Hydrogenization reforming system, hydrogenization reforming process, and aromatic products of coal liquefaction full distillate

A reforming system and whole distillate technology, which is applied in the field of aromatics products and coal liquefaction whole distillate oil hydroreforming system, can solve the problems of complex hydroreforming process, simplify the structure, improve economic benefits, and improve aromatics The effect of content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

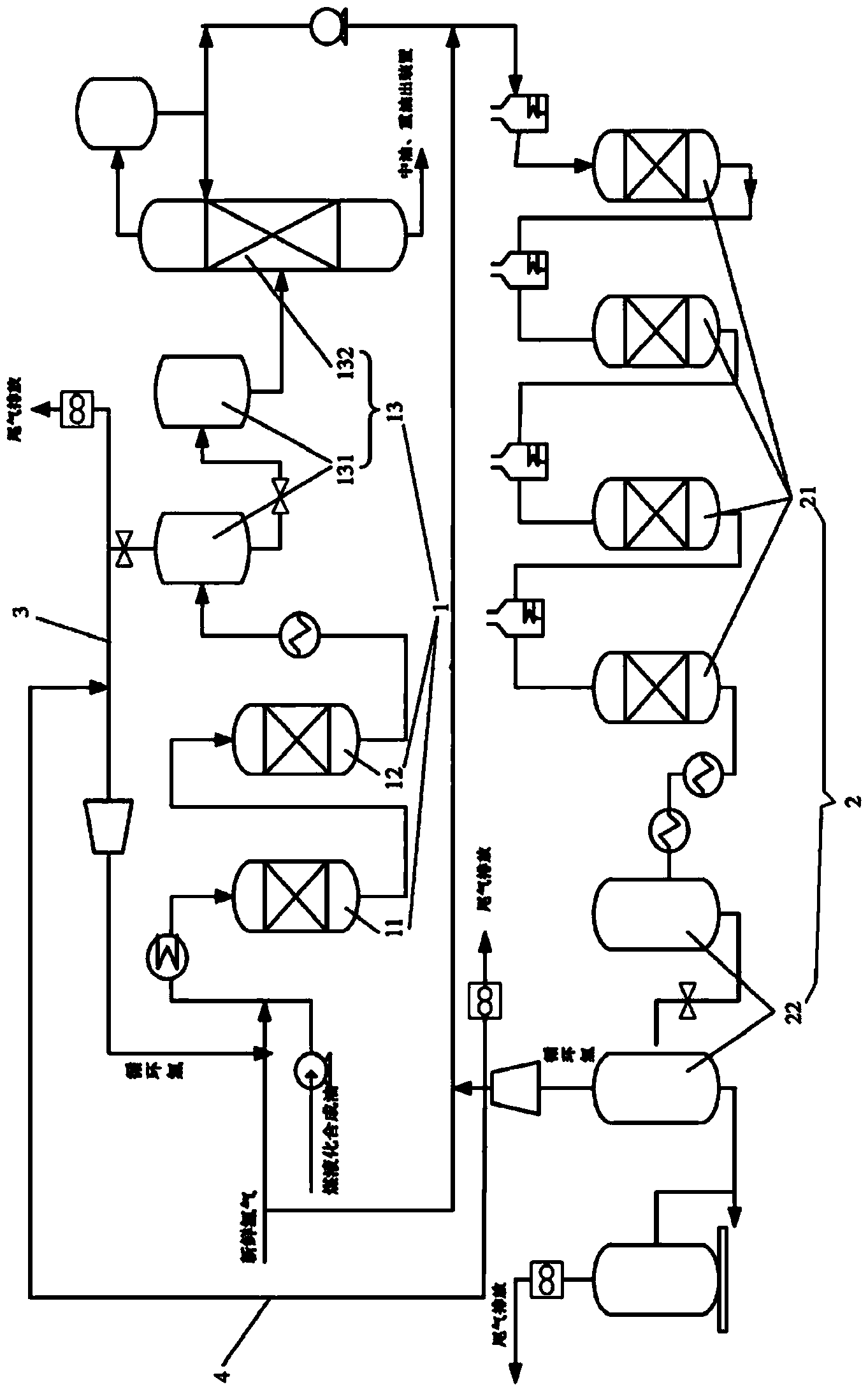

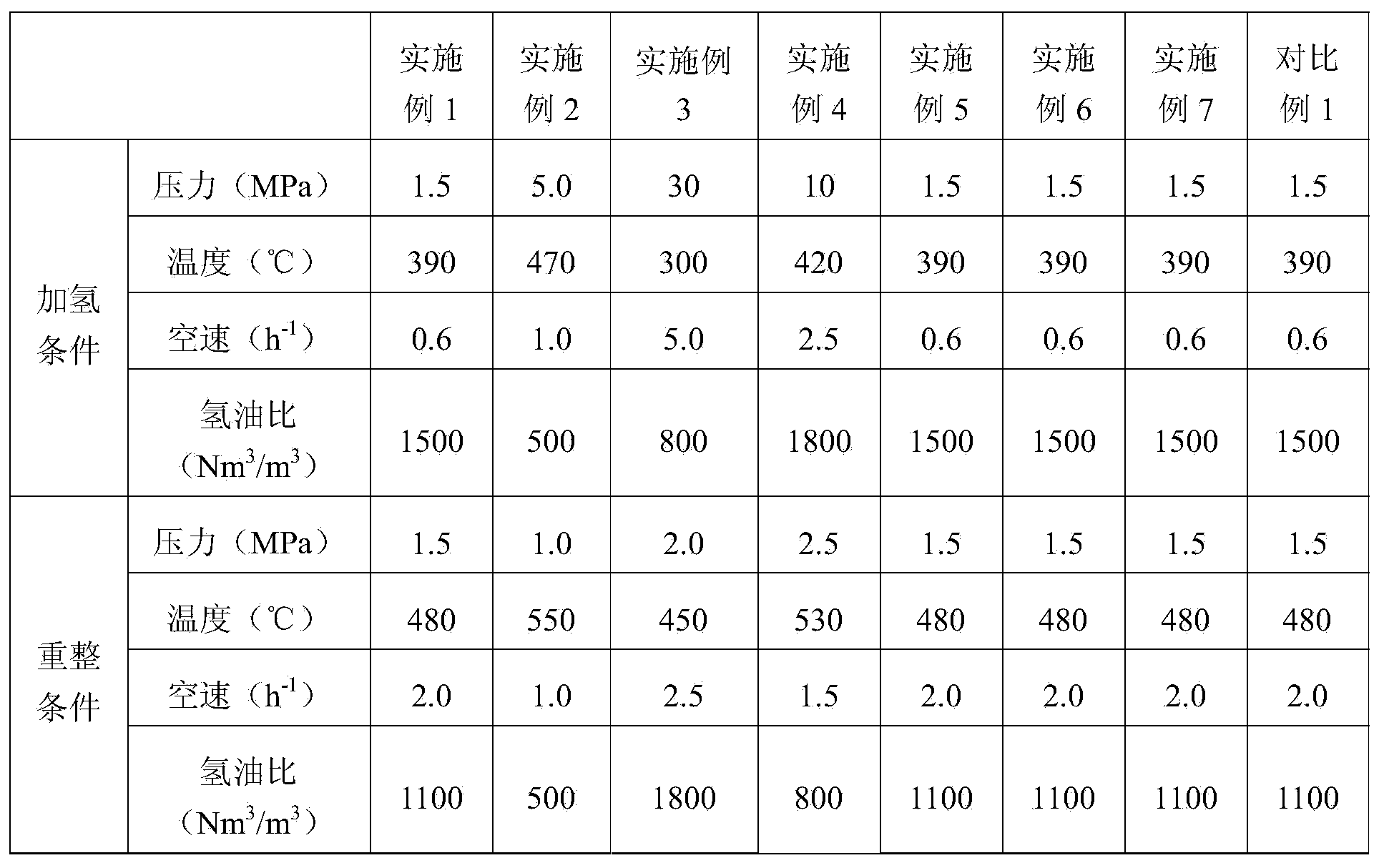

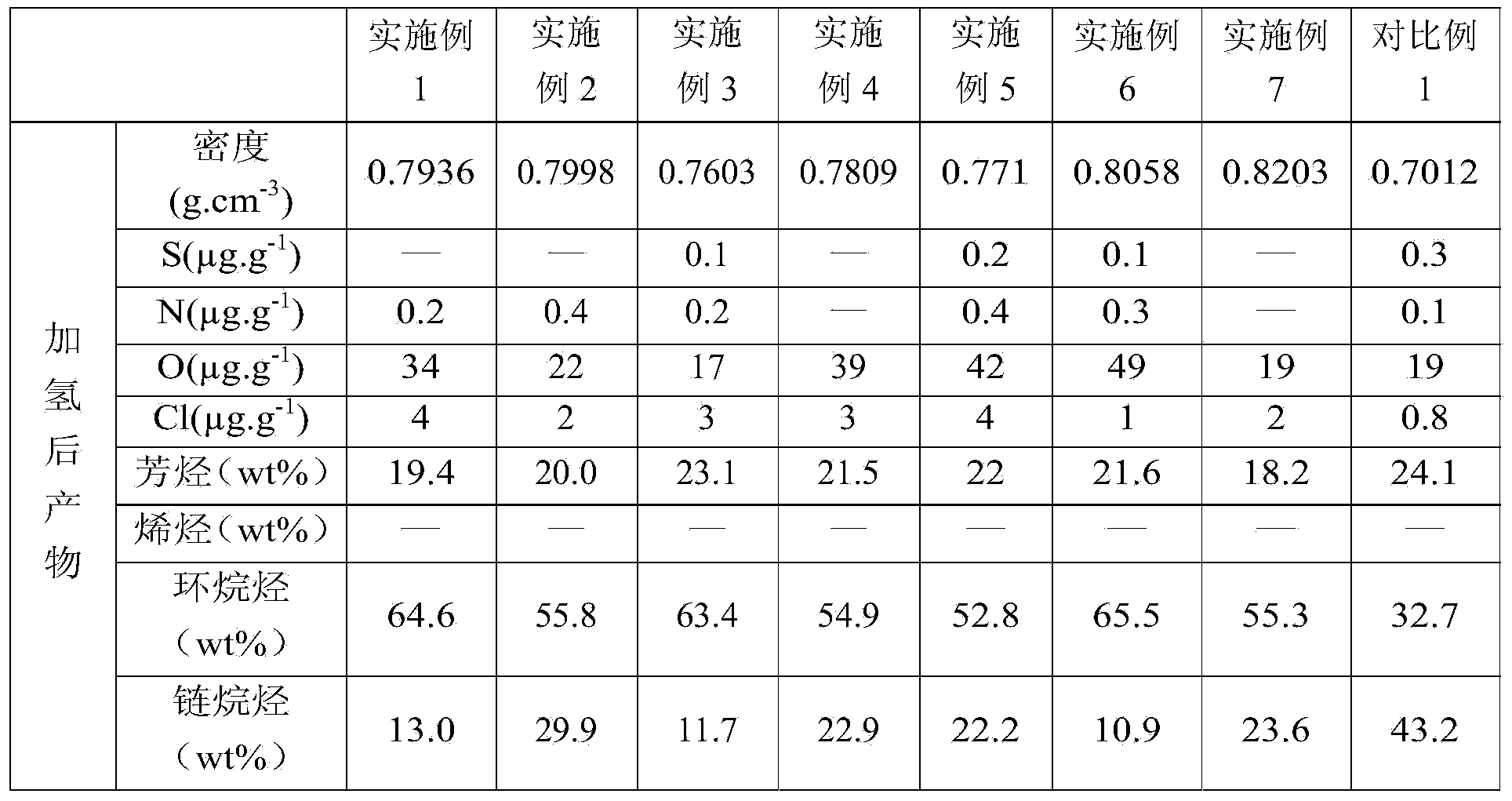

[0059]The raw material oil is the coal liquefaction whole distillate oil obtained by the H-Coal coal liquefaction process. figure 1 The shown hydroreforming system performs hydroreforming, and the specific process is as follows:

[0060] Use the raw oil pump to mix the coal liquefied whole distillate oil and hydrogen, heat it to 300°C with an electric heater, and then enter the first hydrotreating reactor from the top for preliminary hydrofining. The reaction product flows out from the bottom of the reactor and enters the second hydrogenation reactor for deep hydrotreating to further remove heteroatoms and impurities such as sulfur and nitrogen. The process conditions of the second hydrogenation reactor are the same as those of the first hydrogenation reactor. The hydrorefined product is cooled to 54°C by the cooler, and then enters the high-pressure separator and the low-pressure separator for product flash separation, and a part of the gas at the top of the high-pressure sep...

Embodiment 2

[0063] The raw material oil is the coal liquefaction whole distillate oil obtained by the H-Coal coal liquefaction process. figure 1 The hydroreforming system shown performs hydroreforming. Wherein the first hydrogenation reactor and the second hydrogenation reactor used are ebullating bed reactors, the first reforming semi-regenerative reactor, the second reforming semi-regenerative reactor, the third reforming semi-regenerative reactor and the second The four reforming semi-regenerative reactors are all fixed-bed semi-regenerative reactors.

Embodiment 3

[0065] The raw material oil is the coal liquefaction whole distillate oil obtained by the H-Coal coal liquefaction process. figure 1 The hydroreforming system shown performs hydroreforming. Wherein the first hydrogenation reactor used is an ebullating bed reactor; the second hydrogenation reactor is a fixed bed reactor, the first reforming semi-regenerating reactor, the second reforming semi-regenerating reactor, the third reforming semi-regenerating reactor Both the regenerative reactor and the fourth reforming semi-regenerative reactor are fluidized bed semi-regenerative reactors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com