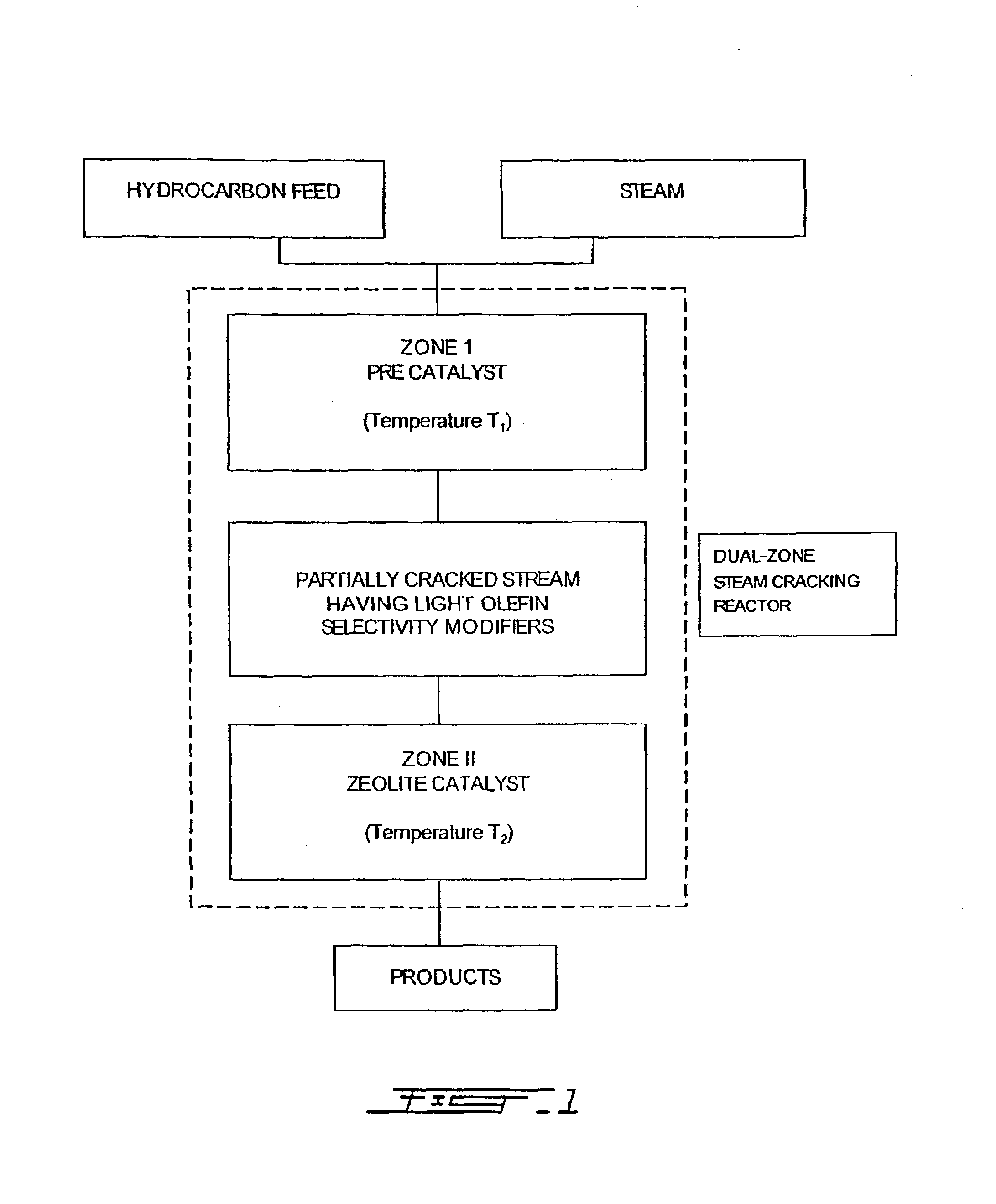

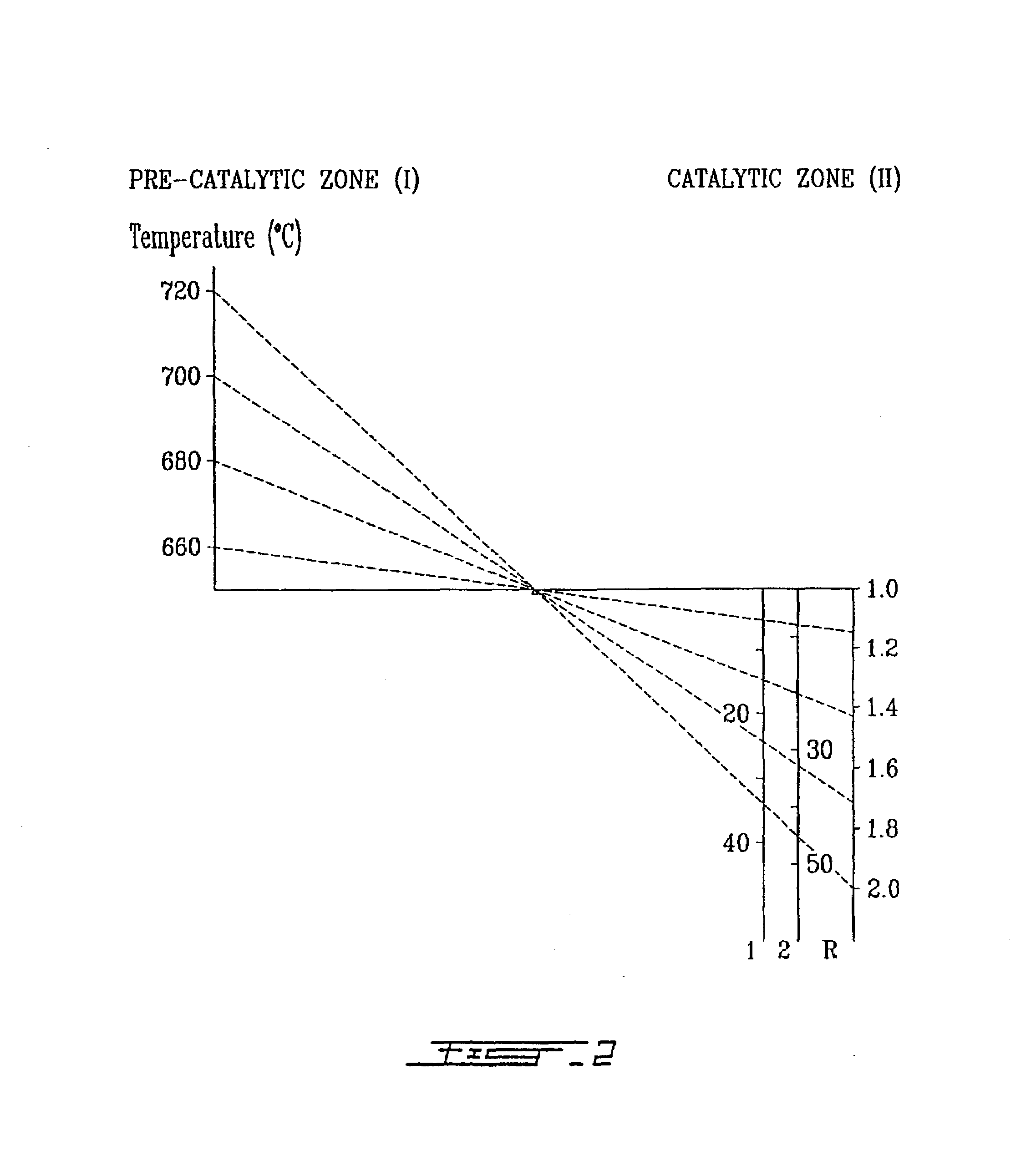

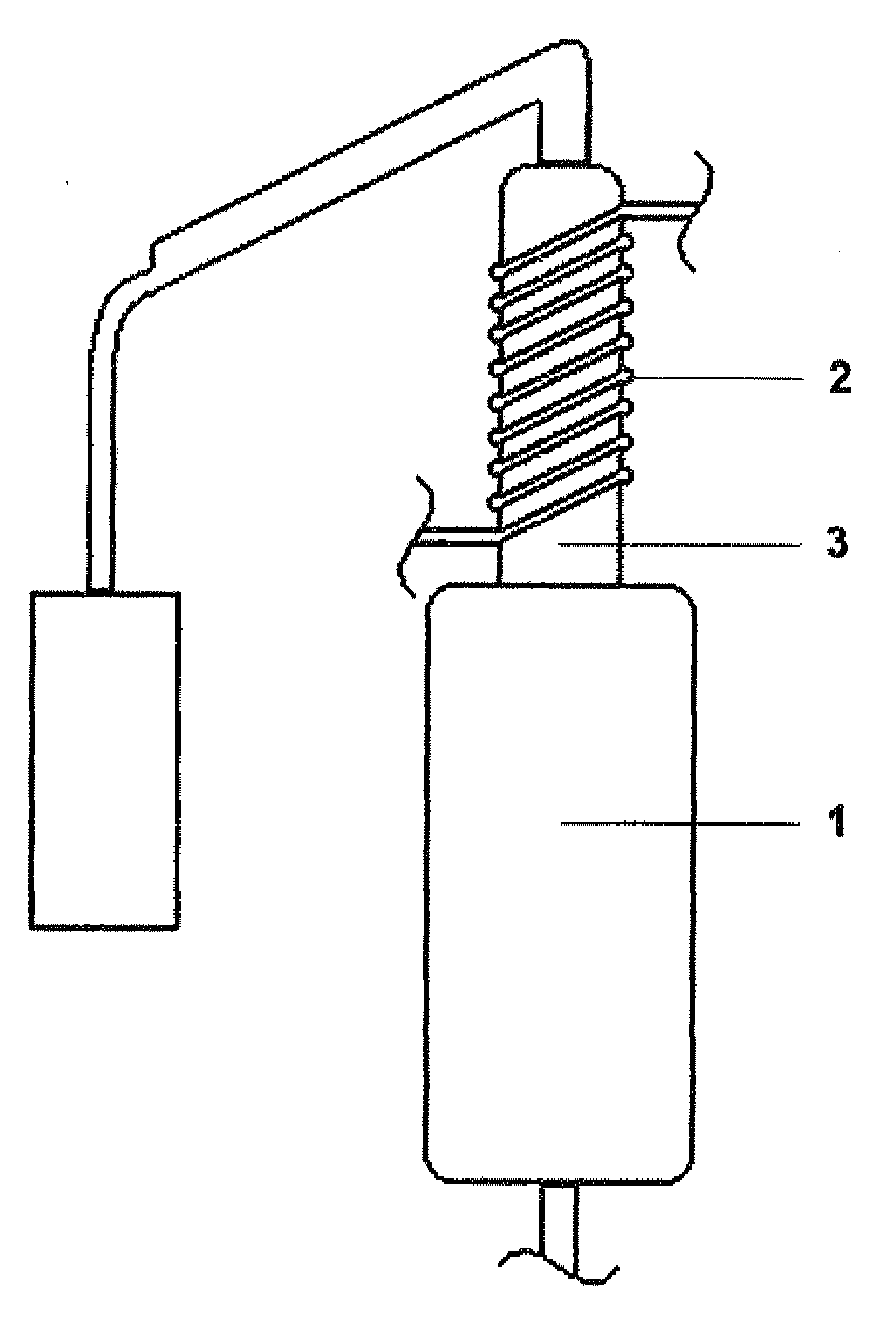

Method and apparatus for selective deep catalytic cracking of hydrocarbons

InactiveUS7135602B1Speed up the conversion processImprove light outputMolecular sieve catalystCatalystsPetroleum naphthaProduct gas

Provided herein is a method and apparatus for selective deep catalytic cracking of petroleum naphthas or other hydrocarbon feedstocks. The feed comprising the hydrocarbons to be cracked and steam, in well-defined proportions, is first sent into a precatalytic zone (Zone I) of a cracking reactor, preferably a tubular reactor. In a preferred embodiment, Zone I, contains beads of some catalytically mildly active porous material such as quartz or quartz doped with Cr—Al, is set at a temperature T1. The gas steam flows then through a catalyst bed, called Zone II, where the catalytic reaction takes place. Zone II is set at temperature T2 and contains a zeolite type catalyst, preferably ZSM5 zeolite or, most preferably, a hybrid zeolite catalyst. It is shown that by moderately increasing the temperature T1 of Zone I, it is possible to have an increased total conversion of n-hexane used as model molecule for petroleum naphthas and an increased yield of light olefins (and aromatics), when compared to the parent ZSM-5 zeolite catalyst The ethylene / propylene product ratio is closely dependent of the temperature T1, if all other reaction parameters are kept constant and can be widely varied (from 1.0 to 2.0 for instance) for a limited range of variation of temperature T1.

Owner:VALORBEC PARTNERSHIP

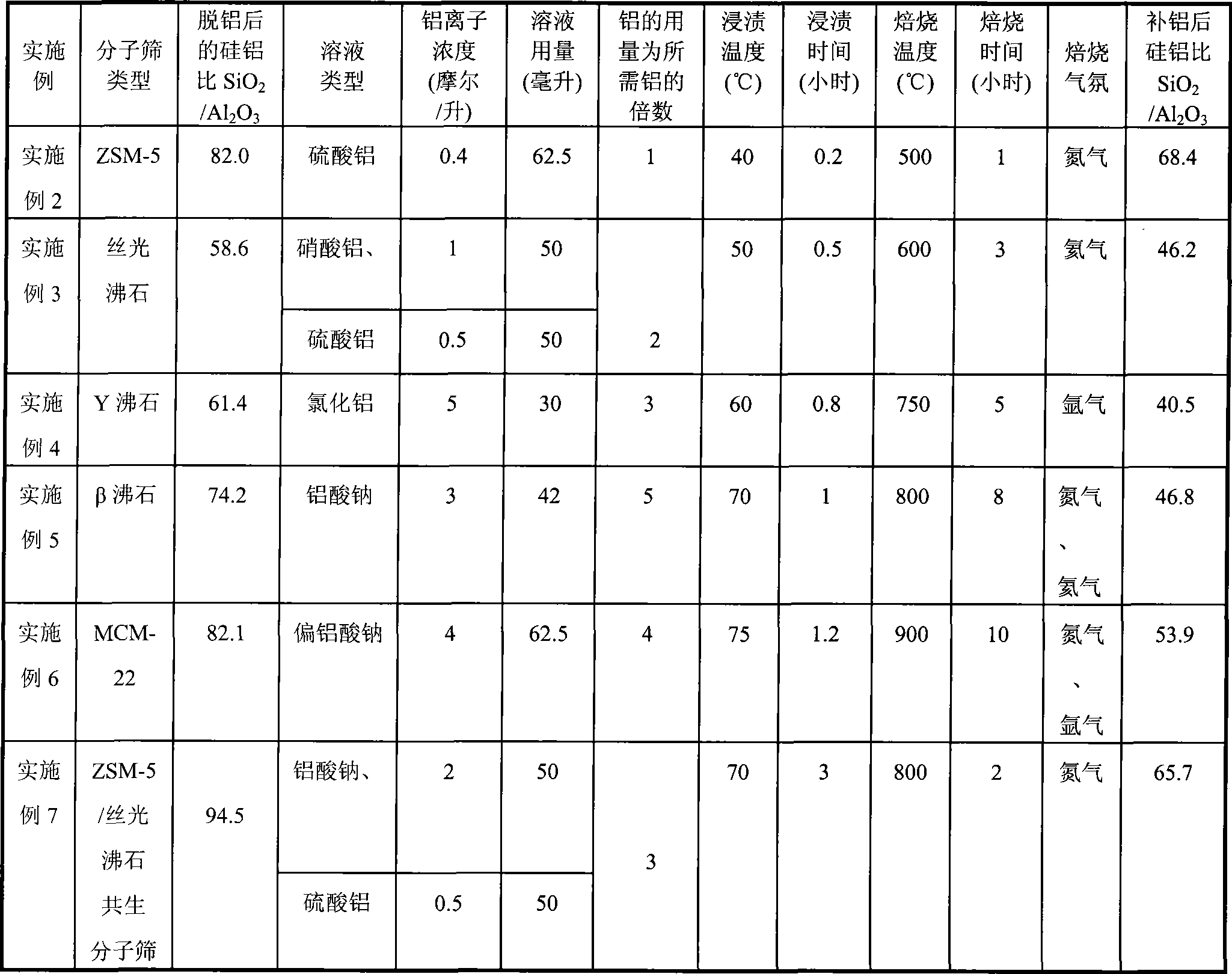

Regeneration method of molecular sieve catalysts

ActiveCN101428235ARestore aluminum concentrationMolecular sieve catalystsCatalyst regeneration/reactivationMolecular sievePetroleum naphtha

The invention relates to a regeneration method for molecular sieve catalysts, and mainly solves the problems that the regenerated molecular sieve catalyst fails to long-term repeated use and the prior regeneration method has complicated process. The regeneration method comprises the following steps: firstly removing carbon deposits or other surface-attached substances by burning dealuminated deactivated molecular sieve catalyst in oxygen-enriched atmosphere; then compounding an aluminum salt solution (aluminum concentration in the range from 0.4 mol / L to 4 mol / L) containing aluminum in an amount 1 to 5 times of the required Si-Al ratio, calculated on the basis of the molecular sieve contained in the catalyst in the form of pure silicon molecular sieve; and finally allowing the impregnation contact between the aluminum salt solution and the catalyst, drying, and calcining in inert atmosphere to obtain the regenerated catalyst. With the realumination technical scheme, the regeneration method overcomes the problems in the prior art and is applied to the industrial production of alkenes via catalytic cracking of petroleum naphtha.

Owner:CHINA PETROLEUM & CHEM CORP +1

Two-stage hydrocracking method used for producing high-quality jet fuel

ActiveCN103773473AReduce the impactIncrease hydrogen partial pressureTreatment with hydrotreatment processesAlkaneMolecular sieve

The invention discloses a hydrocracking method used for producing high-quality jet fuel from inferior raw materials. The hydrocracking method comprises following steps: (1) inferior raw material oil is subjected to hydrofinishing reaction; (2) a hydrofinishing effluent is subjected to gas-liquid separation, and an obtained liquid material is subjected to fractionation; (3) tail oil obtained via fractionation is subjected to hydrocracking reaction, wherein a hydrocracking reaction zone comprises a hydrocracking catalyst I and a hydrocracking catalyst II with different molecular sieve contents; and (4) a hydrocracking effluent is subjected to separation, and an obtained liquid product is subjected to fractionation so as to obtain corresponding products. The upper part of the hydrocracking reaction zone is filled with the hydrocracking catalyst I; the hydrocracking catalyst I possesses relatively high aromatic hydrocarbon transformative capacity, and is capable of transforming aromatic hydrocarbons in heavier components of the raw materials into smaller molecules, and distributing the smaller molecules into heavy petroleum and jet fuel fractions; the lower part of the hydrocracking reaction zone is filled with the hydrocracking catalyst II; and the hydrocracking catalyst II possesses relatively high hydrocarbon alkyl cracking capacity. The two catalysts are combined, so thathydrocracking product quality is improved obviously, and especially, smoke point of jet fuel fractions is increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

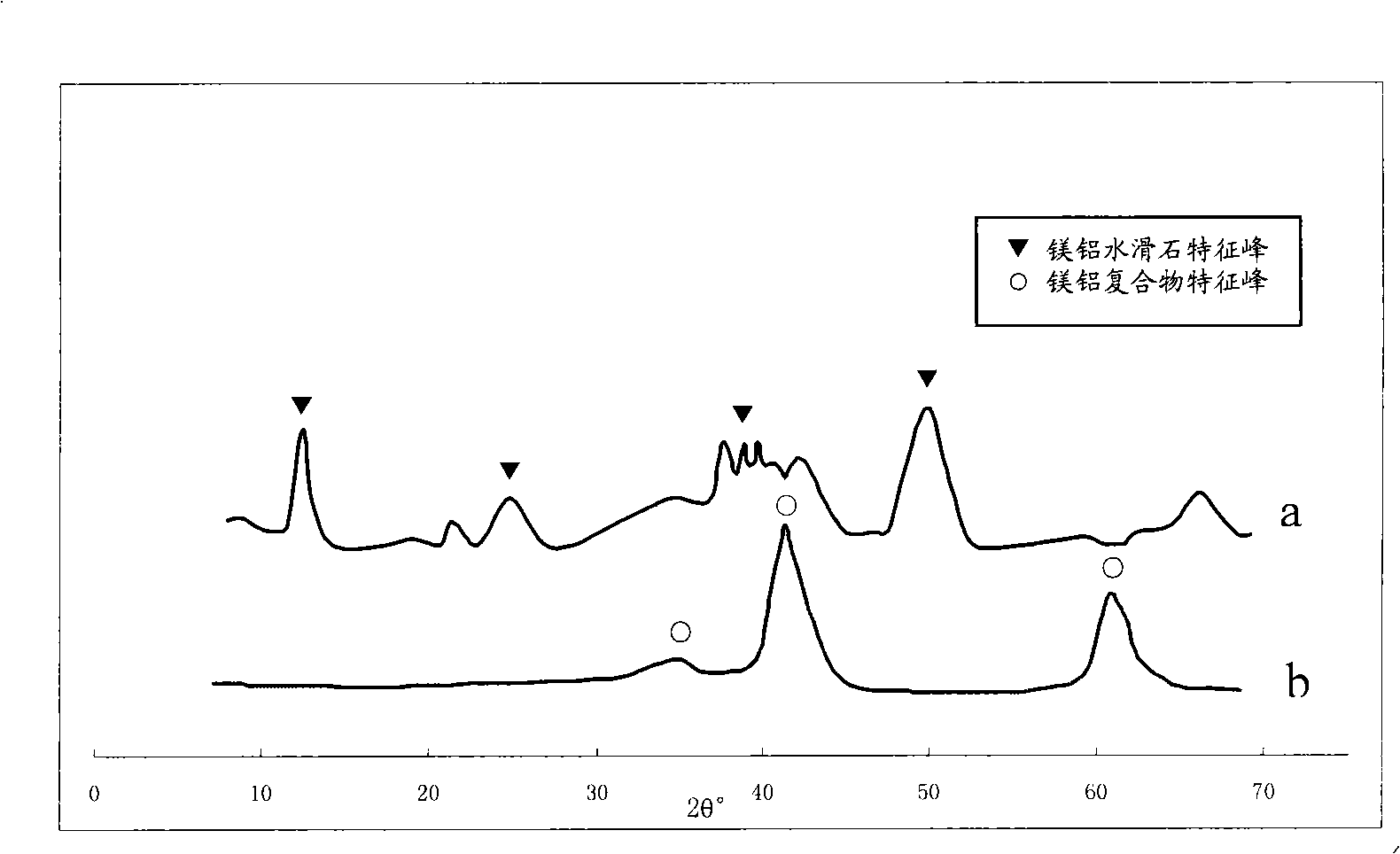

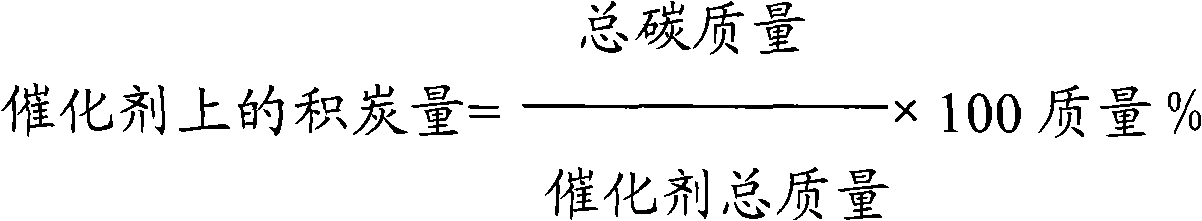

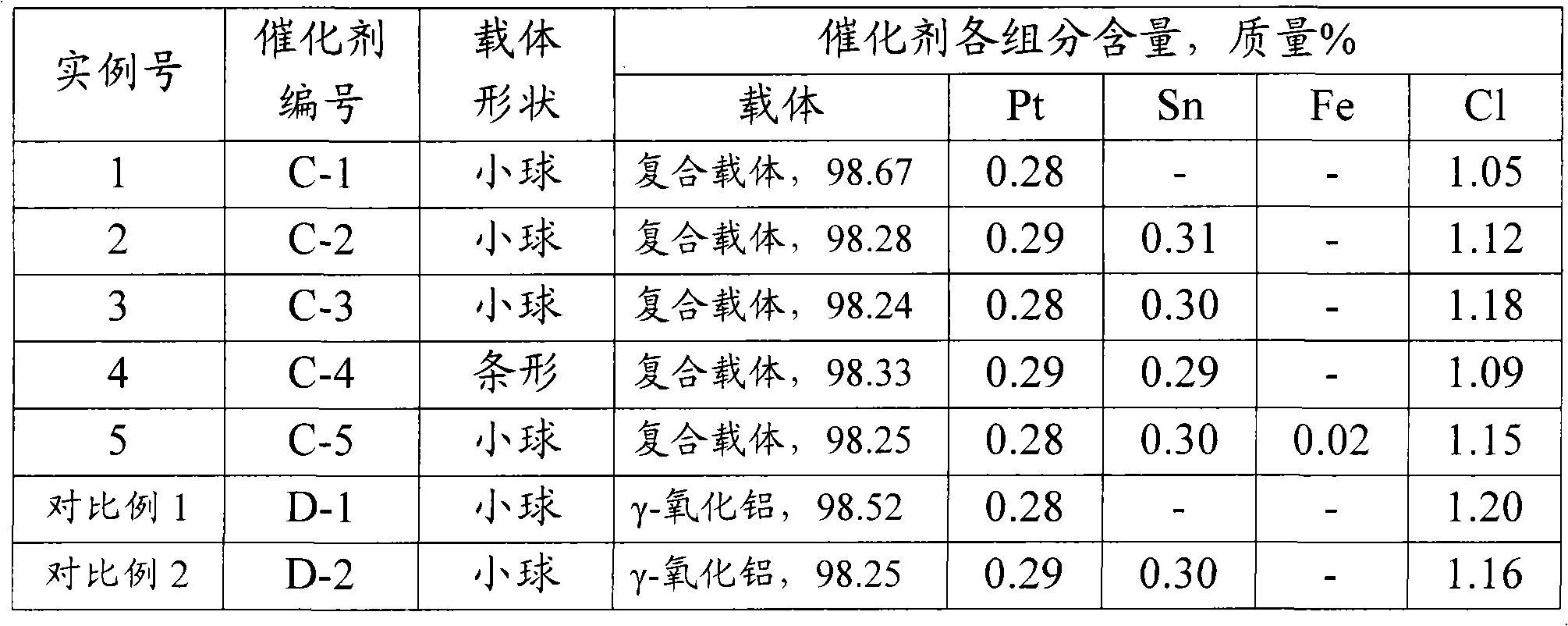

Petroleum naphtha reforming catalyst and preparation method thereof

ActiveCN101294102AReduce carbon depositionImproves hydration resistanceNaphtha reformingPetroleum naphthaAromatic hydrocarbon

A naphtha reforming catalyst comprises composite carriers 93 to 99wt%, noble metals 0.01 to 5.0wt% and halogen 0.1 to 5.0wt%, wherein the composite carriers comprise aluminum oxide and Mg(Al)O composite oxide, wherein the mass ratio of MgO to Al2O3 is 1:(100 to 250). The catalyst is used for naphtha reformation reaction and has the advantages of higher yield of aromatic hydrocarbon and higher anti-coking capacity.

Owner:CHINA PETROLEUM & CHEM CORP +1

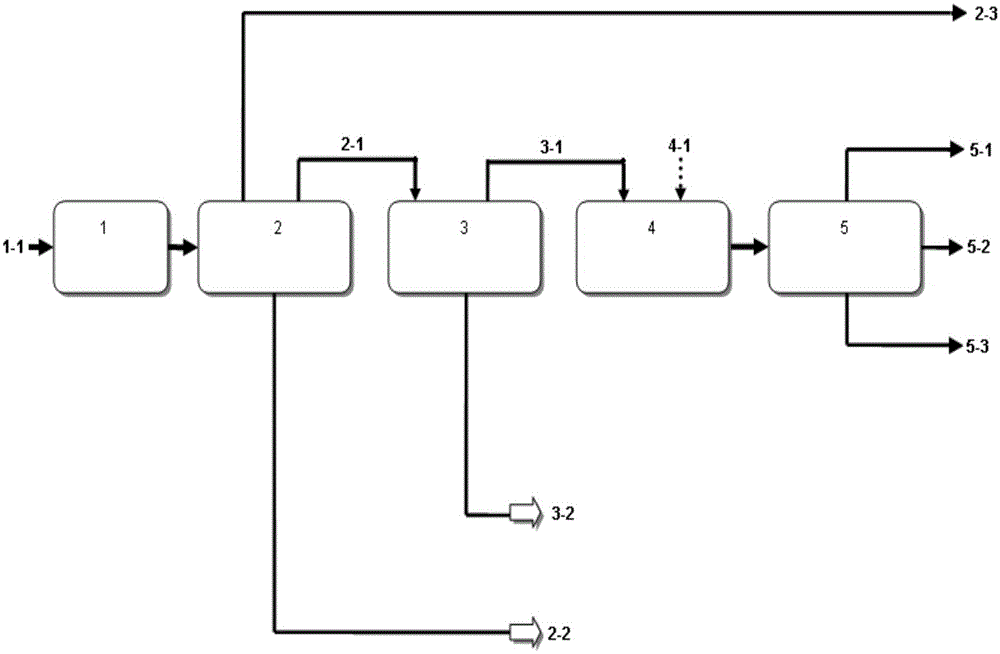

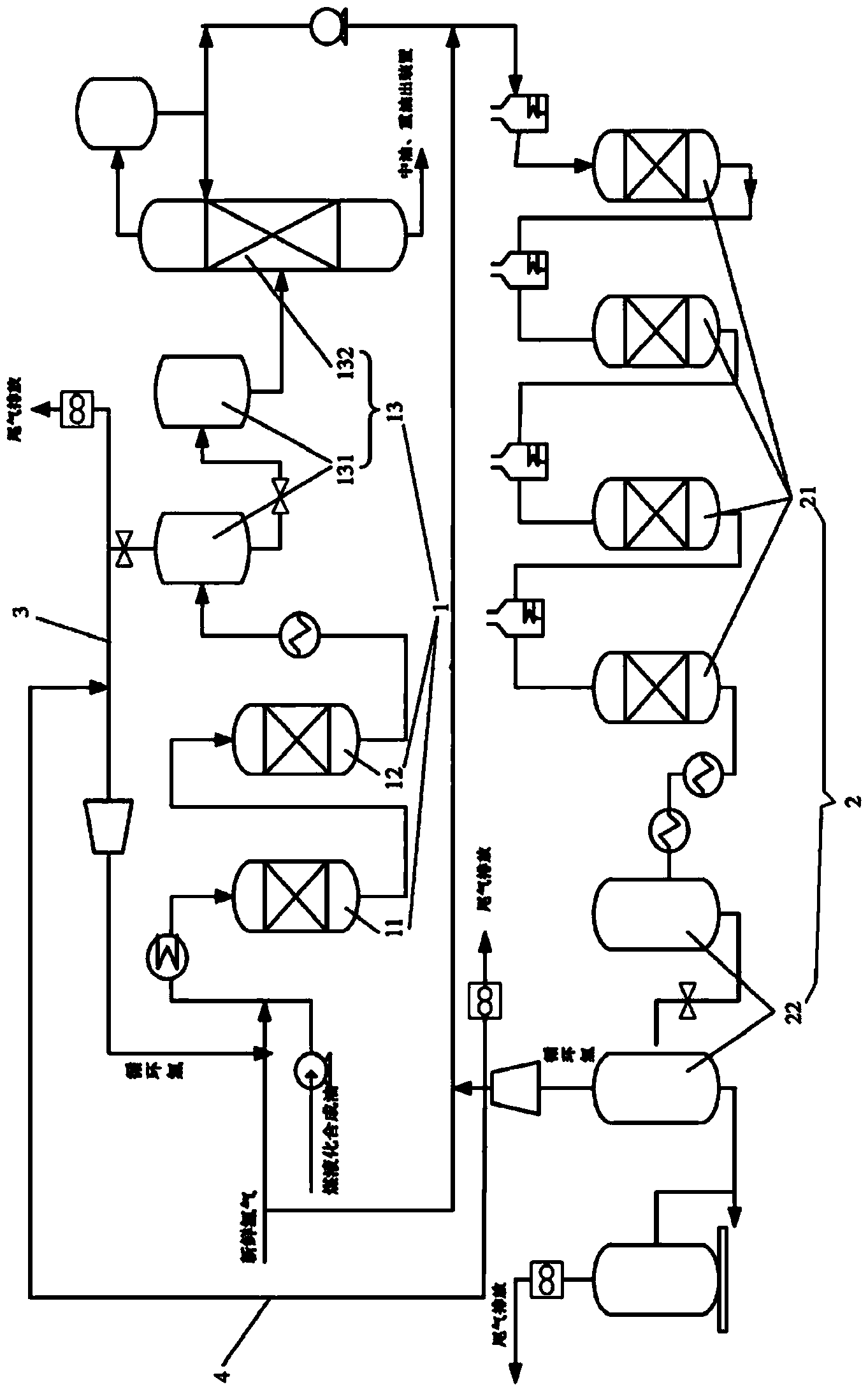

Method for preparing catalytic thermal cracking raw materials from full-fraction shale oil

ActiveCN105154134AImprove utilization efficiencyImprove the level of comprehensive utilizationDispersed particle separationTreatment with hydrotreatment processesPetroleum naphthaResidual oil

The invention discloses a method for preparing catalytic thermal cracking raw materials from full-fraction shale oil, relates to a full-fraction shale oil deep processing process, and aims to solve the technical problems of 'more money on exhibit and less money on counterfoil' and insufficiency in 'oil-chemical' combination degree of the current oil shale industrial structure in the conventional method. The method is conducted in the following units: 1, a raw material pretreatment unit; 2, an atmospheric distillation unit; 3, a reduced pressure distillation unit; 4, a hydrotreating unit; 5, a product fractional distillation unit. According to the method, the utilization ratio of the shale oil resource is effectively increased; the main product is hydrofined wax oil used as the raw material for a follow-up catalytic thermal cracking device; the by-products are high-value LPG, hydrogenated petroleum naphtha and hydrogenated diesel oil; light shale oil (lower than or equal to 350 DEG C) and residual oil (higher than 500 DEG C) which are thrown away from the process device can be further processed and utilized in a downstream device. The method belongs to the field of full-fraction shale oil deep processing.

Owner:ENERGY & ENVIRONMENT RES INST OF HEILONGJIANG PROVINCE

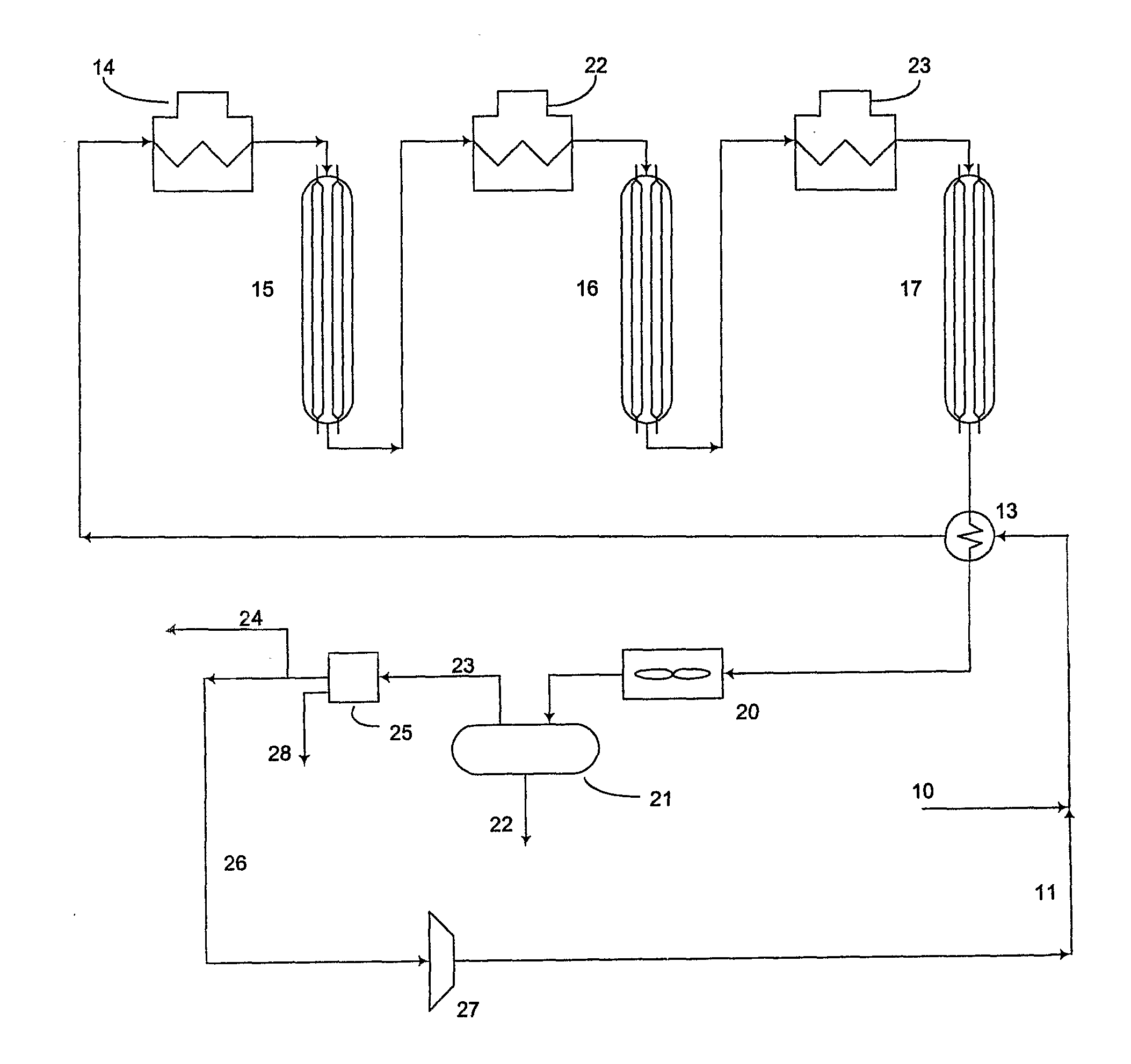

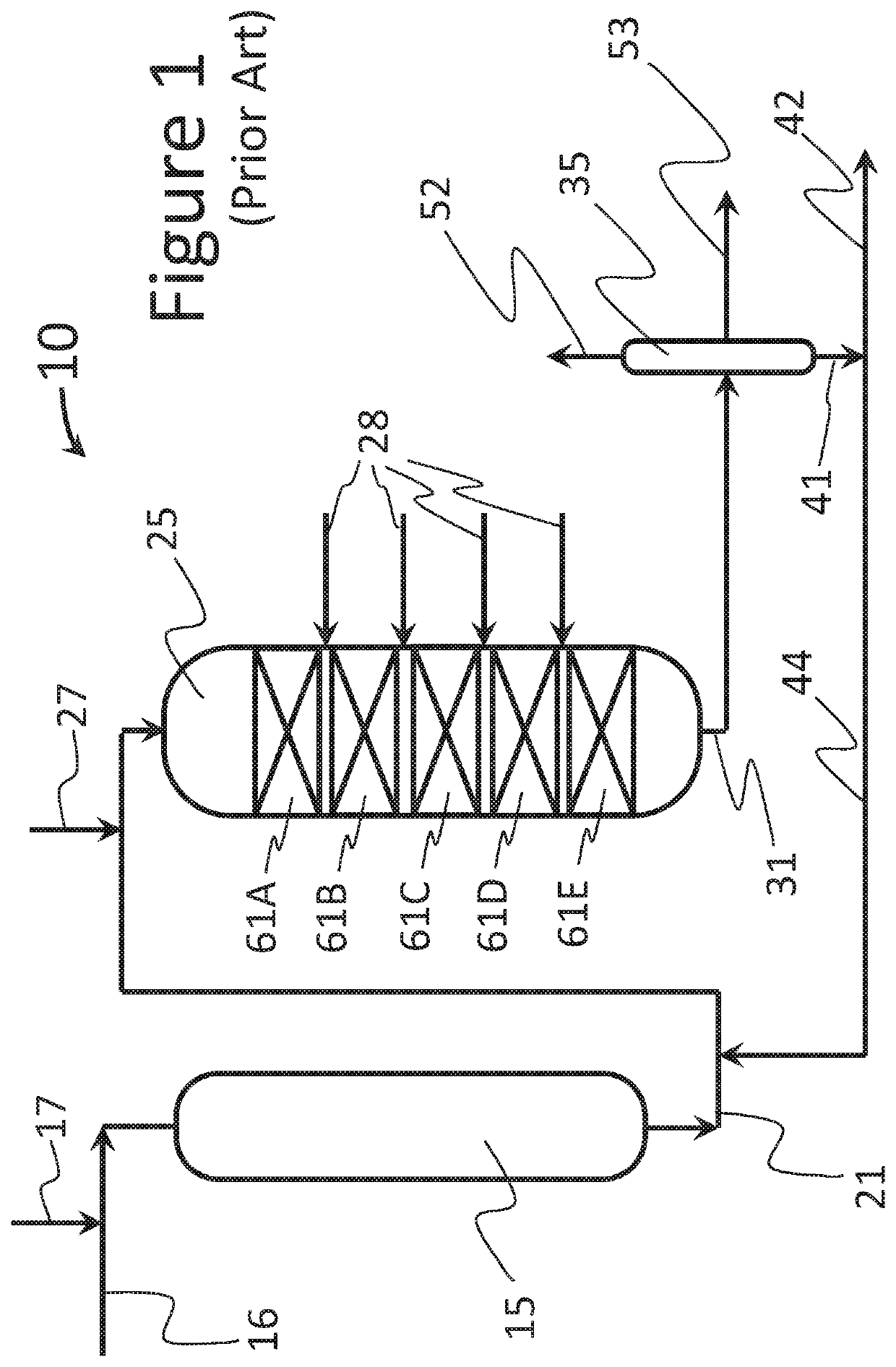

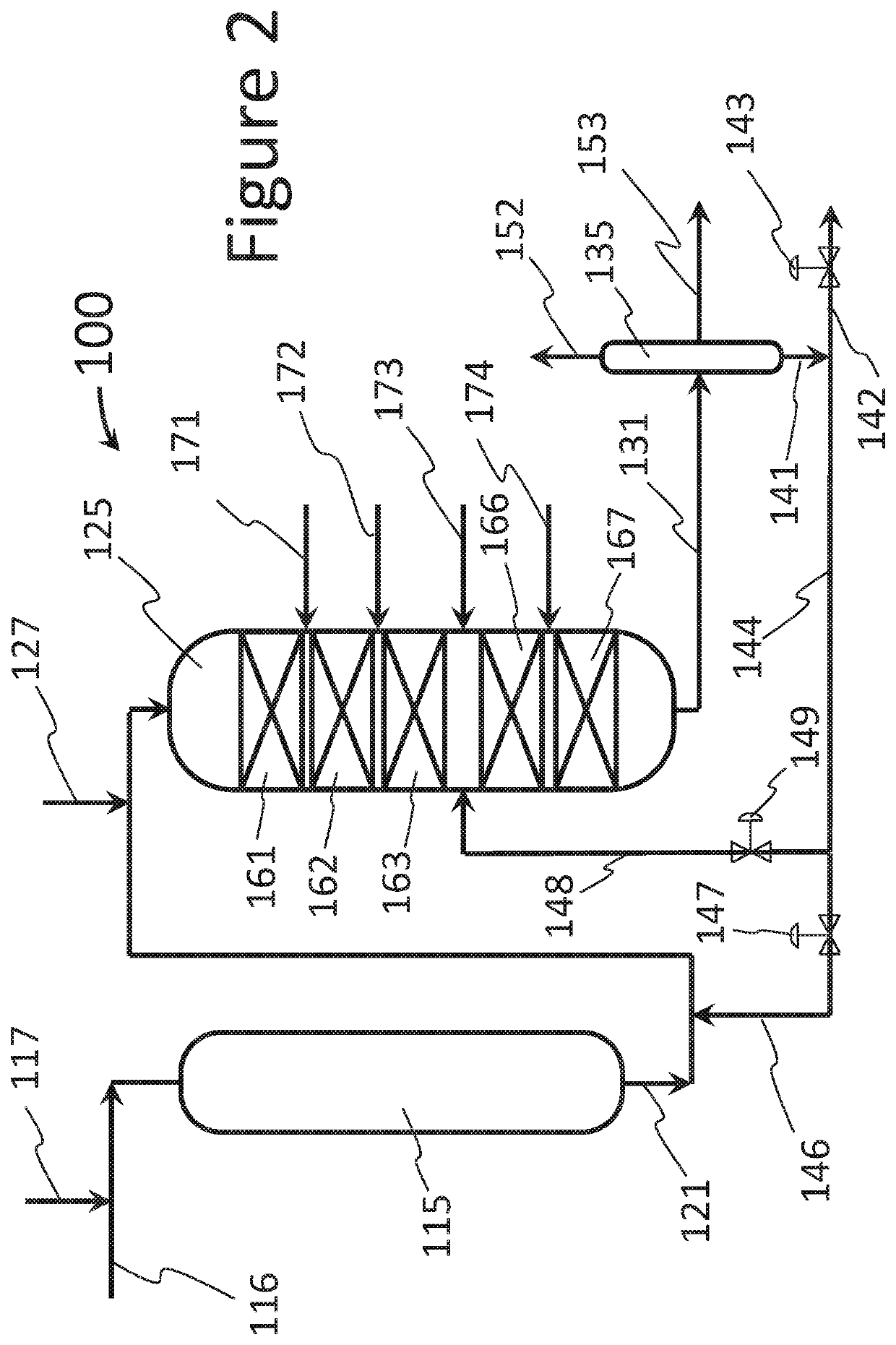

Catalytic Reformer Unit and Unit Operation

ActiveUS20110147270A1High purity hydrogenLower overall pressure dropGas treatmentHydrogen separation using solid contactCatalytic reformingPetroleum naphtha

An improved process for catalytic reformers and their use for the catalytic reforming of petroleum naphthas. More particularly, the invention relates to an improved reformer unit which can be operated at higher throughput relative to compressor size. The invention utilizes pressure swing adsorption to improve the hydrogen content of hydrogen containing streams generated by and utilized in catalytic reforming processes. The invention also has the capability of enabling compressor-limited catalytic reforming units to be operated at increased capacities.

Owner:EXXON RES & ENG CO

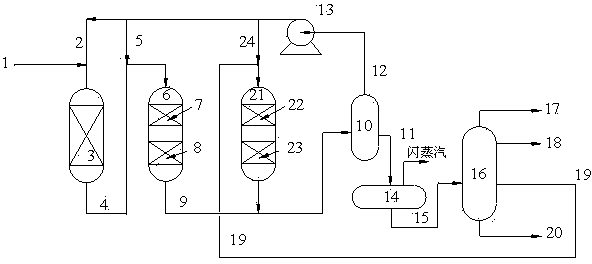

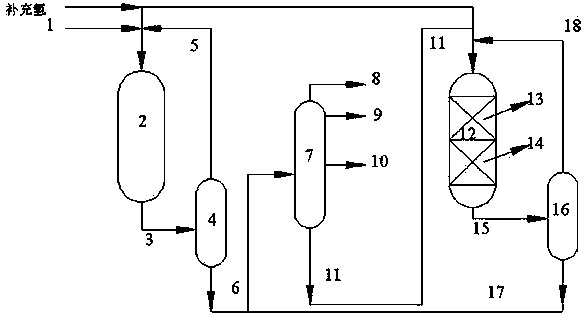

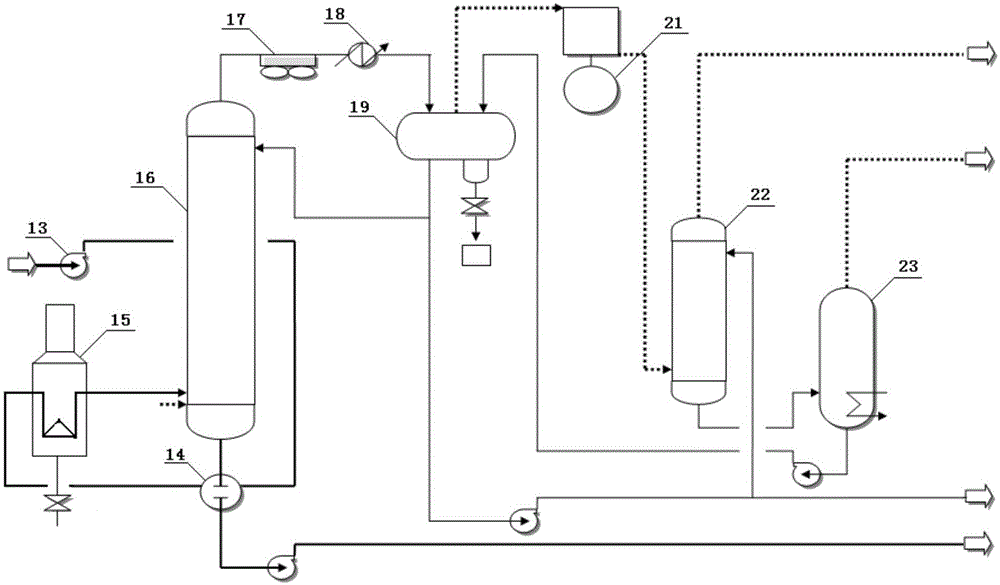

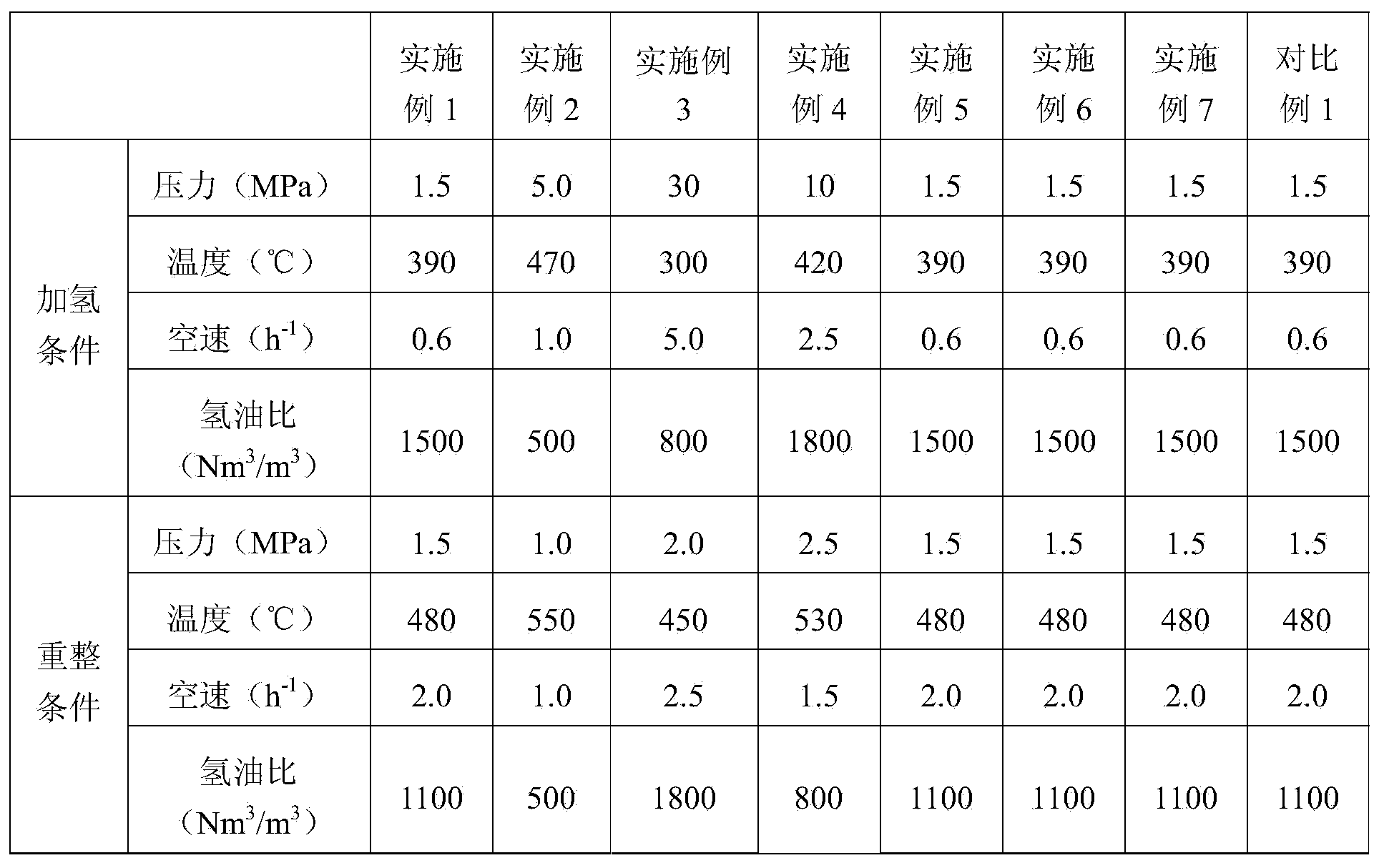

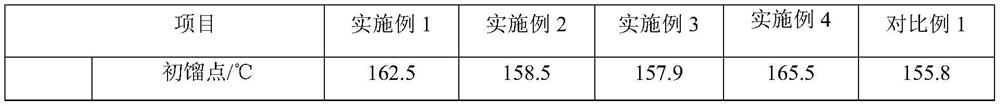

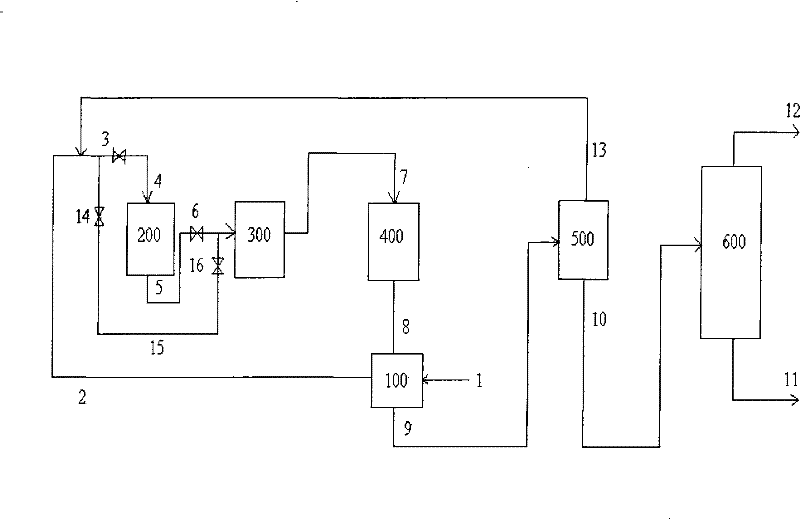

Hydrogenization reforming system, hydrogenization reforming process, and aromatic products of coal liquefaction full distillate

InactiveCN103965961ASimple structureIncrease contentTreatment with hydrotreatment processesCatalytic reformingPetroleum naphtha

The invention provides a hydrogenization reforming system, a hydrogenization reforming process, and aromatic products of coal liquefaction full distillate. The hydrogenization reforming system comprises a hydrorefining unit which comprises a first hydrogenation reactor, a first fractionation device which is communicated with the first hydrogenation reactor and used for fractionizing the hydrorefining product fractionation into petroleum naphtha fraction, intermediate distillate and heavy distillate, a catalytic reforming unit which comprises a catalytic reforming reactor, is communicated with the first fractionation device, and is used for performing catalytic reforming for the petroleum naphtha fraction, wherein only one fractionation treatment for the hydrorefining products is conducted by the hydrogenization reforming system. The hydrogenization reforming system fully utilizes the characteristics that the coal liquefaction full distillate is rich in aromatics, cyclane, and hetero-atom compound, obtains petroleum naphtha with high aromatic potential content via only one time of fractionation by performing deep hydrorefining, lowering sulphur, nitrogen and other hetero-atom contents on the coal liquefaction full distillate, simplifies the structure of hydrotreating unit, and increases aromatic content in the reformed products.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Catalysts for deep catalytic cracking of petroleum naphthas and other hydrocarbon feedstocks for the selective production of light olefins and method of making thereof

Provided herein are monocomponent and hybrid catalyst compositions for use in steam-cracking of hydrocarbon feeds to selectively produce light olefins. The catalyst compositions being characterized by a first catalytic component comprising oxides of aluminum, silicon, chromium, and optionally, oxides of monovalent alkaline metals, and further comprising a binder, preferably bentonite clay. Preferably, the catalyst compositions will comprise a catalytic component in accordance with the following formula: (a) SiO2·(b) A12O3·(c) Cr2O3(d) alk2O, with alk being a monovalent alkaline metal, preferably selected from sodium, potassium and lithium. The second catalytic component is selected from a crystalline zeolite or a silica molecular sieve. Also provided in the present invention are methods of making the catalyst compositions.

Owner:VALORBEC PARTNERSHIP

Composite lead-free gasoline and its preparation method

InactiveCN1766061AImprove evaporation effectGood explosion resistanceLiquid carbonaceous fuelsAdjuvantPetroleum naphtha

The invention relates to a composite lead-free gasoline which comprises 90# petroleum product, methanol, low gravity oil, petroleum naphtha, 120# solvent oil, ethylene glycol monobutyl ether, isopropyl alcohol, benzene and addition agent, and the addition agent comprises zinc oxide, anti-oxidant, metal deactivator, coloring agent, smoke abatement and combustion adjuvant. The invention relates to a the preparing process.

Owner:鲁希诺

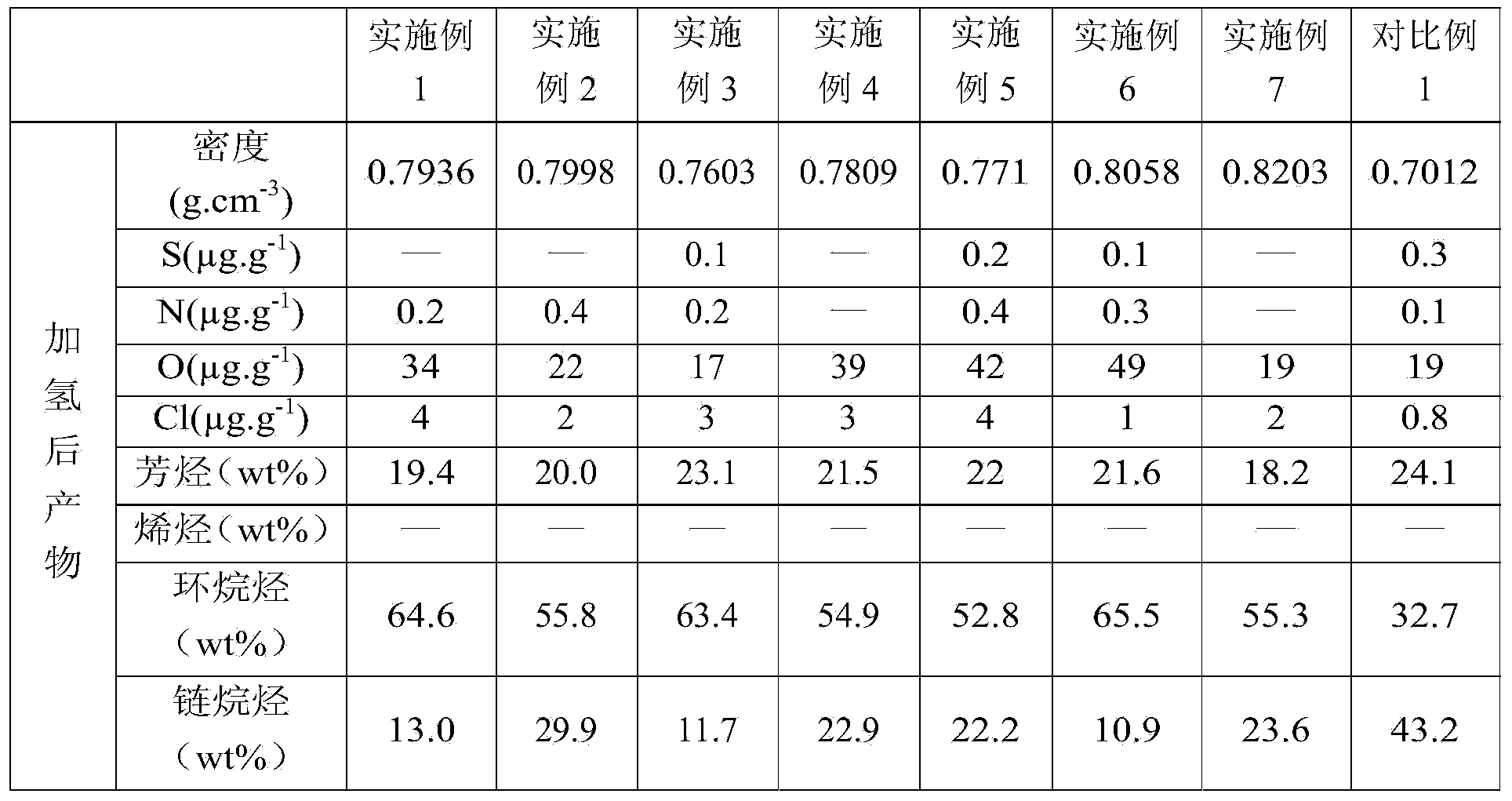

Formula and preparation method of novel PM (particulate matter) clean biological CHO motor gasoline

ActiveCN103525484AEnhanced torque powerPromote degradationLiquid carbonaceous fuelsDimethyl malonatePetroleum naphtha

The invention discloses a formula and a preparation method of a novel PM clean biological CHO motor gasoline. The formula comprises components as follows: light hydrocarbon, aromatics, petroleum naphtha, dimethyl carbonate, isopropyl alcohol, propylene glycol methyl ether acetate, acetic acid sec-butyl ester, dimethyl malonate and an additive. The method comprises the steps as follows: light hydrocarbon, dimethyl malonate, aromatics and petroleum naphtha are sequentially added; then, S-100A-C# heavy aromatics and a clean biological CHO motor gasoline compound additive are sequentially added; circular stirring and blending is that an anti-explosion circulating pump is utilized to circularly and uniformly stir components in a blending component tank, and all that is needed is to uniformly mix the components during the circulation process; a blended product is filtered by a piece of 200-mesh copper wire cloth; a product is prepared, and a qualified product is put in storage. The method is simple, the exhaust gas is clean, the environment is well protected, a part of indexes are superior to state V standard, requirements of modern clean energy regulations are met, and the preparation method of the novel PM clean biological CHO motor gasoline is provided.

Owner:CHUANHUA GRP

A kind of preparation method of high-quality mesophase pitch

ActiveCN107474866BReduce dosageLow softening pointWorking-up pitch/asphalt/bitumen by chemical meansPetroleum naphthaHydrogenation process

Owner:上海高强高模新材料科技有限公司

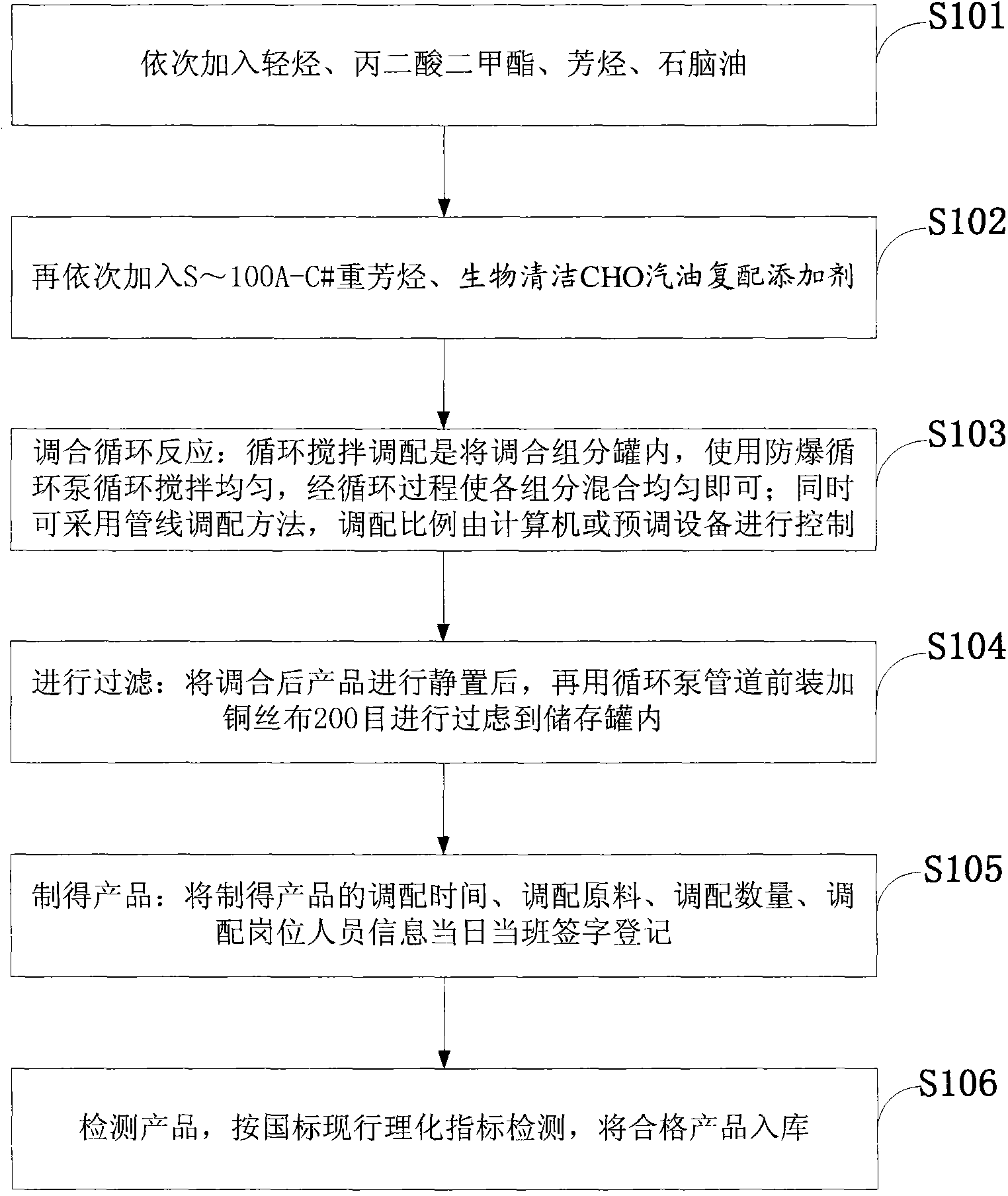

Preparation method of Fischer-Tropsch synthesis kerosene and method for preparing semisynthetic aviation kerosene from Fischer-Tropsch synthesis kerosene

ActiveCN113105913AExcellent isomerization performanceLowering the freezing pointTreatment with hydrotreatment processesPetroleum naphthaKerosene

The invention provides a preparation method of Fischer-Tropsch synthesis kerosene. The method comprises the following steps: (1) carrying out hydrofining reaction on Fischer-Tropsch synthesis oil, fractionating the generated hydrofining product, extracting tower top and side line products, carrying out hydrocracking reaction on hydrofining tail oil, enabling the generated hydrocracking product to enter a fractionating tower, carrying out fractionation to obtain a diesel oil component at the fraction section of 160-350 DEG C and a crude naphtha component at the fraction section of 45-205 DEG C, carrying out a hydroisomerization reaction on hydrocracking vacuum bottom oil, enabling the generated hydroisomerization product to enter a hydrocracking fractionating tower, and carrying out fractionation; and (2) mixing the diesel oil component and the crude naphtha component to obtain a mixed oil product, and carrying out distillation cutting on the mixed oil product to obtain a cut fraction which is the Fischer-Tropsch synthesis kerosene. According to the invention, the method has the advantages that the cost is saved, the operation flexibility is high, and the process is easy to adjust; and the semi-synthetic aviation kerosene prepared from the Fischer-Tropsch synthetic kerosene has the characteristics of almost no sulfur and nitrogen impurities, low freezing point and low aromatic hydrocarbon.

Owner:CHINA ENERGY GRP NINGXIA COAL IND CO LTD

Catalyst of fluid bed for preparing ethane and propylene through catalytic cracking

ActiveCN1915509ARaise the reaction temperatureLow reaction temperaturePhysical/chemical process catalystsHydrocarbon by dehydrogenationPetroleum naphthaFluidized bed

A catalyst for preparing ethene and propene by catalytic cracking of petroleum naphtha on fluidized bed is composed of the carrier chosen from SiO2, Al2O3 and their mixture and the active component Mo1.0VaPbAcBdOx. It has high low-temp activity, selectivity and low reaction temp.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking method

ActiveCN110938468ASmall average pore sizeExtended stayTreatment with hydrotreatment processesHydrocarbon oils treatment productsMolecular sievePtru catalyst

The invention discloses a hydrocracking method, which comprises the following steps: (1) mixing a diesel oil raw material and hydrogen, feeding the mixture into a hydrofining reactor, and carrying outa desulfurization, denitrification and aromatic hydrocarbon saturation reaction; and (2) feeding the effluent obtained in the step (1) into a hydrocracking reactor, wherein the hydrocracking reactorcomprises first to nth catalyst bed layers in a material direction, n is greater than or equal to 3, preferably n is 3 or 4, the first to (n-1)th catalyst bed layers are filled with a hydrocracking catalyst containing a modified Y molecular sieve, and the nth catalyst bed layer is filled with a hydroisomerization catalyst containing a beta or ZSM molecular sieve and other molecular sieves with strong isomerization performance. According to the method, diesel oil is used as a raw material, and through reasonable combination of hydrocracking catalysts with different functions, the yield of heavynaphtha with high aromatic potential is increased, and the low-temperature fluidity of aviation kerosene and diesel oil products is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for maximizing production of aromatic hydrocarbon by catalyzing diesel oil hydro-conversion

PendingCN111100705ABalance activitySolve the problem of low yield and non-compliance for a long timeTreatment with hydrotreatment processesPetroleum naphthaPtru catalyst

The invention discloses a method for maximizing production of aromatic hydrocarbon by catalyzing diesel oil hydro-conversion, comprising the following steps: (1) high aromatic hydrocarbon catalytic diesel oil and recycle hydrogen are mixed and enter a hydrofining reaction zone for reaction, the hydrofining reaction zone is provided with at least two catalyst beds, and the vulcanization degree of the catalyst in the material flow direction is in a decreasing trend; (2) the generated oil obtained in the step (1) enters a hydrocracking reaction zone to be in contact with at least two sulfurized hydrocracking catalysts to carry out ring-opening conversion reaction of polycyclic aromatic hydrocarbon; (3) the generated oil obtained in the step (2) passes through a separation system to obtain gas, gasoline and diesel oil fractions, and the diesel oil fractions are completely recycled back to the hydrofining reaction zone; and (4) naphtha obtained in the step (3) enters an aromatic hydrocarbonextraction device, and a BTX product is obtained through solvent extraction. Hydrogenation catalysts with different vulcanization degrees are used through grading, the initial activity of the catalyst is balanced, and the problems that the initial adjustment period is long in the technical application process and the octane number of a main target product gasoline fraction is low for a long timeare solved.

Owner:CHINA PETROLEUM & CHEM CORP +1

High cleanness composite gasoline

InactiveCN101235326ADischarge cleaningRich sourcesLiquid carbonaceous fuelsPetroleum naphthaHazardous substance

The invention relates to high-cleanness compound gasoline, the gasoline source on the existing market is simpler, which has high production cost, the combination is not complete, and dynamic can not be completely released, exhaust emission contains more harmful substance, which has great pollution to environment. The main character of the high-cleanness compound gasoline is that the invention comprises three raw materials which are methanol, isopropanol and petroleum naphtha, which has the advantages of rich resource, low production cost and simple production technique, which does not contain any heavy metal iron such as plumbum, aluminum, manganese, zinc and the like, and has little pollution to environment. The high-cleanness compound gasoline can be used as fuel.

Owner:于涛

Process for the distillation of decanted oils for the production of petroleum pitches

InactiveUS20100078356A1Improve production yieldImprove chemical qualityWorking-up pitch/asphalt/bitumen by distillationHydrocarbon distillation control/regulationPetroleum naphthaHot zone

This invention describes a process for the distillation of decanted oil to improve the efficiency of the production of pitches having excellent physical and chemical properties through the development of a distillation process which basically comprises the introduction of a stage of condensation of light volatile compounds derived from distillation of the decanted oil, causing these light compounds to be recycled to the hot zone of the still and react with the raw material acting as a solvent phase which has a lower viscosity than the reaction system, within a particular temperature range and for a particular time.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

Method for preparing high-quality ethylene raw material with petroleum naphtha hydrogenation

ActiveCN101343557BImprove qualityIncrease productionOrganic chemistryBulk chemical productionVegetable oilPetroleum naphtha

Owner:CHINA PETROLEUM & CHEM CORP +1

Method and composition for the preservation of film

InactiveUS6712994B1Photography auxillary processesOther chemical processesPetroleum naphthaAliphatic hydrocarbon

The present invention provides a non-evaporating lubricant and cleaner formulation that protects all types of film by forming a slick protective coating that reduces or eliminates dirt, scratches and static charges. An embodiment of the present invention comprises an organic mixture of greater than ninety-five percent (95%) aliphatic hydrocarbons. A preferred embodiment of the present invention comprises aliphatic petroleum naphtha, aliphatic petroleum distillates and petroleum base oil.

Owner:MILLER BRAD A

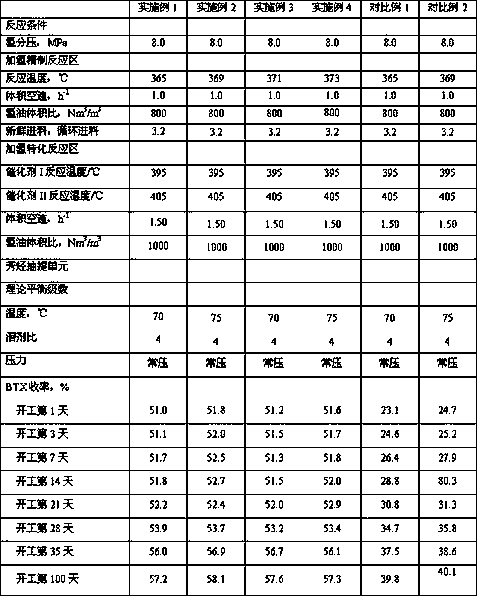

Method for improving running period of hydrogenation plant for poor petroleum naphtha

ActiveCN101343566BReduce cokingLess investmentTreatment with hydrotreatment processesPetroleum naphthaReaction temperature

The invention relates to a method for enhancing the running period of a poor-quality naphtha hydrogenising device. The invention adopts the method that a reactor is additionally arranged before a heating furnace, and the poor-quality naphtha first performs a selective diene hydrogenising and removing organosilicon compounds reaction at a lower reaction temperature, and then passes through a main reactor and performs a hydrogenising reaction to remove sulphur and nitrogen impurity and olefin saturation. Compared with the prior art, the method has the advantages that the process is simple, the heating furnace tube and the heat exchanger shell side coking are effectively alleviated and the organosilicon compounds are removed, and the running period of the device is prolonged. The method can be applied to various secondary processing naphtha hydrofining processes.

Owner:CHINA PETROLEUM & CHEM CORP +1

Alcohol gasoline and preparation method thereof

The invention discloses an alcohol gasoline and a preparation method thereof. The alcohol gasoline comprises, by weight, 15 to 55 parts of naphtha, 5 to 15 parts of mixed xylenes, 5 to 25 parts of toluene, 2 to 14 parts of methanol, 1 to 13 parts of isopropanol, 5 to 15 parts of C9 petroleum hydrocarbon, 1 to 15 parts of isopentane, 1 to 17 parts of methyl tert-butyl ether and 1 to 17 parts of ethyl tert-butyl ether. The alcohol gasoline has the advantages of good stability, low corrosion to an engine, good cost performance and low emission of pollutants from automobile exhaust. Meanwhile, the preparation method for the alcohol gasoline is simple and easily practicable and can be easily implemented.

Owner:李尧

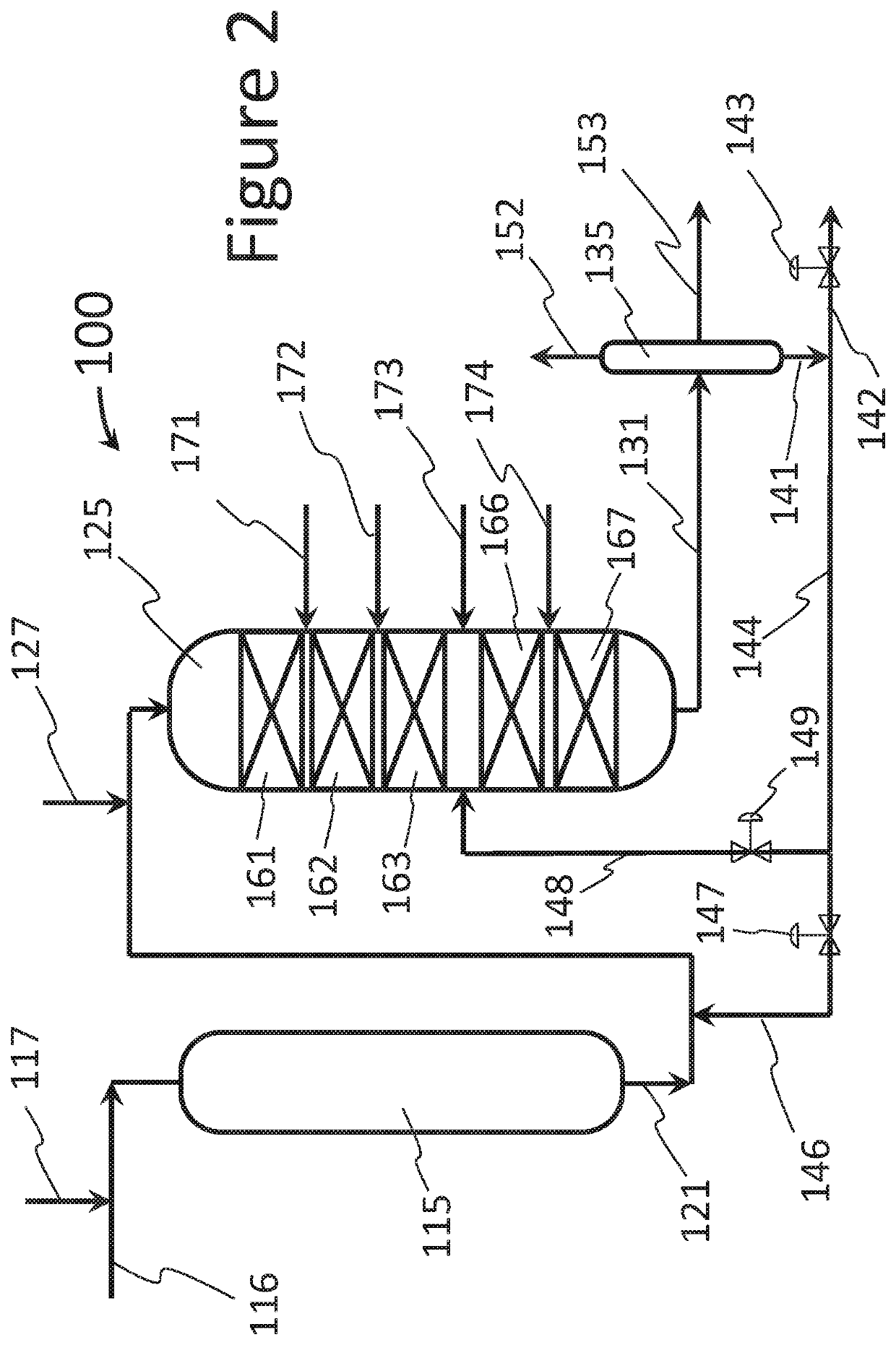

Hydrocracking system for producing distillate or naptha

ActiveUS20200181512A1Better pHydrocarbon oil crackingTreatment with hydrotreatment processesPtru catalystPetroleum naphtha

The invention relates to a catalytic hydrocracker with two different catalyst beds within the reactor where each is loaded with a catalyst that has different hydrocracking properties. A first catalyst bed preferably cracks heavy oil more aggressively than the catalyst in the second bed. The catalytic hydrocracker includes further two recycle lines such that one directs unconverted oil through both hydrocracker beds and a bypass inlet is positioned between the first and second catalyst beds to admit unconverted oil to pass only through the second less aggressive hydrocracker catalyst bed. When gasoline prices favor the production of gasoline, less unconverted oil is recycled through the bypass therefore making more gasoline, but when prices favor the production of j et and diesel, more recycle is directed through the bypass recycle thus making less gasoline and more diesel and jet fuel.

Owner:PHILLIPS 66 CO

Hydrocracking process for producing distillate or naptha

ActiveUS20200181511A1High priceHydrocarbon oil crackingTreatment with hydrotreatment processesPtru catalystPetroleum naphtha

The invention relates to a catalytic hydrocracker with two different catalyst beds within the reactor where each is loaded with a catalyst that has different hydrocracking properties. A first catalyst bed preferably cracks heavy oil more aggressively than the catalyst in the second bed. The catalytic hydrocracker includes further two recycle lines such that one directs unconverted oil through both hydrocracker beds and a bypass inlet is positioned between the first and second catalyst beds to admit unconverted oil to pass only through the second less aggressive hydrocracker catalyst bed. When gasoline prices favor the production of gasoline, less unconverted oil is recycled through the bypass therefore making more gasoline, but when prices favor the production of jet and diesel, more recycle is directed through the bypass recycle thus making less gasoline and more diesel and jet fuel.

Owner:PHILLIPS 66 CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com